Stellen Sie sich das vor: Ein Lagerleiter lädt lebensrettende Impfstoffe auf einen Lastwagen, der in Richtung Bergdörfer fährt. Ein Fischhändler bringt Thunfisch zu Flughäfen, bevor die Taifun-Saison beginnt. Eine Apothekenkette sorgt dafür, dass Insulin während eines Sommerausfalls eingefroren bleibt. Hinter diesen kritischen Vorgängen verbirgt sich eine unsichtbare Belegschaft –Verteiler-Eisbeutel– die stillen Hüter der Integrität in Großkühlketten.

Warum Vertriebsqualität wichtig ist: Jenseits der grundlegenden Kühlung

Während Verbraucher-Eisbeutel Lunchboxen handhaben, Vertriebslösungen stehen vor brutalen Anforderungen:

-

Skalieren Sie Herausforderungen: Palettengroße Sendungen, die eine gleichmäßige Stabilität bei -20 °C erfordern

-

Sicherheitsrisiken: Herkömmliches Trockeneis verursacht CO₂-Erstickung in geschlossenen LKWs

-

Kostspielige Ausfälle: 1°C-Abweichung verdirbt Biologika im Wert von über 25.000 US-Dollar (CDC 2024)

-

Nachhaltigkeitslücken: 92% der industriellen Gelpackungen landen auf Mülldeponien

Die Ingenieure von Tempk verbrachten 3 Jahre lang haben wir den Schutz der Kühlkette für große Mengen neu gedacht und uns diesen Herausforderungen direkt gestellt.

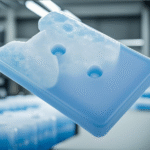

Tempk DryIcePro™: Massenkühlung revolutioniert

1. Extreme Leistung, Keine Gefahr

-

Pflege -50° C für 120+ Std.—4× länger als herkömmliches Trockeneis

-

CO₂-freie Technologie (keine Erstickungsgefahr in LKWs/Flugzeugen)

-

Patentiert “FrostGuard” Die Beschichtung verhindert oberflächliche Verbrennungen

2. Intelligente Skalierbarkeit

-

Modulare Designstapel wie LEGO®-Steine zur Palettenoptimierung

-

PhaseSync™-Technologie: Die verteilte KI-Kühlung gewährleistet eine Gleichmäßigkeit von ±1 °C bei 2-Tonnen-Sendungen

-

Visuelle Statusanzeigen (blau = optimal, rot = ersetzen)

3. Ökologische Entsorgung

-

Wasserlösliche Pellets: Bei Kontakt neutralisieren (0 Mülldeponie)

-

Kompostierbare Verpackungen: In Dünger verwandeln 30 Tage

-

CO2-negative Produktion durch Methanabscheidung

4. Händlerorientiertes Design

-

Massenaktivierung: Aktivieren 500+ packt ein 90 Sekunden

-

Roboterhandhabung: QR-codiert für automatisierte Lager

-

Bruchfest: Hält einer Verdichtung von 200 kg während des Transports stand

Wirkliche Auswirkungen: Zahlen, die zählen

Fall eines Pharmahändlers (Deutschland 2024)

Nach dem Wechsel zu Tempk:

→ 99.2% Temperaturkonformität über 12.000 Impfstofflieferungen

→ $480k gespeichert bei den Kosten für den Kühlmittelaustausch

→ 0 CO₂-Vorfälle In 8 Monate

Durchbruch in der Meeresfrüchtelogistik (Japan)

-

Ablehnungsrate der Thunfischqualität: 31% → 0.6%

-

Reduzierung des Kühlmittelgewichts: 40% (Senkung der Frachtkosten)

-

CO2-Fußabdruck: 73% Reduktion vs. traditionelles Trockeneis

Die verborgene Wissenschaft: Warum Profis sich für Tempk entscheiden

-

Arctic Protein Tech: Biomimikry aus Fisch-Frostschutzproteinen verhindert die Eiskristallisierung

-

MoistureLock™: Kieselsäurefreies Trockenmittel pflegt <10% Luftfeuchtigkeit

-

ImpactShield™: Die Aerogel-Matrix schützt Fläschchen bei rauem Transport

Jenseits von Pharma: Unerwartete Anwendungen

-

Weltraumlogistik: Transport von Mars-Rover-Proben

-

Gourmet-Vertrieb: Lieferung von Zutaten mit Michelin-Stern

-

Erhaltung: Transport von Embryonen gefährdeter Arten

-

Krisenreaktion: Medikamententransport im Überschwemmungsgebiet

Die Großkühlkette von morgen schon heute

Tempks 2025 Innovationen:

-

Solar-Ladepakete: Tageslicht verlängert die Abkühlung 30%

-

Blockchain-Tracking: Echtzeitüberwachung der Palettentemperatur

-

Selbstkühlende Paletten: Wasseraktivierte Massenkühlung

Abschluss

In der hochriskanten Welt der Massenlogistik, Kühlakkus von Händlern verwandeln sich von Gebrauchsgegenständen in kritische Infrastrukturen. Tempk beweist, dass Kühlung im industriellen Maßstab gleichzeitig leistungsstark sein kann, sicher, und nachhaltig. Denn sei es die Sicherung der Impfstoffe eines Dorfes oder die Trüffellieferung eines Kochs im Wert von 10.000 US-Dollar, Bei Exzellenz in der Kühlkette geht es nicht nur um die Temperatur – es geht um Vertrauen, das durch Tausende von Lieferungen vervielfacht wird, Tag für Tag.