Der Versand temperaturempfindlicher Waren erfordert eine effektive und zuverlässige Kühlmethode, um sicherzustellen, dass die Artikel frisch und sicher bleiben. Mit Folie ausgekleidete Trockeneisbeutel sind eine Schlüssellösung für Unternehmen, die verderbliche Produkte wie Arzneimittel versenden, Essen, und biologische Materialien. In diesem Leitfaden wird die Funktionalität erläutert, Vorteile, Best Practices, und die neuesten Trends bei der Verwendung von mit Folie ausgekleideten Trockeneisbeuteln zur Aufrechterhaltung der Temperaturkontrolle während des Transports.

Was sind mit Folie ausgekleidete Trockeneisbeutel??

Mit Folie ausgekleidete Trockeneisbeutel sind spezielle Verpackungen, die dazu dienen, temperaturempfindliche Gegenstände während des Transports kühl zu halten. Diese Taschen bestehen aus mehreren Materialschichten, Die Innenschicht besteht typischerweise aus einer reflektierenden Folie, um Strahlungswärme zu blockieren. Diese Folie wird mit isolierenden Materialien wie Schaumstoff kombiniert, um Gegenstände vor äußeren Temperaturschwankungen zu schützen und die Sublimation von Trockeneis zu verlangsamen.

Hauptvorteile der Verwendung von mit Folie ausgekleideten Trockeneisbeuteln

Verbesserte Isolierung: Die reflektierende Folie fungiert als Barriere, die bis zu reflektiert 97% von strahlender Hitze. Dadurch wird die Wärmeübertragung deutlich reduziert, Halten Sie Ihre Produkte über einen längeren Zeitraum bei extrem niedrigen Temperaturen.

Haltbarkeit und Stärke: Mit Folie ausgekleidete Trockeneisbeutel sind so konzipiert, dass sie den Anforderungen des Versands standhalten, einschließlich grober Handhabung und langer Transportzeiten. Ihre Konstruktion stellt sicher, dass Ihre Produkte nicht nur isoliert, sondern auch vor physischen Schäden geschützt sind.

Kostengünstig und leicht: Trotz hervorragender Isolierung, Diese Taschen sind leicht und kostengünstig zu versenden. Dies trägt dazu bei, die gesamten Transportkosten einzusparen.

Auslaufsicher und belüftet: Die Beutel sind so konzipiert, dass sie das Austreten von Kohlendioxidgas verhindern und gleichzeitig eine kontrollierte Entlüftung ermöglichen. Dies ist von entscheidender Bedeutung, da Trockeneis sublimiert und CO₂-Gas freisetzt, das sicher entweichen muss, ohne dass es zu einem Druckaufbau im Beutel kommt.

Wie funktionieren mit Folie ausgekleidete Trockeneisbeutel??

Die Funktionalität von mit Folie ausgekleideten Trockeneisbeuteln beruht auf ihrer Fähigkeit, die Wärmeübertragung durch drei Hauptmechanismen zu minimieren: Strahlung, Leitung, und Konvektion. Die reflektierende Folienschicht blockiert Strahlungswärme, während der Schaum- oder Blasenkern im Inneren des Beutels sowohl die Wärmeleitung als auch die Konvektionswärmeübertragung verlangsamt. Durch diese Kombination entsteht ein hocheffizientes Kühlsystem, das über längere Zeiträume eine kalte Temperatur aufrechterhalten kann.

Zusätzlich zur Reduzierung der Wärmeübertragung, Mit Folie ausgekleidete Beutel helfen auch dabei, die Sublimationsrate von Trockeneis zu regulieren. Dies sorgt dafür, dass Trockeneis länger hält und der Abfall minimiert wird, Dies macht sie zu einer praktischen Wahl für den Fernversand.

Best Practices für die Verwendung von mit Folie ausgekleideten Trockeneisbeuteln

Um die maximale Wirksamkeit von mit Folie ausgekleideten Trockeneisbeuteln zu gewährleisten, Folgen Sie diesen Best Practices:

1. Richtige Beutelgröße und Trockeneismenge

-

Wählen Sie die richtige Taschengröße: Stellen Sie sicher, dass die Tasche genau zu Ihrer Sendung passt, um übermäßigen Trockeneisverbrauch zu vermeiden. Ein perfekt angepasster Beutel maximiert die Isolationseffizienz und reduziert den Abfall.

-

Berechnen Sie die richtige Menge Trockeneis: Typischerweise, 5–10 Pfund Trockeneis pro Transporttag halten Produkte bis zu kalt 24 Std.. Passen Sie die Temperatur entsprechend der Umgebungstemperatur und den spezifischen Anforderungen Ihrer Sendung an.

2. Richtige Verpackungstechniken

-

Schichtung: Legen Sie Trockeneis auf den Boden des Beutels, mit darauf platzierten temperaturempfindlichen Gegenständen. Dies ermöglicht eine optimale Kühlung.

-

Belüftung: Stellen Sie sicher, dass der Beutel eine ordnungsgemäße Entlüftung des CO₂-Gases ermöglicht, um einen Druckaufbau zu verhindern. Dies ist für die Sicherheit und eine effektive Kühlung unerlässlich.

3. Einhaltung der Vorschriften

-

Kennzeichnung und Dokumentation: Stellen Sie sicher, dass die äußere Verpackung ordnungsgemäß mit gekennzeichnet ist “Trockeneis” oder “Kohlendioxid, Solide,” zusammen mit dem Nettogewicht des Trockeneises (Und 1845).

-

Carrier-Anforderungen: Verschiedene Spediteure können spezifische Regeln für den Versand von Trockeneis haben. Bestätigen Sie stets die Anforderungen des von Ihnen gewählten Anbieters, insbesondere für Luft- und internationale Sendungen.

2025 Trends in der foliengefütterten Trockeneisbeuteltechnologie

Während sich die Kaltkettenindustrie weiterentwickelt, Mit Folie ausgekleidete Trockeneisbeutel profitieren von mehreren technologischen Fortschritten:

1. Intelligente Verpackungen

Intelligente Verpackungslösungen gewinnen an Bedeutung, mit Temperatursensoren und Echtzeit-Tracking, die in mit Folie ausgekleidete Trockeneisbeutel integriert werden. Diese Innovationen ermöglichen eine Fernüberwachung, Bereitstellung von Live-Daten über die Temperatur Ihrer Sendung während des Transports. Dadurch wird sichergestellt, dass etwaige Temperaturabweichungen schnell behoben werden können.

2. Nachhaltigkeit und biologisch abbaubare Materialien

Mit zunehmenden Umweltbedenken, Hersteller beginnen, biologisch abbaubare und recycelbare Materialien für die Herstellung von mit Folie ausgekleideten Trockeneisbeuteln zu verwenden. Diese Materialien bieten hervorragende Isoliereigenschaften und reduzieren gleichzeitig die Umweltbelastung durch Verpackungen.

3. Hybridkühlungslösungen

Kombination von Phasenwechselmaterialien (PCMs) mit Trockeneis kommt immer häufiger vor. PCMs absorbieren und geben Wärme bei bestimmten Temperaturen ab, Dies kann dazu beitragen, die Haltezeit von Trockeneissendungen zu verlängern und gleichzeitig die Menge an benötigtem Trockeneis zu reduzieren.

Mit Folie ausgekleidete Trockeneisbeutel vs. Andere Verpackungsoptionen

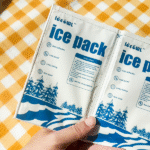

Beim Vergleich von mit Folie ausgekleideten Trockeneisbeuteln mit anderen Verpackungsoptionen, wie Gelpacks oder Styroporbehälter, Mit Folie ausgekleidete Beutel bieten deutliche Vorteile für Langzeitsendungen, die tiefgefroren werden müssen. Nachfolgend finden Sie eine Vergleichstabelle:

| Besonderheit | Folie mit Trockeneisbeutel mit Folien gefüttert | Gelpackungen | Styroporbehälter |

|---|---|---|---|

| Temperaturbereich | Unter -78,5 ° C. (Trockeneis) | 32° F bis 50 ° F. (Gekühlt) | 32° F bis 50 ° F. |

| Haltbarkeit | Hoch, pünktlich-resistent | Mäßig | Hoch, isoliert |

| Versanddauer | Langanhaltende Kühlung über Tage hinweg | Kürzere Abkühldauer | Moderate Kühldauer |

| Kosten | Teurer | Günstiger für Kurztrips | Mittelklassepreis |

Mit Folie ausgekleidete Trockeneisbeutel sind die ideale Wahl für Sendungen, die tiefgefroren bleiben müssen (-78.5° C oder unten). Jedoch, wenn Sie Produkte versenden, die gekühlt werden müssen (32° F bis 50 ° F.), Optionen wie Gelpackungen oder Styroporbehälter können ausreichen und könnten für kürzere Zeiträume kostengünstiger sein.

FAQs

Q1: Wie lange ist Trockeneis in einem mit Folie ausgekleideten Beutel haltbar??

A1: Die Wirkungsdauer von Trockeneis hängt von der Isolierung ab, Umgebungstemperatur, und die Menge des verwendeten Trockeneises. Unter optimalen Bedingungen, Mit Folie ausgekleidete Beutel mit ausreichend Trockeneis können Gegenstände bis zu 24–96 Stunden kalt halten.

Q2: Sind mit Folie ausgekleidete Trockeneisbeutel für den Lebensmittelversand geeignet??

A2: Ja, Mit Folie ausgekleidete Trockeneisbeutel eignen sich perfekt für den Versand gefrorener Lebensmittel. Sie sorgen dafür, dass die Temperatur im erforderlichen Bereich bleibt, Aufrechterhaltung der Qualität verderblicher Lebensmittel während des Transports.

Q3: Welche Vorschriften sollte ich beim Versand mit Trockeneis beachten??

A3: Der Versand von Trockeneis erfordert die Einhaltung der Kennzeichnung, Verpackung, und Dokumentationsstandards, die von Regulierungsbehörden wie IATA und UPS festgelegt werden. Stellen Sie immer sicher, dass Ihre Sendung diese Anforderungen erfüllt, um Verzögerungen zu vermeiden.

Abschluss

Mit Folie ausgekleidete Trockeneisbeutel sind ein unverzichtbares Hilfsmittel in der Kühlkettenschifffahrtsbranche, Bietet eine hervorragende Isolierung und gewährleistet den sicheren Transport temperaturempfindlicher Güter. Indem wir ihre Eigenschaften verstehen, Best Practices befolgen, und über Branchentrends und Vorschriften auf dem Laufenden zu bleiben, Sie können Ihre Versandprozesse im Hinblick auf Effizienz und Compliance optimieren 2025.

Über Tempk

Tempk ist ein führender Anbieter von Kühlkettenverpackungslösungen. Unsere mit Folie ausgekleideten Trockeneisbeutel sind mit der neuesten Technologie ausgestattet, um optimale Isolierung und Haltbarkeit für den Versand verderblicher Artikel zu gewährleisten. Kontaktieren Sie uns noch heute, um mehr über unsere innovativen Lösungen zu erfahren.