Trockeneisbeutel xl: Wie man Größe und versendet in 2025

Aktualisiert: August 18, 2025 — 7–9 Minuten Lesezeit

Wenn Sie verderbliche Sachen versenden, Trockeneisbeutel XL Helfen Sie dabei, die Temperatur mit weniger Teilen und einfacherer Handhabung länger zu halten. Verwenden Sie XL-Gel- oder PCM-Packs für 2–8 °C und die meisten gefrorenen Bahnen; Steigen Sie nur dann auf Trockeneis um, wenn Sie ultrakalte oder besonders lange Strecken benötigen. Planen Sie Trockeneis mit etwa 5–10 Pfund pro 24 Stunden ein, Und denken Sie daran, dass USPS Luftpost auf ≤5 Pfund pro Stück begrenzt. Validierung mit Spurtests und einem Logger.

-

Wie Trockeneisbeutel XL unterscheiden sich von Trockeneis, und wann man sie jeweils auswählt

-

XL-Größen, Abmessungen, und Passformtipps für 24–96-Stunden-Bahnen

-

Ein Kopieren und Einfügen Packout-Schätzer für Gel/PCM und Trockeneis

-

2025 Regeln: Und 1845, Class9 -Label, Netzmasse, Entlüftung (Luft & Post-)

-

Trends: −21 °C PCM, abflusssichere Gele, EPR-gesteuerte Wiederverwendungsprogramme

Was sind „Trockeneisbeutel XL?“,” und wann sollten Sie sie verwenden?

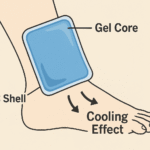

Kurze Antwort: Trockeneisbeutel XL sind extragroße Gel- oder PCM-Steine (oft 48–64 Unzen) die ein Zielband halten (Z.B., 2–8°C oder –20°C Klasse) ohne Gefahrstoffstufen. Verwenden Sie sie für gekühlte oder mäßig gefrorene Sendungen. Wählen Sie Trockeneis (festes CO₂ bei −78,5°C) für ultrakalte Ziele oder lange, heiße Bahnen, auf denen Gel/PCM nicht halten kann.

Warum ist es wichtig: Gele und PCMs „parken“ die Temperatur nahe ihrem Phasenpunkt, Reduzierung von Frostschäden an empfindlichen Lebensmitteln oder Biologika. Trockeneis ist viel kälter und hält länger, löst jedoch die Kennzeichnung und Entlüftung nach UN1845/Klasse9 aus. Eine praktische Standardeinstellung: Trockeneisbeutel XL für 2–8°C und viele Tiefkühlartikel; Trockeneis nur dann, wenn das Routenrisiko dies erfordert.

XL-Größen und passend für Trockeneisbeutel XL

Mit standardisierten XL-Footprints können Sie einmal entwerfen und später zwei Quellen verwenden.

| XL-Referenz | Typisches Gewicht | Typische Größe (L×B×H) | Was es für Sie bedeutet |

|---|---|---|---|

| XL-Gel-Pack | 48 oz | ~10,25″×7,75″×1,5″ | Weniger Teile für 48–72-Stunden-Bahnen; einfaches Training. |

| XL+ Gel/PCM | 64 oz | ~11″×8″×2″ | Höhere Kaltmasse für 72–96 Stunden; reduziert Luftspalte. |

| −21 °C PCM-Stein | 48–64oz | 7–10″×11″ Klasse | Minustemperaturen halten ohne Unterkühlung von −78,5 °C. |

Tipp passen: Enge Passform schlägt zusätzliche Masse. Beseitigen Sie Hohlräume, bevor Sie weiteres Kühlmittel hinzufügen. Für frostempfindliche Nutzlasten, Mit Wellpappe puffern oder auf PCMs mit 4–5 °C umstellen.

Praktische Tipps, die Sie heute verwenden können

-

Voraussetzung: Gele/PCMs fest einfrieren (24–48h bei ≤−18°C); den Versender vorschreien.

-

Platzierung: Für Gel/PCM, Ringen Sie die Seiten und den Deckel; für Trockeneis, Legen Sie es darauf und halten Sie die Lüftungsschlitze frei.

-

Meeresfrüchte: Verwenden Sie niemals Trockeneis mit lebenden Meeresfrüchten – verwenden Sie nur Gel/PCM.

Real -World -Ergebnis: Eine Marke für gefrorene Leckereien tauschte vier 32-Unzen-Packungen gegen zwei 64-Unzen-Packungen Trockeneisbeutel XL plus einen kleinen Sommer-Trockeneis-„Topper“. RMAs gingen um etwa 70 % zurück und die Lieferfenster auf Hot-Lanes wurden um 6–10 Stunden erweitert.

Wie viele Trockeneisbeutel XL brauchst du??

Schnellstart: Für 2–8 ° C., Als Ausgangspunkt sollten Sie etwa 1 Pfund Gel pro Fuß³ pro 24 Stunden anstreben. Für die −20°C-Klasse, Testen Sie zuerst das PCM bei −21 °C; Fügen Sie nur dann einen kleinen Trockeneis-Booster hinzu, wenn die Versuche fehlschlagen. Wenn Sie Trockeneis verwenden müssen, Planen Sie etwa 7,5 Pfund pro 24 Stunden als Mittelpunkt ein und beschriften Sie UN1845 mit der Nettomasse (kg). Validieren Sie immer auf Ihrer Route.

Kopieren Sie diesen Schätzer und passen Sie ihn für Ihre Spur an:

Wichtig: Isolierung, fit, Vorkonditionierung, und Ambient-Drive-Ergebnisse. Verwenden Sie einen Datenlogger und führen Sie vor der Skalierung zwei bis drei Pilotversuche durch.

Welcher Kühlpfad passt zu Ihrem Ziel??

| Kühloption | Typisches Ziel | Planungssignal | Was es für Sie bedeutet |

|---|---|---|---|

| XL-Gel (0 ° C) | 2–8 ° C | 24–48H (isolierungsabhängig) | Mahlzeiten, Molkerei; Kein Hazmat. |

| XL PCM –16/–21 °C | Weich bis tiefgefroren | 24–72H | Minusgrade ohne Ultrakälterisiko; Sicherer Handling. |

| Trockeneis (–78,5 ° C.) | Tiefgefroren/ultrakalt | ~5–10 Pfund pro 24 Stunden | Lange/heiße Fahrspuren; Etikett, Entlüftung, Nettomasse aufzeichnen. |

Umsetzbare Tipps

-

Kurze Sommerwege (≤48h): 2–3 Trockeneisbeutel XL pro ~5kg Nutzlast, um die Seiten und den Deckel legen.

-

Eiscreme (−12 bis −18 °C): Führen Sie XL −21 °C PCM um den Umfang herum aus; Fügen Sie im Juli/August einen kleinen Trockeneisaufsatz hinzu.

-

Klinische Abstrichtupfer/Fläschchen (Ultrakold): Belüfteter Trockeneis-Versandbehälter; Liste UN1845 und Nettomasse (kg) auf dem Etikett/Luftfrachtbrief.

Trockeneis vs Trockeneisbeutel XL: welches für Ihre Spur das Richtige ist?

Fazit: Wählen Trockeneisbeutel XL für die meisten gekühlten und viele gefrorene Sendungen. Verwenden Sie Trockeneis für den Unterricht bei −70 °C oder länger, Heiße Gassen. Trockeneis unterliegt der UN1845-Regulierung (Class9), Benötigt eine belüftete Verpackung, und muss eine Netto-Trockeneismasse aufweisen (kg). USPS-Luftpost ist auf ≤5 Pfund pro Stück begrenzt.

2025 Beschriftung & Entlüftungs-Checkliste (Luft & Post-)

-

Markieren Und 1845 und zeige a Class9 Gefahrendiamant (≥100mm).

-

Aufzeichnen Netto -Dry -Ice -Masse (kg) auf dem Etikett/Luftfrachtbrief.

-

Behalten Sie den Versender entlüftet; Trockeneis niemals in einem luftdichten Behälter verschließen.

-

USPS -Luft: ≤5lb Trockeneis pro Schreibputz; Es gelten zusätzliche Verpackungs-/Kennzeichnungsvorschriften.

Sicherheitsnotiz: CO₂-Belastungsgrenzwerte sind an Verpackungslinien und in Fahrzeugen von Bedeutung. Der 8-Stunden-TWA der OSHA beträgt ~5.000 ppm; NIOSH STEL beträgt ~30.000 ppm. Lüften, Monitor, und trainieren.

2025 Einhaltung & EHS für Trockeneisbeutel XL und Trockeneis

-

Iata 2025: Nutzen Sie die aktuelle Abnahmecheckliste für Trockeneis als Kältemittel; Bei der Kühlung ungefährlicher Güter ist keine DG-Erklärung erforderlich, aber UN1845, Netzmasse, und Entlüftung sind zwingend erforderlich.

-

Trägerspezifikationen: Befolgen Sie die UPS/FedEx-Arbeitshilfen für Etikettengröße und -text; Überprüfen Sie vor der Buchung die Betreibervarianten.

-

USPS Pub 52 (Luft): ≤5-Pfund-Kappe pro Postsendung; Oberflächendienste können überschreiten.

2025 Trends in der Kühlkette und Trockeneisbeutel XL

-

Wiederverwendbares −21 °C PCM „Trockeneis-Alternativen“: Durch mehr Fahrspuren können Gefahrstoffe vermieden und gleichzeitig die Minustemperaturziele erreicht werden; auf Ihrer Route validieren.

-

Abflusssicher & „No-Sweat“-Gele: Besseres Auspacken und einfachere Entsorgungsanleitung für DTC-Programme.

-

EPR-Dynamik: Oregons Recycling Modernization Act wurde am 1. Juli 2025 ins Leben gerufen; CA/CO/MN sind da 2025 Phasen. XL PCM-Programme und Rücknahmekreisläufe reduzieren den Einweg-Kältemittelabfall.

Häufig gestellte Fragen

Q1: Sind „Trockeneisbeutel XL“ im wahrsten Sinne des Wortes Trockeneis??

NEIN. Es handelt sich um extragroße Gel- oder PCM-Packungen, die Trockeneis-Hazmat-Schritte vermeiden. Verwenden Sie sie bei 2–8 °C oder mäßig gefroren; Trockeneis für ultrakalt oder lange aufbewahren, heiße Routen.

Q2: Wie viele Trockeneisbeutel xl für 36 Stunden bei 2–8 °C??

In der Nähe beginnen 0.25 Packmasse pro kg Nutzlast und fügen Sie einen Sommerfaktor hinzu (Z.B., ×1,2). Validierung mit einem Logger und einem kleinen Piloten.

Q3: Werden gefrorene Gele Impfstoffe einfrieren??

Ja, sie können. Für gekühlte Biologika, Verwenden Sie PCMs mit 4–5 °C und fügen Sie eine Pufferschicht hinzu.

Q4: Kann ich Trockeneis verschicken??

Ja, im Inland, Aber USPS-Lufthöchstgrenzen für Trockeneis auf ≤5 Pfund pro Postsendung und erfordern eine spezielle Verpackung und Belüftung.

Q5: Wie schnell „verschwindet“ Trockeneis??

Planen Sie etwa 5–10 Pfund pro 24 Stunden ein; Fügen Sie einen Tag Spielraum für Verzögerungen hinzu. Testen Sie auf Ihrer Spur.

Zusammenfassung & Empfehlungen

Verwenden Trockeneisbeutel XL für die meisten 2–8°C und viele gefrorene Sendungen; Wechseln Sie bei extrem kalten Temperaturen oder längeren Sommerrouten zu Trockeneis. Vorbedingungspakete, beseitigen Sie Hohlräume, und legen Sie Gele/PCMs um die Seiten und den Deckel. Wenn Trockeneis vorhanden ist, Etikett UN1845, Zeigen Sie den Diamanten der Klasse 9 an, Nettomasse aufzeichnen (kg), und entlüften Sie die Schachtel. Führen Sie vor der Skalierung eine Validierung mit Piloten und einem Logger durch.

Nächste Schritte (CTA):

-

Ordnen Sie SKUs nach Temperaturziel und Routendauer zu.

-

Testen Sie zwei Packouts (Nur XL-PCM vs. Hybrid mit einem kleinen Trockeneis-Topper).

-

Standardisieren Sie die Etikettierungs-/Entlüftungs-SOPs, wenn Trockeneis auftritt.

-

Starten Sie zur Unterstützung eine XL-PCM-Rückgabe-/Wiederverwendungsschleife 2025 EPR-Ziele. Sprechen Sie mit Tempk für ein schnelles Packout-Audit.

Über Tempk

Wir entwerfen, prüfen, und standardisieren Sie passive Kühlkettenverpackungen, die Kosten senken, ohne Nutzlasten zu gefährden. Unser Team ist auf XL-PCM-Steine und Gelsysteme für 2–8 °C und gefrorene Bahnen spezialisiert – und bei Bedarf auf konforme Trockeneis-Arbeitsabläufe. Kunden sehen weniger Lieferungen außerhalb der Spezifikationen und niedrigere Versandkosten durch genaue Größenbestimmung, bessere Isolierung, und klare SOPs, die darauf abgestimmt sind 2025 Vorschriften.