Como dominar o armazenamento de vacinas e a cadeia de frio em 2025?

Artigo atualizado: novembro 17 2025

Vacinas salvam vidas, mas a sua potência depende da manutenção da temperatura certa durante o armazenamento e transporte. Como profissional de saúde ou gerente de logística, você preciso entender armazenamento de vacinas e gestão da cadeia de frio para salvaguardar cada dose. Este guia completo responde a perguntas comuns, explica os requisitos de temperatura, explora equipamentos de monitoramento e apresenta o 2025 tendências que estão remodelando o cenário da cadeia de frio. Você encontrará dicas práticas, exemplos do mundo real e ações claras para implementar - tudo baseado nas evidências e diretrizes mais recentes.

Quais são as faixas de temperatura recomendadas para armazenamento de vacinas e por que elas são importantes?

Como você escolhe e organiza equipamentos da cadeia de frio, como geladeiras, freezers e unidades ultrafrias?

Quais dispositivos e procedimentos de monitoramento garantem que as vacinas permaneçam dentro do alcance?

Que desafios comuns ameaçam a cadeia de frio das vacinas, e como você pode mitigá-los?

Quais inovações – blockchain, energia solar, Sensores de IoT, IA e embalagens sustentáveis — estão transformando a gestão da cadeia de frio em 2025?

Que tendências e mudanças de mercado você deve observar à medida que a indústria da cadeia de frio evolui?

Quais são os requisitos críticos de temperatura para armazenamento de vacinas?

Manter as vacinas dentro da faixa de temperatura correta preserva sua potência. De acordo com as diretrizes do CDC, refrigeradores padrão devem manter 2 °C – 8 °C (36 °F – 46 °F) e freezers devem ficar entre −50 °C e −15 °C (−58 °F – 5 °F). Funcionam freezers ultrafrios para vacinas específicas entre −90 °C e −60 °C (−130 °F – −76 °F). Essas faixas se aplicam à maioria das vacinas, embora certos produtos tenham requisitos especializados; consulte sempre a bula do fabricante.

Geladeiras e freezers devem ter termostatos ajustados no ponto médio para minimizar variações de temperatura. Registrando temperaturas mínimas e máximas duas vezes ao dia e usando registradores de dados digitais calibrados (DDLs) é recomendado para monitoramento preciso. Nunca guarde vacinas nas portas de geladeiras ou freezers; coloque-os na prateleira do meio com espaço para circulação de ar.

Por que a temperatura é importante

As vacinas são produtos biológicos. A exposição a temperaturas fora da faixa recomendada pode causar degradação irreversível e perda de potência. Por exemplo, o programa VFC de Nova York alerta que o armazenamento inadequado resulta em milhões de dólares em desperdício de vacinas a cada ano. Vacinas refrigeradas como a gripe, MMR e hepatite nunca devem ser congeladas, enquanto certas vacinas vivas, como varicela ou mpox, requerem armazenamento ultrafrio. As variações de temperatura também podem levar à revacinação de pacientes, perda de confiança do público e surtos de doenças evitáveis.

Escolhendo o equipamento de armazenamento certo

Diferentes tipos de vacinas exigem equipamentos específicos. Selecionar a unidade certa é a primeira linha de defesa.

| Tipo de equipamento | Faixa de temperatura recomendada | Vacinas armazenadas | Implicações Práticas |

| Frigorífico (grau farmacêutico) | 2 °C – 8 °C (36 °F – 46 °F) | A maioria das vacinas de rotina (gripe, DTaP, HPV, MMR, etc.) | Uma unidade autônoma é preferível a uma combinação de refrigeradores/freezers para manter temperaturas estáveis e evitar congelamento acidental. Ponto médio ideal de 5 °C (41 °F). |

| Freezer (grau médico) | −50 °C – −15 °C (−58 °F – 5 °F) | Varicela, algumas vacinas COVID 19 (Moderna ou Spikevax) | Deve manter ≤ 5 °F (−15°C) e estar separado da geladeira. Unidades de degelo manual requerem manutenção periódica. |

| Congelador ultrafrio | −90 °C – −60 °C (−130 °F – −76 °F) | Certas formulações COVID 19 e vacinas de mRNA | Crítico para preservar vacinas e produtos biológicos baseados em células. Requer DDLs e alarmes especializados para temperaturas ultra frias. |

Dicas e conselhos práticos

Use unidades de qualidade farmacêutica em vez de aparelhos domésticos “estilo dormitório” para garantir temperaturas estáveis.

Organize as vacinas por tipo e data de validade; mantenha os frascos nas caixas originais para proteger da luz e rastrear datas de uso posteriores.

Permitir circulação de ar adequada evitando a superlotação e colocando as caixas de vacinas no centro da prateleira.

Seções de armazenamento de etiquetas claramente para minimizar erros e evitar armazenar diluentes ou itens não relacionados com vacinas.

Exemplo do mundo real: Em 2024, uma clínica no norte do estado de Nova York sofreu uma falha no freezer. Porque a equipe manteve uma unidade de backup, manteve documentação sobre a capacidade da unidade de manter 2 °C – 8 °C e teve procedimentos de emergência, eles transferiram vacinas rapidamente e evitaram desperdício $20,000 valor do estoque.

Como monitorar e gerenciar processos da cadeia de frio?

O monitoramento contínuo da temperatura é o coração do gerenciamento da cadeia de frio. Um registrador de dados digital (DDL) é um dispositivo calibrado que registra a temperatura em intervalos regulares e alerta a equipe quando as leituras ficam fora da faixa segura. O CDC recomenda DDLs porque eles fornecem informações detalhadas, históricos de temperatura para download e são mais precisos que os termômetros padrão. Muitos estados, como Nova York, exigir que os provedores mantenham pelo menos um DDL de backup para cada unidade.

Registradores de dados digitais e monitoramento de temperatura

O monitoramento contínuo evita que pequenos desvios se transformem em perda de vacinas. Considere estes recursos ao selecionar DDLs:

| Recurso DDL | Por que isso importa | Benefícios para suas instalações |

| Sonda de temperatura tamponada | Protege o sensor contra mudanças repentinas de temperatura do ar quando as portas abrem ou fecham | Fornece leituras que refletem a temperatura da vacina, não apenas a temperatura do ar |

| Alarme para temperaturas fora da faixa | Notifica a equipe imediatamente sobre excursões | Permite resposta rápida para evitar perdas |

| Intervalo de registro programável pelo usuário (por exemplo, todo 30 minutos) | Determina com que frequência as temperaturas são registradas | Equilibra detalhes com gerenciamento de dados; intervalo recomendado ≤ 30 minutos |

| Certificado de calibração com incerteza ± 0.5 °C | Verifica se o dispositivo atende aos padrões nacionais | Essencial para auditorias e garantia de qualidade |

| Dados para download e conectividade em nuvem | Permite acesso remoto e análise de tendências a longo prazo | Suporta manutenção preditiva e conformidade regulatória |

Sugestões de implementação

Instale um DDL em cada unidade de armazenamento, inclusive durante o transporte. Certifique-se de que o dispositivo mede a temperatura real da vacina (use uma sonda tamponada com glicol ou esfera de vidro).

Baixe e revise os dados pelo menos a cada duas semanas ou sempre que ocorrer uma excursão. Documente as leituras e mantenha registros por pelo menos três anos.

Mantenha DDLs de backup disponível para cada geladeira e freezer. Teste-os regularmente e substitua as baterias de acordo com as orientações do fabricante.

Treine toda a equipe na leitura de alarmes DDL e na tomada de ações corretivas. Use exercícios práticos com seu plano de emergência.

Estudo de caso: Uma farmácia comunitária notou um alarme DDL em 6 sou. A equipe registrou temperaturas mínimas/máximas (34 °F e 39 °F) e identificou que a porta da geladeira ficou entreaberta durante a noite. Porque eles documentaram as temperaturas e responderam prontamente, as vacinas permaneceram dentro do alcance e não foram desperdiçadas.

Lidando com variações de temperatura e emergências

Mesmo com bons equipamentos, quedas de energia ou erros humanos podem causar variações de temperatura. O kit de ferramentas do CDC recomenda manter geradores ou baterias de reserva capazes de operar armazenamento refrigerado por pelo menos 72 horas. Tenha um plano de emergência por escrito que inclua:

Instalação de armazenamento alternativa com uma faixa de temperatura adequada (2 °C – 8 °C ou −50 °C – −15 °C).

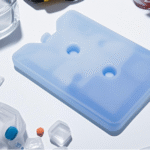

Procedimentos para embalagem e transporte de vacinas usando garrafas de água condicionadas ou compressas frias; vacinas refrigeradas e congeladas separadas.

Lista de contatos para gerenciamento de edifícios, departamentos de segurança e saúde locais.

Rotulagem clara de “NÃO usar” para vacinas que possam ter sido comprometidas até que a viabilidade seja confirmada.

Quais são os desafios e soluções comuns na cadeia de frio de vacinas?

Desafio 1: Variabilidade e infraestrutura de equipamentos

Muitas clínicas ainda usam unidades domésticas ou combinadas de geladeira/freezer, o que pode levar a temperaturas inconsistentes e episódios de congelamento. A atualização para unidades autônomas de nível médico é essencial. Manutenção de rotina, como limpeza de bobinas e teste de termostatos, garante confiabilidade.

Solução: Desenvolva um plano de capital para substituir equipamentos antigos. Considere modelos energeticamente eficientes com alarmes integrados e monitoramento remoto. Marca da unidade de documento, modelo e especificações para verificar a estabilidade da temperatura.

Desafio 2: Erro humano e fluxo de trabalho

Os funcionários podem inadvertidamente deixar portas abertas ou perder vacinas. Unidades superlotadas podem restringir o fluxo de ar e causar flutuações de temperatura.

Solução: Implementar procedimentos operacionais padrão (POPS) que atribuem responsabilidades pelas verificações diárias de temperatura, rotação de estoque e ações emergenciais. Use dicas visuais e etiquetas de armazenamento para organizar as vacinas.

Desafio 3: Excursões de temperatura durante o transporte

O transporte de vacinas entre instalações ou para clínicas de extensão aumenta o risco de excursões. Cada tipo de vacina requer materiais de embalagem e temperaturas de transporte específicos.

Solução: Use recipientes isolados com bolsas de gelo condicionadas ou materiais de mudança de fase. Incluir DDLs em cada contêiner de transporte para monitorar continuamente a temperatura. Treinar a equipe para embalar produtos refrigerados e congelados separadamente e registrar os horários em que os contêineres são abertos.

Tecnologias emergentes e inovações moldando a cadeia de frio de vacinas

Os rápidos avanços tecnológicos estão transformando a gestão da cadeia de frio. Aqui estão as principais inovações que remodelam 2025 e além.

Blockchain para rastreabilidade ponta a ponta

A tecnologia Blockchain cria uma prova de adulteração, cadeia cronológica de transações. Cada etapa da cadeia de fornecimento – do fabricante à clínica – é registrada, aumentando a transparência e a segurança. Na farmacêutica, blockchain ajuda compartilhe dados em tempo real sobre temperatura, umidade e tempo de trânsito com todas as partes interessadas. Esta transparência reduz o risco de produtos falsificados e garante a conformidade regulamentar.

Benefício prático: A implementação do blockchain pode alertá-lo instantaneamente sobre variações de temperatura e fornecer um registro imutável para auditorias ou recalls.

Unidades frigoríficas movidas a energia solar

Em regiões com eletricidade não confiável, unidades movidas a energia solar fornecer armazenamento sustentável e confiável. Reduzem os custos de energia através da utilização de energia renovável e mantêm vacinas em áreas remotas. Os EUA. A Energy Information Administration informou que em 2024, os usuários comerciais pagaram em média 13.10 centavos por quilowatt-hora, enquanto o armazenamento solar refrigerado poderia reduzir isso para 3.2–15,5 centavos por kWh. As soluções solares não só apoiam os cuidados de saúde rurais, mas também reduzem os custos operacionais e as pegadas de carbono.

Sensores inteligentes habilitados para IoT

Internet das coisas (IoT) sensores conectar geladeiras, freezers e contêineres de transporte para a nuvem. Esses sensores coletam dados em tempo real sobre temperatura e localização, enviando alertas se as condições saírem dos parâmetros seguros. Eles também permitem rastreamento por GPS, permitindo que as equipes de logística respondam rapidamente a atrasos e redirecionem as remessas conforme necessário. Sensores ativos podem reduzir a perda de produto e melhorar a eficiência operacional.

Inteligência artificial para otimização de rotas e análise preditiva

Inteligência artificial (IA) combina dados em tempo real com tendências históricas para otimizar rotas de entrega, prever a demanda e identificar necessidades de manutenção de equipamentos. A otimização de rotas orientada por IA usa dados de tráfego e meteorológicos para reduzir o tempo de trânsito e reduzir a degradação da qualidade. A análise preditiva pode antecipar variações de temperatura e permitir respostas proativas, aumentando a confiabilidade e a segurança do paciente.

Congeladores criogênicos portáteis

Inovações em tecnologia criogênica fornecem freezers portáteis capaz de manter −80 °C a −150 °C. Essas unidades são vitais para produtos biológicos, terapias celulares e certas vacinas de mRNA. Eles oferecem rastreamento de temperatura em tempo real e notificações de alarme, permitindo transporte seguro para áreas remotas onde falta infraestrutura. Congeladores criogênicos portáteis suportam medicina personalizada, terapias genéticas e futuras plataformas de vacinas.

Soluções de embalagens sustentáveis

À medida que as preocupações ambientais crescem, empresas da cadeia de frio estão adotando contêineres isolados recicláveis, envoltórios térmicos biodegradáveis e compressas frias reutilizáveis. As embalagens sustentáveis protegem os produtos sensíveis à temperatura, ao mesmo tempo que reduzem o desperdício e a pegada de carbono. Estas inovações estão alinhadas com a responsabilidade social corporativa e as regulamentações emergentes.

2025 Desenvolvimentos e Tendências da Cadeia de Frio

A indústria da cadeia de frio está passando por rápidas mudanças devido aos avanços tecnológicos, crescimento do mercado e mudanças nas expectativas dos consumidores. Aqui estão os principais tendências para 2025 você precisa saber.

Visão geral das tendências

Automação e robótica: A indústria enfrenta escassez de mão de obra e custos crescentes. Sistemas automatizados de armazenamento e recuperação (AS/RS) e manipuladores robóticos agilizam processos, reduzir erros e operar continuamente. Estudos mostram sobre 80 % dos armazéns ainda não são automatizados, revelando um potencial de crescimento significativo.

Sustentabilidade como valor fundamental: As regulamentações e a pressão dos consumidores estão a pressionar as empresas a adoptarem uma refrigeração energeticamente eficiente, energia renovável e embalagens ecológicas. A cadeia global de frio alimentar contribui com cerca de 2 % das emissões globais de CO₂, estimulando o investimento em soluções mais ecológicas.

Visibilidade de ponta a ponta com rastreamento em tempo real: Dispositivos e software IoT fornecem insights contínuos sobre localização, temperatura e condição. O segmento de hardware foi responsável 76.4 % do mercado de rastreamento da cadeia de frio em 2022, refletindo uma forte adoção. O rastreamento em tempo real permite a otimização da rota, reduz a deterioração e melhora a satisfação do cliente.

Modernizando a infraestrutura: Instalações frigoríficas antigas estão sendo atualizadas com refrigeração avançada, melhor isolamento e sistemas de energia renovável. Os investimentos na eficiência energética e na recolha moderna de dados reduzem a exposição aos custos voláteis da energia.

IA e análise preditiva: Ai ajuda a otimizar as rotas, prever a demanda e prever a manutenção do equipamento. A análise preditiva reduz os riscos analisando dados históricos e em tempo real.

Crescimento na cadeia de frio farmacêutica: A pandemia acelerou os investimentos em armazenamento ultrafrio. Aproximadamente 20 % de novos medicamentos são terapias genéticas ou celulares que exigem controle rigoroso de temperatura. O mercado global da cadeia de frio farmacêutico deverá atingir US$ 1.454 bilhões por 2029, com um CAGR de 4.71 % de 2024 - 2029.

Logística alimentar e entrega de última milha: Espera-se que o mercado norte-americano da cadeia de frio alimentar atinja $86.67 bilhão por 2025, impulsionado pela demanda do consumidor por produtos frescos e alternativas à base de plantas. O crescimento nas vendas diretas ao consumidor exige melhores estratégias de entrega na última milha.

Parcerias estratégicas e integração: Colaboração entre fabricantes, fornecedores de embalagens e fornecedores de tecnologia aumentam a eficiência e a resiliência. Por 2025, 74 % espera-se que os dados logísticos sejam padronizados, permitindo uma integração perfeita em toda a cadeia de abastecimento.

Crescimento e resiliência do mercado: O mercado global de logística da cadeia de frio foi avaliado em USD 293.58 bilhão em 2023 e está projetado para crescer até USD 862.33 bilhão por 2032 (Cagr 13 %). Prevê-se que o sector farmacêutico, por si só, atinja US$ 1.454 bilhões por 2029. Este crescimento sublinha a necessidade de uma integração, soluções resilientes para cadeia de frio.

Últimos destaques do progresso

Adoção de automação: Apenas cerca de 20 % dos armazéns atualmente usam automação, indicando grande vantagem para a robótica em 2025.

Energia renovável: Unidades frigoríficas movidas a energia solar reduzem os custos operacionais de 13.10 centavos por kWh para um valor tão baixo quanto 3.2 centavos por kWh.

Penetração de rastreamento em tempo real: Hardware contabilizado 76.4 % do mercado de rastreamento e monitoramento em 2022.

Projeções de crescimento: O mercado farmacêutico da cadeia de frio deverá ultrapassar US$ 1,4 trilhão até 2029; espera-se que o mercado global de logística ultrapasse o USD 862 bilhão por 2032.

Insights de mercado

Fatores geopolíticos pode afetar os tempos de trânsito e a capacidade. 2024 interrupções afetaram a disponibilidade de espaço de armazenamento refrigerado e transporte, mas a resiliência da indústria melhorou.

Produtos emergentes (proteínas à base de plantas, terapias genéticas) exigem capacidades especializadas na cadeia de frio e criam oportunidades para pequenos produtores.

Modernização da infraestrutura acelerará à medida que as regulamentações eliminarem gradualmente os refrigerantes nocivos e incentivarem o design sustentável.

Parcerias de logística integrada oferecer experiência e alcance de rede para pequenas empresas que entram em mercados globais.

Perguntas frequentes

Por que a gestão da cadeia de frio das vacinas é importante?

Manter as vacinas dentro das temperaturas prescritas garante que elas permaneçam potentes e seguras. A exposição ao calor ou ao congelamento pode degradar as vacinas e levar a surtos de doenças evitáveis. A gestão adequada da cadeia de frio protege os pacientes e minimiza as perdas financeiras.

Qual é a faixa de temperatura recomendada para armazenamento de vacinas?

A maioria das vacinas deve ser armazenada entre 2 °C e 8 °C em uma geladeira e −50 °C a −15 °C em um freezer. Vacinas ultrafrias podem exigir -90 ° C a -60 ° C.

Como os registradores de dados digitais melhoram a segurança das vacinas?

DDLs fornecem suporte contínuo, monitoramento preciso da temperatura e registro de históricos de temperatura em intervalos predefinidos. Eles alertam a equipe sobre temperaturas fora da faixa, permitindo ação imediata e prevenindo a deterioração da vacina.

As vacinas podem ser armazenadas em uma geladeira doméstica?

Não. As unidades combinadas domésticas muitas vezes apresentam flutuações de temperatura e correm o risco de congelar as vacinas. Recomenda-se refrigeradores e freezers autônomos de qualidade médica para manter temperaturas estáveis.

O que devo fazer se houver uma variação de temperatura?

Registre o tempo e a temperatura assim que descobrir a excursão. Mova as vacinas para uma unidade de armazenamento alternativa que mantenha a faixa de temperatura correta. Marque as vacinas afetadas como “Não usar” e consulte o seu programa de imunização ou o fabricante da vacina antes da administração.

Resumo e recomendações

Takeaways -chave:

Manter faixas de temperatura corretas (2 °C – 8 °C para refrigeradores; −50 °C – −15 °C para congeladores; −90 °C – −60 °C para unidades ultrafrias) é essencial.

Use sozinho, equipamento de nível médico; organize as vacinas nas prateleiras do meio e evite o armazenamento na porta.

Empregue registradores de dados digitais calibrados com alarmes e sondas com buffer; baixe e revise dados regularmente.

Prepare-se para emergências com energia reserva, locais de armazenamento alternativos e limpar SOPs.

Fique atento a inovações como blockchain, energia solar, Sensores de IoT, IA e embalagens sustentáveis.

Monitore as tendências do setor: adoção de automação, sustentabilidade, rastreamento em tempo real, modernização da infraestrutura, IA, crescimento em produtos farmacêuticos, logística de última milha e parcerias estratégicas.

Plano de ação:

Avalie seu equipamento atual de cadeia de frio. Atualize para unidades de nível farmacêutico e planeje capacidade ultra fria se você manusear mRNA ou terapias genéticas.

Implementar monitoramento contínuo. Use DDLs em todas as unidades de armazenamento e transporte; treinar a equipe para responder a alarmes e documentar registros de temperatura.

Desenvolva e ensaie um plano de emergência. Identifique locais de armazenamento de backup, manter energia reserva, e criar listas de verificação para transporte e excursões.

Explorar novas tecnologias. Considere sensores IoT, soluções blockchain e unidades movidas a energia solar para melhorar a visibilidade e a resiliência.

Mantenha-se informado sobre as tendências do setor. Fique de olho na automação, sustentabilidade e crescimento do mercado para antecipar necessidades e oportunidades futuras.

Sobre Tempk

No Tempk, somos especialistas em soluções para cadeia de frio. Nossa equipe projeta e fabrica refrigeradores de qualidade farmacêutica, freezers e unidades ultrafrias projetado para consistência e confiabilidade. Nós integramos Sensores IoT e registradores de dados digitais calibrados em nossos equipamentos, fornecendo dados de temperatura e localização em tempo real para ajudá-lo a manter a conformidade e evitar perda de produto. Nossas soluções são energeticamente eficientes, minimizando custos operacionais e impacto ambiental.

Se você gerencia uma farmácia hospitalar, clínica de saúde pública ou centro de pesquisa, nós faça parceria com você para adaptar sistemas de armazenamento e monitoramento às suas vacinas e fluxos de trabalho específicos. Nossos especialistas auxiliam na instalação, treinamento de pessoal e suporte contínuo, garantindo que sua cadeia de frio permaneça segura e eficiente.

Pronto para melhorar a cadeia de frio da sua vacina? Contate-nos para uma consulta e descubra como o Tempk pode ajudá-lo a proteger suas vacinas e seus pacientes.