Rabatt auf Trockeneisbeutel: So kaufen Sie Smart und versenden kälter

Wenn Sie auf der Suche nach einem sind Rabatt auf Trockeneisbeutel das erreicht immer noch eine Leistung von -78,5 °C, Sie möchten Einsparungen ohne Verlust. Dieser Leitfaden zeigt, wie Sie die richtige Packungsgröße auswählen, Berechnen Sie die Sublimation, und entsprechen der IATA PI 954 im Klartext – so können Sie sich kältere Fahrspuren sichern und gleichzeitig die Stückkosten senken.

-

So wählen Sie Größen und Formate für Fernstrecken aus (VIP, EPS, EVP)

-

Wie viele Pfund Trockeneis benötigen Sie tatsächlich pro Tag? (mit Puffer)

-

Welche Vorschriften und Etiketten müssen Sie für UN1845-Sendungen anwenden?

-

Wo „Rabatt“ wirklich lebt: MOQ, Frachtklasse, und Pack-out-Design

-

2025 Trends: wiederverwendbare Systeme, VIP-Liner, und intelligentere Prognosen

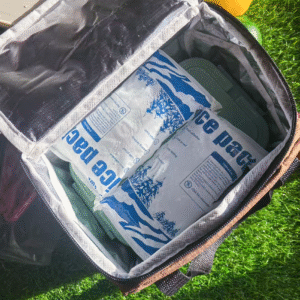

Wie wählen Sie den richtigen günstigen Trockeneisbeutel für Ihre Spur aus??

Kurze Antwort: Passen Sie die Kältemittelgewichte an die reale Sublimation an und kombinieren Sie es mit der kleinsten Box, die Ihrem Haltezeitziel entspricht. Beginnen Sie mit der Spurzeit während des Transports, Fügen Sie einen Verzögerungspuffer hinzu, Wählen Sie dann einen Rucksack aus, der zur Box passt und über einen Luftstrom zur Belüftung verfügt.

Warum funktioniert es

Denken Sie in Tagen, nicht Meilen. Wenn Ihre Spur ist 48 Stunden von Tür zu Tür, planen für 2 Tage der Sublimation plus 20–30 % Puffer für Hitze und Verzögerungen. Viele Versender nutzen 5–10 lb per 24 H als Planungsbereich und dann nach Piloten abstimmen. Dies hält die Materialliste schlank und schützt gleichzeitig die Produktqualität auf heißeren Routen.

Welches Packungsformat eignet sich am besten für „Discount“-Käufer??

Blöcke vs. Pellets vs. Blätter

Blöcke halten pro Pfund länger; Pellets füllen Toträume besser aus. Die Blätter/Beutel sind aufgeräumt und können mit kürzerer Kommissionierzeit zusammengestellt werden. Verwenden Sie Blöcke für lange Strecken, bei denen eine minimale Oberfläche die Sublimation verringert; Wechseln Sie zu Pellets, wenn Sie Kältemittel um ungewöhnlich geformte Waren herum verstauen müssen.

| Format | Am besten für | Achtung | Was es für Sie bedeutet |

|---|---|---|---|

| Block | Lange Gassen, große Kisten | Langsameres Herunterziehen, weniger Kontaktfläche | Weniger Stücke, längeres Leben, einfachere SOP |

| Pellets | Enge Räume, schnelles Herunterziehen | Schnellere Sublimation bei loser Verpackung | Ideal für E-Kommunikationskits mit verschiedenen SKUs |

| Blätter/Beutel | Sauberes Kitting, standardisierte SKUs | Kann mehr pro Pfund kosten | Schnelleres Packen, weniger Trainingszeit |

Praktische Tipps zur Stückkosteneinsparung

-

Konstruieren Sie zuerst die Box. Optimieren Sie interne Dimmungen, Kaufen Sie dann das günstigste Kältemittel, das Ihren Spezifikationen entspricht.

-

Push-Konsolidierung. Größere Umkartons reduzieren die Fracht pro Pfund und den Umgang mit Kältemitteln.

-

SKU-Disziplin. Standardisieren Sie 2–3 Packungen, die die Abdeckung abdecken 80% von Bestellungen; Kaufen Sie diese Packungen in großen Mengen und profitieren Sie von Preisnachlässen.

-

Thermische Vorkonditionierung. Waren und Innenverpackungen vorkühlen; Ein kälterer Start kann das Kältemittelgewicht spürbar reduzieren.

Mini-Gehäuse aus der realen Welt: Eine Marke für Essenssets an der Westküste wechselte von Ad-hoc-Pelletschaufeln zu einem Zwei-Block-Standard in einem 1,5-Zoll-Urethan-Versandbehälter mit einem 25% Verzögerungspuffer. Der Verderb fiel weiter unten 0.5%, und die Kosten pro Bestellung sanken um 9% aufgrund der schnelleren Packzeit und geringeren Überfüllung.

Welche Vorschriften gelten, wenn Sie einen günstigen Trockeneisbeutel per Flugzeug versenden??

Kurze Antwort: Verwenden Sie die korrekte Versandbezeichnung „Kohlendioxid, solide,” Markierung UN1845, Wenden Sie die Klasse an 9 Etikett, Geben Sie das Nettogewicht von Trockeneis an, und stellen Sie sicher, dass die Verpackung CO₂-Gas entlüftet. Für Passagier- und Frachtflugzeuge gelten Mengenbeschränkungen und Betreiberschwankungen. Überprüfen Sie immer den neuesten PI 954 vor der Ausschreibung.

-

Markierungen: Adresse des Absenders/Empfängers, korrekte Versandbezeichnung und UN-Nummer, Nettogewicht Trockeneis.

-

Verpackung: muss eine Entlüftung ermöglichen, um einen Druckaufbau zu verhindern; CO₂ niemals in einem dichten Behälter verschließen.

-

Menge: Typische Grenzwerte erlauben je nach Flugzeugtyp und Trägervariante bis zu ~200 kg pro Paket.

-

Dokumentation: Stimmen Sie Ihren Luftfrachtbrief und Ihre interne SOP mit PI ab 954 Sprache.

Wie viele Pfund Trockeneis pro Tag sollten Sie einplanen??

Faustregel: 5–10 lb per 24 H in einem gut isolierten Transporter – fügen Sie dann einen 20–30 %igen Wärmepuffer hinzu, Verzögerungen, und Wochenendübergaben. Für eine zweitägige Transportstrecke mit einem Produktgewicht von ≤ 12,5 Pfund, Budget um 20 lb aus Trockeneis, dann nach Piloten verfeinern. Wenn Sie einen dünnen EPS-Versender verwenden, Tendenz zum oberen Ende; mit VIP, Sie können oft Gewicht verlieren, indem Sie die Zeit einhalten.

Warum ist die Sublimation so unterschiedlich??

Oberfläche, Isolationswert (VIP vs. EPS), Umgebungszeit, Und es kommt darauf an, wie Sie die Packungen platzieren. Bei der FAA-Prüfung kleiner Pakete, durchschnittliche Sublimation um ~2 %/Stunde wurde unter bestimmten Bedingungen beobachtet; Die realen Ergebnisse unterscheiden sich je nach Boxdesign, Auspacken, und Wetter. Aus diesem Grund sind Post-Pilot-Telemetrie und Stichproben Teil einer guten Qualitätssicherungsschleife.

| Treiber | Kostengünstiger Umzug | Wirkung auf Pfunde | Was es für Sie bedeutet |

|---|---|---|---|

| Isolierung | Upgrade auf 1,5–2,0 Zoll Urethan- oder VIP-Liner | ↓ 10–40 % | Weniger Kältemittel, kleinere Box |

| Packplatzierung | Halten Sie das Kältemittel im Luftstrom über dem Produkt | ↓ 5–15 % | Besseres kaltes Waschbecken, sichereres Entlüften |

| Starttemperatur | Nutzlast vorkühlen & Dunnage | ↓ 5–10 % | Schnellerer Zugang, weniger Abfall |

| Kartongröße | Kopfspace reduzieren | ↓ 5–20 % | Günstigere Fracht, weniger Packungen |

Schnellrechner (Einsatz bei Piloten)

-

Spurdauer (Std.) ÷ 24 = Basistage

-

Multiplizieren Sie mit 7.5 LB/Tag (Mittelpunkt von 5–10)

-

Hinzufügen 25% Puffer

-

Auf den nächsten Wert aufrunden 5 lb Blockgröße

Wie verändern VIP-Versender die Rechnung für Rabattkäufer??

Kurze Antwort: VIP (vakuumisoliertes Panel) Liner verlängern die Haltezeit um das Zwei- bis Dreifache im Vergleich zu. herkömmlicher Schaum, So können Sie Kältemittel-Pfund und -Fracht einsparen. Für Fahrspuren vorbei 72 H, VIP-Lösungen erzielen trotz höherem Stückpreis häufig einen Gesamteinstandspreis. Viele serienmäßige VIP-Kits können Temperaturen von 2–8 °C oder Tiefkühlbereichen darüber hinaus aufrechterhalten 120 Std., insbesondere in Kombination mit PCM oder abgestuftem Kältemittel.

Wann solltest du? nicht Wählen Sie VIP?

Wenn Ihre durchschnittliche Spur ist <36 h und die Umgebung ist mild, Möglicherweise erhalten Sie die zusätzlichen Materialkosten nie zurück. Testen Sie beide Optionen: wo der Verderb bereits nahe Null liegt, Bleiben Sie bei EPS/EPP und konzentrieren Sie sich auf die Auspackgeschwindigkeit.

Woher kommt eigentlich das Wort „Rabatt“??

-

MOQ-Stufen: Fragen Sie die Anbieter nach Preisnachlässen unter 500, 1,000, Und 5,000 Einheiten; mit der Prognose abstimmen.

-

Frachtklasse: Versenden Sie dichtere Blöcke auf Paletten; Vermeiden Sie Maßzuschläge für flauschiges Stauholz.

-

Kitting-Arbeit: Eine saubere SOP spart oft mehr als nur eine kleine Preissenkung beim Kältemittel.

-

Richtige Größe: Eliminieren Sie eine Kartongröße und konsolidieren Sie die Volumina, um die Einkaufswirkung zu verbessern.

2025 Entwicklungen, die die Rabattstrategie für Trockeneisbeutel prägen

Großes Bild: Die Nachfrage nach Kühlketten in der Lebensmittel- und Pharmabranche steigt, während wiederverwendbare Systeme und intelligentere Isolierung die laufenden Kosten senken. Allein der Verpackungsbereich verzeichnet ein milliardenschweres Wachstum, und VIP-/wiederverwendbare Systeme nehmen zu, da Marken nach Kosten- und Nachhaltigkeitsvorteilen streben.

Schnelle Takes

-

Wiederverwendbare Kits werden erweitert. Wiederverwendbare Produkte senken langfristig die Stückkosten und den Abfall, insbesondere auf vorhersehbaren Rückwärtslogistikspuren.

-

VIP wird Mainstream. 2–3× Haltezeitgewinne machen den Kältemittelplan leichter; weniger Pfund = weniger Fracht.

-

Die Prognose verbessert sich. Eine bessere Spuranalyse verringert das Risiko von Überfüllungen und Fehlbeständen bei Kältemittel-SKUs.

Market insight: Erwarten Sie ein stetiges Wachstum bei temperaturkontrollierten Verpackungen und wiederverwendbaren Produkten 2030+, angetrieben durch E-Lebensmittel und Biologika. Budget für höhere Serviceniveaus, Planen Sie jedoch, dies durch eine intelligentere Isolierung und standardisierte Verpackungen auszugleichen.

FAQ

Q1: Ist ein günstiger Trockeneisbeutel dasselbe wie ein Gelbeutel??

NEIN. Trockeneis enthält festes CO₂ -78.5°C für den Tiefkühlversand. Gelpacks oder PCMs halten bei höheren Sollwerten (Z.B., 0°C, 2–8 ° C). Wählen Sie basierend auf dem erforderlichen Temperaturbereich Ihres Produkts.

Q2: Kann ich einen vergünstigten Trockeneisbeutel per Flugzeug ins Ausland verschicken??

Ja, aber folgen Sie PI 954. Markieren Sie „Kohlendioxid, solide,” UN1845 hinzufügen, Klasse 9 Etikett, und geben Sie das Nettogewicht des Trockeneises an. Stellen Sie die Entlüftung sicher und prüfen Sie die Abweichungen der Luftleitungen.

Q3: Warum verschwand mein Trockeneis schneller als erwartet??

Wahrscheinlich hohe Umgebungstemperaturen, dünne Isolierung, zu viel Kopfraum, oder lose Pellets. Straffen Sie die Verpackung und erwägen Sie ein Upgrade auf Urethan- oder VIP-Auskleidungen.

Q4: Wie viele Packungen sollte ich vorrätig haben??

Planen Sie den Bestand anhand von Spurprognosen und einem Wochenendpuffer. Standardisieren Sie auf 2–3 SKUs und kaufen Sie diese in großen Mengen, um echte Rabatte zu erhalten.

Q5: Kann VIP Geld sparen, wenn es im Voraus mehr kostet??

Oft, Ja. Wenn es 30–40 % des Kältemittelgewichts einspart und die Box schrumpft, Sie sparen das ganze Jahr über Fracht und Schäden – insbesondere auf 72–120-Stunden-Fahrten.

Zusammenfassung & Nächste Schritte

Schlüsselpunkte: Packouts standardisieren, Größe des Kältemittels aus der Spurdauer, fügen Sie a hinzu 25% Puffer, und beschriften Sie PI 954 korrekt. Verwenden Sie VIP, wenn die Fahrspuren lang oder heiß sind, und jagen Sie Rabatte durch Mindestbestellmengen, Rechtsgröße, und die Arbeit gewinnt – nicht nur der Preis pro Pfund.

Aktionsplan: Pilotieren Sie zwei Packouts (EPS vs. VIP) Auf deiner längsten Spur, Protokollzeit, Sichern Sie sich dann Großeinkäufe auf der Stufe, bei der Sie einen deutlichen Preisnachlass erzielen. Benötigen Sie Hilfe bei der Größenbestimmung oder SOPs? Sprechen Sie mit uns – Tempk kann Ihre Spur modellieren und innerhalb weniger Tage ein validiertes Packout zurückgeben.

Über Tempk

Wir entwickeln praktische Kühlkettenlösungen für Lebensmittel und Biowissenschaften. Unsere Pack-Out-Sets, VIP-Liner, und die Spuranalyse helfen Ihnen, kälter und mit weniger Pfund Kältemittel zu versenden. Kunden wählen uns wegen schneller Piloten und messbaren Einsparungen. Lassen Sie uns ein Rabattprogramm für Trockeneisbeutel auf Ihre Fahrspuren zuschneiden.

CTA: Schicken Sie uns eine E-Mail an sales@tempk.com oder buchen Sie eine Fahrspurbewertung auf unserer Website.