Das rasante Wachstum des E-Commerce und der Lieferdienste für Essenspakete hat die Bedeutung von erhöht Versandkartons für kalte Lebensmittel bei der Aufrechterhaltung der Produktqualität und -sicherheit. Diese spezialisierten Behälter kombinieren die thermische Effizienz, Haltbarkeit, und Nachhaltigkeit, um die strengen Anforderungen des verderblichen Warenverkehrs zu erfüllen. In diesem Artikel werden die neuesten Fortschritte untersucht, Herausforderungen, und Tempks führende Lösungen in der Kaltkettenverpackung.

1. Materialinnovationen für optimale Wärmeleistung

Moderne Kühlboxen nutzen technische Materialien, um die Frische zu verlängern:

-

Vakuum -isolierte Panels (VIPs): Mit ultra-niedriger Leitfähigkeit (0.004 W/m · k), VIPs halten 0–4 ° C für beibehalten 100+ Std., Outperformance traditioneller EPS -Schaum durch 300%.

-

Bio-basierte PCM-Liner: Phasenveränderungsmaterialien wie Soja-Wachs-Derivate stabilisieren die Temperaturen (-18° C bis 5 ° C.) für 72 Std., Eliminierung der Abhängigkeit von Trockeneis.

-

EVP (Erweiterter Polypropylen): Tempks proprietäres EPP -Schaumangebot 98% Recyclingbarkeit und 2x höhere Wirkung als EPS als EPS, kritisch für grobe Transitbedingungen.

2. Wichtige Anwendungen und Industriestandards

-

Mahlzeiten: USDA-konforme Boxen mit PLA-beschichteten Linern verhindern Kondensation und halten die Zutaten für 48-Stunden-Lieferungen frisch..

-

Meeresfrüchte Transport: Gefrierblöcke auf Gelbasis in Kombination mit Aerogel-Isolierung halten bei transkontinentalen Sendungen eine Temperatur von -22 °C aufrecht.

-

Pharma-Food-Hybride: Boxen mit Zweizonen-Fächern (2–8 ° C und -20 ° C.) Temperaturempfindliche Nutrazeutika sicher versenden.

3. Nachhaltigkeit Herausforderungen und Lösungen

-

Kosten vs. Öko-Impact: Isolationskosten auf pflanzlicher Basis 25% Mehr als Erdölschäume, Aber Lebenszyklusanalysen zeigen es 60% geringerer CO2-Fußabdruck.

-

Recyclingbarrieren: Mehrschichtmaterialien (Z.B., Folien-PU-Verbundwerkstoffe) erfordern fortschrittliche Trenntechnik, mit unten aufgeführten EU-Recyclingquoten 18%.

-

Vorschriftenregulierung: ASTM D6868 und FDA 21 CFR-Standards schreiben strenge Tests für Lebensmittelkontaktmaterialien vor, R fahren&D in ungiftigen Beschichtungen.

4. Intelligente Technologien gestalten die Zukunft

-

IoT -Sensoren: Bluetooth-fähige Logger verfolgen interne Bedingungen (± 0,3 ° C Genauigkeit) und synchronisieren Sie Daten mit Cloud-Plattformen für Echtzeit-Compliance-Berichte.

-

Selbstkühlboxen: Ammoniak-Absorptionssysteme aktivieren die Kühlung bei Bedarf, 4°C im Inneren erreichen 15 Minuten ohne externe Stromversorgung.

-

Myzelverpackung: Pilz-Wurzel-Verbundwerkstoffe bieten 0.033 W/m·K isolieren und zersetzen 45 Tage, entwickelt sich zu einer Alternative zu Polystyrol.

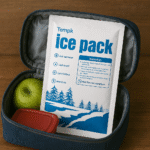

5. Tempks isolierte Kisten: Ein Maßstab in Sachen Kühlketten-Exzellenz

Tempks EcoFresh-Serie definiert den Kaltversand neu:

-

Mehrschichtiges EPP-Design: Die dreiwandige Konstruktion hält 0–4 °C aufrecht 120 Std., selbst in Umgebungen mit 40 °C.

-

Closed-Loop-System: 100% recycelbar über das Rücknahmeprogramm von Tempk, Reduzierung von Deponieabfällen um 90% im Vergleich zu Einwegboxen.

-

Ergonomische Merkmale: Nestbare Designs reduzieren den Stauraum 35%, während von der FDA zugelassene antimikrobielle Liner das Bakterienwachstum hemmen.

Durch die Verbindung modernster Materialien mit Prinzipien der Kreislaufwirtschaft, Tempk bietet unübertroffene Zuverlässigkeit für die Logistik verderblicher Waren.