Isolierte Lebensmittelbeutel: Wie Sie wählen 2025?

Zuletzt aktualisiert: Dezember 2025

Insulated food delivery bags help you protect taste, Textur, and safety during the messiest part of delivery: the last mile. Auf realen Strecken, a small delay can turn fries limp, soups leaky, and cold desserts soft. With insulated food delivery bags, you slow temperature change, reduce “arrived cold” complaints, and make packing more repeatable. Many operators see the biggest wins in the first 30–60 minutes—when customer expectations are highest.

This guide will help you understand:

-

How insulated food delivery bags keep meals hot or cold longer (without adding power)

-

Which insulated food delivery bags work best for pizza, Suppen, and stacked orders

-

A simple insulated food delivery bags sizing guide that reduces wasted air space

-

How long do insulated delivery bags keep food hot An dein Routen (test method included)

-

An insulated food delivery bags cleaning routine that stops odors and callbacks

Why are insulated food delivery bags essential in 2025?

Insulated food delivery bags are essential because they turn unpredictable delivery time into consistent food quality. When quality is consistent, you get fewer refunds, fewer remakes, and better repeat orders.

Isolierte Lebensmittellieferbeutel

Think of insulated food delivery bags like a “thermos for your menu.” They don’t cook food or chill food. They simply slow heat transfer so your meal arrives closer to “just served.” That extra buffer time matters when drivers face traffic, Aufzüge, or stacked stops.

How insulated food delivery bags reduce refunds and remakes

| Where you lose money | What happens in delivery | What insulated food delivery bags change | Was es für Sie bedeutet |

|---|---|---|---|

| Refunds + chargebacks | “Arrived cold/melted” | Slower temperature swing | Fewer disputes, steadier margin |

| Remakes during rush | Quality varies by route | More predictable outcomes | Less chaos at peak time |

| Bad reviews | Texture fails fast | Better hot/cold separation | Higher ratings, more repeats |

Praktische Tipps, die Sie heute verwenden können

-

Treat insulated food delivery bags as a quality-control tool, not a “nice-to-have.”

-

Stage orders inside the bag at handoff to reduce “door-open time.”

-

Replace worn bags before they fail—zippers and liners usually go first.

Isolierte Lebensmittellieferbeutel

Beispiel für reale Welt: One operator reduced temperature complaints after upgrading insulated food delivery bags and enforcing “bag closed between stops.”

Isolierte Lebensmittellieferbeutel

How do insulated food delivery bags protect temperature and texture?

Insulated food delivery bags protect food by reducing heat transfer using layered materials that trap air. Air is a poor heat conductor, so trapped air slows temperature change.

Isolierte Lebensmittellieferbeutel

In einfachen Worten, insulated food delivery bags create a small “micro-environment.” The outer layer blocks wind and weather. The middle layer slows heat flow. The inner layer often reflects heat and resists moisture so cleanup is easier.

Insulation layers explained without the physics

| Layer or material | Was es bewirkt | Am besten für | Was es für Sie bedeutet |

|---|---|---|---|

| Foam padding | Verlangsamt die Wärmeübertragung | Short to medium routes | Licht, affordable performance |

| Reflective lining | Reflektiert strahlende Wärme | Hot meals | Better heat stability when sealed |

| Multi-layer composite | Higher overall insulation | Längere Strecken / Mischbeladungen | Better consistency, slightly bulkier |

Praktische Tipps und Empfehlungen

-

Thicker insulation = longer hold time, but packing can be slower.

-

Tighter closures = better temperature control, but can trap steam for fried food.

-

Structure matters: stiff walls protect pizza boxes and stacked bowls.

Isolierte Lebensmittellieferbeutel

Beispiel für reale Welt: Pizza programs improved presentation by switching to stiffer insulated food delivery bags with flat bases.

Isolierte Lebensmittellieferbeutel

What temperature targets should insulated food delivery bags support?

Your insulated food delivery bags should support clear “hot stays hot, cold stays cold” targets—especially for time/temperature control foods. Many operators use common benchmarks like cold near 41°F (5°C) oder unten Und hot near 135°F (57°C) oder höher, then confirm local requirements for their region.

Isolierte Lebensmittellieferbeutel

The practical point is not the number—it’s the habit. Delivery is full of tiny delays. Insulated food delivery bags buy you time, but only if you pack and close them consistently.

Schnelles Entscheidungstool: temperature control or time control?

Use this simple rule for your delivery lanes:

-

If you can reliably keep items heiß oder kalt with insulated food delivery bags → use temperature control + spot checks.

-

If you cannot hold temperature reliably → consider time-based controls only if your local rules allow it, and discard after the allowed limit.

| Control strategy | What you manage | Am besten für | Was es für Sie bedeutet |

|---|---|---|---|

| Temperaturregelung | “Stay hot or stay cold” | Most delivery programs | More consistent quality |

| Time control | “Serve/discard by time” | Planned service windows | Requires written procedures |

Praktische Tipps, die Sie heute verwenden können

-

Hot foods: pre-warm the insulated food delivery bags in a warm staging area (not on a heater).

-

Cold foods: use cold sources and keep them away from engine heat.

-

Mixed orders: verwenden two insulated food delivery bags (one hot, one cold) wann immer möglich.

Isolierte Lebensmittellieferbeutel

Which insulated food delivery bags are best for pizza, Suppen, and mixed orders?

The best insulated food delivery bags match your menu’s “failure mode.” Pizza fails when boxes bend and steam collapses the crust. Soups fail by tipping and leaking. Fried foods fail when steam gets trapped.

Isolierte Lebensmittellieferbeutel

If you buy one “universal” option, you often overpay and still lose quality. Stattdessen, match bag style to your most common order patterns.

Bag type comparison for your delivery model

| Bag type | Am besten für | Schwachstelle | Was es für Sie bedeutet |

|---|---|---|---|

| Backpack insulated bag | Bike delivery, stairs | Can crush delicate items | Fast movement, hands-free |

| Soft-sided zip bag | Mixed hot meals | Can sag if overloaded | Great starter option |

| Pizza-specific carrier | Flat boxes | Less flexible | Best insulated food delivery bags for pizza |

| Hard-shell insulated box | Gastronomie, hält länger | Höhere Vorabkosten | Maximum stability |

| Hybrid designs | Mixed fleets | Braucht Schulung | Flexible across routes |

Praktische Tipps und Empfehlungen

-

Pizza: choose stiff walls + flat base + minimaler Kopfraum.

-

Soups and sauces: prioritize rigid structure and upright packing rules.

-

Mixed hot/cold: don’t “share air.” Two bags beat one mega-bag.

Isolierte Lebensmittellieferbeutel

Beispiel für reale Welt: A ramen brand reduced spills after adding rigid inserts and enforcing a no-tilt loading rule.

Isolierte Lebensmittellieferbeutel

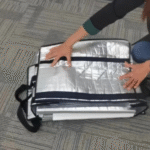

How to right-size insulated food delivery bags with a simple sizing guide

Right-sizing insulated food delivery bags is one of the fastest upgrades you can make. Extra air space is wasted money because it accelerates temperature change and encourages sloppy stacking.

Isolierte Lebensmittellieferbeutel

A smaller bag that fits well often outperforms a larger bag holding the same food. You also pack faster when items “lock in” neatly.

Insulated food delivery bags sizing guide (3 Schritte)

-

Measure your top containers (Länge × Breite × Höhe).

-

Add 10–15% clearance for quick loading and removal.

-

Standardize two sizes max for daily operations.

Isolierte Lebensmittellieferbeutel

Entscheidungstool: pick your size in 60 Sekunden

Answer these:

-

Are orders mostly Wohnung (Pizza) oder tall (bowls, Suppen)?

-

Do you often carry two orders at once during rush?

-

Do drinks travel in the same trip?

If flat: pizza carrier + small side bag

If tall: medium vertical bag with a firm base

If stacked routes: two medium insulated food delivery bags (heiß + kalt)

How long do insulated delivery bags keep food hot?

Most insulated food delivery bags maintain usable quality for roughly 30–90 minutes, Abhängig von der Isolierung, closure discipline, und Wetter. For many hot meals, the “45–60 minute” window is realistic when bags stay closed. Cold items often need extra cold sources and strict separation.

Isolierte Lebensmittellieferbeutel

Instead of guessing, test your real lanes. This turns insulated food delivery bags into a repeatable system.

Howto: the 7-step route test for insulated food delivery bags

-

Pick one common heiß item and one common kalt item.

-

Record starting condition (temperature if possible, or photo + Notizen).

-

Pack exactly like a real dispatch.

-

Lauf a 30-Minute route simulation (car or bike).

-

Record end condition (photo + Notizen).

-

Repeat with a different bag or packing layout.

-

Choose the setup that meets quality goals at the lowest cost.

Isolierte Lebensmittellieferbeutel

Route Test Log (kopieren/einfügen)

-

Date/time:

-

Ambient conditions:

-

Bag type/size:

-

Closure used (zip/flap/hybrid):

-

Hot item outcome (Dampf, crispness, Textur):

-

Cold item outcome (melt, Kondensation, firmness):

-

Notizen:

| Test category | What you check | “Good” looks like | Was es für Sie bedeutet |

|---|---|---|---|

| Heat retention | Pommes, Reis, pizza base | still enjoyable | better ratings |

| Feuchtigkeitskontrolle | soggy boxes, coatings | minimal soggy bottom | weniger Beschwerden |

| Cold protection | Desserts, Salate | no melt puddles | weniger Abfall |

| Handling speed | load/unload | schnell, no fumbling | more orders/hour |

How to pack insulated food delivery bags to prevent spills and sogginess

Packing insulated food delivery bags is a skill, not an afterthought. Your goals are stability (no tipping), separation (hot vs cold), and smart airflow control (reduce heat loss without trapping steam).

Isolierte Lebensmittellieferbeutel

The stacking order that saves meals

-

Wohnung, heavy base: sturdy bowls and sealed containers

-

Leak-prone items centered: soups upright, supported by rigid inserts

-

Crisp items away from steam: fried items on top or in a vent-friendly zone

-

Cold items isolated: desserts/salads/sushi in a cold-only bag

| Packing mistake | Was geschieht | Better move | Was es für Sie bedeutet |

|---|---|---|---|

| Soup on the edge | tips and leaks | Center + rigid base | cleaner delivery |

| Fries under hot bowls | steam damage | separate/vent | better texture |

| Cold dessert with hot meal | warms/melts | two bags | better reviews |

Praktische Tipps und Empfehlungen

-

Close the bag between stops. Open air rides kill performance.

-

Separate drinks. Drinks ruin presentation faster than temperature does.

-

Use dividers only if staff truly uses them. Ansonsten, they slow packing.

Isolierte Lebensmittellieferbeutel

Beispiel für reale Welt: A chicken shop improved crispness by using “no stacking on fried items” rules inside insulated food delivery bags.

Isolierte Lebensmittellieferbeutel

How to clean insulated food delivery bags and stop odors

Insulated food delivery bags often fail because of hygiene, not insulation. A bag can hold temperature well and still damage your brand if it smells. Odor usually comes from trapped moisture and residue.

Isolierte Lebensmittellieferbeutel

Your goal is a routine that is quick, konsistent, and easy to enforce.

Insulated food delivery bags cleaning routine: a simple SOP

-

Remove crumbs, packets, und Einlagen.

-

Wipe the liner with warm soapy water (or approved cleaner).

-

Wipe handles, Nähte, and zippers.

-

Air-dry fully with the bag open.

-

Log damage (cracked liner, torn seams, sticky zipper).

Isolierte Lebensmittellieferbeutel

| Cleaning habit | Gute Praxis | Bad practice | Was es für Sie bedeutet |

|---|---|---|---|

| Trocknen | offen + Luftstrom | closed overnight | odor and mold risk |

| Spill response | wipe immediately | “later” cleaning | stains and smells |

| Inspektion | weekly seam check | ignore small tears | shorter bag life |

Beispiel für reale Welt: Odor complaints dropped after a team added an “open-dry rack” near dispatch.

Isolierte Lebensmittellieferbeutel

How to standardize insulated food delivery bags for scale

Scaling insulated food delivery bags means making outcomes predictable across people and shifts. Fewer options, clearer rules, fewer “personal styles.”

Isolierte Lebensmittellieferbeutel

Start with three standards:

-

Bag assignment: who carries what (hot vs cold)

-

Packing layout: heavy bottom, liquids upright, crisp protected

-

Ausnahmen: what to do for oversized orders (no improvising)

Self-test: Are your insulated food delivery bags “system-ready”?

Gib dich selbst 1 point for each “yes”:

-

You use separate insulated food delivery bags for hot and cold items.

-

Bags stay closed between stops.

-

You have a spill-proof standard for soups and sauces.

-

You follow a cleaning schedule and dry bags open.

-

New hires can pack correctly after 15 minutes of training.

Isolierte Lebensmittellieferbeutel

Punktzahl:

-

0–2: High refund risk

-

3–4: Solid program

-

5: Scalable program

How to budget and calculate ROI for insulated food delivery bags

ROI from insulated food delivery bags comes from fewer failures, not cheaper purchase price. A “cheap” bag becomes expensive if it causes refunds. A higher-quality bag can be cheaper if it lasts longer and reduces complaints.

Isolierte Lebensmittellieferbeutel

A simple cost-per-delivery model

Cost per delivery (bag only) =Bag cost ÷ expected deliveries before replacement

Then estimate value:

Savings per delivery =(old refund rate − new refund rate) × average refund cost

If savings exceed cost-per-delivery, the upgrade pays for itself.

| Eingang | Lower case | Higher case | Was es für Sie bedeutet |

|---|---|---|---|

| Bag lifespan | 300 Lieferungen | 800+ Lieferungen | longer life lowers unit cost |

| Refund rate | 2% | 5%+ | higher failure lanes benefit more |

| Avg refund cost | klein | groß | premium menus justify better gear |

2025 trends in insulated food delivery bags

In 2025, operators are optimizing insulated food delivery bags for Geschwindigkeit, separation, und wiederverwenden. The winning teams treat the bag as part of an operating system: packing rules, hot/cold split, wipe-down routines, and route testing.

Isolierte Lebensmittellieferbeutel

Latest developments to watch

-

Lighter insulation foams: similar performance with less driver fatigue

-

Modular compartments: faster hot/cold separation for mixed orders

-

Cleaner liners: faster wipe-down, fewer odor complaints

-

More “two-bag workflows”: one hot, one cold for reliable outcomes

Isolierte Lebensmittellieferbeutel

Häufig gestellte Fragen

Q1: How long do insulated delivery bags keep food hot?

Oft 45–60 Minuten when bags stay closed, but route time, Wetter, and packaging change results. Run the 7-step route test to be sure.

Isolierte Lebensmittellieferbeutel

Q2: Do I need separate insulated food delivery bags for hot and cold items?

If you deliver mixed orders often, Ja. Separation reduces melt, sogginess, and complaints.

Q3: Are insulated food delivery bags waterproof?

Einige sind es. Look for a wipe-clean liner and leak-resistant seams to reduce odors and turnaround time.

Isolierte Lebensmittellieferbeutel

Q4: What are the best insulated food delivery bags for pizza?

Choose a pizza carrier with stiff walls and a flat base so boxes stay flat and presentable.

Isolierte Lebensmittellieferbeutel

Q5: What size insulated food delivery bags should I buy first?

Beginnen Sie mit two sizes based on your top orders. Right-sized bags often outperform oversized bags.

Q6: How do I stop insulated food delivery bags from smelling?

Wipe after spills, clean daily, Und dry open every time. Smell usually means trapped moisture.

Isolierte Lebensmittellieferbeutel

Zusammenfassung und Empfehlungen

Insulated food delivery bags help you protect temperature, Textur, and safety during last-mile delivery. Your biggest wins come from right-sizing, hot/cold separation, closing discipline, and a cleaning routine that keeps liners dry and odor-free. Use the route test to turn “bag opinions” into real results.

Isolierte Lebensmittellieferbeutel

Was als nächstes zu tun ist (CTA)

-

Standardisieren two insulated food delivery bag sizes for daily operations.

-

Run the 7-step route test on your worst-performing menu items.

-

Enforce one hot bag + one cold bag during peak hours.

-

Implementieren Sie die dry-open cleaning SOP and track complaints by category.

Über Tempk

Und Tempk, we focus on practical temperature-control solutions for food delivery and cold chain logistics. We design insulated systems that balance performance, Haltbarkeit, and real-world usability—so your team packs faster, spills less, and delivers more consistent quality.

Isolierte Lebensmittellieferbeutel

Nächster Schritt: Share your menu type, average delivery time, and top order sizes, and we’ll help you map a simple insulated food delivery bags standard your staff can follow this week.