Sind Trockeneisbeutel sicher für Insulin und temperaturempfindliche Medikamente??

Der Transport von Insulin und anderen temperaturempfindlichen Medikamenten erfordert eine präzise Temperaturkontrolle, um ihre Wirksamkeit aufrechtzuerhalten. In vielen Fällen, dry ice is considered as a solution due to its ability to keep items extremely cold. Jedoch, is it the best choice for transporting such sensitive goods? In diesem Artikel, we will explore the pros, Nachteile, and best practices for using dry ice in the shipment of insulin and other temperature-sensitive medicines.

What Makes Dry Ice Ideal for Transporting Temperature-Sensitive Medicines?

Trockeneis, oder festes Kohlendioxid (Co₂), is widely used as a cooling agent in pharmaceutical transport because it maintains temperatures as low as -78.5°C (-109.3° F), far colder than regular ice or gel packs. This feature makes dry ice a valuable asset for shipping biologics and vaccines that require ultra-low temperatures, often in the -20°C to -80°C range. While this is ideal for certain pharmaceuticals, it is not always suitable for insulin, which requires a much higher temperature range.

-

Langanhaltende Kühlung: Dry ice can sustain low temperatures for long durations, oft bis zu 48 Std., making it ideal for short-duration shipments.

-

Kostengünstig: It’s generally more affordable compared to other refrigerants like liquid nitrogen, particularly for shorter shipments.

-

Efficient for High-Volume Shipments: Dry ice can effectively cool large amounts of pharmaceuticals without risk of water leakage, which can be an issue with regular ice.

While these benefits make dry ice attractive for certain types of transport, its suitability for insulin and other temperature-sensitive medicines needs careful consideration.

Why Dry Ice is Not Suitable for Insulin Transport

Insulin, as well as many biologics and vaccines, must remain within a narrow temperature range (2° C - 8 ° C., or 36°F–46°F). When exposed to temperatures outside this range, especially freezing, the chemical structure of insulin can degrade, es unwirksam machen.

Risks Involved in Using Dry Ice for Insulin Transport

-

Freezing Damage: Direct contact with dry ice can cause insulin to freeze, which destroys its potency.

-

CO₂ Gas Build-Up: Trockeneis unterschwellt zu Kohlendioxidgas. If this gas accumulates in a sealed space, Es kann Sauerstoff verdrängen, leading to asphyxiation hazards.

-

Erfrierungen und Verbrennungen: Trockeneis ist extrem kalt, and improper insulation can cause severe cold burns to both the product and personnel handling it.

daher, while dry ice is beneficial for some pharmaceuticals, it is unsuitable for insulin, which must avoid freezing at all costs.

Safer Alternatives for Insulin Transport

Given the risks of using dry ice, it is essential to select safer, more appropriate cooling methods for insulin and other temperature-sensitive medicines.

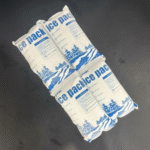

1. Gelpackungen

Gel packs are typically used for shipments requiring cooling at 2°C–8°C. They maintain consistent temperatures within this range and are much safer for insulin transport.

-

Ideal für: Insulin, Impfungen, and other biologics that require cooling within the 2°C–8°C range.

-

Vorteile: Sicher, leicht zu handhaben, and reliable for short to medium-duration shipments.

2. Phasenveränderungsmaterial (PCMs)

PCMs are substances that absorb or release heat at a specific temperature. Für den Insulintransport, PCMs with a melting point of 4°C–5°C offer a stable and controlled environment to prevent freezing while maintaining the appropriate temperature range.

-

Ideal für: Insulin and other biologics requiring tight temperature control.

-

Vorteile: Highly accurate temperature control with minimal risk of overcooling.

3. Portable Refrigerated Containers

Für Langzeitlieferungen, refrigerated containers provide an active cooling environment that maintains the desired temperature range for extended periods.

-

Ideal für: Large-scale shipments or long-distance travel.

-

Vorteile: Zuverlässig, effizient, and capable of maintaining precise temperature control over extended durations.

Best Practices for Packing Insulin and Temperature-Sensitive Medicines

When shipping insulin or other sensitive medicines, it is crucial to follow the right packing procedures to ensure that the product remains within its required temperature range. Here are some key tips:

-

Isolierte Verpackung: Use well-insulated boxes or coolers to protect the medication from temperature fluctuations.

-

Use of a Temperature Logger: Always include a temperature logger inside the shipment to monitor the internal temperature throughout the journey. This ensures that the product has remained within the acceptable range.

-

Avoid Direct Contact with Coolants: Ensure that there is no direct contact between the cold packs (Gelpackungen, PCMs, oder Trockeneis) and the medication. Use spacers or insulation material to create a protective buffer.

How to Package Insulin for Transport:

-

Line the shipping box with insulation.

-

Place the insulin in its original packaging.

-

Add phase-change material (PCM) packs pre-conditioned to 4°C–5°C.

-

Seal the box and include a temperature logger for monitoring.

Regulatory Considerations for Transporting Insulin

When using any cooling method, einschließlich Trockeneis, it is essential to comply with regulations from governing bodies such as the Internationale Luftverkehrsvereinigung (Iata), Die FDA, und die CDC.

Compliance-Anforderungen:

-

IATA-Vorschriften: Für Trockeneissendungen, ensure that the packaging is vented and clearly marked as “Dry Ice/UN1845”. Keep the net weight of the dry ice below the allowed limits for air transport.

-

FDA Labeling Guidelines: Insulin must always be labeled with its storage requirements, einschließlich des Temperaturbereichs (2° C - 8 ° C.), and must not be exposed to freezing conditions.

2025 Trends in der Kaltkette -Logistik

Während sich die Kaltkettenindustrie entwickelt, we see several key trends emerging, especially for temperature-sensitive medications:

-

Recycelbare Verpackung: Increasing demand for sustainable solutions is driving the use of recyclable insulation and PCM systems that still meet the stringent temperature requirements of pharmaceutical transport.

-

IoT -Integration: Smart sensors and tracking devices allow real-time temperature monitoring, offering enhanced visibility and control over shipments.

-

CEIV Pharma Certification: More companies are adopting the CEIV Pharma certification, ensuring that their cold chain practices meet the highest standards for safety and compliance.

Häufig gestellte Fragen

Q1: Can I use dry ice to transport insulin or temperature-sensitive medicines?

NEIN. Dry ice is too cold and can cause freezing, which compromises insulin’s efficacy. Use gel packs or phase-change materials (PCMs) for these medications instead.

Q2: What temperature range should insulin be kept at during transport?

Insulin should be kept between 2°C and 8°C (36°F bis 46°F) wirksam zu bleiben.

Q3: How can I ensure insulin is transported safely without dry ice?

Verwenden Sie isolierte Verpackungen, Gelpackungen, or PCMs and include a temperature logger to monitor the temperature throughout the journey.

Q4: Are there any exceptions where dry ice may be used for insulin transport?

Allgemein, dry ice is not recommended for insulin, but in specific cases, such as for extremely short transport durations with proper insulation and monitoring, it may be used. Consult with a logistics expert.

Abschluss

While dry ice is effective for maintaining ultra-low temperatures, it is not suitable for transporting insulin and most 2–8°C medications. The risk of freezing and degrading these products outweighs the benefits. Safer alternatives, wie zum Beispiel Gelpackungen, Phasenveränderungsmaterial, und Kühlcontainer, provide reliable solutions to ensure the safe transport of temperature-sensitive medications.

For more information on how to safely transport insulin and other critical medicines, or to get personalized cold chain solutions, Kontakt Tempk Heute.

Über Tempk

Tempk provides validated cold chain solutions for the pharmaceutical industry, einschließlich Isolierbehältern, Phasenveränderungsmaterial, and real-time temperature monitoring systems. We ensure your sensitive products stay safe and effective throughout their journey.

Contact Tempk for more information.