Wie man Trockeneis zum sicheren Versand von gefrorenem Fleisch sicher packt?

Der Versand von gefrorenem Fleisch ohne Qualitätseinbußen erfordert eine präzise Temperaturkontrolle, insbesondere bei der Verwendung von Trockeneis. It is crucial to understand the right amounts of dry ice, the best packing materials, and the regulations you must follow to ensure that meat products remain frozen during transit and arrive in perfect condition. In diesem Leitfaden, we’ll cover the essentials of So verpacken Sie Trockeneis für den Versand von gefrorenem Fleisch sicher, helping you stay compliant with 2025 guidelines while optimizing the shipping process.

-

How much dry ice do you need per 24–72 hours for safe frozen meat shipping?

-

What packaging design and venting rules must you follow for compliance?

-

How do you layer insulation, Fleisch, and dry ice to maintain temperature?

-

What regulatory labeling, Dokumentation, and safety precautions are required?

-

What trends are emerging in the cold chain logistics of 2025?

How Much Dry Ice Should You Use to Ship Frozen Meat Over 1–3 Days?

Kernantwort:

You should estimate 5–10 lbs of dry ice per 24 hours for typical shipping conditions. Jedoch, this amount may need adjustment depending on the duration of the shipment, Umgebungstemperatur, und Isolierung verwendet.

Erläuterung:

Dry ice sublimates at approximately 5–10 lbs per 24 Std., depending on the shipping conditions and the quality of insulation. Zum Beispiel, beim Versand 10 lbs of meat, you may need around 7 lbs of dry ice per day for a short transit. In warmer weather or longer distances, Sie brauchen mehr. Testing your shipment with temperature loggers helps ensure optimal results.

| Versanddauer | Typical Dry Ice Amount | Risk of Underestimating | Praktische Anwendung |

|---|---|---|---|

| 1 Tag (über Nacht) | 5–8 Pfund (2.3–3.6 kg) | Partial thaw, warm edges | Local shipments |

| 2 Tage | 10–15 Pfund (4.5–6,8 kg) | Meat warms or partially thaws | Cross-state shipments |

| 3 Tage | 15–20 Pfund (6.8–9 kg) | Full thaw, quality loss | Long-distance or remote areas |

Tipp: For longer transit times or in hot climates, it is advisable to increase the dry ice load by 20% or use thicker insulation materials to slow down sublimation.

What Packaging Design & Venting Rules Must You Follow?

Kernantwort:

Your packaging must always allow CO₂ gas to vent, Versiegeln Sie niemals luftdicht, and should include the necessary labels: "Trockeneis" oder "Kohlendioxid", Solide," UND 1845, and net dry ice weight in kg.

Erläuterung:

Als Trockeneis untermauert, Es veröffentlicht Co₂ -Gas. Wenn die Verpackung luftdicht ist, the pressure can build up and rupture the container. Um dies zu vermeiden, the outer packaging must have vents, and the inner cooler must not be sealed tightly. Packaging materials should comply with hazardous materials guidelines to ensure safety.

Required Labels:

-

"Trockeneis" oder "Kohlendioxid", Solide"

-

UN -Nummer: Und 1845

-

Nettogewicht des Trockeneis (kg)

-

Klasse 9 Gefahrmaterial Etikett

-

Absender & recipient addresses

Packaging Process:

-

Outer Box: Use a corrugated fiberboard or durable plastic box.

-

Isolierung: Add EPS foam panels or rigid insulation around the meat and dry ice.

-

Belüftung: Ensure the package can vent CO₂ by not sealing the inner cooler too tightly.

How to Layer Insulation, Fleisch & Dry Ice for Temperature Control?

Kernantwort:

When packing frozen meat with dry ice, the dry ice should surround the meat on all sides and be placed on top to ensure the cold air sinks through the product. Insulation should be used to slow down heat ingress, and all voids should be filled with packing materials.

Erläuterung:

-

Meat Placement: Place vacuum-sealed meat in the center of the cooler to minimize air exposure.

-

Trockeneisplatzierung: Place dry ice on top and around the sides of the meat, but avoid direct contact with the meat to prevent freezer burn. Ensure that the dry ice is not tightly packed and can sublimate without restriction.

-

Isolierung: Use foam or other insulating materials to fill gaps and reduce the chances of temperature fluctuations.

Packaging Layering Example:

-

Vacuum-seal meat and place it in the center.

-

Surround the meat with approximately 10 LBS Trockeneis.

-

Verwenden 2 inches of foam insulation around the dry ice.

-

Fill any voids with crumpled paper or cellulose insulation to prevent shifting.

-

Ensure the cooler lid is slightly open or has vent holes to allow gas to escape.

What Regulatory Labeling, Dokumentation & Safety Steps Are Required?

Kernantwort:

Complying with regulations is essential when shipping dry ice. This includes labeling the package properly and ensuring it is handled by certified personnel familiar with hazardous materials shipping protocols.

Erläuterung:

Dry ice is considered a Class 9 Gefahrgut, and shipping it requires careful attention to regulatory guidelines to ensure safety and compliance.

Key Documentation & Sicherheit:

-

Richtige Kennzeichnung: Always label the outer box with “Dry Ice” or “Carbon Dioxide, Solide,” include the UN number, und das Netto-Trockeneisgewicht.

-

Versendererklärung: For air shipments of more than 5.5 lbs (2.5 kg), include a shipper’s declaration for dangerous goods.

-

Vorsichtsmaßnahmen zur Handhabung: Always handle dry ice with insulated gloves and work in well-ventilated areas to avoid CO₂ buildup.

Compliance Tips:

-

Verschließen Sie die Verpackung niemals luftdicht. Ensure that CO₂ can vent freely.

-

Verify that the packing and labeling meet carrier-specific rules (Z.B., FedEx, UPS, USPS).

-

Use temperature data loggers to monitor internal conditions during transit.

2025 Trends in Dry Ice Shipping and Cold Chain Innovations

Trendübersicht:

In 2025, Die Kühlkettenlogistikbranche entwickelt sich weiter, with a focus on smarter packaging, Echtzeit-Temperaturüberwachung, and the use of eco-friendly materials to improve efficiency and reduce costs.

Neueste Innovationen:

-

Smartemperaturüberwachung: IoT-connected sensors alert you if the temperature deviates from the desired range during transit.

-

Umweltfreundliche Materialien: High-performance, sustainable materials such as VIP liners are becoming more common, providing better insulation while reducing environmental impact.

-

AI-powered Route Optimization: Delivery platforms are using artificial intelligence to optimize routes based on temperature conditions, minimizing transit times and reducing dry ice usage.

Markteinsichten:

As consumer demand for direct-to-consumer frozen meat shipments grows, it’s essential to adopt these innovations to improve reliability, Abfall reduzieren, and build customer trust. Brands that optimize their dry ice packing methods while embracing sustainability will gain a competitive edge.

Häufig gestellte Fragen (FAQ)

Q1: How much dry ice do I need to ship frozen meat for 48 Std.?

You typically need 10–15 lbs (4.5–6,8 kg) Trockeneis für 48 Std., abhängig von Isolationsqualität und Umgebungstemperatur. Always perform a test with temperature loggers.

Q2: Can I seal the shipping box tightly?

NEIN, the box must allow for venting to prevent pressure buildup from the CO₂ gas. A tightly sealed box can rupture during transit.

Q3: What if my shipment is delayed and dry ice runs out?

To mitigate this risk, always include a buffer (Extra Trockeneis), choose fast transit routes, and work with carriers who can replenish dry ice if needed.

Zusammenfassung & Empfehlungen

Key Takeaways:

To pack dry ice for shipping frozen meat safely, Sorgen Sie stets für eine ausreichende Belüftung, accurate labeling, and the right amount of dry ice. Use insulated packaging to maintain low temperatures and follow regulatory guidelines to ensure compliance. Test shipments with temperature loggers to adjust dry ice quantities.

Die nächsten Schritte für Sie:

-

Audit your packaging to ensure it’s optimized for your specific shipping conditions.

-

Implement a dry ice calculator for better load estimation.

-

Train your team on handling dry ice and understanding the required regulations.

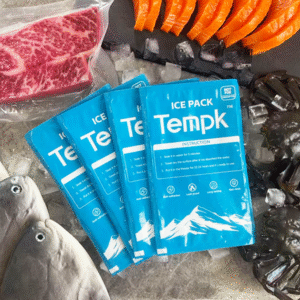

Über Tempk

We specialize in providing cold-chain solutions for the shipping industry, particularly in the transportation of frozen food and biothermal products. Our innovative, eco-friendly packaging options, combined with our expertise in temperature management, ensure that your products arrive safely and on time. Whether you need a tailored cold-chain plan or advice on regulatory compliance, Tempk ist hier, um zu helfen.