Aktualisiert: Januar 6, 2026

Insulated Box Supplier for Cold Chain Logistics?

Wenn Sie sich für eine entscheiden insulated shipping box supplier Kaltkettenlogistik teams can trust, you’re buying repeatable protection—not “a box.” Your lane will face real temperature swings, and ISTA’s 7E thermal profiles are built from real-world parcel transport data, not lab daydreams. A high-performance option like VIP insulation can deliver extremely low thermal conductivity (um 0.004 W/(m·K) in pristine condition), but only if the full system is designed and handled correctly.

Dieser Artikel hilft Ihnen bei der Beantwortung:

-

How to use an insulated shipping box supplier cold chain logistics selection checklist that fits your lanes

-

What specs to define so your insulated shipping box supplier cold chain logistics quote is measurable, not vague

-

How to compare EPS, EVP, Pu, and VIP for insulated shipping box supplier cold chain logistics for 2–8°C shipments

-

What “proof” matters most in insulated shipping box supplier cold chain logistics performance testing (BELIEBIG + ASTM)

-

How to audit, Pilot, and scale an insulated shipping box supplier cold chain logistics program without surprises

How do you choose an insulated shipping box supplier cold chain logistics teams can trust?

Choose the supplier that matches your lane and proves it with repeatable results. A good insulated shipping box supplier cold chain logistics partner controls tolerances, documents tests, and gives you a trainable pack-out SOP. ISTA’s thermal standards exist because parcel lanes vary daily, and 7E provides a comparable profile language for thermal performance.

To keep this simple, define success first. Write your temperature band, Dauer, worst-case ambient exposure, and acceptable damage rate. Then compare suppliers on evidence, keine Versprechen. This aligns with Google’s “helpful, zuverlässig, people-first content” principle: clarity beats hype, and specifics beat slogans. Google for Developers

A selection checklist you can use in an RFQ

| Supplier factor | What to ask for | Wie „gut“ aussieht | Was es für Sie bedeutet |

|---|---|---|---|

| Lane fit | Similar products + similar durations | Real use cases + clear limits | Fewer surprises after scale |

| Nachweisen | Thermal traces + pack-out SOP | Multiple sensors + repeat runs | Fewer temperature disputes |

| Qualitätskontrolle | Lot coding + dimensional checks | Schriftliche Verfahren + Änderungskontrolle | Less “random” variation |

| Liefersicherheit | Lead time history + peak plan | Stable dates + safety stock options | Weniger Fehlbestände |

| Unterstützung | Escalation path + validation help | One owner + quick response | Faster fixes |

Praktische Tipps und Vorschläge

-

Wenn Sie wöchentlich versenden: standardize 1–2 shipper sizes and lock one SOP per lane.

-

If you ship mixed climates: require seasonal pack-outs (Sommer + Winter), not one “universal” setup.

-

If you ship high-value goods: pay for validation evidence, nicht nur dickere Wände.

Beispielszenario: A team blamed carriers for warm arrivals, but the real issue was lid-fit variation. After adding incoming lid-fit checks and tightening change control, Ausflüge entfallen.

What specs should you request from an insulated shipping box supplier cold chain logistics partner?

The fastest way to stabilize an insulated shipping box supplier cold chain logistics program is to request specs you can verify at receiving and on the packing line. If you only ask “How many hours does it last?” you will get marketing answers. Ask for measurable definitions: Abmessungen, Toleranzen, Materialien, Verschlussmethode, outer carton strength, and the exact test profile.

Auch, define hold time correctly. ISTA 7E profiles are meant to represent parcel exposures; ASTM methods help you test distribution hazards that cause cracking, Lecks, and crushed corners. Internationaler Verband für sichere Transporte+2ASTM International | ASTM+2

Define hold time the right way (and avoid “lab fantasy”)

Include these five items in your URS (user requirements spec):

-

Zieltemperaturbereich (2–8 ° C, 15–25°C, ≤ -18°C)

-

Umgebungsprofil (include peaks + verweilen + Zeit vor der Haustür)

-

Dauer (24/48/72/96 Std.)

-

Nutzlast (Masse, Geometrie, fill level, “must not freeze” risks)

-

Pass/fail criteria (time-in-range, max/min limits, Logger -Standorte)

| Spec you request | Beispiel | Warum ist es wichtig | Was es für Sie bedeutet |

|---|---|---|---|

| Temp-Band | 2–8 ° C | Defines pass/fail clearly | Less debate in claims |

| Umgebungsprofil | 35°C peak + doorstep wait | Determines heat load | Fewer summer failures |

| Nutzlast | 3 kg, zerbrechlich, “no-freeze” | Drives layout + Puffer | Weniger Produktschäden |

| Packaging tolerance | ±2 mm critical dims | Controls repeatability | Stable thermal curve |

| Kontrolle ändern | Written notice before changes | Prevents silent drift | Weniger Überraschungsausflüge |

Praktische Tipps und Vorschläge

-

Ask for sensor maps: Spitze, unten, Seite, and payload zone—never one sensor only.

-

Ask for pack photos: photos reduce “we packed it differently” arguments.

-

Ask for lot labeling: it makes troubleshooting fast.

Beispielszenario: A chilled product froze occasionally because packs touched the payload. After adding buffers and conditioning rules, damage stopped.

How do materials compare for insulated shipping box supplier cold chain logistics in 2026?

Choose the simplest material system that passes your lane test. Material numbers are useful signals, but system design decides real results. For reference, EPS thermal conductivity is often around 0.028–0.032 W/(m·K) (varies by density and conditions). 材料与产品数据库 VIPs can be around 0.004 W/(m·K) when pristine, but performance depends on edges, puncture risk, und Umgang mit Disziplin. Wissenschaftsexpress

That’s why your insulated shipping box supplier cold chain logistics partner should show system-level traces, not only material datasheets.

Material comparison you can share with QA and finance

| Material | Practical strengths | Practical limits | Best-fit lanes |

|---|---|---|---|

| EPS | Kostengünstig, gemeinsam, easy to scale | Kann knacken; lower reuse | Stable single-use lanes |

| EVP | Hart, wiederverwendbar, impact resistant | Höhere Stückkosten | Return Loops + raues Handling |

| Starres PU | Strong insulation per thickness | End-of-life varies by region | Longer lanes in rigid cases |

| VIP | Highest insulation in thin walls | Needs protection + careful design | Lange hält, tight bands, hoher Wert |

Praktische Tipps und Vorschläge

-

If freight cost is high: higher insulation can reduce coolant weight and total spend.

-

If damage claims are high: durability improvements often beat “more gel packs.”

-

If compliance evidence is required: pick the system that’s easiest to validate and repeat.

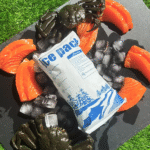

Beispielszenario: A seafood lane improved after upgrading insulation and reducing coolant mass, lowering both weight and temperature swings.

What testing should your insulated shipping box supplier cold chain logistics program provide in 2026?

Testing is your insurance policy. A credible insulated shipping box supplier cold chain logistics partner can explain thermal testing, Wiederholbarkeit, and distribution hazard testing in plain language. ISTA STD-7E is designed for thermal transport packaging in parcel systems and uses hot/cold profiles developed from real-world transport data.

For physical hazards, ASTM D4169 provides a structured approach to distribution cycles using established methods at levels representing real distribution. ASTM International | ASTM ASTM D5276 covers free-fall drop testing of loaded containers—critical because many “thermal failures” start as impact damage. ASTM International | ASTM

A minimum viable validation plan (Thermal- + Verteilung)

1) DQ (Designqualifikation): Write URS + lane assumptions.

2) OQ (Betriebsqualifikation): Lab test under chosen profile(S), with repeat runs.

3) PQ (Leistungsqualifizierung): Pilot in real shipments or realistic simulations.

WHO’s guidance on shipping container qualification describes DQ, OQ, and PQ as sequential stages for proving a container system is fit for use. WHO also emphasizes route profiling as a prerequisite for representative OQ/PQ because it lets you build realistic ambient profiles.

Praktische Tipps und Vorschläge

-

Run repeats: do at least three runs; variability matters as much as averages.

-

Test worst hot + worst cold: protect against melt and freeze.

-

Test after drops: impacts can change lid fit and thermal behavior.

-

Sperren Sie die SOP: if anything changes (Kasten, Band, Kühlmittel, Liner), erneut testen.

Beispielszenario: A shipper “passed” once in mild conditions, then failed in heat. Requiring a peak profile fixed the gap.

How do you audit an insulated shipping box supplier cold chain logistics program like a pro?

Audit process discipline, not factory tours. A strong insulated shipping box supplier cold chain logistics audit checks traceability, dimensional control, sealing quality, Dokumentation, and change control. This matters because “silent changes” can shift your thermal curve without warning.

If you ship pharma or want pharma-grade rigor, EU GDP guidance focuses on maintaining product quality and integrity across the distribution chain. EUR-Lex Even if you’re not regulated, customers may demand GDP-like evidence.

Supplier reliability scorecard (simple scoring)

Bewerten Sie jedes Element 0–2 (0 = fehlt, 1 = teilweise, 2 = strong).

| Audit area | Was zu überprüfen | What it protects | Punktzahl (0–2) |

|---|---|---|---|

| Materials control | Incoming inspection + Loscodes | Chargenkonsistenz | |

| Dimensional stability | Critical tolerances + fit checks | Repeatable pack-outs | |

| Kontrolle ändern | Written notice + approvals | No surprise drift | |

| Testing maturity | ISTA profile literacy + logger maps | Valid claims | |

| Kapazitätsplanung | Peak season plan + lead time history | No stockouts |

Praktische Tipps und Vorschläge

-

Require raw traces: a “pass” statement is not enough.

-

Ask for version control: SOP and BOM must have versions.

-

Add receiving checks: Deckel passt + key dimensions catch issues early.

Beispielszenario: A team saw sporadic failures after a material change. A strict change-notice rule prevented repeat issues.

How do you standardize pack-outs so insulated shipping box supplier cold chain logistics performance repeats daily?

Your box is only half the system. The other half is coolant + Auspackdisziplin. The best insulated shipping box supplier cold chain logistics programs ship “lane kits” with photo SOPs, so packers don’t improvise. WHO describes passive containers as insulated enclosures using a finite amount of preconditioned Kühlmittel, meaning conditioning rules must be written and repeatable.

Wenn Sie mit Trockeneis versenden, packaging must permit CO₂ gas release to prevent pressure build-up—this requirement appears in IATA packing instructions and U.S. Gefahrstoffvorschriften.

Pack-out elements to lock before you scale

| Auspackelement | Standardize this | Warum ist es wichtig | Was es für Sie bedeutet |

|---|---|---|---|

| Kühlmitteltyp + Masse | One rule per lane | Prevents guessing | Stable cost + weniger Fehler |

| Platzierungskarte | Photo-based layout | Avoids hot corners | Fewer complaints |

| Buffer materials | No direct contact zones | Prevents freeze damage | Schützt empfindliche Güter |

| Conditioning rules | Zeit + Standort | Controls starting temp | Better repeatability |

| Pack time limit | Door-open max time | Reduces drift | More consistent outcomes |

Praktische Tipps und Vorschläge

-

Build two SOPs: one for summer, one for winter, even with the same box.

-

Use kitting: Kasten + Liner + Kühlmittel + insert as one pickable set.

-

Limit “packer creativity”: variability is the enemy of cold chain.

Beispielszenario: After switching to a one-page photo SOP, a team saw steadier logger traces and fewer escalations.

Interaktives Entscheidungstool: Which insulated shipping box supplier cold chain logistics option fits your lane?

Answer these in order and follow the recommendation.

Schritt 1 — Temperature band

-

A: 2–8 ° C (gekühlt)

-

B: 15–25°C (CRT)

-

C: ≤ -18°C (gefroren)

-

D: Trockeneis (deep cold)

Schritt 2 — Duration

-

0- 24 Stunden / 24-48h / 48-72H / 72H+

Schritt 3 — Shipping mode

-

Paket: use ISTA STD-7E thermal profiles as a baseline for comparison.

-

Fracht: use route profiling + distribution simulation (ASTM D4169) + drop testing (ASTM D5276).

Schritt 4 — Return loop?

-

NEIN: favor simpler single-use designs that still pass validation.

-

Ja: favor durable reuse-ready bodies (often EPP) plus cleaning/asset rules.

Quick output guidance

-

Heiß + 48-72H: Isolierung verbessern vor adding coolant mass.

-

Must not freeze: add buffers + placement control, then validate cold-worst-case.

-

High damage lanes: prioritize structure and post-drop thermal checks.

Self-assessment score (0–12)

Add points if true:

-

You have stable lanes and stable box sizes (+2)

-

You can condition coolant consistently (+2)

-

You use temperature logging (+2)

-

Products are high-value/high-risk (+2)

-

You can enforce a pack SOP (+2)

-

You have long doorstep exposure (+2)

Score-Bedeutung

-

10–12: invest in a high-control supplier + lane validation now

-

6–9: standardize pack-outs first, then upgrade materials

-

0–5: fix workflow basics before spending on premium insulation

2026 latest insulated shipping box supplier cold chain logistics trends

In 2026, buyers are converging on one idea: repeatability beats overpacking. ISTA’s thermal standards push more standardized “profile language” so suppliers can be compared apples-to-apples. Gleichzeitig, qualification language (DQ/OQ/PQ) is spreading beyond pharma because it reduces arguments and speeds approvals.

Aktueller Fortschritts-Snapshot

-

More lane-based pack-outs: fewer “one-size-fits-all” designs

-

More documented SOPs: photo instructions become standard training

-

More compliance-friendly evidence: customers ask for traceability and validation

-

More cost-per-protected-shipment thinking: fewer refunds beats cheaper cartons

Market insight

Food shippers also face “sanitary transportation” expectations that emphasize preventing risky practices like failure to properly refrigerate and inadequate cleaning. UNS. Food and Drug Administration When your insulated shipping box supplier cold chain logistics program supports documentation, you buy confidence—not just packaging.

Häufig gestellte Fragen

Q1: What should I ask an insulated shipping box supplier cold chain logistics vendor before ordering?

Ask for measurable specs (dims, Toleranzen), raw thermal traces, test profiles used (Z.B., BELIEBIG), and a written pack-out SOP. Require repeat runs and clear pass/fail criteria to avoid “one lucky pass.”

Q2: Is ISTA STD-7E necessary for every shipment?

It’s most relevant for parcel lanes because it targets parcel delivery thermal exposures using standardized profiles. For freight, route profiling plus distribution hazards testing may fit better.

Q3: What tests reduce cracked corners and wet cartons?

Use distribution simulation (ASTM D4169) plus drop testing (ASTM D5276) with real payload mass and worst-case orientations. Many thermal failures start after physical damage. ASTM International | ASTM+1

Q4: How do I avoid freezing chilled products (2–8 ° C)?

Prevent direct contact between frozen packs and product, add buffer layers, and standardize conditioning rules. Validate cold-worst-case, not only hot-worst-case, then train packers on a photo SOP.

Q5: What’s the biggest hidden risk when switching suppliers?

Silent variation: small changes in foam density, Abmessungen, or lid fit can change your thermal curve. Require written change control and lot traceability, then retest after any change.

Q6: If I ship with dry ice, what must packaging do?

It must allow CO₂ gas to vent so pressure cannot build up and rupture the packaging. Add venting guidance and labeling steps to your SOP.

Zusammenfassung und Empfehlungen

Choosing an insulated shipping box supplier cold chain logistics teams can trust is about repeatable protection. Define your lane and success criteria, request measurable specs, and compare suppliers using thermal traces—not claims. Use ISTA profiles for parcel lanes and add ASTM hazard tests to prevent damage-driven excursions. Standardize pack-outs with photo SOPs and change control so performance stays stable all year.

Next-step action plan (7 Tage)

-

Write a one-page URS (temp band, Dauer, Ambient, Nutzlast).

-

Shortlist 2–3 supplier candidates and request raw test evidence.

-

Run a mini pilot (3 repeats) mit Holzfällen + Fotos.

-

Lock one SOP per lane and add receiving checks.

-

Scale only what your team can repeat.

Über Tempk

Bei Tempk, we help cold chain teams build packaging systems that perform the same way every day—because consistency is what reduces claims. We support lane-based insulated shipper design, pack-out SOPs your warehouse can follow, and validation-ready documentation for audits and customer reviews. Our focus is practical: stable dimensions, controlled materials, klare Änderungskontrolle, and test plans aligned to real distribution risks.

CTA: Teilen Sie Ihr Temperaturband, Dauer, Versandart, und im schlimmsten Fall der Umgebungsexposition, and we’ll help you build a lane-ready validation plan.