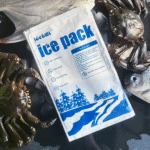

Trockeneisbeutel sind in der Kühlkettenlogistikbranche von entscheidender Bedeutung, Wird zur Aufrechterhaltung niedriger Temperaturen für verderbliche Waren verwendet. But how long do they actually last? In diesem Leitfaden, we’ll explore the factors that affect dry ice pack duration, how to maximize their lifespan, and tips for ensuring optimal performance during shipments. Egal, ob Sie Pharmazeutika versenden, Essen, or any temperature-sensitive products, understanding dry ice longevity is key to preserving quality and preventing spoilage.

-

How long do dry ice packs last Während des Versands?

-

What factors influence the duration of dry ice packs?

-

How can you optimize the use of dry ice packs for longer-lasting cooling?

-

What are the best practices for using dry ice packs in cold chain logistics?

How Long Do Dry Ice Packs Last During Shipping?

Trockeneisbeutel dauern normalerweise dazwischen 18 Zu 24 Std., but their longevity is heavily influenced by various factors such as the Menge an Trockeneis, Die quality of insulation, und die Umgebungstemperatur.

In more insulated containers, dry ice can remain effective for a longer duration as these containers slow the sublimation process (the transition from solid to gas). Zum Beispiel, smaller shipments or shorter shipping durations will usually require less dry ice, and dry ice is typically sufficient for keeping products at low temperatures for a full 24-hour period.

Factors Influencing Dry Ice Pack Longevity

Understanding how long your dry ice lasts is essential for planning cold chain logistics. The longevity of dry ice packs is affected by the following factors:

| Faktor | Impact on Duration | Erläuterung |

|---|---|---|

| Isolierung | Increases longevity | Better insulation slows down sublimation by reducing the heat exchange from the outside environment. |

| Umgebungstemperatur | Decreases longevity | Higher temperatures accelerate sublimation, causing dry ice to dissipate more quickly. |

| Trockeneismenge | Increases longevity | More dry ice means a longer cooling duration, as larger blocks have a slower sublimation rate. |

| Belüftung | Decreases longevity | Proper ventilation is necessary for safe gas release but excessive airflow can cause dry ice to sublimate quicker. |

How to Maximize the Lifespan of Dry Ice Packs?

To ensure that your dry ice lasts as long as possible, follow these strategies:

-

Verwenden Sie hochwertige Isolierbehälter: Invest in thicker insulation to slow down the sublimation process and protect dry ice during transport.

-

In kühlen Umgebungen lagern: Vor dem Versand, ensure the dry ice is kept in a cool area to minimize early sublimation.

-

Control ventilation exposure: While proper ventilation is crucial for safety, avoid excessive airflow as it can cause dry ice to sublimate faster.

-

Increase the amount of dry ice: If the shipment will be in transit for a longer duration or exposed to warmer conditions, adding more dry ice will help maintain a stable temperature throughout the journey.

Welche Faktoren beeinflussen die Haltbarkeit von Trockeneisbeuteln??

Several factors impact how long dry ice remains effective in cold chain logistics. Dazu gehören Temperatur, Trockeneismenge, Isolierung, Und Belüftung. Let’s delve into how these variables influence sublimation rates.

Ambient Temperature and Its Impact

Der Umgebungstemperatur plays a crucial role in determining the longevity of dry ice. Beim Versand verderblicher Waren über große Entfernungen, the external temperature can significantly shorten dry ice lifespan. Zum Beispiel, heißes Wetter will accelerate sublimation, causing dry ice to dissipate faster.

To counter this, it’s essential to use thicker insulation in warmer months or during heiße Klimazonen. Ähnlich, colder environments will help the dry ice last longer.

Insulation Materials for Longer Dry Ice Duration

Der Isolierung used in packaging is a critical determinant of how long dry ice will last. High-quality materials like Schaum, erweiterter Polystyrol (EPS), Und reflective materials are commonly used to reduce heat transfer and slow down the sublimation process.

-

Schaumisolierung: Provides strong protection against external temperatures, Damit eignet es sich ideal für den Versand über große Entfernungen.

-

Reflective Foil: Moderately effective for short-term, low-cost shipping.

-

High-density EPS: Highly recommended for temperature-sensitive goods, wie Pharmazeutika.

Zum Beispiel, dry ice in a foam-insulated box can last up to 24 Std., whereas a less-insulated box may only keep it effective for 12 Std..

Best Practices für die Verwendung von Trockeneis in Kaltkettenlogistik

Using dry ice effectively requires following best practices to ensure the safety and efficiency of your shipments.

Plan for Dry Ice Sublimation

Because dry ice sublimates over time, it’s essential to account for this process when planning shipments. Für Kurztrips, dry ice might suffice to maintain the required temperature. Jedoch, für longer trips, you may need to either replace the dry ice midway or combine it with other cooling methods.

Wählen Sie eine geeignete Verpackung

The packaging material plays an essential role in dry ice longevity. Isolierte Behälter with tight seals help to minimize heat exchange, ensuring dry ice remains effective for longer periods. Zusätzlich, packaging with proper Lüftungslöcher allows CO₂ gas to escape safely without accelerating sublimation.

| Verpackungsmaterial | Effectiveness for Dry Ice | Bester Anwendungsfall |

|---|---|---|

| Erweiterter Polystyrol | Hochwirksam | Fernlieferungen |

| Reflective Foil | Moderately effective | Kurzfristig, low-cost shipping |

| Schaumisolierung | Very effective | Pharmazeutika |

Optimize Ventilation

Excessive ventilation accelerates sublimation, while inadequate ventilation can cause dangerous pressure buildup. It’s crucial to use packaging that allows controlled gas release without excessive airflow. A well-ventilated container can improve the cooling duration by 50%, as seen in real-life applications for shipping biologics.

How Can You Optimize the Use of Dry Ice Packs for Longer-Lasting Cooling?

Maximizing the longevity of your dry ice packs involves several strategies for optimizing the various factors at play.

Monitor External Temperature

Tracking the Umgebungstemperatur during transit allows you to adjust the amount of dry ice and the insulation accordingly. In warmer climates, consider adding extra dry ice or choosing insulated packaging that provides better protection against heat.

Use Dry Ice Blocks for Longer Transit Times

Blocks of dry ice tend to last longer than pellets because they have a lower surface area relative to volume, slowing down the sublimation process. For shipments requiring extended cooling, Trockeneisblöcke are your best option. A study showed that using blocks increased cooling duration by 20% compared to pellets.

2025 Trends in Dry Ice Pack Usage

Die Kühlkettenlogistikbranche entwickelt sich weiter, with several key advancements in 2025 that will affect the way dry ice is used.

Aufkommende Trends in der Trockeneisstechnologie

-

Smart Dry Ice Packaging: New packaging integrates IoT sensors to monitor dry ice levels and temperature in real-time, providing better control over shipments.

-

Nachhaltige Materialien: More companies are focusing on using Umweltfreundliche Verpackung solutions that don’t compromise the effectiveness of dry ice.

-

Advanced Insulation Techniques: Mehrschichtige Isolierung kommt immer häufiger vor, helping to reduce dry ice sublimation rates and improve cooling efficiency.

Häufig gestellte Fragen

How long does dry ice last in an insulated package?

Trockeneis dauert normalerweise dazwischen 18-24 Std. in a high-quality insulated container, depending on the environmental conditions.

What is the best way to extend the life of dry ice?

To extend the life of dry ice, verwenden hochwertige Isolierung, store the package in a coole Umgebung, Und limit ventilation exposure. You can also increase the amount of dry ice if needed.

Schlussfolgerung und Empfehlungen

Key Takeaways:

-

Trockeneis dauert 18-24 Std., je nach Verpackung, Isolierung, und äußere Bedingungen.

-

Key factors like temperature, Trockeneismenge, and insulation quality influence sublimation rates.

-

Best Practices befolgen, such as pre-chilling containers and using the right quantity of dry ice, can extend cooling time.

Nächste Schritte:

To ensure the optimal use of dry ice, consider using advanced insulation materials, incorporating real-time monitoring, and optimizing your packaging strategies. Kontaktieren Sie uns for expert guidance on cold chain logistics and dry ice solutions tailored to your needs.

Über Tempk

Bei Tempk, Wir sind auf die Bereitstellung fortschrittlicher Kühlkettenlogistiklösungen spezialisiert. Unsere Produkte gewährleisten sich sicher, effizient, und umweltfreundlicher Transport temperaturempfindlicher Güter, using high-density foam, vakuumisolierte Paneele, and phase-change materials to optimize performance.

Kontaktieren Sie uns: Für maßgeschneiderte Kühlkettenlösungen, consult with our experts today!