Beim Transport von temperaturempfindlichen Gütern wie Pharmazeutika oder verderblichen Lebensmitteln, Die Wahl der Kühllösung ist entscheidend. Sind Trockeneisbacken oder Polymergelkältemittel -Packs besser für Ihre Sendung? Dieser Artikel bricht die Unterschiede ab, Vorteile, und Sicherheitsüberlegungen beider Optionen, mit denen Sie die richtige Lösung für Ihre spezifischen Anforderungen auswählen können.

-

Was sind trockene Eisbeutel und Polymergelkältemittelpackungen?

-

Was sind die Sicherheitsauswirkungen der Verwendung von Trockeneis und Gelpackungen?

-

Wann sollten Sie Trockeneis über Gelkältemittel -Packs wählen und umgekehrt?

-

Was sind die ökologischen und regulatorischen Bedenken??

-

Wie wirken sich die neuesten Trends in der Kaltkette -Logistik auf Ihre Versandentscheidungen aus??

Was sind trockene Eisbeutel und Polymergelkältemittelpackungen?

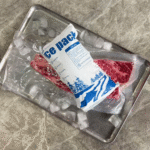

Trockeneisbeutel aus massivem Kohlendioxid bestehen (Co₂), die bei -78,5 ° C direkt in Gas untermüßt (-109.3° F). Es wird in erster Linie für ultra gekaltete Versandanforderungen verwendet, wie gefrorene Lebensmittel, Impfungen, und biologische Proben. Polymergelkältemittel Packs, auf der anderen Seite, werden typischerweise aus Wasser und Polymeren wie Natriumpolyacrylat hergestellt. Diese Packs absorbieren Wärme und sind so ausgelegt, dass sie die Temperaturen in 2–8 ° C aufrechterhalten. (35.6–46,4 ° F.) Reichweite, sie für temperaturempfindliche Medikamente und verderbliche Waren geeignet machen.

Schlüsselunterschiede

| Besonderheit | Trockeneisbeutel | Polymergelpackungen |

|---|---|---|

| Temperaturbereich | -78.5°C (-109.3° F) | 2° C - 8 ° C. (35.6° F - 46,4 ° F.) |

| Kühldauer | Erweitert (Abhängig von der Isolierung) | Mäßig (24-48 Std.) |

| Sicherheit | Erfordert eine sorgfältige Handhabung (Erfrischungsrisiko) | Sicher zu handhaben, Keine besonderen Vorsichtsmaßnahmen |

| Regulatorische Anforderungen | Sonderkennzeichnung und Dokumentation erforderlich | Wenige Vorschriften, Einfacher Handling |

| Wiederverwendbarkeit | Einweg | Oft wiederverwendbar |

Trockeneisbeutel: Wann und warum sollten Sie sie verwenden??

Trockeneisbeutel sind ideal für ultra kaufende Versandanforderungen, insbesondere für Gegenstände, die während des Transports eingefroren bleiben müssen. Zum Beispiel, Biologische Proben, Tiefkühlkost Wie Fleisch, Meeresfrüchte, und Eis, oder Medikamente Das muss bei Temperaturen unter Null bleiben können von der extremen Kühlleistung von Trockeneis profitieren.

Vorteile von Trockeneisbeutel:

-

Verlängerte Kühlung: Die niedrigen Temperatur von Trockeneis hält die Produkte für lange Dauern eingefroren.

-

Keine Restflüssigkeit: Trockeneis untermauert direkt in Gas, Verhindern Sie flüssiges Chaos.

-

Raumeffizienz: Trockeneis ist kompakt und lässt mehr Platz in Versandbehältern.

Nachteile von Trockeneisbacken:

-

Vorsichtsmaßnahmen zur Handhabung: Benötigt Handschuhe und Sicherheitsprotokolle, um Erfrierungen und Kaltverbrennungen zu vermeiden.

-

Regulatorische Anforderungen: Trockeneis muss nach IATA beschriftet und behandelt werden (Internationale Luftverkehrsvereinigung) Richtlinien für den Luftverkehr.

-

Begrenzte Dauer: Im Laufe der Zeit, Trockeneis untermauert in Gas, Reduzierung der Kühlungseffizienz.

Reale Anwendung:

Ein Pharmaunternehmen Schifffahrtsimpfstoffe bei ultra -niedrigen Temperaturen verwendet Trockeneis, um eine konsistente Temperatur von -80 ° C aufrechtzuerhalten. Die Kühldauer, gepaart mit regulatorischer Einhaltung (entlüftete Verpackung und angemessene Kennzeichnung), Gewährleistet eine sichere Lieferung ohne Temperaturausflüge.

Polymergelkältemittel Packs: Wann sollten Sie sie verwenden?

Polymergelkältemittel Packs eignen sich am besten für temperaturempfindliche Sendungen, die Kühlung erfordern, aber nicht einfrieren. Dazu gehören Medikamente wie Insulin, temperaturempfindliche Lebensmittel Wie Milchprodukte, Und Kosmetika Das muss während des Transits cool bleiben.

Vorteile von Polymergelkältemittel -Packungen:

-

Ungiftig und sicher ohne besondere Ausrüstung zu handhaben.

-

Kostengünstig: Niedrigere Anfangskosten im Vergleich zu Trockeneis, Besonders bei kürzeren Transitdauern.

-

Wiederverwendbar: Kann mehrmals verwendet werden, Reduzierung von Abfällen und Senkung der Versandkosten.

Nachteile von Polymergelkältemittel -Packungen:

-

Begrenzte Kühldauer: Am besten geeignet für Sendungen von 24-48 Std., Wenn ihr Kühlwirkung im Laufe der Zeit verblasst.

-

Gefrierrisiko: Wenn nicht ordnungsgemäß verwaltet, Gelpakete können empfindliche Artikel einfrieren, sie unwirksam machen.

Reale Anwendung:

Ein Online -Food -Lieferservice verwendet Polymer -Gel -Packungen, um frische Produkte und Mahlzeiten zu versenden. Die Packungen halten eine stabile Temperatur innerhalb des erforderlichen 2-8 ° C-Bereichs bei, Gewährleistung der Produktfrische und bietet Kunden eine leicht zu handhaben.

Wählen Sie zwischen Trockeneis und Polymergelkältemittel -Packungen

Bei der Entscheidung, welche Kühllösung verwendet werden soll, Betrachten Sie diese Faktoren:

-

Temperaturanforderungen: Verwenden Trockeneis Für Produkte, die gefroren bleiben müssen (-20° C oder unten) Und Polymergelpackungen für diejenigen, die cool bleiben müssen (2–8 ° C).

-

Vorschriftenregulierung: Trockeneis Erfordert strenge Kennzeichnung und spezielle Handhabungsverfahren aufgrund ihrer potenziellen Gefahren, wohingegen Polymergelpackungen sind nicht schüchtern und leichter zu handhaben.

-

Versanddauer: Trockeneis dauert länger und eignet sich besser für den Fernversand, während Gelpackungen sind ideal für kurze bis mittlere Transitzeiten.

-

Kosten- und Umweltauswirkungen: Während Trockeneis kann aufgrund der Handhabungs- und Verpackungsanforderungen teurer sein, Polymergelpackungen sind kostengünstig, wiederverwendbar, und umweltfreundlich.

Beispiel Entscheidungsprozess:

Für eine Biotech -Firma Versand Insulin, Polymergelpackungen sind die bevorzugte Lösung, Während sie die Temperatur innerhalb des erforderlichen 2–8 ° C -Bereichs halten und sicherstellen, dass das Arzneimittel sicher ist, ohne das Gefrierrisiko. Wenn die Sendung für gefrorene biologische Exemplare vorliegt, Trockeneis Wäre die bessere Wahl aufgrund seiner Fähigkeit, ultra-niedrige Temperaturen aufrechtzuerhalten.

2025 Trends in der Kaltkette -Logistik

Die Kaltkette-Logistikbranche entwickelt sich, um die wachsende Nachfrage nach umweltfreundlichen Lösungen zu befriedigen, Kosteneffizienz, und Compliance. Hier sind einige wichtige Trends, die die Zukunft der Kühltechnologien prägen:

-

Umweltfreundliche Verpackung: Erwarten Sie nachhaltigere Optionen für die Kaltkette Verpackung, wie recycelbare Gelpakete und biologisch abbaubare Materialien.

-

Smartemperaturüberwachung: Mit IoT und KI, Die Echtzeitverfolgung von Sendungen wird zur Norm, Gewährleistung der Produktsicherheit und der Einhaltung von regulatorischen Vorschriften.

-

Hybridlösungen: Kombinieren Trockeneis Und Polymergelpackungen Erstellt Multi-Zonen-Temperaturumgebungen für Sendungen, die unterschiedliche Temperaturbereiche erfordern.

Häufig gestellte Fragen

Q1: Kann ich Trockeneis verwenden, um Insulin zu transportieren??

A1: Während Trockeneis ultralahme Temperaturen aufrechterhalten kann, Es kann dazu führen, dass Insulin friert, Das macht Polymergelpackungen zu einer besseren Wahl für den Transport von Insulin.

Q2: Sind Polymer -Gel -Kältemittelpackungen sicher zu bedienen?

A2: Ja, Polymergelkältemittelpackungen sind ungiftig und sicher zu handhaben. Jedoch, Es wird empfohlen, die Richtlinien des Herstellers zu befolgen, um potenzielle Probleme mit Lecks zu vermeiden.

Q3: Kann ich Gelpackungen wiederverwenden??

A3: Ja, Viele Polymergelpakete sind wiederverwendbar. Stellen Sie sicher.

Schlussfolgerung und Empfehlungen

Abschließend, Trockeneis Und Polymergelkältemittel Packs Beide haben je nach den Versandanforderungen unterschiedliche Vorteile. Wenn Ihre Sendung erfordert Ultra-kaufende Bedingungen, Trockeneis ist die klare Wahl. Für Kühlbedarf innerhalb des Bereichs von 2–8 ° C, Polymergelpackungen sind die sichereren, kostengünstigere Option. Bewerten Sie immer die Temperaturtoleranz Ihres Produkts, Transitzeit, und regulatorische Anforderungen vor einer Entscheidung.

Für eine maßgeschneiderte Lösung, Kontakt tempk, Experten für Kaltkettenlogistik, Um die richtigen Verpackungs- und Kühllösungen für Ihr Unternehmen auszuwählen.

Über Tempk

Tempk ist führend in der kalten Kettenlogistik, Bieten Sie fortschrittliche Verpackungslösungen für temperaturempfindliche Sendungen an. Spezialisiert auf Trockeneis Und Polymer -Gel -Kältemittel, Wir bieten umweltfreundlich, kostengünstig, und konforme Lösungen, die auf Ihre Bedürfnisse zugeschnitten sind. Lassen Sie uns Ihnen helfen, die Qualität und Wirksamkeit Ihrer Produkte während des Transports zu schützen.

Für personalisierte Ratschläge und Lösungen, Kontakt tempk Heute!