Qualitätskontrolle dunkler Schokolade in der Kühlkette?

You want your bars to arrive glossy and on-spec. Cold chain dark chocolate quality control keeps chocolate stable, not icy. Cocoa butter can soften in the low 30s °C and melt around 32–34°C, so one hot van can undo your work.

cold chain dark chocolate quali…

Aim for 15–18°C with 45–55% RH, then add rules for excursions and sealed acclimation at handoffs.

cold chain dark chocolate quali…

Cold chain dark chocolate quality control protects your brand.

Dieser Artikel wird antworten:

-

Wie cold chain dark chocolate quality control prevents bloom and soft bars during last mile delivery

-

Was dark chocolate shipping temperature Und ideal humidity for storing dark chocolate should look like in 2025

-

Welche passive packaging for dark chocolate delivery works without overcooling

-

Wie man läuft cold chain monitoring for food with practical data logger settings for chocolate cold chain

-

So verwenden Sie a receiving inspection checklist for chocolate shipments and a simple “keep / halten / rework” decision tool

What does cold chain dark chocolate quality control mean in plain English?

Cold chain dark chocolate quality control means you control temperature, Luftfeuchtigkeit, Zeit, and handling so quality stays stable.

cold chain dark chocolate quali…

It is not “make it as cold as possible.” It is “keep it comfortable and consistent.” Think of chocolate like a candle: heat and sweat both change the surface.

In der Praxis, cold chain dark chocolate quality control has three pieces:

-

A target band (your comfort zone)

-

Ein excursion rule (what short spikes are acceptable)

-

A handoff routine (how you avoid condensation between climates)

The defects you should prevent first

Your customers judge quality in seconds. Start with the defects they notice fastest.

| Customer-visible defect | Typical trigger | Fast field check | Was es für Sie bedeutet |

|---|---|---|---|

| Fettblüte (smooth white haze) | Warm spike + long warm dwell | Rub lightly; haze may smear | Looks “old,” increases returns |

| Zuckerblüte (dusty, gritty) | Kondensation + humidity swings | Feels gritty; may not smear | Looks “dirty,” hurts premium perception |

| Erweichung / Verformung | Sustained warmth | Corners dent easily | Smears and breakage during unwrapping |

| Risse / Bruch | Tropfen + Vibration | Fracture lines | More replacements and negative reviews |

| Geruchsaufnahme | Strong-odor storage | Smell test | “Warehouse taste” complaints |

These triggers and quick checks are the practical heart of cold chain dark chocolate quality control.

cold chain dark chocolate quali…

Praktische Tipps, die Sie heute bewerben können

-

If you see bloom, check temperature history before blaming temper.

-

If you see sugar bloom, fix transitions first. Condensation is the enemy.

-

If bars crack, fix cushioning and void space before changing box size.

Fall der realen Welt: A shipper saw bloom complaints mainly in coastal cities. The root cause was humid air plus cold packaging, not the recipe.

cold chain dark chocolate quali…

Cold chain dark chocolate quality control temperature: what shipping temperature and humidity should you use?

Für die meisten Bahnen, cold chain dark chocolate quality control works best at 15–18°C and 45–55% relative humidity.

cold chain dark chocolate quali…

This range keeps texture stable and lowers condensation risk. The goal is consistent “mid-teens,” not refrigerator cold.

If you go warmer, you raise softening and fat migration risk. If you go much colder, you raise dew-point risk during handoffs.

A simple target + alarm approach

Use one target and one alert band you can actually run.

| Spurtyp | Suggested target | Practical alert band | Ihr Vorteil |

|---|---|---|---|

| Climate-controlled storage | 16–18°C | 15–20°C | Stable gloss and snap |

| Controlled linehaul | 15–18°C | 12–20°C | Fewer hot spikes at hubs |

| High-risk last mile | 15–18°C | 12–20°C | Fewer doorstep failures |

Praktische Tipps, die Sie heute bewerben können

-

Write time limits, not just temperature limits. Carriers can manage time.

-

Keep staging short. "Nur 20 minutes” repeats all day.

cold chain dark chocolate quali…

-

Offer cooler delivery windows in hot seasons wenn du kannst.

Fall der realen Welt: After enforcing “no sun staging” and adding a pallet cover, one team saw fewer soft bars on the same route.

cold chain dark chocolate quali…

Cold chain dark chocolate quality control: how to prevent fat bloom during chocolate transport?

In cold chain dark chocolate quality control, fat bloom is your most visible heat-related failure.

To prevent fat bloom during chocolate transport, reduce heat spikes and long warm dwell times. Bloom is often caused by temperature fluctuations that disturb cocoa butter crystals. When warm-cool cycles repeat, the surface can “reset” like candle wax.

Cold chain dark chocolate quality control wins here by focusing on repeatability. You do not need perfect weather. You need fewer surprises.

The “heat spike” checklist

Use this as a quick audit of your lane.

-

Are cartons staged in warm areas before loading?

-

Do hubs expose cartons to sun on docks?

-

Does last mile include porch exposure and delays?

If you answered “yes” to any, your cold chain dark chocolate quality control plan needs stronger handoffs and packaging.

Praktische Tipps, die Sie heute bewerben können

-

Cut dock dwell time first. It is often the biggest win.

-

Label cartons “Keep out of direct sun.” Behavior beats packaging.

-

Track peak temperature plus duration. That is what bloom “feels.”

cold chain dark chocolate quali…

Fall der realen Welt: A brand found most failures happened at a sorting hub dock, nicht auf der Straße. After tightening the handoff rule, complaints dropped fast.

cold chain dark chocolate quali…

Cold chain dark chocolate quality control: ideal humidity for storing dark chocolate and stopping sugar bloom

In cold chain dark chocolate quality control, sugar bloom is usually a moisture-and-transition problem, not a recipe problem.

Ideal humidity for storing dark chocolate is moderate and stable—often around 45–55% RH—so cartons stay dry and don’t “sweat.”

cold chain dark chocolate quali…

Sugar bloom is usually a moisture problem, not a heat problem.

Here is the trap: you can run a “good temperature” and still fail cold chain dark chocolate quality control if you open a cool carton in warm, humid air.

The 30-second “sealed acclimation” rule

If cartons feel cool to the touch:

-

Keep them sealed.

-

Let them warm slowly.

-

Open only after the carton is near room conditions.

This one habit prevents many sugar bloom claims, and it costs almost nothing.

| Transition moment | Was kann schief gehen | Was Sie tun | Was Sie gewinnen |

|---|---|---|---|

| Cool truck → warm dock | Condensation forms fast | Hold sealed cartons | Cleaner surfaces |

| Cold room → packing area | Moist air hits cold product | Keep packaging closed | Fewer “dusty” bars |

| Fridge “just to be safe” | Feuchtigkeit + odor risk | Avoid; wenn verwendet, luftdicht versiegeln | Better aroma and texture |

Praktische Tipps, die Sie heute bewerben können

-

Dehumidify where you pack, not only where you store.

-

Avoid loading during rain or fog if you can.

-

Use a moisture barrier liner im Inneren des Versenders.

Fall der realen Welt: One team reduced “white dust” complaints after switching from frozen packs to conditioned packs and adding a sealed barrier.

cold chain dark chocolate quali…

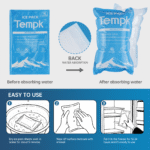

Cold chain dark chocolate quality control: passive packaging for dark chocolate delivery that actually works

In cold chain dark chocolate quality control, packaging is your portable climate buffer.

Passive packaging for dark chocolate delivery works when it slows temperature change without overcooling. Your box is a small climate buffer. If it swings slowly, chocolate stays stable.

Cold chain dark chocolate quality control packaging has four jobs:

-

Buffer heat

-

Block moisture

-

Reduce odor pickup

-

Prevent breakage

Gelpackungen, PCM, oder Trockeneis?

For most dark chocolate lanes, dry ice is too cold. It can create cold spots and later condensation. Conditioned gel packs can work, but only if they are not “ice cold.” Cool-range PCM can be ideal because it sits near a setpoint.

cold chain dark chocolate quali…

| Kühloption | How it behaves | Risikostufe | Beste Passform |

|---|---|---|---|

| Conditioned gel packs | Cold sink that warms over time | Medium | Short lanes with good barriers |

| Cool-range PCM | Holds near target band | Niedrig | Premium lanes and summer shipping |

| Trockeneis | Extrem kalt | Hoch | Usually avoid for chocolate |

| Insulation only | Slows heat gain | Mittelhoch | Mild season, kurze Wege |

Checkliste für das Verpackungsdesign (the “no surprises” build)

-

Barriere zuerst: moisture-resistant inner liner

-

Kein direkter Kontakt: put a layer between coolant and product

-

Enge Passform: Luftlücken reduzieren

-

Dämpfung: protect corners and stop vibration cracks

-

Beschriftung: “keep out of sun” + “keep sealed until warm”

cold chain dark chocolate quali…

Praktische Tipps, die Sie heute bewerben können

-

If you see sugar bloom at receiving, your coolant may be too cold.

-

If you see fat bloom in summer, you may need more insulation or better handoffs.

-

If bars crack, fix void space before adding more coolant.

Fall der realen Welt: A team reduced bloom by switching from very cold gel packs to cool-range PCM and adding a sealed barrier.

cold chain dark chocolate quali…

Cold chain dark chocolate quality control: cold chain monitoring for food and data logger settings

In cold chain dark chocolate quality control, monitoring is how you prove stability and learn fast.

Cold chain monitoring for food turns cold chain dark chocolate quality control from guesswork into proof. You do not need fancy dashboards first. You need consistent data you can act on.

Start with the three numbers that explain most outcomes:

-

Max temperature (the worst spike)

-

Time above your limit (how long it lasted)

-

Luftfeuchtigkeit / condensation risk marker (RH or dew-point proxy)

cold chain dark chocolate quali…

A 5-question quiz: do you need loggers on every lane?

Gib dich selbst 1 Punkt für jedes „Ja“:

-

You need proof for claims or chargebacks.

-

You ship through hot or humid zones seasonally.

-

You have handoffs you don’t fully control.

-

You sell premium bars where defects hurt trust.

-

You want fast feedback to optimize packaging.

Punktzahl:

-

0–1: low-risk lane (spot checks may be enough)

-

2–3: standard loggers (routine verification)

-

4–5: richer monitoring + stronger SOPs

Data logger settings for chocolate cold chain (simple defaults)

Keep settings consistent so lanes are comparable:

-

Sampling interval: frequent enough to catch spikes

-

Thresholds: match your spec tier (Ziel / alert / reject)

-

Start/stop: measure the real trip, not warehouse storage

Praktische Tipps, die Sie heute bewerben können

-

Platzieren Sie die Sensoren auf Produktebene, not on the box wall.

-

Review data after every shipment for your first test month.

-

Change the process first, then the packaging.

cold chain dark chocolate quali…

Fall der realen Welt: After adding dock dwell time as a KPI, a shipper fixed staging, keine Isolierung, and reduced excursions.

cold chain dark chocolate quali…

Cold chain dark chocolate quality control: receiving inspection checklist for chocolate shipments

In cold chain dark chocolate quality control, receiving is your last chance to catch defects before customers do.

A receiving inspection checklist for chocolate shipments keeps bad lots from reaching customers. It also reduces arguments with carriers because decisions are consistent.

Cold chain dark chocolate quality control at receiving has three steps:

-

Visuell + packaging check

-

Temperature/history review

-

Release, halten, or escalate decision

cold chain dark chocolate quali…

A 15-minute receiving checklist for busy teams

| Schritt | Zeit | Kriterien bestehen | Aktion bei Fehlschlag |

|---|---|---|---|

| Kontrolle des Umkartons | 2 min | No crush, no wet marks | Halten + photo record |

| Seal and barrier check | 3 min | Innere Barriere intakt | Halten + genauer untersuchen |

| Logger-Rezension | 5 min | Innerhalb der Spezifikation oder zulässigen Abweichung | Escalate if outside |

| Schneller sensorischer Check | 5 min | Glanz + Snap akzeptabel | Bei Verdacht in Quarantäne |

This checklist is designed to keep cold chain dark chocolate quality control fast and repeatable.

cold chain dark chocolate quali…

Praktische Tipps, die Sie heute bewerben können

-

If cartons feel cool, do sealed acclimation before opening.

-

Record three facts: arrival time, condition notes, temperature summary.

-

Sample high-risk SKUs first (thin bars, high gloss finishes).

Fall der realen Welt: A receiver stopped opening cartons immediately in summer. Sugar bloom complaints fell within weeks.

cold chain dark chocolate quali…

Cold chain dark chocolate quality control: corrective action when the lane fails

When cold chain dark chocolate quality control fails, your next move should be calm and repeatable.

You need a calm playbook. Ohne es, teams guess, argue, and waste product.

Use a simple CAPA flow:

-

Contain the lot

-

Review temperature/humidity history

-

Entscheiden: freigeben, halten, nacharbeiten, downgrade, verwerfen

-

Find root cause

-

Prevent recurrence (SOP, Verpackung, Trägerregeln)

Halten / halten / nacharbeiten: a 60-second decision tool

-

If peak temperature stayed within allowed excursion: check snap and gloss, then release.

-

If peak temperature exceeded the limit briefly: halten 24 Std.; release if no haze appears.

-

If temperature stayed high for long: hold and evaluate downgrade or rework.

-

If condensation is confirmed: hold and assess sugar bloom risk versus your brand standard.

cold chain dark chocolate quali…

Praktische Tipps, die Sie heute bewerben können

-

Write your “brand tolerance” for cosmetic haze vs rejection.

-

Document with photos and timestamps to reduce disputes.

-

Fix the handoff, not just the box. Many failures are operational.

Cold chain dark chocolate quality control in 2025: neueste Entwicklungen und Trends

In 2025, cold chain dark chocolate quality control is getting more data-driven and more customer-visible. Teams are moving from reactive claims to predictable lane performance. They also want less packaging waste without more risk.

cold chain dark chocolate quali…

What’s changing right now

-

Smarter lane qualification: seasonal tests and tighter lane segmentation

-

Better passive systems: designs that reduce swings without extreme cold

-

Faster exception response: standard alarm rules and reports

-

Nachhaltigkeitsdruck: right-sizing and more reusable components

-

Customer experience focus: fewer doorstep failures through delivery-window tactics

Häufig gestellte Fragen

Q1: What is the ideal temperature for cold chain dark chocolate quality control?

Most brands target a stable cool band like 15–18°C with defined short excursions.

cold chain dark chocolate quali…

Q2: How do I prevent fat bloom during chocolate transport?

Reduce heat spikes and long warm dwell times. Track peak temperature plus duration.

Q3: What is the ideal humidity for storing dark chocolate?

Aim for moderate RH (oft 45–55%) and avoid cold-to-warm opening that causes condensation.

Q4: Should I use dry ice for dark chocolate shipping?

Normalerweise nein. Dry ice can overcool and increase moisture-shock risk later.

Q5: What is the fastest receiving inspection checklist for chocolate shipments?

Check carton condition, review temperature history, and do a quick snap/gloss spot-check.

Zusammenfassung und Empfehlungen

Cold chain dark chocolate quality control works when you control the few things that truly change chocolate. Cold chain dark chocolate quality control is a lane system, not a single box: Hitzespitzen, moisture shocks, und raues Handling. Keep a realistic spec with time limits, choose packaging that stabilizes instead of overcooling, and monitor the first and last mile. Use a fast receiving checklist and a calm corrective action plan.

cold chain dark chocolate quali…

Ihr nächster Schritt (einfacher Plan)

-

Pick one high-risk lane (heiße Jahreszeit + long last mile) and define cold chain dark chocolate quality control success.

-

Set a target band and excursion rules.

-

Laufen 10 Testsendungen mit Loggern.

-

Fix the biggest handoff first (Inszenierung, Schatten, versiegelte Akklimatisierung).

-

Then right-size packaging based on real lane data.

Über Tempk

Und Tempk, we build practical tools for temperature-sensitive shipments, including insulated packaging systems and shipment monitoring support. We help you turn cold chain dark chocolate quality control into a repeatable routine. Cold chain dark chocolate quality control becomes easier when your SOPs and packaging match the lane.

Aufruf zum Handeln: Share your lane length, peak summer conditions, and delivery model (B2B or D2C). Strong cold chain dark chocolate quality control starts with lane reality, keine Vermutung. We’ll map a spec tier, packaging approach, and monitoring plan you can run without unnecessary cost.