Eisbeutel für kühle Taschen: Das tragbare Kraftpaket der modernen Kaltkette

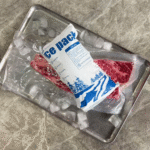

Nur wenige Gegenstände haben die tägliche Temperaturregelung genauso neu erfunden wie der bescheidene Kühlbeutel gepaart mit einem Hochleistungseispackung. Von Gourmet -Mahlzeit -Kits, die in City Apartments bis hin zu Insulinstiften in einen Rucksack gesteckt wurden, Kühle Taschen überbrücken jetzt die „letzten fünfzig Meter“ der kalten Kette, Inhalt in Sicherheit aufbewahren, lange nachdem sie gekühlte Lieferwagen verlassen haben. Doch das wahre Arbeitstier ist der Eisbeutel im Inneren. Verstehen, wie diese Packs gestaltet sind - und wie man den richtigen auswählt -, wird Einzelhändlern helfen, Kuriere und sogar Wochenend-Camper schützen temperaturempfindliche Güter mit Zuversicht.

Warum kühle Taschen spezielle Eisbeutel brauchen

Kühle Taschen sind im Wesentlichen flexible Miniaturkälteläume: dünne Wände, Begrenzte Isolierung und ständige Öffnungen. Sie verlassen sich eher auf gespeicherte "kalte Energie" als auf eine betriebene Kühlung. Ein speziell gebautes Eisbeutel:

-

Liefert kontrollierte Schmelze -Technische Gele oder Phasenveränderungsmaterialien (PCMs) Wärme in einer definierten Temperaturkurve absorbieren, Holding 0 °C, 5 ° C oder –10 ° C nach Bedarf.

-

Widersteht Lecks und Punktionen -Multi-Layer-PE- oder HDPE, Tropfen und scharfe Lebensmittelverpackungen.

-

Schnell wieder einfrieren - Wesentlich für tägliche Kurierrunden oder Wiederholung von Freizeitreisen.

Schlüsseldesignelemente

-

Kernmaterial

-

Wassergel: niedrige Kosten; Gut für Tagesausflüge, bei denen kurze Abkühlungen ausreichen.

-

PCM Slurries: formuliert, um bei präzisen Versatzteilen zu schmelzen; Halten Sie die Zeit zwei aus zwei- auf dreifach und reduzieren Kondensation.

-

-

Shell -Geometrie

-

Flache Ziegel: Setzen Sie sich an der Basis oder an den Seiten einer kühlen Tasche, Maximierung der Kontaktfläche.

-

Flexible Kissen: Wickeln Sie sich um unangenehme Formen - drehen Sie Flaschen um, medizinische Fläschchen-fällige Luftlücken, die das Aufwärmen beschleunigen.

-

-

Einfrierenprotokoll

-

Vor dem Pack eine vollständige 24 H bei –18 ° C (Inländischer Gefrierschrank) oder 12 H bei –25 ° C (Explosion Gefrierschrank) Für maximale "Ladung" latente Hitze.

-

Laden Ersatzteile flach; Das vertikale Einfrieren kann eine thermische Schichtung in großer Schichtung erzeugen, dicke Ziegel.

-

Passendes Pack zur Mission

| Anwendungsfall | Ideales Paket | Tipps |

|---|---|---|

| Lebensmittelklick und Sammel | Mittlerer PCM -Ziegel bei 0–4 ° C | Kombinieren mit reflektierender Liner, um die Strahlungswärmegewinnung zu verlangsamen. |

| Pharmazeutische Eigenheimlieferung | Slim PCM -Platte bei 2–8 ° C | Fügen Sie den Temperatur -Logger in der Tasche hinzu, um einen Audit Trail zu erhalten. |

| Picknick & Outdoor -Sport | Gelkissen | Bringen Sie zwei: eine für Essen, eine für Getränke, um häufige Deckelöffnungen zu vermeiden. |

| Gefrorene Desserts | Starr –18 ° C Ziegelstein | Positionieren Sie oben und unten, um Kaltluftabfälle zu nutzen. |

Betriebseinsparungen

Effiziente Eisbeutel tun mehr als kalt. Durch die Verlängerung des Kühllebens, sie erlauben:

-

Kleiner, Leichtere kühle Taschen - Reduzierung von Kurierlastgrenzen und Kraftstoffverbrennung.

-

Weniger Ersatzpackungen in der Rotation - Schneiden von Gefrierschrankenergie und Kapitalausgaben.

-

Niedrigere Verderbsraten - Schutz der Gewinnmargen und der Markenreputation.

Wo Tempk Packs fügen zusätzlichen Wert hinzu

-

Verlängerte Haltezeit - ein proprietärer PCM -Kern (Wärmeleitfähigkeit ≤ 2.3 MW M⁻¹ K⁻¹) Hält 2–8 ° C fast doppelt so lang wie Standardgelpackungen, Perfekt für Mehrfach-Stop-Lieferrunden.

-

Haltelige Hütten für Lebensmittelqualität -punktressistentes HDPE mit Ultraschalldichtungen überlebt schwere Klopfe, bleibt jedoch vollständig recycelbar.

-

Schnelles Einfrieren -Optimiertes Verhältnis von Massen zu Oberfläche bedeutet, dass Packungen für die nächste Schicht in weniger als vier Stunden bei –25 ° C bereit sind.

-

Performance-Nachweis -Jedes Produktionslose verlässt das CNAS-akkreditierte Labor von Tempk mit digitalem Schmelzkreis und Lecketestszertifikaten, Staffeln von Kundenprüfungen.

-

Nachhaltigkeit eingebaut -Recycled-Resin-Inhalt bis zu 50 % und ein optionales Take-Back-Programm kann Einweg-Plastikmüll durchschneiden 70 %.

Egal, ob Sie eine landesweite Mahlzeit-Kit, Tempks Eisbeutel geben kühle Taschen die Ausdauer, die sie brauchen - Mile nach Meile, Ausflug nach dem Ausflug.