1. Die Art und Weise, wie die Backwaren verpackt sind

Damit Backwaren beim Transport frisch und lecker bleiben, Die richtige Verpackung ist unerlässlich. Erste, Wählen Sie Verpackungsmaterialien in Warenqualität aus, wie Ölpapier, hochwertige Plastiktüten und Luftpolsterfolie, um Warenfeuchtigkeit zu verhindern, Verschlechterung, oder Schaden. Zweitens, die Verwendung des Inkubators und der Eisbeutel mit Wärmeisolationsfunktion, um sicherzustellen, dass die Backwaren während des Transports die richtige Temperatur beibehalten, um zu verhindern, dass Temperaturschwankungen die Warenqualität beeinträchtigen. Zusätzlich, Ordnen Sie den Verpackungsraum an, um Extrusion und Kollisionen zwischen Waren zu vermeiden, um das Aussehen und den Geschmack der Backwaren zu erhalten. Endlich, Bei der Verpackung sollten die Haltbarkeits- und Lagerungsempfehlungen angegeben werden, um sicherzustellen, dass Verbraucher beim Verzehr das beste Geschmackserlebnis haben.

2. Transportart von Backwaren

Temperaturkontrolle und Stoßschutz sollen dafür sorgen, dass die Ware am Zielort noch frisch und lecker ankommt. Erstens, Mithilfe der Kühlkettenlogistiktechnologie werden Kühlfahrzeuge und tragbare Kühlschränke eingesetzt, um eine geeignete Umgebung mit niedrigen Temperaturen aufrechtzuerhalten und zu verhindern, dass Waren aufgrund hoher Temperaturen verderben. Zweitens, Wählen Sie den richtigen Transportweg, Reduzieren Sie die Transportzeit und Turbulenzen, um die sichere Lieferung von Waren in kürzester Zeit zu gewährleisten. Zusätzlich, Die Temperatur sollte während des Transportvorgangs regelmäßig überwacht und rechtzeitig angepasst werden, um die Stabilität der gesamten Temperaturregelung sicherzustellen. Endlich, um zu verhindern, dass Güter während des Transports gequetscht und kollidiert werden, Puffermaterialien, wie Schaumstoffmatte oder Luftpolsterfolie, kann zum Schutz von Backwaren vor Stößen eingesetzt werden.

3. So transportieren Sie Tieftemperatur-Backwaren?

Für Backwaren, die kalt gehalten werden müssen, Um sicherzustellen, dass die Ware in der gesamten Lieferkette frisch und sicher bleibt, ist die Wahl der Verpackungs- und Transportmethoden besonders wichtig. Hier sind die detaillierten Verpackungs- und Versandschritte:

1. Verpackung

1.1 Verpackungsmaterialien in Warenqualität

Erste, Verpacken Sie die Backwaren separat in ölbeständigem Papier oder Plastiktüten in Lebensmittelqualität. Diese Materialien können Luft und Feuchtigkeit wirksam isolieren und verhindern, dass Waren feucht werden.

1.2 Vakuumverpackung

Für Backwaren, die leicht verderben, Mithilfe der Vakuumverpackungstechnik kann die Luft aus der Verpackung entfernt werden, Dadurch verlängert sich die Haltbarkeit der Ware.

1.3 Wärmedämmmaterial

Fügen Sie eine Schicht Isoliermaterial hinzu, wie Luftpolsterfolie oder Schaumstoffpolster, bis zur Außenschicht der Ware, Dies trägt dazu bei, einen Pufferraum im Verpackungskarton zu bilden, um den direkten Einfluss der Außentemperatur auf die Ware zu verhindern.

1.4 Isolierbox und Eisbeutel

Endlich, Legen Sie die verpackten Backwaren in einen Inkubator und legen Sie ausreichend Eis darauf. Diese Kühlakkus können während des Transports kontinuierlich kalte Luft abgeben, Aufrechterhaltung einer Umgebung mit niedrigen Temperaturen und Gewährleistung der Frische der Waren.

2. Transport

2.1 Kühlkettentransport

Nutzen Sie professionelle Kühlkettenlogistikdienste, um sicherzustellen, dass der gesamte Transportprozess strengen Temperaturkontrollbedingungen unterliegt. Die Kühlfahrzeuge und Tiefkühltruhen sollten in einem geeigneten Kältebereich gehalten werden, normalerweise zwischen 0°C und 4°C, um eine Verschlechterung der Ware zu verhindern.

2.2 Wählen Sie die Schnelltransportroute

Wählen Sie den schnellsten Transportweg, reduzieren Sie die Transportzeit, und versuchen Sie, einen langen Transportprozess zu vermeiden. Dies kann die Zeit, in der Waren der äußeren Umgebung ausgesetzt sind, wirksam verkürzen und ihre Frische gewährleisten.

2.3 Temperaturüberwachung

Während des Transportprozesses, Die Temperaturüberwachungsausrüstung ist so ausgestattet, dass sie die Temperatur im Kühlkettenwagen in Echtzeit überwacht. Wenn die Temperatur abnormal ist, Es können rechtzeitig Maßnahmen ergriffen werden, um sicherzustellen, dass die Ware immer die beste Lagertemperatur hat.

4. Was kann Huizhou für Sie tun??

Beim Transport von Backwaren ist die Aufrechterhaltung der Temperatur und Qualität der Ware von entscheidender Bedeutung. Huizhou Industrial Cold Chain Technology Co., Ltd. bietet eine Reihe effizienter Produkte für den Kühlkettentransport, mit denen Sie sicherstellen können, dass Backwaren während des Transports im besten Zustand bleiben. Hier ist unser professionelles Programm.

1. Huizhou -Produkte und deren Anwendungsszenarien

-Wassereinspritzeisenbeutel:

-Hauptantragstemperatur: 0℃

-Anwendbares Szenario: Für Backwaren, die bei etwa 0 °C aufbewahrt werden müssen, wie zum Beispiel einige Waren, die niedrig gehalten, aber nicht eingefroren werden müssen.

-Salzwassereisbeutel:

-Hauptantragstemperaturbereich: -30℃ bis 0 ℃

-Anwendbare Szenarien: Für Backwaren, die niedrige Temperaturen erfordern, aber keine extrem niedrigen Temperaturen erfordern, wie Sahnetorten und einige Füllungen, die gekühlt werden müssen.

-Gel -Eisbag:

-Hauptantragstemperaturbereich: 0℃ bis 15 ℃

-Anwendbares Szenario: Geeignet für Backwaren bei leicht niedrigen Temperaturen, wie Sahne und Kuchen, die eine bestimmte Härte beibehalten müssen.

-Organische Phasenwechselmaterialien:

-Hauptantragstemperaturbereich: -20℃ bis 20 ℃

-Anwendbares Szenario: Geeignet für den Transport verschiedener Temperaturbereiche mit präziser Temperaturregelung, wie zum Beispiel die Aufrechterhaltung der Raumtemperatur oder die Kühlung hochwertiger Backwaren.

-Eisbox -Eisbox:

-Hauptantragstemperaturbereich: -30℃ bis 0 ℃

-Anwendbares Szenario: Backwaren für den Kurzstreckentransport und bei einer bestimmten Kühltemperatur.

2.Isolierung kann

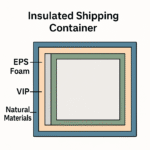

-VIP -Isolierung kann:

-Merkmale: Verwenden Sie die Vakuum -Isolationsplatten -Technologie, um den besten Isolierungseffekt zu erzielen.

-Anwendbares Szenario: Geeignet für den Transport hochwertiger Backwaren, um die Stabilität bei extremen Temperaturen zu gewährleisten.

-EPS -Isolierung kann:

-Merkmale: Polystyrolmaterialien, niedrige Kosten, Geeignet für den allgemeinen thermischen Isolationsbedarf und den Kurzstreckentransport.

-Anwendbares Szenario: geeignet für den Transport von Backwaren, die eine mäßige Isolationswirkung erfordern.

-EPP -Isolierung kann:

-Merkmale: Schaumstoff mit hoher Dichte, bieten eine gute Isolationsleistung und Haltbarkeit.

-Anwendbares Szenario: Geeignet für Transportanforderungen, die eine lange Isolierung erfordern.

-PU -Isolierung kann:

-Merkmale: Polyurethanmaterial, Ausgezeichneter thermischer Isolierungseffekt, Geeignet für den Ferntransport und hohe Anforderungen der thermischen Isolationsumgebung.

-Anwendbares Szenario: Geeignet für den Ferntransport von hochwertigen Backwaren.

3.Thermobeutel

-Oxford -Stoffisolationsbeutel:

-Merkmale: leicht und langlebig, geeignet für den Kurzstreckentransport.

-Anwendbares Szenario: geeignet für den Transport kleiner Backwarenmengen, leicht zu tragen.

-Nicht gewebte Stoffisolierungstasche:

-Merkmale: umweltfreundliche Materialien, Gute Luftdurchlässigkeit.

-Anwendbares Szenario: Geeignet für den Kurzstreckentransport für allgemeine Isolationsanforderungen.

-Aluminiumfolie -Isolationsbeutel:

-Merkmale: reflektierte Hitze, Ein guter thermischer Isolierungseffekt.

-Anwendbares Szenario: Geeignet für den Transport über mittlere und kurze Distanzen sowie für Backwaren, die Isolierung und Feuchtigkeit erfordern.

4.Je nach empfohlener Backwarensorte

4.1 Sahnetorte und Sahnegebäck

-Empfohlene Lösung: Verwenden Sie einen Gel-Eisbeutel oder einen Salz-Eisbeutel, gepaart mit einem PU-Inkubator oder einem EPP-Inkubator, um sicherzustellen, dass die Temperatur zwischen 0℃ und 10℃ gehalten wird, um die Stabilität und Textur der Creme zu erhalten.

-Gefrorene Teige und frische Sahneprodukte bei extrem niedriger Temperatur:

-Empfohlene Lösung: Verwenden Sie einen salzhaltigen Eisbeutel oder eine Eisbox mit einem VIP-Inkubator, um sicherzustellen, dass die Temperatur bei -30 °C bis 0 °C gehalten wird, um den gefrorenen Zustand und die Frische des Produkts aufrechtzuerhalten.

4.2 Backwaren bei Zimmertemperatur (wie Kekse, brot, usw.)

-Empfohlenes Schema: Verwenden Sie organische Phasenwechselmaterialien, mit Oxford-Stoff-Isolationsbeutel oder nicht gewebter Isolationsbeutel, Um sicherzustellen, dass die Temperatur bei etwa 20 ℃ gehalten wird, um Feuchtigkeit und Beschädigung der Waren zu verhindern.

4.3 Hochwertige Backwaren zum Kühlen (wie Premium-Desserts, spezielle Füllungen, usw.)

-Empfohlene Lösung: Verwenden Sie organische Phasenwechselmaterialien oder Gel-Eisbeutel, gepaart mit einem PU -Inkubator oder einem EPS -Inkubator, um sicherzustellen, dass die Temperatur zwischen 0℃ und 5℃ gehalten wird, um die Qualität und den Geschmack der Waren zu erhalten.

Durch die Verwendung von Huizhous Kältemittel- und Isolierungsprodukten, Sie können sicherstellen, dass Backwaren während des Transports die beste Temperatur und Qualität behalten. Wir sind bestrebt, unseren Kunden die professionellsten und effizientesten Kühlkettentransportlösungen anzubieten, um den Transportanforderungen verschiedener Arten von Backwaren gerecht zu werden.

5. Temperaturüberwachungsservice

Wenn Sie die Temperaturinformationen Ihres Produkts während des Transports in Echtzeit erhalten möchten, Huizhou bietet Ihnen einen professionellen Temperaturüberwachungsdienst zur Verfügung, Dies führt jedoch zu den entsprechenden Kosten.

6. Unser Engagement für nachhaltige Entwicklung

1. Umweltfreundliche Materialien

Unser Unternehmen verpflichtet sich der Nachhaltigkeit und nutzt umweltfreundliche Materialien in Verpackungslösungen:

-Recycelbare Isolationsbehälter: Unsere EPS- und EPP -Behälter bestehen aus recycelbaren Materialien, um die Umweltauswirkungen zu verringern.

-Biologisch abbaubares Kältemittel und thermisches Medium: Wir bieten biologisch abbaubare Gel -Eisbeutel und Phasenwechselmaterialien, sicher und umweltfreundlich, Abfall reduzieren.

2. Wiederverwendbare Lösungen

Wir fördern die Verwendung wiederverwendbarer Verpackungslösungen, um Abfall zu senken und Kosten zu senken:

-Wiederverwendbare Isolationsbehälter: Unsere EPP- und VIP -Container sind für mehrere Verwendung ausgelegt, Bereitstellung von langfristigen Kosteneinsparungen und Umweltvorteilen.

-Wiederverwendbares Kältemittel: Unsere Gel -Eisbeutel und Phasenänderungsmaterialien können mehrmals verwendet werden, Reduzierung der Notwendigkeit von Einwegmaterialien.

3. Nachhaltige Praxis

Wir halten uns an nachhaltige Praktiken in unseren Operationen ein:

-Energieeffizienz: Wir implementieren Energieeffizienzpraktiken während der Herstellungsprozesse, um den CO2 -Fußabdruck zu verringern.

-Abfall reduzieren: Wir bemühen uns, Abfall durch effiziente Produktionsprozesse und Recyclingprogramme zu minimieren.

-Grüne Initiative: Wir sind aktiv an grünen Initiativen beteiligt und unterstützen Umweltschutzbemühungen.