Beim Versand temperaturempfindliche Lebensmittel, Die Aufrechterhaltung der Frische ist der Schlüssel. Trockeneis zum Verpacken von Lebensmitteln ist eine vertrauenswürdige Lösung, um sicherzustellen, dass Ihre verderblichen Waren während des gesamten Transports gefroren bleiben. Dieser Leitfaden erklärt, wie Trockeneis funktioniert, die Best Practices für die Verwendung, und die Branchen, die davon profitieren.

-

Warum Trockeneis zum Verpacken von Lebensmitteln verwenden??

-

Wie konserviert Trockeneis gefrorene Lebensmittel während des Transports??

-

Best Practices und Sicherheitstipps für die Verwendung von Trockeneis in Lebensmittelverpackungen.

-

Branchen, die beim Versand von Lebensmitteln auf Trockeneis angewiesen sind.

Warum Trockeneis zum Verpacken von Lebensmitteln verwenden??

Trockeneis, eine feste Form von Kohlendioxid, ist äußerst effektiv beim Einfrieren von Lebensmitteln. Im Gegensatz zu normalem Eis, das schmilzt und erzeugt Wasser, Trockeneis untermauert direkt in Gas, hinterlässt keine Feuchtigkeit. Dadurch ist es ideal für die Pflege Temperaturstabilität von Tiefkühlkost, vor allem während Fernlieferungen.

Wie Trockeneis in der Lebensmittelverpackung funktioniert

Trockeneis ist die beste Option zum Konservieren gefrorenes Essen Während des Transports, da es eine Temperatur von aufrechterhält -78.5°C (-109.3° F). Es wird häufig zum Verpacken von Lebensmitteln verwendet, z Fleisch, Meeresfrüchte, Eiscreme, Und gefrorene Früchte. Trockeneis absorbiert beim Sublimieren Wärme, Dadurch wird die Temperatur im Inneren der Verpackung gesenkt und unter dem Gefrierpunkt gehalten.

Best Practices für die Verwendung von Trockeneis in Lebensmittelverpackungen

Beim Verpacken von Lebensmitteln mit Trockeneis, Es ist von entscheidender Bedeutung, die richtigen Verfahren einzuhalten, um sowohl die Sicherheit der Sendung als auch die Konservierung der Lebensmittel zu gewährleisten.

1. Bestimmen Sie die richtige Menge Trockeneis

Die Menge an benötigtem Trockeneis hängt von Faktoren wie ab Versanddauer und die Art des Essens transportiert wird. Typischerweise, Du brauchst herum 5 Zu 10 Pfund Trockeneis für jeden 24 Stunden des Versands. Eine Überschätzung der Menge trägt dazu bei, die Temperatur bei Verzögerungen oder ungeplanten Ereignissen aufrechtzuerhalten.

2. Verwenden Sie Isoliermaterialien

Damit das Trockeneis nicht zu schnell sublimiert, Stellen Sie sicher, dass Sie qualitativ hochwertige Produkte verwenden isolierende Verpackungsmaterialien. Kühler aus Styropor oder Thermofutter werden üblicherweise verwendet, um das Trockeneis zu schützen und es über einen längeren Zeitraum kühl zu halten. Diese Materialien tragen auch dazu bei, dass Ihre Lebensmittel die richtige Temperatur behalten.

3. Stellen Sie eine ordnungsgemäße Belüftung sicher

Da Trockeneis bei der Sublimation Kohlendioxidgas freisetzt, es ist lebenswichtig Belüften Sie die Verpackung. Verschlossene Behälter ohne Belüftung können zur Gasbildung führen, Erstellen Druck im Paket. Dies könnte die Lebensmittel beschädigen oder sogar zu Sicherheitsrisiken führen. Verwenden Sie immer Behälter mit Entlüftungslöcher oder Atemventile.

| Verpackungsmethode | Trockeneisverpackung | Traditionelle Eisbeutel |

|---|---|---|

| Kühldauer | 24-72 Std. | 12-24 Std. |

| Feuchtigkeitsrisiko | Kein Wasser, Keine Lecks | Gefahr einer Leckage |

| Temperaturregelung | Ständig unter dem Gefrierpunkt | Temperatur über dem Gefrierpunkt |

| Ideal für | Gefrorenes Essen, Meeresfrüchte | Kurzfristige Kühlung |

Branchen, die von Trockeneisverpackungen profitieren

Mehrere Branchen verlassen sich bei der Lebensmittelverpackung auf Trockeneis, insbesondere diejenigen, die an der Schifffahrt beteiligt sind gefrorenes Essen oder verderbliche Güter. Hier sind einige Schlüsselsektoren, die von Trockeneisverpackungen profitieren:

-

Lebensmittelindustrie: Trockeneis ist ideal für den Versand verderbliche Güter, vor allem diejenigen, die aufbewahrt werden müssen Temperaturen der Unter Null, wie gefrorene Mahlzeiten, Eiscreme, und Fleisch.

-

Medizinisch & Pharmazeutisch: Obwohl es nicht mit Lebensmitteln zu tun hat, Dieser Sektor verwendet Trockeneis auch für den Versand temperaturempfindlicher Artikel wie Impfungen Und Biologische Proben, die eine präzise Temperaturkontrolle erfordern.

-

Meeresfrüchteindustrie: Meeresfrüchteprodukte, die sehr leicht verderblich sind, Trockeneis hilft oft dabei, die Frische zu bewahren Langstreckentransport.

Warum Trockeneis für diese Lebensmittel bevorzugt wird

-

Gefrorene Mahlzeiten & Eiscreme: Trockeneis sorgt dafür, dass gefrorene Lebensmittel an ihrem Platz bleiben die richtige Temperatur und verhindert Schmelzen oder Verderb Während des Transits.

-

Fleisch und Meeresfrüchte: Beides erfordert eine Tiefkühllagerung, um dies zu verhindern Bakterienwachstum Und Qualitätsverlust. Trockeneis schützt sie wirksam, bis sie ihr Ziel erreichen.

-

Verderbliche Früchte & Gemüse: Einige zarte Früchte oder Gemüse, vor allem solche, die eingefroren werden müssen, können auch von Trockeneisverpackungen profitieren, um die Haltbarkeit zu verlängern.

Sicherheitsüberlegungen zur Verwendung von Trockeneis in Lebensmittelverpackungen

Dabei ist Trockeneis eine zuverlässige Lösung, es geht mit Sicherheitsaspekten einher. Die ordnungsgemäße Handhabung und Lagerung ist für einen sicheren Versandprozess von entscheidender Bedeutung.

-

Handling mit Trockeneis: Immer tragen Isolierte Handschuhe beim Umgang mit Trockeneis zu verhindern Erfrierung. Berühren Sie es niemals direkt mit nackter Haut.

-

Versandvorschriften: Trockeneis gilt als Gefahrgut und erfordert richtige Kennzeichnung beim Versand per Flugzeug. Stellen Sie sicher, dass alle Versandvorschriften eingehalten werden.

-

Lagerung: Trockeneis in lagern belüftete Bereiche, Von direkter Sonneneinstrahlung und Wärmequellen fernhalten, um eine schnelle Sublimation zu verhindern.

Beispiel für reale Welt: Eine Speditionsfirma gefrorene Meeresfrüchte An einen entfernten Ort wurde Trockeneis zum Verpacken verwendet. Das Trockeneis hielt die Produkte bei -20° F (-29°C) für über 48 Std., Sicherstellen, dass die Meeresfrüchte frisch und sicher gefroren ankommen.

2025 Trends bei Trockeneis für Lebensmittelverpackungen

Als die Nachfrage nach zuverlässig, Die Zahl langlebiger Kühlkettenlösungen nimmt zu, Trockeneisverpackungen entwickeln sich weiter. Hier sind einige der neuesten Trends:

-

Umweltfreundliche Lösungen: Unternehmen konzentrieren sich auf nachhaltige Trockeneisproduktion, Sicherstellen, dass der Prozess minimiert wird Kohlenstoffemissionen.

-

Intelligente Verpackungen: Mit dem Aufstieg von intelligente Verpackungen, Trockeneisbehälter sind jetzt damit ausgestattet Temperatursensoren die die Kühlniveaus in Echtzeit überwachen und anpassen, Erhöhung der Sicherheit von Sendungen.

-

Automatisierung in der Kühlkettenlogistik: Zur Berechnung kommen automatisierte Systeme zum Einsatz optimale Menge benötigtes Trockeneis basierend auf der Zielklima Und Versanddauer.

Jüngste Entwicklungen

-

Innovative Isolierung: Neu Thermoverpackung Technologien erweitern die Dauer der Kühlleistung von Trockeneis, Dies ermöglicht Sendungen über längere Distanzen.

-

Reduzierung der Kohlenstoffemissionen: Die Trockeneisindustrie übernimmt umweltfreundlichere Praktiken durch die Verwendung von recyceltem Kohlendioxid, Beitrag zur Nachhaltigkeit.

Häufig gestellte Fragen {#FAQ}

Wie lange kann Trockeneis Lebensmittel während des Versands gefroren halten??

Trockeneis kann Lebensmittel gefroren halten 24 Zu 72 Std., Abhängig von der Isolierung und der verwendeten Menge.

Ist Trockeneis für Lebensmittelverpackungen geeignet??

Ja, Trockeneis ist bei sachgemäßer Verwendung sicher für Lebensmittelverpackungen. Sorgen Sie stets für eine ausreichende Belüftung der Verpackung.

Kann ich Trockeneis bei mir zu Hause aufbewahren??

Ja, aber Trockeneis sollte darin gelagert werden belüftete Bereiche und mit Vorsicht gehandhabt, um dies zu vermeiden Erfrierung und Gasbildung.

Zusammenfassung und Empfehlungen

Trockeneis ist eine effektive und zuverlässige Lösung für Lebensmittel verpacken, insbesondere für lange Sendungen, die konstante Gefriertemperaturen erfordern. Durch Befolgen geeigneter Sicherheitsmaßnahmen und Best Practices, Sie können sicherstellen, dass Ihre verderblichen Waren sicher und in einwandfreiem Zustand an ihrem Bestimmungsort ankommen.

Nächste Schritte: Erwägen Sie eine Integration Trockeneis zum Verpacken von Lebensmitteln in Ihrer Lieferkette für Produkte, die eine langfristige Temperaturkontrolle erfordern. Kontakt a Experte für Kühlkettenlogistik um Ihre Versandpraktiken zu optimieren.

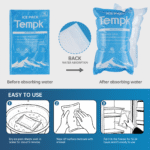

Über Tempk

Bei Tempk, Wir sind darauf spezialisiert, hochwertige Lösungen für Kaltkettenverpackungen bereitzustellen, einschließlich Trockeneisverpackungen für die Lebensmittelindustrie. Unsere Dienstleistungen stellen sicher, dass Ihre verderblichen Waren während des gesamten Transports die optimale Temperatur behalten.

Kontaktieren Sie uns Erfahren Sie noch heute, wie wir Ihnen helfen können, Ihre Lebensmittelversandlogistik mit Trockeneislösungen zu verbessern.