Cadeia de Frio para Gestão de Alimentos Congelados: 2025 Guia para manter as mercadorias seguras

Keeping frozen foods safe throughout the cold chain is critical to your business and your customers. AS dezembro 2, 2025 the cold chain industry faces tighter regulations, rising energy costs and evolving consumer expectations, so understanding how to manage frozen foods has never been more important. Este guia explica cold chain for frozen foods management in simple terms and shows you how to maintain ideal temperatures, comply with regulations and leverage new technologies. Para contexto, Projeta-se que o mercado de logística da cadeia de frio cresça de USD 324.85 bilhão em 2024 para USD 862.33 bilhão por 2032, um 13 % Cagr, and refrigeration systems already account for 20 % do consumo global de eletricidade. The sooner you master frozen food logistics, the more you’ll protect your product quality and bottom line.

Why cold chain management matters for frozen foods: learn how inadequate cold chains lead to food loss and energy waste and why frozen foods must stay at sub zero temperatures.

How to maintain ideal temperature ranges: discover the temperature categories (frio, congelado, ultracongelado) and why frozen goods should stay between −10 °F and 0 °F.

Best practices for receiving, storing and transporting frozen foods: explore techniques like pre cooling goods, embalagem validada, IoT monitoring and contingency planning.

Regulations and compliance in 2025: understand how FSMA Rule 204, HACCP and Good Distribution Practices shape recordkeeping and traceability.

Emerging trends and technologies: see how plant based products, instalações atualizadas, sustainability initiatives and real time visibility will reshape frozen food logistics.

Why does cold chain management matter for frozen foods in 2025?

Frozen foods rely on stable sub zero temperatures to prevent microbial growth and preserve quality, yet the global refrigeration industry faces mounting pressures. De acordo com o Instituto Internacional de Refrigeração (IIR), 12 % da produção global de alimentos é perdida devido à insuficiência de cadeias de frio, and expanding cold chain infrastructure could save 475 milhões de toneladas de alimentos. Ao mesmo tempo, refrigeração é responsável por 20 % of global electricity consumption and 7.5 % das emissões globais de CO₂, underscoring the energy and climate stakes. The cold chain logistics market, avaliado em USD 324.85 bilhão em 2024, está projetado para atingir USD 862.33 bilhão por 2032. As demand for frozen foods, pharmaceuticals and vaccines grows, the pressure to maintain flawless temperature control increases.

The scale of the frozen food cold chain

The frozen foods cold chain touches almost every household. Aproximadamente 70 % of food consumed in the United States relies on cold chain infrastructure, e sobre 5.4 billion refrigeration systems operate worldwide. Frozen foods—including meat, frutos do mar, ready meals and ice cream—must remain at temperatures between −10 °F and 0 °F (−23 °C to −18 °C) to retain texture and prevent microbial growth. Produtos ultracongelados, such as ice cream and high grade seafood, often require temperatures below −20 °F (−29 °C). When temperatures rise, moisture evaporates, ice crystals expand and cells rupture, leading to freezer burn, texture loss and spoilage.

| Razão | Evidência | O que isso significa para você |

| Food waste and security | Até 12 % of global food production is lost due to inadequate cold chains. | Improving frozen food logistics prevents losses, protects profits and reduces hunger. |

| Energy and climate impact | Refrigeration uses 20 % da eletricidade global and contributes 7.5 % das emissões de CO₂. | Efficient equipment and insulation lower your energy bills and carbon footprint. |

| Crescimento do mercado | The cold chain market is projected to crescer para USD 862.33 bilhão por 2032. | Investment in state of the art equipment and training positions your business for growth. |

| Demanda do consumidor | Plant based foods and high value seafood require strict temperature control. | Ensuring your cold chain can handle new product categories opens up fresh revenue streams. |

Practical tips for understanding the value of your frozen food cold chain

Quantify losses: calculate how much product you lose annually due to temperature excursions; even a two hour deviation can spoil a shipment worth $500 k or more.

Avalie a infraestrutura: identify whether your freezers and reefer trucks are over 40 anos; outdated insulation and refrigerants reduce efficiency.

Considere a sustentabilidade: track energy consumption and choose low GWP refrigerants to align with climate targets.

Eduque sua equipe: emphasise how cold chain failures lead to wasted food and energy, regulatory fines and customer dissatisfaction.

Caso do mundo real: A produce distributor extended shelf life by investing in insulated packaging and IoT sensors. Quando a porta de um caminhão foi deixada aberta, temperature data alerted staff, evitando deterioração e salvando a remessa.

How to maintain ideal temperatures in a frozen food cold chain?

Maintaining proper temperatures is the core of frozen food safety, yet different products require distinct temperature categories. For refrigerated goods like fresh meat and dairy, a constant 40 °F (4 °C) ou abaixo retarda o crescimento microbiano. Alimentos congelados, no entanto, must remain at or below 0 °F (-18 ° C.) according to the Nebraska Department of Agriculture’s TCS guide. Deep frozen items such as premium seafood and ice cream often travel at −20 °F to −30 °F (−29 °C to −34 °C) to prevent ice crystals and preserve texture. Temperature categories help you map each product’s needs and select appropriate equipment.

Temperature ranges by product type

Different food categories thrive at different temperatures. Use the following guide to match products with their ideal ranges and understand why those ranges matter:

| Categoria de temperatura | Faixa (°C / °F) | Alimentos Típicos | O que isso significa para você |

| Banana / Tropical | 12–14ºC (54–57°F) | Bananas, abacaxi | Keep tropical fruits in this higher range to avoid chilling injury. |

| Frio (Refrigerado) | 2–4ºC (35–39°F) | Produção fresca, laticínio | Maintains crispness and prevents bacterial growth. |

| Congelado | −10 °C a −20 °C (14 °F to −4 °F) | Legumes congelados, carnes | Must stay abaixo 0 °F to maintain texture; hold at 0 °F or lower during transportation. |

| Congelado | −25 °C a −30 °C (−13 °F to −22 °F) | Sorvete, frutos do mar premium | Evita cristais de gelo e preserva o sabor. |

| Refrigerado (Em geral) | 2–7 °C (35–45°F) | Frutas frescas, laticínio | Evite congelar; manter a umidade para evitar a desidratação. |

| Temperature Controlled (Ambiente) | 10–21ºC (50–70°F) | Chocolate, vinho | Moderate temperatures prevent melting or chemical changes. |

Dicas práticas para controle de temperatura

Pré-resfrie tudo: Reefer trailers maintain cold conditions but cannot rapidly cool warm cargo. Pre chill frozen foods, packaging and vehicles before loading.

Use embalagens validadas: Select insulated shippers with gel packs, dry ice or phase change materials tailored to your product’s needs.

Load properly: Empilhe os produtos para permitir a circulação de ar e evitar bloquear as aberturas de ventilação; overpacking restricts airflow and causes temperature gradients.

Monitore continuamente: Employ data loggers and real time IoT sensors to record temperature and humidity across the journey.

Calibrar equipamento: Regularly calibrate thermometers and refrigeration units to ensure accurate readings.

Documente e responda: Keep digital records of any temperature excursions, including duration, cause and corrective actions.

Caso real: A dairy processor added humidity sensors to refrigerated trailers to prevent condensation on milk cartons. Adjusting ventilation improved product appearance and reduced returns.

Best practices for receiving, storing and transporting frozen foods

A robust frozen food cold chain involves precise processes from receiving to delivery, not just temperature control. Each touchpoint—receiving goods, armazenar, preparação, carregando, transport and delivery—introduces risks of contamination, temperature excursions and delays. Best practices minimise these risks.

Receiving and storage

Inspecione após o recebimento: Verify that incoming shipments arrive at the correct temperature; reject loads that exceed acceptable ranges. Use calibrated thermometers to check core temperatures. Para alimentos congelados, ensure they are solidly frozen.

Use áreas de preparação: Mantenha uma área de preparação com temperatura controlada perto das docas de carga para minimizar a exposição durante a transferência. Avoid leaving frozen goods at ambient temperatures for more than duas horas; reduzir para uma hora quando a temperatura ambiente exceder 90 °F.

Armazéns de zona: Separe as áreas de armazenamento por categoria de temperatura – frio, frozen and deep frozen—to prevent cross contamination and maintain consistent conditions.

Girar inventário: Follow first in, primeiro a sair (FIFO) principles to minimise aging stock and maintain product quality. Track shelf life and freeze by dates in your warehouse management system.

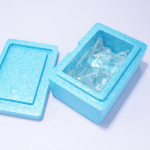

Packaging and preparation

Escolha a embalagem certa: Use active packaging (resfriamento mecânico), embalagem passiva (pacotes de gel, gelo seco) or hybrid solutions depending on the product and journey length. Packaging should create a protective microclimate and remain intact through the transport duration.

Rotule e documento: Incluir tipo de produto, código de lote, storage requirements and expiration date on each package. Clear labeling speeds up inspections and traceability.

Cargas seguras: Arrange boxes to allow air circulation and avoid crushing delicate items. For pallet shipments, use pallet wraps or netting to stabilise the load.

Pre cool packaging materials: Pacotes de gel legais, phase change materials and dry ice prior to packing so they can immediately absorb heat.

Transport and delivery

Inspeções pré-viagem: Check reefer settings, níveis de combustível, door seals and sensor functionality before departure.

Monitoramento contínuo: Use IoT sensors and telematics to track temperature, umidade e localização em tempo real, permitindo ações corretivas imediatas.

Otimização de rota: Plan the fastest paths, avoid congested or hot routes and schedule runs during cooler parts of the day.

Comunicação: Provide real time updates to customers about estimated arrival times, reducing missed deliveries.

Leve suprimentos de backup: Estoque de pacotes de gel sobressalentes, gelo seco, portable generators and have emergency contact lists ready. Develop contingency plans with clear temperature triggers and actions.

Packaging and monitoring innovations

Technological advances are reshaping how frozen foods are packaged and monitored:

| Inovação | Descrição | Beneficiar |

| Embalagem térmica validada | Insulated shippers with gel packs or phase change materials maintain target temperatures throughout transit. | Offers long lasting cooling and reduces energy draw from reefers. |

| Reboques multizona | Trucks with separate chambers allow chilled, frozen and deep frozen goods to ride together. | Optimises routing and reduces the number of vehicles needed. |

| Sensores IoT e registradores de dados | Sensors provide continuous temperature, dados de umidade e localização. | Real time alerts prevent spoilage and supply chain blind spots. |

| Geofencing e alertas | Systems trigger notifications when vehicles deviate from planned routes or doors open unexpectedly. | Enables quick response to delays or theft attempts. |

| Controle de umidade | Sensors help maintain optimal humidity, preventing dehydration and condensation. | Enhances product appearance and reduces label damage. |

Practical tips for receiving, armazenamento e transporte

Accept or reject: When receiving goods, document temperature readings and reject shipments outside the acceptable range.

Minimise exposure: Transfer frozen goods quickly between environments; use temperature controlled staging areas.

Separate and rotate: Maintain distinct zones for chill, frozen and deep frozen goods and follow FIFO principles.

Use data: Analyse sensor data to identify routes or handlers that cause temperature excursions; adjust training or equipment accordingly.

Plano para emergências: Designate backup drivers, alternate routes and cold storage facilities; drill staff to execute contingency plans when triggers (por exemplo, 10 °C) are reached.

Caso real: A frozen meal manufacturer installed geofencing alerts that notified drivers and managers when a truck deviated from its route. A breakdown occurred, but the system automatically dispatched a backup vehicle and transferred the load within 40 minutos, preserving the shipment’s integrity.

Regulatory and compliance landscape in 2025

Food safety regulations underpin the frozen food cold chain, e 2025 brings important changes. Os EUA. Lei de Modernização da Segurança Alimentar (FSMA) Regra 204, also known as the Food Traceability Rule, sets additional recordkeeping requirements for high risk foods. The FDA originally set the compliance date for Janeiro 20, 2026, but has proposed extending it by 30 meses até julho 20, 2028. Companies subject to the rule must record Key Data Elements (KDEs) para eventos críticos de rastreamento (CTEs) e fornecer informações ao FDA dentro 24 horas. Alongside FSMA, Análise de perigos e pontos críticos de controle (HACCP), Boas Práticas de Distribuição (PIB) e ISO 22000 require systematic hazard identification, controle de temperatura, documentation and continuous improvement.

Major regulations and their requirements

| Regulamento/Norma | Requisitos principais | Significado prático |

| Regra FSMA 204 (Regra de Rastreabilidade Alimentar) | Record KDEs (o que, onde, quando, Quem) for CTEs (colheita, embalagem, envio, recebendo); fornecer dados dentro 24 horas; assign traceability lot codes. | Facilitates rapid recall and protects public health. Ensures that high risk frozen foods like seafood and ready meals can be traced quickly in case of contamination. |

| HACCP | Identificar perigos (por exemplo, crescimento microbiano, contaminação cruzada); estabelecer limites críticos (temperatura, tempo); define corrective actions and verification. | Builds preventive controls into each step of the frozen food cold chain; mandates continuous monitoring and documentation. |

| PIB (Boas Práticas de Distribuição) | Emphasises proper packaging, documentação, staff training and risk management for temperature sensitive products. | Ensures that warehouses and carriers maintain consistent practices and training across the distribution network. |

| ISO 22000 / ISO 9001 | Provide quality management frameworks requiring documented procedures, responsibilities and continuous improvement. | Helps align cold chain operations with international quality and food safety standards; supports certification and customer trust. |

| FSMA 204 compliance date extension | The FDA proposed extending the compliance date from Janeiro 20, 2026 para Julho 20, 2028. | Gives businesses more time to implement digital traceability systems; still important to start now due to resource requirements. |

Practical steps to meet compliance

Avalie seu cenário regulatório: Determine which rules apply to your products—FSMA 204 (alimentos de alto risco), PIB (distribuição), Lei de Segurança da Cadeia de Abastecimento de Medicamentos (produtos farmacêuticos), Normas HACCP e ISO.

Mapeie sua cadeia de suprimentos: Document every Critical Tracking Event (colheita, processamento, armazenar, transporte) and assign Key Data Elements for each.

Atualizar tecnologias de monitoramento: Invista em sensores IoT e plataformas em nuvem para temperatura em tempo real, dados de umidade e localização.

Implementar documentação digital: Garanta que os registros sejam interoperáveis, seguro e facilmente pesquisável; move away from paper or isolated spreadsheets.

Treine sua equipe: Provide role specific training on regulatory requirements, documentação e procedimentos de emergência. Untrained staff can misread temperature logs or ignore SOPs.

Fornecedores de auditoria: Include temperature requirements in contracts and regularly audit supplier compliance.

Planeje contingências: Prepare-se para falhas de equipamento, delays or temperature deviations with backup plans and clearly defined actions.

Estudo de caso: Um distribuidor de produtos agrícolas enfrentando a FSMA 204 deadlines adopted blockchain based traceability. Ao atribuir códigos de lote e capturar KDEs na colheita, embalagem e envio, the company reduced recall response time from days to hours. Digital records combined with IoT temperature logs satisfied auditors and boosted consumer confidence.

2025 trends and innovations shaping frozen food cold chains

A indústria da cadeia de frio está evoluindo rapidamente. De acordo com a Maersk 2024/2025 panorama, five key trends will define 2025:

Market changes and geopolitical influences: Geo political unrest and trade disruptions have impacted transit times and capacity availability. Cold chain operators are investing in resilience to cope with changing demand and black swan events.

Visibilidade mais forte: 2025 will see continued investment in software that improves visibility across the supply chain. Uninterrupted data for location tracking and temperature monitoring allows operators to handle disruptions proactively.

Novas categorias de produtos: The rise of plant based and gluten free products introduces new temperature requirements. Alimentos à base de plantas podem ser responsáveis por 7.7 % do mercado global de proteínas por 2030, requiring cold chains that can adapt to small batch shipments.

Instalações atualizadas: Ageing cold storage facilities—many 40–50 years old—are being replaced or refurbished. As regulamentações estão eliminando gradualmente refrigerantes nocivos como HCFCs e HFCs, pushing operators to invest in automation and sustainability.

Better distribution and proximity to customers: New cold storage construction near ports, production areas and retail hubs will enhance access and reduce transit times.

Beyond these industry wide trends, several technological innovations are emerging:

Monitoramento de IoT em tempo real: Leading operators deploy networks of sensors across warehouses, caminhões e veículos de última milha. Esses sensores monitoram a temperatura, humidity and handling conditions in real time and send alerts immediately when deviations occur.

Integrated supply chain platforms: Systems linking warehouse management (WMS), transport management (EMT), planejamento de recursos empresariais (ERP) and IoT dashboards provide end to end visibility. Managers can track each pallet and detect bottlenecks before problems arise.

Embalagem térmica avançada: Insulated containers with phase change materials and optimized pallet layering maintain consistent temperatures across long transit routes. These packages are tested for worst case scenarios (high ambient heat, tempos de trânsito estendidos) to ensure product integrity.

Análise preditiva e IA: Data from sensors and historical shipments can be analyzed to predict temperature excursions and optimize routes. Identifying patterns such as hot routes or frequently failing equipment helps prevent future losses.

Tecnologias de refrigeração sustentáveis: Low global warming potential (PAG) refrigerantes, energy efficient heat pumps and district cooling systems reduce energy consumption and emissions. Replacing HCFCs and HFCs with natural refrigerants (por exemplo, Co₂, amônia) helps meet environmental regulations.

Insights de mercado

The frozen food sector is not only growing but also diversifying. Demographic changes and urbanisation drive demand for convenient frozen meals, while health trends encourage plant based alternatives. Fortune Business Insights projects the global cold chain market to grow at 13 % CAGR de 2024 para 2032, alcançando USD 862.33 bilhão por 2032. Pharmaceutical cold chain revenue is expected to grow 4.71 % anualmente através 2029, alcançando USD 1.454 trilhão por 2029. Enquanto isso, the healthcare cold chain market is projected to reach USD 17.8 bilhão por 2033. These figures indicate a need for versatile cold chain infrastructure that can handle foods, biologics and vaccines simultaneously.

Perguntas frequentes

Q1: How cold should frozen foods be kept during transport?

Frozen foods must remain at or below 0 °F (-18 ° C.) durante o transporte. Deep frozen items like ice cream and premium seafood often need temperatures between −25 °C e −30 °C. Maintaining these ranges preserves texture and flavour. Use calibrated sensors to monitor temperature continuously and discard products if they stay outside the range for more than two hours.

Q2: Why is real time monitoring important for frozen foods?

Mesmo um two hour temperature deviation can spoil an entire shipment worth $500 k or more. Real time monitoring via IoT sensors provides immediate alerts when temperatures drift outside safe zones, allowing you to reroute shipments or deploy backup equipment before products are compromised. Sem dados em tempo real, excursions may go unnoticed until it’s too late.

Q3: What regulations govern frozen food cold chains in 2025?

O FSMA Food Traceability Rule (Regra 204) requires companies handling high risk foods to record Key Data Elements for Critical Tracking Events and provide them to the FDA within 24 horas. The FDA proposed extending the compliance date from Janeiro 20, 2026 para Julho 20, 2028. HACCP mandates hazard analysis and critical limits, GDP emphasises proper packaging and documentation, e ISO 22000/9001 require quality management systems.

Q4: How can I reduce energy consumption in my frozen food cold chain?

Refrigeration accounts for 20 % do consumo global de eletricidade, so improving efficiency saves money and reduces emissions. Upgrade to energy efficient compressors, insulate walls and doors, and use variable speed drives to match cooling output to demand. Consider low GWP refrigerants and heat recovery systems. Regularly maintain equipment and monitor energy usage. Efficient route planning and multi zone trailers also reduce energy per shipment.

Q5: What should I do if a temperature excursion occurs during transport?

Document the excursion’s duration, cause and corrective actions immediately. Activate your contingency plan: move cargo to backup refrigeration, deploy additional gel packs or dry ice, and reroute to the nearest cold storage facility. Inform stakeholders and keep records for compliance purposes. Analyse the incident later to prevent recurrence.

Resumo e recomendações

Takeaways -chave: Frozen food cold chain management hinges on strict temperature control, robust processes, regulatory compliance and continuous innovation. Product specific temperature ranges—0 °F or lower for frozen foods e −25 °C to −30 °C for deep frozen goods—must be maintained. Insufficient cold chains cause up to 12 % da perda global de alimentos and consume 20 % da eletricidade global. Best practices include pre cooling goods, embalagem validada, continuous IoT monitoring, documentação, and emergency planning. Regulatory frameworks—FSMA 204, HACCP, GDP and ISO—require digital traceability and preventive controls. Emerging trends such as real time visibility, upgraded facilities and plant based products will shape the market in 2025.

Plano de ação:

Conduza uma auditoria da cadeia de frio: Map each step of your frozen food supply chain, record temperature requirements and identify weak links.

Atualizar equipamento: Invest in energy efficient freezers, multi zone trailers and validated packaging solutions. Consider low GWP refrigerants to reduce emissions.

Implementar monitoramento de IoT: Deploy sensors and integrated platforms for real time visibility and immediate alerts; integrate data with your WMS and TMS.

Develop a digital documentation system: Adopt cloud based recordkeeping to meet FSMA 204 requirements and simplify audits.

Treinar e capacitar a equipe: Provide comprehensive training on temperature control, análise de perigo, resposta de emergência e documentação. Use performance data to coach employees and reduce errors.

Fique à frente dos regulamentos: Monitore atualizações para FSMA 204 and other standards; begin implementation now despite the extended compliance deadline.

Sobre Tempk

Tempk é um fornecedor líder de soluções de embalagem para cadeia de frio, insulation materials and IoT monitoring technologies. Our team combines decades of experience in food and pharmaceutical logistics with research driven product development. Nós nos concentramos ecológico, produtos reutilizáveis e recicláveis da cadeia de frio, using high quality insulation and refrigerants to ensure consistent temperatures. Nosso R&D centre continually tests new materials and designs, while our quality guarantee ensures every product meets strict performance standards. Em parceria com o Tempk, you gain access to innovative packaging, real time monitoring and expert guidance to streamline your frozen food cold chain.

Chamado à ação: Ready to strengthen your frozen food cold chain? Contact our experts for a tailored assessment and discover how our insulated boxes, IoT sensors and consulting services can protect your products and boost profitability. Let’s build a safer, more sustainable cold chain together.