Kryo-Trockeneis-Packplatten sind spezielle Kühlkissen, die festes Kohlendioxid enthalten (Co₂) in flexiblen Zellen eingeschlossen. Bei sachgemäßer Anwendung, Diese Platten halten Temperaturen weit unter dem Gefrierpunkt, Damit eignen sie sich ideal für den Transport von Impfstoffen, Meeresfrüchte, biologische Proben und Gourmet-Lebensmittel. Denn das CO₂ sublimiert (geht direkt von fest in gasförmig über), Trockeneis sorgt für intensive Kälte, ohne Wasserrückstände zu hinterlassen. Dieser Leitfaden beantwortet Ihre dringendsten Fragen zur Auswahl, Verwendung und Entsorgung von kryogenen Trockeneis-Packplatten, Einbeziehung der neuesten 2025 Branchendaten und Sicherheitsvorschriften.

Was genau sind kryogene Trockeneis-Packplatten und wie funktionieren sie??

So wählen Sie die richtige Größe und Menge an Trockeneis-Packplatten für verschiedene Produkte und Transportzeiten aus

Wichtige Sicherheits- und Regulierungsrichtlinien beim Versand mit kryogenem Trockeneis

Vorteile und Einschränkungen im Vergleich zu Gelpackungen und Phasenwechselmaterialien

Neu 2025 Innovationen, Nachhaltigkeitstrends und Markteinblicke

Häufig gestellte Fragen, die Ihnen dabei helfen, sicher zu versenden

Was sind kryogene Trockeneis-Packblätter??

Kryo-Trockeneis-Packplatten sind flexible Polster, die mit Trockeneispartikeln gefüllt sind, die in atmungsaktiven Zellen eingeschlossen sind. Wenn es Umgebungstemperaturen ausgesetzt wird, Das Trockeneis untermüßt (dreht sich direkt von fest zu Gas um) bei etwa −78,5 °C (−109,3 °F), erzeugt einen starken Kühleffekt, ohne zu schmelzen Weil es keine flüssige Phase gibt, Produkte bleiben trocken – ein wichtiger Vorteil für die Pharma- und Elektronikbranche.

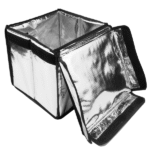

Die Packblätter sind so konzipiert, dass CO₂-Gas sicher abgelassen wird. Traditionelles Trockeneis gibt es in Blöcken oder Pellets; Packblätter verteilen das Kohlendioxid gleichmäßig und können passend für jeden Behälter zugeschnitten werden. Sie werden häufig mit isolierten Boxen oder vakuumbeschichteten Transportbehältern kombiniert, um eine stabile kryogene Umgebung aufrechtzuerhalten.

Wie Trockeneissublimation funktioniert

Trockeneis ist einfach die feste Form von Kohlendioxid (Co₂). Unter normalem Atmosphärendruck, CO₂ sublimiert bei –78,5 °C (–109,3 °F). Dies bedeutet, dass es nicht zu einer Flüssigkeit schmilzt, es verwandelt sich direkt in ein Gas. In einer isolierten Umgebung, Das Gas bleibt kalt genug, um Produkte gefroren oder gekühlt zu halten. Das Fehlen einer flüssigen Phase verhindert Wasserschäden beim Transport.

Warum kryogene Trockeneis-Packplatten verwenden??

Zuverlässige Temperaturkontrolle für verderbliche Waren

Trockeneisplatten werden häufig in Branchen wie der Lebensmittelschifffahrt eingesetzt, Arzneimittel, Wissenschaftliche Forschung, Unterhaltung und Industriereinigung. Trockeneis hält verderbliche Lebensmittel wie Fleisch haltbar, Meeresfrüchte, Tiefkühldesserts und Impfstoffe sind beim Versand kalt Denn Trockeneis sublimiert ohne Feuchtigkeit, Es verhindert die Kondensation, die bei Gel-Packs oder nassem Eis auftritt.

Praktische Anwendungen

Lebensmittelkonservierung & Versand – Die Aufrechterhaltung extrem niedriger Temperaturen verhindert den Verderb und bewahrt Geschmack und Textur. Spezialwaren wie Gourmet-Eiscreme oder Schokolade erfordern während des Transports eine zuverlässig kalte Umgebung.

Medizinisch & Pharmazeutischer Transport - Impfungen, Organe und Laborreagenzien werden in kryogenen Umgebungen transportiert, um ihre Lebensfähigkeit aufrechtzuerhalten. Trockeneisbeutel liefern nicht flüssige Kälte, die strenge behördliche Anforderungen erfüllt.

Spezialeffekte in der Unterhaltung – Nebel- und Raucheffekte entstehen, wenn Trockeneis in Wasser gegeben wird, Dies verursacht eine schnelle Sublimation und einen dichten CO₂-Nebel. Trockeneisplatten helfen auch dabei, Schnee oder Wolken auf Filmsets zu simulieren.

Industriell & Wissenschaftliche Verwendungen – Trockeneisstrahlen treibt Pellets mit hoher Geschwindigkeit an, um Verunreinigungen ohne Chemikalien zu entfernen, Verbesserung der Reinigungseffizienz und Reduzierung von Abfall. Labore verwenden Trockeneis, um DNA zu konservieren, Gewebe und Zellkulturen bei kryogenen Temperaturen

Vorteile gegenüber herkömmlicher Kühlung

Keine Wasserrückstände – Trockeneis sublimiert direkt zu Gas, Es bleibt keine Feuchtigkeit zurück, die Verpackung oder Produkte beschädigen könnte.

Unterer Temperaturbereich – Blöcke, Pellets oder Packplatten halten Temperaturen bis –78,5 °C, kälter als die meisten herumschwebenden Gel-Packs 0 °C.

Kompakt & Einstellbar – Packblätter können auf die gewünschte Größe zugeschnitten werden, Dadurch sind sie vielseitig für verschiedene Behälter geeignet.

Reduziertes Gewicht – Trockeneis hat eine hohe Kühlleistung pro Kilogramm, Dadurch können Verlader im Vergleich zu Gel-Packs für eine gleichwertige Kühlung weniger Gewicht verbrauchen.

Bestimmen der richtigen Menge an Trockeneis-Packblättern

Die Wahl der richtigen Trockeneismenge ist entscheidend, um die Produktintegrität ohne übermäßige Ausgaben aufrechtzuerhalten. Vorschriften begrenzen auch die Menge an Trockeneis pro Packung (maximal 200 kg pro Paket gemäß den Richtlinien von FedEx).

Faktoren, die die Menge beeinflussen

Produktgewicht und -dichte – Schwerere Produkte erfordern mehr Kühlleistung.

Transitdauer – Längere Transportzeiten erfordern mehr Trockeneis. Eine allgemeine Empfehlung ist 5–10 Pfund (2.27–4,54 kg) von Trockeneis pro 24 Stunden Transit.

Umgebungstemperatur – Für Sendungen, die durch warme Klimazonen oder in den Sommermonaten reisen, ist zusätzliches Trockeneis erforderlich.

Isolationsqualität – Hochleistungsisolierte Behälter reduzieren die Menge an benötigtem Trockeneis.

Schätzung des Trockeneisbedarfs

Die folgende Tabelle – basierend auf einem Branchenleitfaden – gibt ungefähre Trockeneismengen für verschiedene Produktgewichte und Transportzeiten an. Diese Werte beinhalten zusätzliches Trockeneis zum Ausgleich der Umgebungstemperaturen.

| Produktgewicht | 24 hr Transit | 48 hr Transit | 72 hr Transit | Praktische Bedeutung |

| 2 lb (0.9 kg) | 5 LB Trockeneis | 8 LB Trockeneis | 10 LB Trockeneis | Geeignet für kleine Impfstoffsendungen oder Gourmet-Pralinen |

| 5 lb (2.3 kg) | 6 LB Trockeneis | 9 LB Trockeneis | 12 LB Trockeneis | Ideal für Tiefkühlmenüs oder Meeresfrüchte |

| 10 lb (4.5 kg) | 10 LB Trockeneis | 15 LB Trockeneis | 20 LB Trockeneis | Nützlich für Fleischgroßbestellungen und Diagnoseproben |

| 20 lb (9 kg) | 15 LB Trockeneis | 22 LB Trockeneis | 30 LB Trockeneis | Für große Laborsendungen oder mehrere Impfstofffläschchen |

| 50 lb (22.7 kg) | 20 LB Trockeneis | 33 LB Trockeneis | 45 LB Trockeneis | Großtransporte wie Organtransporte oder Industriereagenzien |

Interaktiver Schätzer

Verwenden Sie diese einfache Formel, um das Gewicht von Trockeneis abzuschätzen (in Pfund) für Ihre Sendung erforderlich:

dry_ice_weight = product_weight * transit_days * 0.5

Multiplizieren Sie das Gewicht Ihres Produkts (in Pfund) nach der Anzahl der Transporttage.

Multiplizieren Sie das Ergebnis mit 0.5 um ein Basis-Trockeneisgewicht zu erhalten.

Je nach Isolationsqualität und Umgebungsbedingungen nach oben oder unten anpassen.

Beispiel: A 10 Pfund-Sendung reist für 3 Tage benötigt ca 10 × 3 × 0.5 = 15 LB Trockeneis.

Sicherheits- und behördliche Überlegungen

Der Versand mit kryogenem Trockeneis erfordert die sorgfältige Einhaltung der Sicherheitsvorschriften. Sowohl die Internationale Luftverkehrsvereinigung (Iata) und die UNS. Verkehrsministerium (PUNKT) Trockeneis als Gefahrgut einstufen (Und 1845). Sie müssen kennzeichnen, Sendungen korrekt kennzeichnen und verpacken, um Bußgelder oder Unfälle zu vermeiden.

Verpackung & Entlüftungsanforderungen

FedEx 2025 Dry Ice Job Aid betont, dass Pakete muss die Freisetzung von Kohlendioxidgas ermöglichen um einen Druckaufbau zu verhindern. Es wird davon abgeraten, Trockeneis in versiegelten Plastiktüten oder luftdichten Kühlboxen aufzubewahren. Stattdessen, Verwenden Sie hochwertige Faserplatten, Kunststoff- oder Holzkisten mit Belüftungslöchern. Eine Schicht aus Polystyrolschaum eignet sich gut als Isolierung, es darf aber nicht luftdicht verschlossen werden. Für größere Mengen, Das maximale Trockeneis pro Packung beträgt 200 kg.

Richtige Kennzeichnung und Etikettierung

Laut Faktenblatt der Pace University:

Gasentlüftung: Pakete müssen Entlüftungssysteme enthalten; Versiegeln Sie niemals Trockeneis in luftdichten Behältern.

Paketintegrität: Die Kartons müssen den Belastungen beim Be- und Entladen standhalten, Schutz des Inhalts vor Vibrationen und Umweltveränderungen.

Verpackungsmaterialien: Vermeiden Sie Kunststoffe, die bei niedrigen Temperaturen spröde werden; Verwenden Sie speziell für Trockeneis geeignete Behälter.

Luftfrachtbrief: Auf dem Luftfrachtbrief muss „Trockeneis“ stehen, 9, UN 1845“ und geben Sie das Nettogewicht des Trockeneises an.

Markierungen: Kennzeichnen Sie Pakete mit dem Namen und der Adresse des Absenders und des Empfängers sowie der Nettomenge Trockeneis in Kilogramm.

Beschriftung: Wenden Sie eine Klasse an 9 Bringen Sie auf beiden Seiten des Kartons ein Gefahrenetikett mit der Angabe „UN“ an 1845 und Nettogewicht.

Ausbildung & Zertifizierung

Mitarbeiter, die Trockeneissendungen vorbereiten, müssen gemäß den Gefahrgutvorschriften geschult werden. FedEx bietet Schulungsseminare an und stellt Sendungen nach Alaska sicher, Bei Hawaii oder internationalen Reisezielen kann es zu Serviceeinschränkungen kommen.

Sicherheitsrisiken und Best Practices

Mit Schutzausrüstung handhaben: Die extreme Kälte von Trockeneis kann Erfrierungen verursachen. Tragen Sie immer isolierte Handschuhe und eine Schutzbrille. Vermeiden Sie direkten Hautkontakt

In gut belüfteten Räumen verwenden: Die Ansammlung von CO₂-Gas in geschlossenen Räumen kann Sauerstoff verdrängen und zur Erstickung führen. Arbeiten Sie in belüfteten Räumen oder im Freien.

Belüftete Behälter verwenden: Lagern Sie Trockeneis nicht in luftdichten Kühl- oder Gefrierschränken; Druckaufbau kann zu Explosionen führen. Wählen Sie Behälter, die für die Entlüftung ausgelegt sind

Nehmen Sie niemals Trockeneis ein: Schon kleine Teile können innere Verletzungen verursachen

Beschriften Sie Behälter: Beschriften Sie die Pakete deutlich mit Gefahrenhinweisen und Handhabungsanweisungen, um die Mitarbeiter darauf aufmerksam zu machen

Personal schulen: Bieten Sie Schulungen zur richtigen Handhabung an, Notfallmaßnahmen und Entsorgung

Sicher entsorgen: Lassen Sie Trockeneis an einem gut belüfteten Ort sublimieren. Entsorgen Sie es nicht in Waschbecken oder Abflüssen, da extreme Kälte die Leitungen beschädigen kann

Zusätzliche Gefahren

Explosionsgefahr: Verschlossene Behälter können durch den Aufbau von CO₂-Druck explodieren

Verätzungen: Durch Kontakt können Kunststoffe oder Gummi beschädigt werden

Transportgefahr: Schlecht isolierte Behälter oder unzureichende Belüftung können zur Gasbildung und zum Ersticken führen

Für einen sicheren Versand ist es wichtig, diese Gefahren zu verstehen und zu mindern.

Vergleich von kryogenen Trockeneis-Packblättern mit Gel-Packs und Phasenwechselmaterialien

Bei der Wahl zwischen Kühlmedien, Es ist wichtig, die Temperaturbereiche zu berücksichtigen, Feuchtigkeitskontrolle und Kosten. Trockeneis bietet weitaus kältere Temperaturen (–78,5 °C) im Vergleich zu Gelpackungen (0 °C bis –18 °C). Es sublimiert ohne Feuchtigkeit, Daher ist es ideal für Gegenstände, die durch Kondenswasser beschädigt wurden. Gelpackungen, Jedoch, sorgen für sanftere Kälte und sind wiederverwendbar. Phasenwechselmaterialien (PCMs) kann präzise Temperaturen aufrechterhalten (Z.B., +2 ° C bis +8 °C) sind aber teurer.

| Kühlmedium | Temperaturbereich | Feuchtigkeitsrisiko | Am besten für | Überlegungen |

| Kryogene Trockeneisplatten | Bis –78,5 °C | Keiner (sublimiert zu Gas) | Versand gefrorener Waren, Impfungen, Eiscreme | Erfordert eine besondere Verpackung und Handhabung; Es gelten die Gefahrstoffvorschriften. |

| Gelpackungen | 0 °C bis –18 °C | Mäßig (schmilzt zu Flüssigkeit) | Gekühlte Waren, Kurzstreckentransporte | Wiederverwendbar; Gefahr von Undichtigkeiten; nicht zum Tiefkühlen geeignet. |

| Phasenwechselmaterialien (PCMs) | Brauch (Z.B., +2 ° C bis +8 °C) | Niedrig (gekapselt) | Biologische Proben erfordern strenge Temperaturbereiche | Teurer; erfordert eine Vorkonditionierung auf die Zieltemperatur. |

Neueste Trends und Innovationen in der kryogenen Trockeneisverpackung (2025)

Wachstum des Marktes für isolierte Versandkartons

A 2025 Marktbericht stellt fest, dass die Die Branche der isolierten Versandkartons wird voraussichtlich von USD aus wachsen 3.8 Milliarden in 2025 in USD 8.5 Milliarden von 2035, repräsentiert ein 8.5 % durchschnittliche jährliche Wachstumsrate (CAGR). Das Wachstum wird von boomenden Sektoren wie der Lebensmittelbranche getragen, Arzneimittel, Biotechnologie und E-Commerce, und durch die erhöhte Nachfrage nach Mehrwegprodukten, umweltfreundliche Verpackung.

Nachhaltige Materialien und Recycling

Hersteller investieren in recycelbare und biologisch abbaubare Isolierung, wie Schäume auf pflanzlicher Basis und Phasenwechselsubstrate, um die Umweltbelastung zu reduzieren. Einige Packblätter bestehen aus kompostierbaren Stoffen oder recyceltem Polyester. Zusätzlich, wiederverwendbare Transportbehälter mit Vakuumisolationspaneelen (VIPs) Erweitern Sie die thermische Leistung und reduzieren Sie gleichzeitig den Abfall.

Smartemperaturüberwachung

IoT-fähige Temperaturkartierung, RFID-fähige Nachverfolgung und in die Verpackung eingebettete Sensoren ermöglichen die Echtzeitüberwachung der Produkttemperaturen. Diese Technologien helfen Unternehmen, die Integrität der Kühlkette zu überprüfen, Reduzieren Sie Produktverluste und halten Sie behördliche Audits ein. Einige Kryo-Packfolien verfügen über eingebaute Temperaturindikatoren, die ihre Farbe ändern, wenn die Temperatur über einen festgelegten Schwellenwert steigt.

Automatisierung und Anpassung

Fortschritte in der Fertigung ermöglichen Automatisiertes Befüllen von Trockeneis-Packplatten mit präziser CO₂-Dosierung, was zu einer konstanten Kühlleistung führt. Anpassbare Packblattgrößen ermöglichen es Unternehmen, die Form ihrer Behälter anzupassen, Reduzierung des Leerraums und Verbesserung der Effizienz.

Verbesserte Sicherheitstrainingstools

Digitale Trainingsplattformen und Augmented Reality (AR) Mithilfe von Simulationen können Mitarbeiter den Umgang mit Trockeneis in virtuellen Umgebungen üben. Diese Programme schärfen das Bewusstsein für Gefahren wie Erstickung und Kälteverbrennungen und werden von großen Logistikdienstleistern übernommen.

Häufig gestellte Fragen (FAQ)

Was ist der Unterschied zwischen Trockeneisplatten und Trockeneispellets??

Trockeneisplatten enthalten kleine Trockeneispartikel, die von einer flexiblen Membran umgeben sind. Sie sorgen für eine gleichmäßige Kühlung und können individuell zugeschnitten werden. Pellets sind lose und müssen in Behälter gefüllt werden. Die Blätter sind einfacher zu handhaben und verringern das Risiko eines direkten Kontakts, während Pellets unregelmäßige Räume leichter füllen können.

Wie lange halten kryogene Trockeneisplatten??

Die Dauer hängt vom Gewicht und der Isolierung ab. Im Allgemeinen, 5–10 lb (2.27–4,54 kg) Trockeneis reicht für ca 24 Std.. Trockeneis sublimiert in warmen Umgebungen oder an der Luft schneller, Halten Sie die Behälter daher geschlossen und isoliert.

Kann ich eine Trockeneisbeutelfolie wiederverwenden??

NEIN. Sobald das Trockeneis sublimiert ist, das Blech verliert seine Kühlleistung. Einige Hersteller bieten nachfüllbare oder wiederaufladbare Versionen an, Die meisten Einweglaken sollten jedoch gemäß den Anweisungen des Lieferanten entsorgt werden.

Ist der Versand mit Trockeneis über alle Transportunternehmen erlaubt??

Nicht alle Anbieter akzeptieren Trockeneis. FedEx und DHL versenden Trockeneis, wohingegen UPS und die USA. Der Postdienst hat restriktive Richtlinien. Überprüfen Sie immer die Richtlinien des Spediteurs und vervollständigen Sie die erforderlichen Unterlagen.

Was soll ich mit übrig gebliebenem Trockeneis machen??

Lassen Sie das verbleibende Trockeneis an einem gut belüfteten Ort sublimieren. Werfen Sie es nicht in Mülltonnen, Waschbecken oder Toiletten. Verwenden Sie niemals heißes Wasser, um die Sublimation zu beschleunigen, da eine schnelle Gasfreisetzung zu Erfrierungen oder Druckaufbau führen kann.

Wie verhindere ich, dass sich Produkte in der Verpackung bewegen, wenn Trockeneis sublimiert??

Verwenden Sie Pappeinlagen oder Schaumstoff-Abstandshalter, um Ihre Gegenstände zu sichern. Stellen Sie sicher, dass die Innenbehälter gepolstert sind, damit sie stabil bleiben, wenn das Trockeneisvolumen während des Transports abnimmt.

Zusammenfassung und Imbissbuden

Kryo-Trockeneis-Packplatten sorgen zuverlässig, Niedrigtemperaturkontrolle für den Versand empfindlicher Produkte. Diese Laken liefern Temperaturen unter dem Gefrierpunkt ohne Feuchtigkeit, Daher sind sie ideal für Impfstoffe, Meeresfrüchte, Speziallebensmittel und wissenschaftliche Proben. Der Die benötigte Menge an Trockeneis hängt vom Produktgewicht ab, Transitdauer, Umgebungsbedingungen und Isolationsqualität, mit einer allgemeinen Richtlinie von 5–10 lb pro 24 Std.. Eine ordnungsgemäße Verpackung muss eine Entlüftung ermöglichen, um einen Druckaufbau zu vermeiden, und Sendungen müssen vorschriftsmäßig gekennzeichnet und beschriftet sein (Und 1845, Nettogewicht und Klasse 9 Gefahrenhinweise). Sicherheitsvorkehrungen – z. B. das Tragen isolierter Handschuhe, Die Verwendung belüfteter Behälter und die Vermeidung einer direkten Einnahme sind unerlässlich

Ich schaue nach vorn 2025 und darüber hinaus, Die Nachfrage nach isolierten Versandkartons und Trockeneis-Packplatten wird weiter steigen da die Kühlkettenlogistik in den Bereichen Lebensmittel und Biowissenschaften zunimmt. Innovationen bei nachhaltigen Materialien, Intelligente Temperaturüberwachung und automatisierte Fertigung erhöhen die Sicherheit und Effizienz. Indem Sie Best Practices befolgen und über Branchentrends auf dem Laufenden bleiben, Sie können kryogene Trockeneis-Packplatten verwenden, um Produkte sicher zu versenden.

Umsetzbare nächste Schritte

Bewerten Sie Ihre Produktanforderungen – Identifizieren Sie den Temperaturbereich und die Transportdauer für Ihre Sendung. Verwenden Sie die Schätzformel, um das Trockeneisgewicht zu berechnen.

Wählen Sie die richtige Verpackung – Wählen Sie isolierte Behälter für Trockeneis und stellen Sie sicher, dass sie über Entlüftungsmechanismen verfügen. Vermeiden Sie Materialien, die bei niedrigen Temperaturen spröde werden.

Bereiten Sie die Sendung vor – Füllen Sie den Luftfrachtbrief mit „Trockeneis“ aus, 9, UN 1845“ und geben Sie das Nettogewicht an. Beschriften Sie das Paket deutlich mit Gefahrenaufklebern und Adressen auf den gegenüberliegenden Seiten.

Trainiere dein Team – Bieten Sie Sicherheitsschulungen zum Umgang mit Trockeneis an, inklusive geeigneter PSA, Belüftung und Entsorgung. Ermutigen Sie Ihre Mitarbeiter, Ressourcen wie die Dry Ice Job Aid von FedEx und Sicherheitshandbücher von Universitäten zu konsultieren.

Entdecken Sie nachhaltige Optionen – Erforschen Sie wiederverwendbare isolierte Transportbehälter und umweltfreundliche Materialien, um Abfall zu reduzieren und gleichzeitig die Leistung aufrechtzuerhalten.

Überwachen Sie Branchenaktualisierungen – Verfolgen Sie Marktberichte und regulatorische Aktualisierungen. Implementieren Sie intelligente Temperaturüberwachungssysteme, um die Transparenz und Compliance zu verbessern.

Über TempPK

TemPK ist ein führender Anbieter von Kühlkettenverpackungslösungen, die auf die Biowissenschaften zugeschnitten sind, Lebensmittel- und Industriesektor. Wir entwerfen und fertigen Hochleistungs-Kryogen-Trockeneis-Packplatten und isolierte Transportbehälter, die über längere Zeiträume extrem niedrige Temperaturen aufrechterhalten. Unsere Produkte sind auf Langlebigkeit ausgelegt, Sicherheit und Einhaltung gesetzlicher Vorschriften. Mit Fokus auf Innovation und Nachhaltigkeit, Wir bieten umweltfreundliche Materialien an, IoT ermöglichte Temperaturverfolgung und anpassbare Lösungen um den sich verändernden Bedürfnissen unserer Kunden gerecht zu werden. Für kompetente Beratung bei der Auswahl der richtigen Kühlkettenverpackung, Kontaktieren Sie unser Team und erfahren Sie, wie TemPK Ihnen dabei helfen kann, sicher zu versenden.

Benötigen Sie Hilfe bei der Auswahl der perfekten kryogenen Trockeneis-Packplatte?? Kontaktieren Sie TempPK noch heute mit einem Kühlkettenspezialisten zu sprechen und eine individuelle Empfehlung zu erhalten.