Folhas de embalagens de gelo seco reutilizáveis: 2025 Guia do comprador

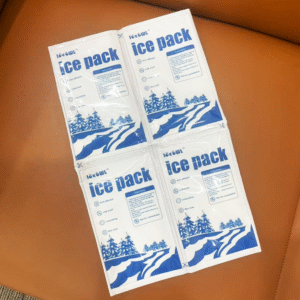

Folhas de gelo seco reutilizáveis help you hold 2–8 °C reliably, cortar vazamento, e evite a papelada de mercadorias perigosas. Use them for chilled and mild frozen lanes; switch to real dry ice for ≤ −60 °C or long, delay‑prone routes. Dry ice is −78.5 °C and requires UN1845/PI954 labeling and vented packaging; sheets are hydratable polymer gels you soak, congelar, e reutilizar.

Última atualização: Setembro 2, 2025

-

When are reusable dry ice pack sheets the better choice for meal kits, frutos do mar, cosméticos, and 2–8 °C pharma.

-

When real dry ice is mandatory and which PI954/UN1845 marks matter most.

-

How many sheets you need with a quick calculator and validation tips.

-

How to pack for fewer excursions using simple spacers, forros, e registradores de dados.

How do reusable dry ice pack sheets work for 2–8 °C?

Resposta curta: Reusable dry ice pack sheets are hydratable gel “ice blankets,” not solid CO₂. You soak, congelar, and reuse them to deliver steady, dry cold for 24–72 h in insulated parcels. That keeps food and health products in the safe zone without hazmat labels. Real dry ice is for ultra‑cold.

Na prática: You hydrate the sheet 2–5 minutes, Pat seco, and freeze flat 12–18 hours. The many small cells store “cold energy” and release it slowly, como uma bateria, keeping your parcel near 2–8 °C. If your lane needs gentler frozen, add more sheets and improve insulation; for ≤ −60 °C, pick dry ice and follow acceptance rules. Food‑safety guidance favors gel packs for chilled delivery and thermometer checks on arrival.

Hydratable ice sheets: ativação & freezing tips

Hydrate until cells swell evenly, then freeze at −10 to −20 °C on trays so sheets stay flat. Pre‑chill your product (por exemplo, 34–36 °F for food) and isolate delicate items with a corrugated pad to avoid “cold burn.” These steps extend hold time and protect sensitive textures.

| Escolha do refrigerante | O que é isso | Faixa típica | O que isso significa para você |

|---|---|---|---|

| Folhas de gelo seco reutilizáveis | Hydratable polymer gel cells | 2–8 ° C., leve congelado | Limpar, reutilizável, no DG paperwork—ideal for groceries and D2C. |

| Gelo seco real (UN1845) | Solid CO₂ at −78.5 °C | ≤ −60 °C holds | Ultra‑cold power; requires PI954 labels and vented packaging. |

| 2–8 °C PCM panels | Set‑point phase‑change packs | 72–120 h with VIP | Tightest control for vaccines/biologics; investimento mais elevado, reutilizável. |

Dicas práticas que você pode aplicar hoje

-

Kits de refeições (30–48h): principal & bottom sheet layers; meats near cold source, greens centered; spot‑check ≤ 40 °F on receipt.

-

Chocolates in summer: add a foil liner to cut radiant heat and a top pad to prevent frosting marks.

-

Frutos do mar (2‑day air): two sheet layers plus absorbent liner; log the first three runs and tune sheet count by ±1.

Caso real: A bakery replaced loose ice with reusable dry ice pack sheets on a 2‑day lane and held 36–41 °F arrivals while eliminating soggy‑box returns—no carton redesign, just disciplined packouts.

When are reusable dry ice pack sheets better than dry ice?

Use reusable dry ice pack sheets for controlled 2–8 °C or mild frozen shipments where hazmat labels, ventilação, and net‑kg markings would slow operations. Use gelo seco de verdade when product specs require ≤ −60 °C or you need long buffers for delays. This “chilled vs ultra‑cold” split aligns with 2025 carrier and food‑safety guidance.

Sizing reusable dry ice pack sheets—quick calculator

Use this first‑pass estimate, then validate with a data logger (ISTA 7D/7E‑style):

# Sheets needed with a 20% buffer

carga_Wh = caixa_U_W_per_C * delta_T * duração_h

folhas = redondo(carregar_Wh / folha_resfriamento_Wh * 1.2)

imprimir(folhas)

Why this helps: You’re matching expected heat gain to sheet capacity, then proving it on the worst lane in summer/winter profiles. ISTA 7E is widely referenced for parcel thermal testing in 2025.

Reusable dry ice pack sheets packout: step‑by‑step HowTo

Answer first: Pre‑condition product, hydrate/freeze sheets, layer top & fundo, add a spacer, e verifique com um madeireiro. This hits temperature targets and reduces returns.

-

Condição prévia product to 2–8 °C.

-

Hidrato sheets 2–5 min; Pat seco.

-

Congelar flat 12–18 h at −10 to −20 °C.

-

Pacote: bottom sheet layer → product in tray → top sheet layer.

-

Adicionar absorbent liner and a core logger.

-

Selo and shake‑test to remove voids.

Avoid freeze damage with reusable dry ice pack sheets

Keep fragile foods and temperature‑sensitive cosmetics off direct contact with frozen surfaces. Add corrugated pads or bubble liners to diffuse cold. Target ≤ 40 °F at delivery for foods; simple probes work.

Reusable dry ice pack sheets vs dry ice: compliance snapshot

Resumindo: Sheets are hazmat‑free; dry ice is Class 9 (UN1845) and must meet PI954. Mark proper shipping name, Número da ONU, NET KG, place the Class 9 label on the same surface, e garantir a ventilação. Operator job aids in 2025 emphasize label placement and net‑kg outside the diamond.

Copy‑ready checklist (apenas gelo seco):

-

Nome adequado: “Gelo seco” ou “Dióxido de carbono, sólido."

-

UN1845 & Aula 9 rótulo, mesma superfície.

-

Peso líquido de gelo seco (kg), claramente marcado.

-

Embalagem ventilada; never seal dry ice in airtight liners.

2025 trends in reusable dry ice pack sheets and PCMs

Visão geral da tendência: Airlines and integrators tightened PI954 acceptance detalhes, while ISTA 7E profiles gained traction for parcel testing. VIP+PCM systems are extending 2–8 °C to 96–120 h, mas reusable dry ice pack sheets remain the simplest, reusable baseline for most chilled D2C lanes.

Último em um olhar

-

Clearer PI954 job aids: standardized marks, net‑kg emphasis, Lembretes de ventilação.

-

Parcel standards shift: more lanes validated against ISTA 7E; easier apples‑to‑apples comparisons.

-

VIP+PCM growth: multiday 2–8 °C holds (>5 days in some qualified kits) for high‑value loads.

Insight de mercado: For non‑pharma, carriers still summarize it simply—gel/sheets for chilled, gelo seco para congelados—a rule that maps well to everyday groceries and meal kits.

Perguntas frequentes

Q1: Are reusable dry ice pack sheets actually dry ice?

Não. They are hydratable polymer gel sheets—hazmat‑free unless you add real dry ice.

Q2: What delivery temperature should I target for food?

Aim for ≤ 40 °F (4 ° c) na chegada; verifique com um termômetro.

Q3: Do I need hazmat labels when I use only sheets?

Não. Hazmat applies to solid CO₂. Se você adicionar gelo seco, follow PI954 with UN1845, Rede - kg, posicionamento da etiqueta, e ventando.

Q4: How many reusable dry ice pack sheets do I need?

Use the calculator above as a starting point, then pilot with a data logger on your riskiest lane and adjust.

Q5: When should I step up to PCM panels?

Use 2–8 °C PCM + VIP when you need 96–120 h holds and tighter temperature bands for validated pharma/biologics.

Resumo & Recomendações

Recapitular: Folhas de gelo seco reutilizáveis win for 2–8 °C and gentle frozen shipments—clean, reutilizável, and compliance‑light. Dry ice covers ≤ −60 °C and delay‑heavy lanes but demands PI954 discipline. Validate with ISTA profiles, tune sheet counts by season, and add spacers to protect sensitive goods.

PRÓXIMOS PASSOS (CTA):

-

Defina sua pista (2–8 °C vs ultra‑cold).

-

Use the sizing calculator; run three instrumented pilots.

-

Bloquear POPs (hydrate time, freeze time, seasonal sheet counts).

-

Need a lane‑specific packout matrix? Request Tempk’s free 2025 matrix based on your stops and dwell times.

Sobre Tempk

Somos uma equipe de engenharia da cadeia de frio focada em embalagens validadas, Projeto VIP+PCM, e conformidade da DG. We help brands cut excursions and simplify audits. Duas vantagens concretas: (1) lane‑specific tools that right‑size reusable dry ice pack sheets conta; (2) a DG‑ready dry‑ice program with automated labels and net‑kg tracking. Talk to a specialist to tailor a packout matrix for your routes.