So wählen Sie das beste Verpackungsmaterial für Trockeneisbeutel aus?

Wenn es um Versandtemperaturenempfindlichkeiten geht, using the right packaging supplies for dry ice packs is essential. Egal, ob Sie verderbliche Lebensmittel versenden, Arzneimittel, or any product that needs to stay cool, selecting the appropriate packaging can make all the difference in preserving product quality. In diesem Leitfaden, we’ll explore the best packaging options, considerations for choosing the right materials, and how to improve your cold chain shipping operations with dry ice packs.

What are the Key Factors in Choosing Packaging Supplies for Dry Ice Packs?

When selecting packaging supplies for dry ice, it’s crucial to consider several factors to ensure safe and efficient shipping. The right materials and design can help maintain the desired temperature throughout the shipping process, ob für 24 hours or up to 72 Std..

-

Durability and Insulation: Insulation is one of the most critical factors in packaging dry ice. High-quality thermal insulation materials prevent heat from entering and ensure that dry ice sublimates slowly, Aufrechterhaltung der kalten Kette.

-

Größe und Passform: Packaging that fits your dry ice packs properly ensures there are no gaps or movement during transit, which can lead to inefficiency in cooling.

-

Vorschriftenregulierung: Many regions have regulations for shipping dry ice, especially concerning quantity and packaging. Ensure your packaging meets these standards to avoid shipping delays or penalties.

What are the Best Materials for Dry Ice Pack Packaging?

Choosing the right materials can significantly impact the longevity and safety of your shipment. Different materials provide various levels of insulation and strength, and each is best suited for specific needs.

-

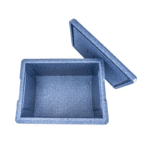

Erweiterter Polystyrol (EPS) Schaum: This material is widely used in the shipping industry due to its excellent insulation properties. EPS foam can keep your dry ice at the desired temperature for longer periods, making it perfect for shipping perishable goods.

-

Polyurethanschaum: Known for its higher thermal resistance compared to EPS foam, polyurethane foam is ideal for longer shipping durations and extreme temperatures.

-

Phasenwechselmaterial (PCMs): PCMs are designed to absorb and release heat, providing a more stable temperature environment. They are highly effective for items that require precise temperature control.

How Do You Determine the Right Size and Fit for Dry Ice Packaging?

To ensure your dry ice packs perform optimally during transport, you must choose packaging that fits the dry ice snugly. A package that’s too large may allow the dry ice to sublimate too quickly due to the increased air exposure, while a package that’s too small could cause unnecessary pressure that may damage the product being shipped.

The size of your dry ice pack should also align with the shipping duration. Zum Beispiel, A 24-Stunde Trockeneisbeutel needs different packaging than a 72-Stunde Trockeneisbeutel. The more time it needs to keep products cool, the more insulation and protection from external heat it requires.

| Verpackungsmaterial | Isolationsleistung | Bester Anwendungsfall | Hauptvorteil |

|---|---|---|---|

| EPS -Schaum | Mäßig | Kurzzeitlieferungen | Cost-effective insulation for up to 24 Std. |

| Polyurethanschaum | Hoch | Long-term shipments | Reliable for up to 72 Std., great for extreme temperatures |

| Phasenwechselmaterial | Sehr hoch | Sensitive goods with precise temperature needs | Stable temperature control throughout the shipping process |

How Can You Comply with Dry Ice Shipping Regulations?

Dry ice is considered a hazardous material by the Department of Transportation (PUNKT) in many countries, including the U.S. und Europa. To ensure compliance with shipping regulations, it’s essential to choose packaging that meets specific standards for dry ice transportation.

-

Beschriftung: Dry ice packages must be clearly marked with the proper hazard labels, einschließlich „Kohlendioxid, Solid“-Label, and the appropriate weight markings.

-

Belüftung: Packaging must also include ventilation holes to allow for the safe release of gases as dry ice sublimates during transit. This helps prevent the buildup of pressure inside the container.

By ensuring your packaging meets these requirements, you can avoid shipping delays and penalties.

Best Practices for Dry Ice Packaging Supply Chain

When setting up your dry ice shipping operation, following best practices for packaging supplies is crucial to enhance both efficiency and safety. Here’s what to keep in mind:

-

Pre-plan the Packaging Process: Pre-assemble your packaging materials before orders come in. This will save time during the shipping process and ensure that every package meets safety standards.

-

Evaluate Temperature-Tracking Technology: Implement temperature monitoring devices inside the package. These devices help confirm that the dry ice was effective during transit and can provide valuable data for improving future shipments.

-

Choose the Right Box Type: Different types of boxes (corrugated, isoliert, or multi-layered) offer varying levels of protection. Choose the box that best suits your product’s needs.

Practical Tips for Packaging Dry Ice Efficiently

-

Avoid Opening the Box: Einmal gepackt, ensure that the box is sealed tightly. Opening the package during transit or in storage will accelerate the sublimation of the dry ice, seine Wirksamkeit verringern.

-

Clever packen: When placing dry ice packs, ensure they are positioned to surround your product on all sides. This maximizes cold retention and reduces the chances of temperature fluctuations.

How Can You Optimize Costs When Choosing Dry Ice Packaging?

For businesses looking to minimize costs while ensuring product quality, it’s important to balance packaging choices with shipping needs. Here are some tips to help you optimize costs:

-

Kaufen Sie in großen Mengen: Purchase packaging materials in bulk to lower your overall cost per shipment. This also ensures consistency in your packaging materials.

-

Use Multi-Purpose Packaging: Multi-use boxes and packaging materials, such as reusable insulated liners, can reduce your costs over time.

-

Select the Right Shipping Carrier: Different carriers have different handling protocols for dry ice. Make sure to choose one that aligns with your packaging needs and offers the best rates for temperature-controlled shipping.

Beispiel für reale Welt: A food delivery company optimized its dry ice packaging system by investing in reusable insulated liners and reducing its average shipping cost per package by 20%. By improving packaging and switching carriers, they also increased on-time delivery reliability.

2025 Trends bei der Verpackung und dem Versand von Trockeneis

In 2025, we expect significant advancements in dry ice packaging materials and shipping technologies. Innovationen in advanced insulating foams Und intelligente Verpackungslösungen are paving the way for more efficient, kostengünstige Kühlkettenlösungen.

Neueste Fortschritte

-

Intelligente Verpackungstechnologie: Emerging technologies like Internet der Dinge (IoT)-enabled temperature sensors are revolutionizing the way we monitor shipments. These devices track the temperature in real-time, ensuring compliance and offering valuable insights into shipment performance.

-

Nachhaltige Verpackungsoptionen: Mit wachsenden Umweltproblemen, more companies are opting for eco-friendly dry ice packaging materials, such as biodegradable foams and recyclable insulation.

Markteinsichten

-

Increase in E-commerce Shipments: The rise in e-commerce for perishable goods means there will be higher demand for optimized dry ice packaging, Besonders für internationale Sendungen.

-

Regulatorische Änderungen: With stricter regulations on hazardous materials, businesses will need to invest in more specialized packaging that meets the evolving standards of the global supply chain.

Häufig gestellte Fragen

What are the most effective materials for packaging dry ice?

The most effective materials include expanded polystyrene (EPS) Schaum, Polyurethanschaum, und Phasenwechselmaterialien (PCMs). Each offers a different level of insulation, with PCMs being the most effective for long-duration shipments.

Can I reuse dry ice packaging?

Ja, many packaging materials such as insulated liners and sturdy boxes can be reused for multiple shipments. Jedoch, make sure the material still meets safety and temperature retention standards before reuse.

Schlussfolgerung und Empfehlungen

To optimize your cold chain shipping and dry ice packaging, consider the factors that directly impact temperature control and safety. From selecting the right materials to complying with regulations, following best practices can enhance your shipping efficiency while reducing costs. Don’t forget to take advantage of emerging technologies to track and optimize your shipments for even better results.

Nächste Schritte:

-

Evaluate your current packaging strategy and identify areas for improvement.

-

Research the latest advancements in temperature monitoring and packaging materials.

-

Start implementing more eco-friendly solutions to stay ahead of regulatory changes and market demands.

Über Tempk

Und Tempk, Wir sind spezialisiert auf eine qualitativ hochwertige Bereitstellung, sustainable cold chain solutions tailored to your shipping needs. Our innovative dry ice packaging and temperature-controlled systems ensure that your products reach their destination in perfect condition. Egal, ob Sie Lebensmittel versenden, Arzneimittel, oder andere sensible Gegenstände, Tempk offers the reliability and expertise you need.

Nehmen Sie noch heute Kontakt mit uns auf to discover how we can enhance your cold chain logistics.