Hochdichte isolierte EPP-Box, beste Wahl in 2025?

Zuletzt aktualisiert: Dezember 19, 2025

If you’re searching for the high-density insulated EPP box best Option, you’re really asking one question: how do you keep product temperature stable on your worst day—without fragile packaging or process chaos? In der Praxis, most failures come from lid gaps, rushed packouts, stacking damage, and inconsistent reuse—not “insulation theory.” This guide gives you simple decision rules, buyer checklists, and a repeatable test plan you can run before scaling.

Dieser Artikel wird für Sie antworten:

-

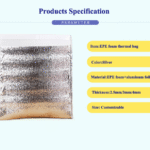

What “high density” means in high density EPP foam g/L selection

-

Wie man wählt EPP box wall thickness for cold chain Haltezeit (without wasting payload space)

-

Which lid and closure details make the high-density insulated EPP box best in real handling

-

How to run a simple validation plan (einschließlich ISTA 7E thermal testing for insulated shippers wenn nötig)

-

So schätzen Sie ab reusable EPP box cost per trip and avoid “expensive reuse that never returns”

-

Ein praktischer food-grade EPP box cleaning checklist for safe, repeatable reuse

Why is the high-density insulated EPP box best for repeatable cold chain?

Direkte Antwort: Der high-density insulated EPP box best choice stays square, seals reliably, and survives repeated handling—so your temperature performance stays consistent across cycles.

Erweiterte Erklärung: EVP (expandiertes Polypropylen) ist ein Leichtgewicht, closed-cell foam often used for reusable insulated shipping. High-density grades feel less “squishy” and more “tool-like,” which matters when boxes get dropped, gestapelt, und wiederverwendet. If a box warps, your lid seal weakens and your packout shifts, creating temperature spikes that look like “bad insulation.”

What changes in real operations with higher density?

| Operational Challenge | Standard foam outcome | High-density EPP outcome | Was es für Sie bedeutet |

|---|---|---|---|

| Repeated stacking | corners crush | corners resist | fewer damaged returns |

| Fast handling | lid loosens | fit stays consistent | fewer temperature spikes |

| Cleaning cycles | surface wears | surface holds up | longer service life |

Praktische Tipps, die Sie heute verwenden können

-

If you reuse weekly: density upgrades often pay back faster than “more insulation.”

-

If your team loads fast: prioritize lid reliability over extra features.

-

If brand trust matters: fewer failures protect reviews and repeat orders.

Praktisches Fallbeispiel: A multi-stop distribution team reduced “lid won’t close” incidents after switching to a more rigid, high-density EPP lid geometry and adding a quick closure check step.

How do you define “high density” for the high-density insulated EPP box best choice?

Direkte Antwort: “High density” is not one universal number. In buying conversations, it means a higher molded density band than your current packaging—chosen to improve shape retention and durability.

Erweiterte Erklärung: Suppliers commonly quote density in g/L. Many packaging-grade EPP systems sit in lower bands, while higher bands target heavy reuse, Stapelung, and abuse. The key is to ask for molded density and design intent, not marketing labels.

High density EPP foam g/L selection: a buyer-friendly cheat sheet

| Practical label | Ca. density band (g/L) | Typical goal | Best-fit scenario |

|---|---|---|---|

| Standard | 20–60 | balance cost + Haltbarkeit | light reuse, low drop risk |

| High density | 60–100 | stronger walls, better fit retention | Routen wiederholen + Stapelung |

| Ultra | 100+ | maximum toughness | high-abuse handling, long service life |

Praktische Tipps und Empfehlungen

-

Buy density with a reuse plan. Density pays back through cycles, keine Versprechen.

-

Ask for molded density. Mold design and geometry change real outcomes.

-

Match density to handling abuse. Gentle lanes should spend on seal + packout first.

Praktisches Fallbeispiel: A returns program stopped corner dents by moving up a density band and adding rib reinforcement—without increasing wall thickness.

How do you choose wall thickness for the high-density insulated EPP box best hold time?

Direkte Antwort: Für die high-density insulated EPP box best result, treat density as a strength knob Und thickness as a hold-time knob. Don’t overpay for one when your lane needs the other.

Erweiterte Erklärung: Thicker walls can improve thermal resistance, but they also reduce internal volume and can increase shipping weight. Many teams “solve” temperature failures by choosing thicker boxes, then lose payload efficiency or packing speed. A better approach is to match thickness to lane duration and fix leaks and packout first.

Selection table you can use immediately

| Box spec focus | Best when you need | Tradeoff | Praktische Bedeutung für Sie |

|---|---|---|---|

| Höhere Dichte | heavy reuse + Stapelung | more weight | weniger Ersatz |

| Thicker walls | längere Haltezeit | less payload space | weniger Ausflüge |

| Medium density + good thickness | balanced lanes | mäßig | strong all-around choice |

| Ultra thick + hohe dichte | extreme lanes | kosten + Schüttgut | specialty use only |

Praktische Tipps und Empfehlungen

-

If boxes return damaged: raise density before raising thickness.

-

If temperature drifts slowly: increase thickness oder improve coolant strategy.

-

If one corner warms: fix packout and lid seal before buying a bigger box.

Praktisches Fallbeispiel: A team fixed “warm corner” failures by standardizing product centering and adding a spacer—no thickness change required.

What lid and seal design makes the high-density insulated EPP box best in real handling?

Direkte Antwort: Der high-density insulated EPP box best design treats the lid like a gasketed door: overlap, consistent compression, and closure force that prevents corner gaps.

Erweiterte Erklärung: In real shipping, the lid is often the weak point. A perfect wall can’t save a lid that’s “almost closed.” Your goal is a closure that works even when staff move fast and handling is imperfect.

Lid reliability checklist (60-second audit)

-

Does the lid seat the same way every time?

-

Do corners stay aligned after stacking and drops?

-

Can staff verify closure at a glance?

-

Does the closure still work after repeated open/close cycles?

Closure style comparison

| Closure style | Stärke | Risiko | Was es für Sie bedeutet |

|---|---|---|---|

| Friction-fit | einfach | depends on shape stability | needs higher density + good geometry |

| Strap closure | forgiving | slower handling, straps can be lost | reduces training mistakes |

| Latch closure | schnell + konsistent | latch wear over time | track maintenance and replacements |

Praktische Tipps und Empfehlungen

-

Do the “paper-strip test.” Close the lid on a strip of paper and pull gently.

-

Inspect corners after impacts. Corner deformation is the first leak path.

-

Use a “two-check rule.” One visual check + one tactile check beats assumptions.

Praktisches Fallbeispiel: A hub cut temperature spikes after switching to a deeper-overlap lid and adding a 3-second closure verification step.

How do you pack out so the high-density insulated EPP box best actually performs?

Direkte Antwort: Der high-density insulated EPP box best still fails with inconsistent packout. Your packout controls hot spots, kalte Stellen, and drift rate.

Erweiterte Erklärung: Think of packout like a recipe. The same ingredients can produce different results if placement changes. Packout variation often looks like “bad insulation,” but it’s really process noise.

The four packout rules that win

-

Zentrieren Sie die Nutzlast (avoid wall contact hot spots)

-

Kältemittel ausgleichen (not “top only”)

-

Den freien Luftraum minimieren (Luft transportiert Wärme)

-

Use buffer layers (avoid direct contact risks)

Packout pattern table

| Packout-Muster | Wenn es funktioniert | Häufiger Fehler | Was es für Sie bedeutet |

|---|---|---|---|

| Top-only refrigerant | sehr kurze Wege | warme Ecken | inkonsistente Ankünfte |

| Seite + Top-Abdeckung | die meisten Fahrspuren | lid gaps matter more | best general approach |

| Voller Surround + Abstandhalter | lange/heiße Fahrspuren | wrong conditioning | most stable hold time |

The “10-minute packout check” (run every shift)

Antworten Sie mit Ja/Nein:

-

Is the product pre-conditioned to the target range?

-

Is the coolant conditioned correctly for your band?

-

Is there a barrier between coolant and sensitive surfaces?

-

Is empty space minimized with safe dunnage?

-

Is closure consistent (strap/latch/tape plan)?

Wenn ja 2+ „Nein“-Antworten, your high-density insulated EPP box best performance will feel random—fix the process first.

Praktisches Fallbeispiel: A seafood shipper improved quality by adding a barrier layer and photo-based coolant placement. Gleiche Kiste. Better results.

User engagement: Decision tool to find the high-density insulated EPP box best for your lane

Use this before you buy. It prevents “over-buying” and “under-buying.”

Schritt 1: Score your lane risk (3–9)

Transitzeit

-

0–24 Stunden (1)

-

24–48 Stunden (2)

-

48–72+ Stunden (3)

Umgebungseinflüsse

-

mild/cool (1)

-

warm (2)

-

hot/extreme (3)

Handhabungsintensität

-

single handoff (1)

-

several handoffs (2)

-

Multistopp + Stapelung (3)

Schritt 2: Match the score to your starting spec

-

3–4 Punkte: medium thickness, medium-to-high density, simple closure

-

5–7 Punkte: dickere Wände, höhere dichte, better overlap lid, defined packout

-

8–9 points: hohe dichte + dicke Wände + strict packout + monitoring/validation

Schritt 3: Pick your “non-negotiable”

Wählen Sie eine aus:

-

maximum hold time

-

maximum durability

-

easiest cleaning

-

lowest shipping weight

-

highest reuse ROI

Dein high-density insulated EPP box best choice is the one that meets your lane risk Und your non-negotiable without adding operational complexity your team won’t follow.

How do you validate the high-density insulated EPP box best with simple tests (und ISTA 7E)?

Direkte Antwort: Validation turns your high-density insulated EPP box best decision from belief into a repeatable spec. Start with simple lane simulations, then use standards like ISta 7e when parcel-style networks or audits demand it.

Erweiterte Erklärung: Without a consistent test plan, you can’t tell if a “better box” helped—or if you just added more coolant that day. Ihr Ziel ist die Vergleichbarkeit: same packout, same sensors, same conditions, repeated runs.

A practical validation plan (3 Schritte)

-

Definieren Sie Ihre Spur: Dauer, Umgebungsbereich, delivery risks (porch, Cross-Dock, tarmac).

-

Lock your packout: product placement, Kühlmitteltyp, Konditionierung, Verschlussmethode.

-

Measure and repeat: laufen mindestens 3 trials per lane condition before scaling.

| Test condition | Ambient simulation | Duration target | Was es für Sie bedeutet |

|---|---|---|---|

| Typischer Tag | 20–25°C | Streckenzeit | checks daily stability |

| Hot risk day | 30–35°C | Route + Puffer | finds summer failures |

| Verzögerungsszenario | typical ambient | +4 Zu +8 Std. | tests disruption risk |

Sensor placement checklist (don’t skip this)

| Sensorstandort | Warum ist es wichtig | Was Sie lernen | Praktischer Sieg |

|---|---|---|---|

| warm corner near lid | gemeinsame Fehlerzone | lid leak impact | better design feedback |

| center of payload | true product condition | compliance evidence | stronger audit story |

| near coolant | Einfrierrisiko | overcooling detection | sicherere Verpackungen |

Praktisches Fallbeispiel: A pharma distributor found the “best box” failed only because staff skipped the strap step. Training fixed it—same box passed consistently.

How do you calculate ROI: reusable high-density insulated EPP box best cost per trip?

Direkte Antwort: Der high-density insulated EPP box best option is often the one with the lowest cost per successful trip, not the lowest purchase price.

Erweiterte Erklärung: Reuse only wins when the box returns, gets cleaned, and ships again. If reverse logistics is weak, single-use can be cheaper in practice. A simple calculator keeps you honest.

Cost-per-trip model (einfach und praktisch)

Kosten pro Fahrt = (Box cost ÷ expected cycles) + Reinigung + Reverse-Logistik + loss risk

Quick break-even logic:

-

If higher density doubles cycles, it can lower cost per trip.

-

If weight increases shipping cost, you need more cycles to win.

Selbsteinschätzung: will you actually get reuse value?

Score 0–2 for each (Max 10):

-

You have a reliable return channel.

-

You can clean and dry boxes quickly.

-

You track IDs or batches and loss rates.

-

You can retire damaged units consistently.

-

You run standardized lanes and packouts.

Score-Bedeutung

-

0–4: reuse risk is high; start with process cleanup and pilots

-

5–7: gemischt; pilot one lane and measure cycles and loss

-

8–10: stark; higher density often pays back quickly

How do you keep reuse safe: a food-grade cleaning checklist for the high-density insulated EPP box best?

Direkte Antwort: Der high-density insulated EPP box best program needs cleaning that people will actually do. Repeatable beats “perfect.”

Erweiterte Erklärung: If cleaning is too complex, it gets skipped. If boxes are stacked while wet, odor and residue problems grow. Build a checklist that fits your throughput and staffing.

Food-grade EPP box cleaning checklist (operationally realistic)

-

Vorspülen: remove debris and liquids immediately after returns

-

Waschen: approved cleaner at correct dilution and contact time

-

Spülen: remove residues

-

Trocken: air dry fully before stacking or storage

-

Überprüfen: check cracks, stains, lid edges, corner deformation

-

Quarantäne: remove damaged units from circulation

| Schritt | Was Sie tun | What you avoid | Was es für Sie bedeutet |

|---|---|---|---|

| Waschen | controlled dilution + scrub points | overly aggressive chemistry | less material wear |

| Trocken | full dry before stacking | wet stacking | weniger Geruchsbeschwerden |

| Überprüfen | check lid edges + Ecken | ignoring small cracks | fewer hygiene and seal risks |

Praktische Tipps und Empfehlungen

-

Set a retire rule: if the lid no longer closes firmly, remove it.

-

Trainieren Sie mit Fotos: show pass vs fail examples.

-

Track cycles simply: barcode, QR, or even batch color tags can work.

Supplier scorecard: what to ask before buying a high-density insulated EPP box best program?

Direkte Antwort: Der high-density insulated EPP box best purchase is a system decision—training, Reinigung, spare parts, and tolerances—not just “a box.”

Erweiterte Erklärung: If a supplier cannot explain validation, closure standardization, and dimensional consistency, you may get a box your team cannot run reliably.

Supplier scorecard: 12 questions that matter

-

Can you share lane-based performance data (not only material claims)?

-

What molded density options exist, and how do they change durability?

-

What lid designs are available, and how is sealing standardized?

-

What cleaning guidance exists, and which chemicals are compatible?

-

Are replacement parts available (Deckel, Riemen, Einsätze)?

-

Can you support a pilot with small quantities?

-

How do you manage dimensional variance across batches?

-

What is the realistic lifecycle expectation for my lane?

-

What quality checks are performed on arrival?

-

What labeling zones or ID options support tracking?

-

Can you support monitoring integration if required?

-

What changes are possible without breaking lead times?

| Supplier factor | Wie „gut“ aussieht | Rote Fahne | Was es für Sie bedeutet |

|---|---|---|---|

| Pilot support | small run + Anleitung | “buy big first” | lower scale risk |

| Konsistenz | clear tolerances | vague answers | fewer packing failures |

| Spare parts | lids/straps available | “replace whole box” | lower downtime costs |

2025 Trends: what’s changing for high-density insulated EPP box best buyers?

Trendübersicht: In 2025, the biggest shift is that reusable packaging is treated like an asset fleet, not a disposable supply. Buyers care less about slogans and more about repeatable execution: closure checks, photo packouts, tracking IDs, and cost-per-success metrics.

Aktueller Fortschritts-Snapshot (what you’ll see more of)

-

Fleet thinking: box IDs, Zyklus zählt, and return workflows

-

Lane-based standardization: weniger SKUs, less training burden

-

Schnelleres Training: line-side photos and short checklists

-

Better ergonomics: grips and designs built for real handling

-

Mehr Validierungskultur: Saisonale Packouts (Sommer/Winter) werden zur Normalität

Market insight: Der high-density insulated EPP box best strategy is usually process-first:

-

standardize packout

-

enforce closure checks

-

track reuse cycles

-

validate critical lanes

-

upgrade materials only where data proves it

This often improves performance faster than buying the most expensive box.

Häufig gestellte Fragen

Q1: What does “high density” mean for the high-density insulated EPP box best choice?

High density typically means a tighter foam structure and higher molded density band, improving durability and shape retention so the lid seal stays consistent.

Q2: Is thicker wall always better for a high-density insulated EPP box best result?

Nicht immer. Thicker walls can improve hold time, but reduce payload space and can increase shipping cost. Match thickness to lane duration first.

Q3: Why do shipments fail even with a high-density insulated EPP box best design?

Most failures come from lid gaps and packout variation. A strong box still needs a photo-based packout and a fast closure check.

Q4: How do I validate the high-density insulated EPP box best for my lane?

Define lane conditions, lock the packout, place sensors consistently, and run at least three repeat tests. Use ISTA 7E when networks and audits require standardized comparison.

Q5: What’s the fastest way to detect lid leaks?

Use the paper-strip test and inspect lid corners after drops. Corner deformation is the most common leak path.

Q6: When should I retire a reusable EPP box?

Retire when the lid no longer closes firmly, corners deform, cracks appear, or cleaning cannot remove residue. A strict retire rule protects the program.

Q7: Is the high-density insulated EPP box best always better than EPS or VIP?

NEIN. EPS can work for one-way, Fahrspuren mit geringem Missbrauch. VIP systems can win for extreme hold time. High-density EPP often wins for repeat routes with heavy handling and reuse.

Zusammenfassung und Empfehlungen

Der high-density insulated EPP box best for you is the one that matches your lane risk, Handhabungsintensität, and reuse reality. High density improves durability and shape stability, which helps the lid seal stay consistent across cycles. Wall thickness supports hold time, but only when paired with strong closure discipline and a standardized packout. If you want fewer excursions, start with seal and process repeatability before buying thicker walls.

Ihr nächster Schritt (klarer CTA)

Pick one high-volume lane today. Score the lane risk, choose one box standard, and build a “gold packout” with photos. Add a 3-second closure check, then run three hot-day simulations before scaling. If you want help, share your lane duration, Umgebungsrisiko, Nutzlastgröße, and reuse method—and request a pilot plan.

Über Tempk

Und Tempk, we help cold chain operators build packaging systems that work under real pressure—not just in theory. We focus on lane-based selection, repeatable packouts, and durable reusable EPP configurations so your team can execute consistently. Our approach prioritizes practical SOPs, validation-driven decisions, and lifecycle thinking, so your high-density insulated EPP box program stays stable across real-world cycles.

Nächster Schritt: Share your lane profile and target temperature band. We’ll outline a lane-matched spec and a pilot validation plan you can run before scaling.