Kaltkette Versandkästen are specialized containers designed to keep temperature sensitive products safe during transit. They rely on insulation and cooling elements rather than powered refrigeration, making them essential for pharmaceuticals, Biologika, Meeresfrüchte und Fertiggerichte. Nach a 2025 Branchenführer, cold boxes typically hold 5–25 L of vaccines and are categorized as short range (minimale Kältelebensdauer von 48 hours at 43 °C) oder große Reichweite (Minimum 96 Std.). With e commerce, biologics and meal kit deliveries surging, the global cold chain packaging market is projected to grow from US$33.67 billion in 2025 to US$75.93 billion by 2033. This guide explains how these boxes work, how to choose the right size and material, and why they are evolving in 2025.

What defines a cold chain shipping box? A clear explanation of passive vs. aktive Systeme, core components and how they maintain temperature.

How should you select the correct box size and insulation? A step by step guide to measuring payloads, choosing insulation (EPS, Pur, VIP), and planning for cooling elements.

Which materials and technologies improve reliability? Discussion on insulation, Kältemittel, Überwachungsgeräte, und nachhaltige Innovationen.

What do market trends look like in 2025? Updated data on market growth, regional leadership, and drivers like pharmaceuticals, E-Commerce und Nachhaltigkeit.

What common questions do people ask about cold chain boxes? Quick answers to high volume queries about materials, duration and compliance.

What Are Cold Chain Shipping Boxes and How Do They Work?

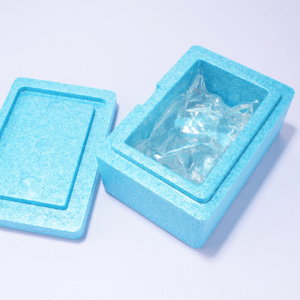

Core definition and functioning: Cold chain shipping boxes are insulated containers designed to keep products within a specific temperature range without powered refrigeration. UNICEF’s procurement guidelines state that cold boxes are passive devices lined with coolant packs; they usually hold 5–25 L and are classified as short range (cold life ≥ 48 hours at 43 °C) oder große Reichweite (cold life ≥ 96 hours). Impfträger sind kleiner (0.8–3.4 L), Bereitstellung 15–30 hours of cold life for health workers on foot. Instead of compressors, passive boxes rely on insulation (such as expanded polystyrene or vacuum insulated panels) and pre conditioned coolant packs to maintain the payload temperature.

Key components explained: A cold chain box consists of several layers. Der insulation layer—made from erweiterter Polystyrol (EPS), polyurethane foam or vacuum insulated panels (VIPs)—minimizes heat transfer and maximizes payload space. Coolants or phase change materials (PCMs) wie zum Beispiel Gelpackungen, dry ice or water bottles absorb or release heat to maintain specific temperature ranges. A packaging enclosure crafted from Polyethylen hoher Dichte, corrugated cardboard or metal shells provides structural integrity and protection. Temperaturüberwachungsgeräte (digitale Datenlogger, IoT sensors or RFID tags) track internal temperature and humidity, sending real time alerts when excursions occur. Endlich, closure mechanisms and gaskets ensure a tight seal to prevent thermal leakage.

Passiv vs. Aktive Systeme

Differences and use cases: Passive boxes use insulation and coolants without external power, während aktive Systeme incorporate compressors and fans powered by electricity or batteries. Passive systems are lighter, cheaper and ideal for last mile deliveries or areas without reliable power. Active boxes, although heavier and costlier, provide precise temperature control for ultra long shipments or when a constant power source is available. The choice depends on shipment duration, temperature range and access to electricity.

| Komponente | Beispielmaterialien | Funktion | What It Means for You |

| Isolierung | EPS, Polyurethanschaum, VIPs | Minimizes heat transfer and maximizes payload volume | Better insulation extends cold life and reduces required coolant packs. |

| Coolants/PCMs | Gelpackungen, Trockeneis, Wasserflaschen | Absorb or release heat to maintain desired temperature | Choosing the right PCM ensures stability for vaccines (2–8 ° C) oder Tiefkühlware (–20°C bis –80°C). |

| Packaging Enclosure | Polyethylen hoher Dichte, Wellpappe, Metallschalen | Provides physical protection and prevents crushing or contamination | Durable enclosures enable reuse and protect high value contents. |

| Temperaturüberwachung | IoT -Sensoren, RFID -Tags, Datenlogger | Tracks internal conditions and location in real time | Monitoring helps you detect excursions early and maintain compliance. |

| Schließung & Siegel | Einrastende Deckel, Silikondichtungen | Seals the container to prevent thermal leakage | Proper sealing protects against spills and maintains internal temperature. |

Tips and Advice for Users

For short range deliveries (Z.B., regional vaccine distribution): Choose a lightweight passive box sized 5–25 L with high quality EPS insulation and gel packs. Ensure coolants are conditioned to 2–8 °C for at least 24 hours before packing.

For long range or ultra cold shipments: Consider boxes with VIP insulation and PCMs tailored to –20 °C or –80 °C. If shipments exceed 96 hours, explore hybrid solutions that combine PCMs with dry ice or choose an active unit.

Für Lieferungen auf der letzten Meile: Vaccine carriers under 3.5 L are portable and maintain 15–30 hours of cold life—perfect for community health workers.

Fall aus der realen Welt: A medical NGO in rural Africa used passive long range cold boxes lined with VIPs and PCM packs to transport vaccines from regional depots to remote clinics. The boxes maintained 2–8 °C for 96 hours without power, allowing health workers to complete immunization campaigns before returning for reconditioning. The NGO reported zero vaccine wastage during this campaign.

How Do You Select the Right Cold Chain Shipping Box Size and Insulation?

Selecting the right box size involves balancing cost, protection and temperature control. Oversized boxes increase shipping costs because of dimensional weight charges, while undersized boxes risk product damage and poor temperature control. Below is a step by step guide based on 2025 industry recommendations.

Measure your product accurately: Determine the product’s length (L), Breite (W) and height (H) using a tape measure; record these dimensions in the order L×W×H. Für unregelmäßige Formen, use string to measure curves. Leave a small buffer of about 1⁄8 inch on each side for cushioning.

Account for insulation and cooling materials: Always leave room for insulation and cooling elements. Use polystyrene or vacuum panels depending on your temperature needs. Plan for cooling elements such as gel packs or dry ice to maintain stability. Label packages clearly for safe handling.

Insulation Materials and Temperature Ranges

Research from the Consortium for Distribution Packaging at Michigan State University provides guidelines on insulation types, Temperaturbereiche und Dauer. The table below summarizes these materials and what they mean for your shipment.

| Isolationsmaterial | Typischer Temperaturbereich | Dauer (ca.) | Bedeutung für Sie |

| Erweiterter Polystyrol (EPS) | 35 °F bis 46°F (1.7 °C to 7.8 °C) | Bis zu 24 Stunden | Erschwinglich und überall verfügbar; suitable for overnight shipments of refrigerated goods. |

| Polyurethane Panels (Pur) | –4 °F to 46 °F (–20 °C to 7.8 °C) | Up to 48 hours | Higher insulation performance; ideal for two day shipments requiring moderate freezing or refrigeration. |

| Vakuum -isolierte Panels (VIPs) | –60 °F to 46 °F (–51 °C to 7.8 °C) | Up to 120 hours | Exceptional thermal resistance with thin walls, maximizing payload space; ideal for long distance or ultra cold shipments. |

Zu berücksichtigende Faktoren

Temperature Sensitivity of Products: Highly sensitive products like vaccines or biologics require strict temperature ranges (2–8°C oder –20°C). Select insulation and PCMs accordingly, and use monitoring devices to verify compliance.

Transitdauer: Longer transit times increase the risk of temperature excursions. Choose insulation and refrigerants that maintain stability for the entire duration. For shipments exceeding 96 hours or requiring –70 °C, consider dry ice combined with VIPs.

Seasonal Conditions: Summer shipments may need thicker insulation or additional cooling packs, while winter shipments might need extra thermal barriers to prevent freezing.

Shipping Budget: Balancing cost with performance is crucial. High quality insulation and PCMs require higher upfront investment but can reduce spoilage and returns.

Sustainability Goals: Choose eco friendly options like recyclable or biodegradable insulation to reduce environmental impact.

Practical Tips

Szenario: Shipping insulin to rural clinics: Use a VIP lined box with PCM packs set to 2–8 °C; measure the insulin vials carefully and allow space for a temperature logger. Choose a box just large enough to accommodate the vials, PCMs and cushioning to avoid excess cost.

Szenario: Delivering meal kits: Use EPS or PUR insulation with gel packs for overnight shipments. For summer months, double the number of gel packs or add a reflective box liner to minimize heat ingress.

Szenario: Export von gefrorenen Meeresfrüchten: Use a combination of VIPs and dry ice to maintain –20 °C to –30 °C. Ensure the box allows for venting of sublimated CO₂ and follow hazardous materials regulations.

Tatsächlicher Fall: A meal kit company switched from oversized corrugated boxes to right sized PUR-insulated containers with optimized gel pack placement. This change reduced dimensional weight fees by 15 %, decreased spoiled shipments by 8 %, und verbesserte Kundenzufriedenheit.

Which Materials and Technologies Improve Cold Chain Reliability?

Isolierung, Refrigerants and Outer Packaging

Effective cold chain packaging requires the right materials. Isolierung ist entscheidend: insulated shipping liners Und thermal pouches create barriers that minimize heat transfer. Wärmeleitbeutel are ideal for short term food storage, während insulated mailers protect small pharmaceutical samples during e commerce delivery. Kältemittel work alongside insulation; phase change materials freeze and melt at specific temperatures, maintaining a stable environment, während Gelpackungen Und Trockeneis provide cooling for refrigerated or frozen shipments. Corrugated cardboard boxes act as sturdy outer packaging and protect products from physical damage during handling.

Monitoring Devices and Data Logging

Temperature monitoring is vital. Digitale Datenlogger, RFID -Tags Und IoT -Sensoren track internal temperature, Luftfeuchtigkeit und Standort in Echtzeit. WHO’s vaccine shipping guidelines recommend including an electronic temperature device in each shipping carton to document temperature excursions and provide a record for compliance. These devices should measure temperatures from –20 °C to +55 °C, with ±0.5 °C accuracy, and include start/stop functions and alarm settings. Real time data allows logistics teams to act quickly if temperatures deviate from the required range.

Nachhaltige Innovationen

Environmental pressure and corporate responsibility are driving innovations in cold chain packaging. Sustainable options include:

Recycelbare und wiederverwendbare Verpackung: Straits Research notes that manufacturers are adopting recyclable plastics and cardboard to reduce single use waste. Companies such as Softbox have introduced the Tempcell ECO, A plastic free parcel shipper made from corrugated cardboard that is 100 % curbside recyclable.

Biologisch abbaubare Materialien: Biodegradable cold boxes made from corn, Stärke, wood fibre and cotton decompose naturally.

Innovative Insulation Materials: Recycled post industrial cardboard fibres can offer strong thermal performance while being recyclable. Vacuum insulated panels and phase change materials are combined to extend cold life and reduce energy consumption.

Smart Packaging and IoT: Sensors embedded in boxes provide real time temperature, Luftfeuchtigkeit und Standortdaten. IoT devices help optimize routes, reduce energy use and automate quality reporting.

Comparing PCMs and Dry Ice

In 2025, packaging developers must choose between Phasenwechselmaterial (PCMs) Und Trockeneis. PCMs absorbieren und geben Wärme bei vordefinierten Temperaturen ab (Z.B., 2–8°C oder –20°C) and are typically reusable. Trockeneis sorgt für extrem kalte Temperaturen (< –70°C) suitable for deep frozen biologics but requires hazardous materials labeling.

| Verpackungstyp | Typischer Temperaturbereich | Beste Anwendungsfälle | Notizen |

| Phasenwechselmaterial | +2 °C bis –20°C | Impfungen, Biologika, Reagenzien, Kits für klinische Studien | Reusable and non hazardous; multiple reuse cycles offset higher upfront cost. |

| Trockeneis | < –70°C | Ultrakalte Biologika, CRISPR, gefrorene Zellen, Plasmaproben | Effective but single use; requires hazardous labeling and vented containers. |

User Tips and Scenario Based Advice

For sustainability minded businesses: Select recyclable or biodegradable insulation and reuse boxes and gel packs. Communicate this choice to customers to enhance brand loyalty.

For shipments with strict regulatory requirements: Use validated PCM systems with data loggers and ensure compliance with Good Distribution Practice (BIP) and FDA regulations. PCMs avoid hazardous labeling and simplify cross border customs clearance.

For extremely low temperatures: Use dry ice in vented containers. Train staff on hazardous materials handling and include appropriate documentation and labels. Consider hybrid systems combining PCMs and dry ice to maintain stability over long durations.

Praktischer Fall: A biotech company switched from gel packs to PCM containers for 2–8 °C payloads and achieved 40 % cost reduction after ten shipments, with zero temperature excursions. Another gene therapy firm adopted dry ice shippers for ultra cold payloads and achieved smooth customs clearance by following hazard labeling and validated protocols.

What Are the Latest Market Trends and Growth Drivers for Cold Chain Shipping Boxes in 2025?

The market for cold chain packaging—particularly insulated shipping boxes—is expanding rapidly due to rising demand for pharmaceuticals, Biologika, meal kits and online groceries. Analysts predict multiple growth trends:

Marktwachstum und Größe

Markt für Kühlkettenverpackungen: Straits Research values the global cold chain packaging market at US$30.41 billion in 2024, projecting it to grow from US$33.67 billion in 2025 to US$75.93 billion by 2033, A CAGR of 10.70 %. Another report forecasts US$89.84 billion by 2034 (11.3 % CAGR).

Insulated packaging market: IMARC Group estimates the global insulated packaging market at US$15.17 billion in 2024, mit einer projizierten US$23.84 billion by 2033 und a CAGR of 4.89 % (2025–2033). Boxes and containers account for 45.7 % of this market, while Asia Pacific leads with more than 35.8 % market share.

Regionale Einblicke: Nordamerika dominierte den Markt für Kühlkettenverpackungen 2024 due to mature logistics networks and stringent FDA regulations. Asia Pacific is expected to grow significantly thanks to rising exports of seafood and pharmaceuticals.

Wachstumsfaktoren: Market growth is driven by vaccine distribution, Biologika, gene therapies and home delivery of medicines; der Fisch, meat and seafood segment dominated in 2024; and e commerce and meal kits require robust insulated boxes.

Drivers and Trends

Pharmazeutik und Biotechnologie: The increasing pipeline of biologics and gene therapies demands stringent temperature control. Pharmaceutical companies are investing in advanced insulated boxes that integrate VIPs, PCMs and active cooling for shipments of GLP 1 drugs, mRNA-Impfstoffe und Gentherapien.

Essen und Getränk: Global trade of perishable foods and the explosion of meal kit services require reliable shipping boxes. Fisch, meat and seafood shipments dominate the market, while meal kits rely on smaller parcel shippers with high performance insulation.

E-Commerce & Direct to Consumer: Online grocery shopping and pharmacy deliveries are growing; consumers demand rapid, temperature controlled shipments. Die USA. direct to consumer pharmaceutical and meal kit sectors are expanding, driving adoption of insulated packaging.

Nachhaltigkeit: Sustainability is a critical driver. A McKinsey survey found that 43 % of consumers consider environmental impact Und 74 % of Americans are interested in refillable packaging. Producers are therefore investing in recyclable, biodegradable and reusable boxes.

Technologische Innovationen: IoT -Sensoren, RFID tags and smart packaging provide real time visibility and data analytics, enabling route optimization and proactive risk management.

Regulierungsdruck: Rules like the Food Safety Modernization Act (FSMA) in den USA. and EU GDP guidelines require validated packaging and traceability. FSMA 204 mandates 24Stundenlange Rückverfolgbarkeit für Lebensmittel mit hohem Risiko, pushing companies to invest in data loggers and standardized packaging.

Challenges and Opportunities

Sustainability vs. Leistung: Balancing thermal performance with eco friendly materials remains a challenge. VIPs and PCMs provide superior insulation but come at higher cost and may not be easily recyclable. Research is ongoing to develop recycled fibre VIPs and biodegradable foams.

Verbrauchererwartungen: Customers increasingly expect packaging to be sustainable and easy to recycle. Businesses that adopt reusable or curbside recyclable boxes can build brand loyalty.

Infrastructure in Developing Regions: Developing countries are investing in cold chain corridors rather than building entire networks, focusing on key exports like seafood or vaccines. India’s approval of 27 new cold chain projects shows how targeted investments can boost agri food exports.

Häufig gestellte Fragen (FAQ)

- What are cold chain shipping boxes made of?

Cold chain boxes are typically made from Isoliermaterialienwie erweiterte Polystyrol (EPS), polyurethane foam or vacuum insulated panels. They include a rigid enclosure(Wellpappe, high density polyethylene or metal) Und Kühlmittelpakete like gel packs or phase change materials to maintain stable temperatures. - How long can a cold chain box maintain temperature?

Cold boxes are classified by cold life. Kurzstreckenboxenmaintain the temperature for a minimum of 48 Std.at 43 °C ambient, während long range boxes maintain it for 96 Std.. Vaccine carriers provide 15–30 hours of cold life. - What’s the difference between active and passive shipping boxes?

Passive boxesuse insulation and coolant packs without external power. They are lightweight and ideal for last mile or short duration shipments. Active boxescontain powered refrigeration units (compressors and fans) and are used for long distance or ultra cold shipments requiring precise control. - Which insulation material should I choose?

EPS is affordable and suitable for shipments up to 24 hours; polyurethane panels offer mid range performance up to 48 hours; VIPs provide the best insulation for shipments up to 120 hours. The choice depends on duration, temperature range and budget. - Are cold chain shipping boxes recyclable?

Many modern boxes use recyclable plastics and corrugated cardboard. Companies are developing plastic free shippers like Softbox’s Tempcell ECO, made entirely of corrugated cardboard. Reusability and recycling reduce waste and align with sustainability goals. - Do I need a temperature logger?

Ja. WHO guidelines recommend including an electronic temperature devicein each international vaccine shipment to record temperatures and verify that limits are not exceeded. Data loggers provide a continuous record and help ensure compliance with GDP and FSMA 204 Vorschriften. - How do PCMs differ from dry ice?

PCMs absorb and release heat at specific set points (Z.B., 2–8°C oder –20°C), are reusable and usually non hazardous. Dry ice sublimes at –78.5 °C and is used for deep freeze shipments (< –70°C) but requires hazardous materials labels. - What regulations affect cold chain boxes in 2025?

In den USA, Die Gesetz zur Modernisierung der Lebensmittelsicherheit (FSMA), Gefahrenanalyse und kritische Kontrollpunkte (Haccp)Und Gesetz zur Sicherheit der Arzneimittellieferkette (DSCSA)require traceability, proper temperature control and documentation. The World Health Organization’s PQS specifications and Good Distribution Practice guidelines set standards for vaccine transport.

Zusammenfassung und Empfehlungen

Key Takeaways: Cold chain shipping boxes are passive or active insulated containers that maintain specific temperature ranges using insulation, coolant packs and monitoring devices. Choosing the right box size requires accurate measurements, room for insulation and the correct combination of EPS, PUR or VIP materials, along with gel packs or dry ice. Market data show that cold chain packaging will grow significantly, getrieben durch Pharmazeutika, Biologika, e commerce and sustainable packaging. Consumers expect environmentally friendly options, and regulations demand reliable traceability and temperature control.

Aktionsplan:

Bewerten Sie die Anforderungen Ihres Produkts: Temperaturbereich identifizieren, transit duration and sensitivity. Use this information to select appropriate insulation and coolant materials.

Richtige Größe Ihrer Box: Measure payload dimensions and leave space for insulation and cooling. Avoid oversize boxes to reduce shipping costs.

Investieren Sie in Überwachung: Include a digital data logger or IoT sensor in every shipment to ensure compliance and provide traceability.

Wählen Sie nachhaltige Optionen: Opt for recyclable or biodegradable materials to align with customer expectations and corporate sustainability goals.

Bleiben Sie über die Vorschriften auf dem Laufenden: Überwachen Sie Updates für FSMA, DSCSA and WHO guidelines to ensure your packaging meets legal requirements and avoids penalties.

Über Tempk

Tempk ist ein führender Anbieter von Kühlkettenlösungen, spezialisiert auf Isolierboxen, Gelpackungen, phase change materials and temperature monitoring devices. Our research and development center continuously explores eco friendly materials and advanced insulation technologies to deliver wiederverwendbare und recycelbare Kühlkettenprodukte. Wir bieten customized packaging designs tailored to food, Pharma- und Biotech-Industrie, ensuring product integrity from origin to destination. Partner with Tempk to optimize your cold chain operations.

Aufruf zum Handeln: Bereit, Ihre Kühlkette zu verbessern? Contact us for a consultation and discover how our innovative boxes, PCMs and monitoring solutions can safeguard your products, reduce waste and help your business meet 2025 compliance standards.