Wie schützt die pharmazeutische Kühlkettenlagerung die Wirksamkeit von Arzneimitteln??

Pharmaceutical cold chain storage keeps drugs in precise temperature ranges to preserve their efficacy and safety. In 2024 the global pharmaceutical cold chain market was worth about US$6.4 billion and is expected to exceed US$6.6 billion in 2025l. Mehr als 85 % of biologics require temperature controlled handlingl, and poor storage practices cause up to 50 % of vaccines to be wasted each year. Durch das Verständnis der Temperaturkategorien, Überwachungstechnologien, Verpackungslösungen und regulatorische Anforderungen, Du can protect product potency, Abfall reduzieren und einhalten 2025 Standards.

Why pharmaceutical cold chain storage matters and what temperatures are required – explore categories like refrigerated (2–8 ° C), gefroren (–20 ° C.) und kryogen (–80°C bis –150°C).

How temperature ranges affect different therapies – learn why biologics, Impfungen, peptides and cell and gene therapy products require specific cold chain conditionsl.

Which technologies improve monitoring and visibility – compare data loggers, IoT -Sensoren, RFID, GPS und intelligente Kühlcontainer und entdecken Sie, wie sie funktionieren.

How packaging solutions protect temperature sensitive products – examine phase change materials, vacuum insulation and smart containers.

What regulations and compliance strategies apply – understand GDP, GMP, USP and ICH guidelines.

How to mitigate risks and handle temperature excursions – apply real time alerts and contingency planning to prevent degradation and losses.

Which trends and innovations will shape 2025 – explore blockchain, Ai, IoT, sustainability and portable cryogenic freezers.

What Is Pharmaceutical Cold Chain Storage and Why Is It Essential?

Direct answer – keeping medicines safe and effective. Pharmaceutical cold chain storage refers to a temperature controlled system spanning storage, Handhabung, Verpackung, Transport und Überwachungl. It ensures that temperature sensitive medicines stay within defined ranges—from controlled room temperature (20–25 ° C.) gekühlt werden (2–8 ° C) and cryogenic storage below –60 °C to –150 °Cl. Without these conditions, Biologika, vaccines and peptides degrade, becoming ineffective or even hazardous.

Expanded explanation – seeing the whole chain. Stellen Sie sich die Kühlkette als einen Staffellauf vor: Rohstoffe, Zwischen- und Fertigprodukte are passed from one temperature controlled “runner” to the next, and any misstep breaks the chain. For contract development and manufacturing organisations (CDMOs), this means integrated infrastructure, specialized equipment like cryogenic freezers, real time monitoring systems and validated processesl. CDMOs coordinate with logistics partners to keep products cold from manufacturing through distribution, ensuring chain of custody documentation and regulatory compliancel. Für dich, understanding these elements translates into fewer excursions, safer products and better patient outcomes.

Temperaturkategorien: understanding storage ranges

Different drugs require distinct temperature ranges. Regulatory guidelines like USP 659 define temperature terms precisely: Gefrierschrank (–25 °C bis –10 °C), Kühlschrank (2 ° C bis 8 °C), kalt (≤8 °C), Cool (8 ° C bis 15 °C), room or ambient (typical working environment) Und kontrollierte Raumtemperatur (20 ° C bis 25 °C). Der ICH Q1A stability guideline specifies refrigerator storage at 5 ± 3 °C and freezer storage at –20 ± 5 °C. Understanding these categories helps you plan storage and transport.

| Temperaturkategorie | Reichweite | Beispiele | Was es für Sie bedeutet |

| Gefrierschrank | –25 °C bis –10 °C | Viele Biologika, Bestimmte Impfstoffe, frozen intermediates | Requires ultra low freezers, backup power and continuous monitoring |

| Kühlschrank | 2 ° C bis 8 °C | Standardimpfstoffe, Insulin, Peptide | Use monitored refrigerators with buffered probes and avoid freezing |

| Kalt | ≤ 8 °C | Temperature controlled storage and transport | Maintain within 2–8 °C; deviations can spoil vaccines |

| Cool | 8 ° C bis 15 °C | Some diagnostic reagents | Manage moderate cooling without freezing |

| Kontrollierte Raumtemperatur | 20 ° C bis 25 °C | Tabletten, capsules, einige Biologika | Prevent heat spikes and humidity; monitor environmental conditions |

Praktische Tipps und Anleitungen

Document temperature requirements early. Record temperature ranges for all ingredients, intermediates and finished products to prevent later confusion.

Trainiere dein Team. Everyone handling cold chain products should understand storage requirements; poor training is a major cause of failures.

Planen Sie Ihre Kühlkette. Analyse every transfer point—from manufacturing to last mile delivery—to identify potential hotspots where temperature excursions can occur.

Wirklicher Fall: Während der Einführung von COVID 19, mRNA vaccines required ultra cold storage between −90 °C and −60 °C. Companies that invested early in ultra low freezers and validated shipping containers avoided spoilage and met demand.

How Do Temperature Ranges Affect Pharmaceutical Stability?

Direct answer – temperature dictates potency. Exposing drugs to temperatures outside their specified range degrades active ingredients, shortens shelf life and can make products unsafe. Standard vaccines must remain between 2 °C und 8 °C, while mRNA vaccines need –60 °C to –90 °C. Bis zu 50 % der Impfstoffe werden verschwendet each year due to temperature excursions, causing billions of dollars in losses and endangering public health.

Expanded explanation – matching therapies with conditions. The cold chain serves an expanding array of therapies. Biologika—monoclonal antibodies, recombinant proteins and biosimilars—make up more than half of the late stage pipeline; um 85 % require cold chain managementl. Impfungen are extremely temperature sensitive; mRNA vaccines need ultra cold storage (−60 °C to −80 °C)l, while many traditional vaccines must be kept at 2 ° C bis 8 °C. Zell- und Gentherapien require cryogenic storage at –150 °C or lowerl, and their short half life makes seamless cold chain logistics essential. Peptides and proteins, such as GLP 1 agonists for diabetes and obesity, must stay refrigeratedl. Specialty products like insulin, blood coagulation factors and certain antibiotics also depend on cold storagel.

Common temperature sensitive therapies

| Therapietyp | Temperaturbereich | Risks if not maintained | Warum ist es wichtig |

| Biologika (monoklonale Antikörper, recombinant proteins) | Refrigerated 2–8 °C to cryogenic –60 °Cl | Loss of potency and structural integrity; immunogenicity | Über 85 % von Biologika require cold chain managementl |

| Impfungen | Standardimpfstoffe: 2–8 ° C; mRNA: –60 °C bis –80 °Cl | Inactive vaccines, reduced immunity; bis zu 50 % wasted | Protects public health and prevents disease outbreaks |

| Zelle & Gentherapien | Cryogenic –80 °C to –150 °Cl | Cell death, loss of transduction efficiency | Market growth projected to exceed US$81 billion by 2029 |

| Peptides & GLP-1-Agonisten | Refrigerated 2–8 °Cl | Denaturation, reduced therapeutic effect | Rising demand for weight loss drugs increases cold chain needs |

| Specialty pharmaceuticals (Insulin, immunoglobulins, ophthalmic drugs) | Typically 2–8 °Cl | Product degradation leads to ineffective therapy | Patients rely on consistent quality and supply |

Useful guidance for you

Monitor every shipment. Even short exposure outside 2–8 °C can invalidate an entire vaccine batch.

Planen Sie extreme Bedingungen ein. Use cryogenic storage for cell therapies and mRNA vaccines; maintain –150 °C using liquid nitrogen vapour phasel.

Train on product specific protocols. Each therapy has unique stability requirements; always consult manufacturer and regulatory guidelines.

Praxisbeispiel: GLP-1-Agonisten (semaglutide and liraglutide) have created explosive demand; they require refrigerated storage and have spurred significant capacity expansion among CDMOsl.

Which Technologies Improve Cold Chain Monitoring and Visibility?

Direct answer – IoT, data loggers and analytics. Modern pharmaceutical cold chain storage uses Datenlogger, IoT -Sensoren, RFID -Tags, GPS-Tracker, BLE-Sensoren Und Intelligente Kühlcontainer to provide real time temperature and location data. These technologies enhance compliance, speed release processes and reduce waste by enabling immediate corrective actions.

Expanded explanation – building a digital nervous system. Traditional monitoring relied on manual checks or retrieving data loggers after delivery, which could not prevent excursions. Heute, Datenlogger record temperature and humidity over time, providing historical evidence but lacking real time alerts. IoT -Sensoren transmit temperature and humidity data continuously via Wi Fi or cellular networks, offering predictive maintenance and instant notifications. RFID-Temperaturetiketten integrate into pallets and packaging, streamlining inventory management. GPS-Tracker Kombinieren Sie Standort- und Temperaturdaten, enabling route optimisation and real time interventions. BLE-Sensoren deliver short range monitoring for warehouses and vehicles with minimal power consumption. Intelligente Kühlcontainer—refrigerated containers with remote monitoring and self regulating systems—provide reliable long distance transport. All these devices feed data into Cloud-Plattformen that aggregate information, generate compliance reports and drive predictive analytics.

Comparing monitoring solutions

| Überwachungslösung | Schlüsselmerkmale | Vorteile für Sie |

| Datenlogger | Record temperature/humidity; manueller Abruf | Erschwinglich, reliable compliance documentation |

| IoT -Sensoren | Continuous wireless monitoring and alerts | Immediate intervention and predictive maintenance |

| RFID -Tags | Automatische kontaktlose Temperaturmessung | Streamlined inventory and reduced manual handling |

| GPS-Tracker | Kombinieren Sie Standort- und Temperaturdaten | Route optimisation and real time visibility during transit |

| BLE-Sensoren | Kurze Reichweite, low power monitoring | Integrate with mobile devices; Ideal für Lagerhallen |

| Intelligente Kühlcontainer | Self regulating containers with remote monitoring | Stable long distance transport; higher energy cost |

Praktische Tipps und Vorschläge

Wählen Sie einen mehrschichtigen Ansatz. Combine affordable data loggers for compliance with IoT sensors for real time alerts.

Investieren Sie in Cloud-Plattformen. Centralized dashboards simplify monitoring across sites and support predictive analytics.

Use GPS tracking for high value shipments. Real time location and temperature data help you react quickly when deviations occur.

Tatsächlicher Fall: Maersk’s remote container management system collects temperature data during ocean transport and allows shippers to start quality release procedures before cargo arrives. This reduces time to market and prevents stock shortages.

H3 – Smart technologies and blockchain

Emerging innovations are reshaping monitoring. Blockchain creates tamper proof records of temperature conditions throughout the supply chain, synchronizing customs data and simplifying audits. Künstliche Intelligenz (Ai) transforms raw sensor data into predictive insights, forecasting demand spikes, optimising routes and preventing stock outs. IoT-fähige intelligente Sensoren send real time alerts; when unsafe temperatures are detected, notifications via email or SMS allow immediate action. Diese Technologien, kombiniert mit solar powered storage units, provide sustainable solutions for remote areas.

| Technologie | Beschreibung | Value to your operation |

| Blockchain | Distributed ledger that records shipment events and temperature logs | Prevents tampering, increases transparency and facilitates regulatory compliance |

| KI-Routenoptimierung | Algorithms analyse traffic and weather data to plan optimal routes | Reduziert die Transitzeit, Kraftstoffverbrauch und Gefahr von Temperaturschwankungen |

| Intelligente IoT-Sensoren | Sensors transmit real time temperature, Luftfeuchtigkeit und GPS-Daten | Provides continuous monitoring and alerts to protect shipments |

| Solarbetriebener Speicher | Solar panels provide energy for refrigeration in areas with unreliable grids | Reduces energy costs and enables cold storage in remote regions |

| Tragbare kryogene Gefriergeräte | Mobile freezers capable of maintaining –80 °C to –150 °C | Enable field transport of cell therapies and biologics, mit Echtzeitverfolgung |

How Do Advanced Packaging Solutions Protect Temperature Sensitive Drugs?

Direct answer – using phase change materials and smart insulation. Packaging is more than a container; es ist ein thermal device designed to maintain narrow temperature ranges. Phasenwechselmaterialien (PCMs) absorb and release heat during melting or freezing, keeping contents stable without active refrigeration. Fortschrittliche isolierte Versender, Vakuumisolationsgremien (VIPs) and active containers protect pharmaceuticals for hours or days. PCMs offer precise temperature control, längere Kühldauer und Wiederverwendbarkeit.

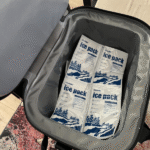

Expanded explanation – from gel packs to smart packaging. Traditional gel packs have been the workhorses of cold chain packaging, but they can fail to maintain narrow ranges over long journeys. PCMs, available as rigid bottles, flexible blankets, weiche Beutel, microencapsulated beads and foam matrices, store thermal energy and release it gradually. Vacuum insulation panels provide high insulation with minimal thickness, ideal for high value shipments. Aktive Container use built in refrigeration units, heaters and batteries to maintain conditions, häufig für Zell- und Gentherapien eingesetzt. Intelligente Verpackungen integrates RFID or BLE sensors to continuously track temperature and location. Nachhaltige Verpackungslösungen, such as biodegradable thermal wraps, recyclable insulation and reusable cold packs, Umweltbelastung reduzieren.

Types of phase change materials and their uses

| PCM-Typ | Beschreibung | Bester Anwendungsfall | Specific benefits |

| Hartflaschen-PCMs | Mit Paraffin gefüllte starre Behälter, Fettsäuren oder Salzhydrate | Long distance shipments requiring secure handling | Provide longer cooling duration and safe handling |

| Pauschale PCMs | Mit PCMs imprägnierte flexible Platten | Odd shaped packages and pallets | Conform to irregular items and offer consistent cooling |

| PCMs mit weicher Tasche | Flexible Beutel mit Paraffin oder Glykolen | Small shipments or packaging around vials | Compact and adaptable |

| Mikroverkapselte PCMs | Winzige PCM-Tröpfchen, eingeschlossen in Polymerhüllen | Integrate into insulation materials or coatings | Offer even temperature distribution |

| Schaum-PCMs | Mit PCMs imprägnierter Schaumstoff | Sorgen Sie für Isolierung und strukturelle Unterstützung | Dual function reduces packaging weight |

Vorteile von PCMs gegenüber herkömmlichen Gelpackungen

Präzise Temperaturregelung: PCMs maintain narrow temperature ranges and minimize excursions.

Längere Kühldauer: PCMs remain effective over extended shipping times.

Wiederverwendbarkeit und Nachhaltigkeit: Many PCMs are non toxic and reusable, Reduzierung von Abfall und Kosten.

Other packaging innovations and recommendations

Vakuumisolationsgremien (VIPs): Bieten Sie eine hervorragende Isolierung bei minimaler Dicke.

Aktive Container: Integrate refrigeration and heating units, making them suitable for ultra cold shipments.

Intelligente Sensoren in Verpackungen integriert: Embed RFID or BLE tags directly into shippers for continuous monitoring.

Nachhaltige Verpackung: Use recyclable insulation and reusable PCMs to reduce environmental footprint.

Tatsächlicher Fall: Die SteadyPac PCMs von TempAid halten präzise Temperaturen aufrecht und können wiederverwendet werden, offering longer cooling duration and eco friendliness compared with traditional gel packs.

What Are the Regulatory Requirements and Compliance Strategies for Cold Chain Storage?

Direct answer – follow GDP, GMP and international standards. Regulatory authorities require pharmaceutical companies to Prozesse validieren, monitor temperatures continuously, document handling Und qualify equipment über die gesamte Kühlkette hinweg. Gute Vertriebspraxis (BIP), Gute Herstellungspraxis (GMP), and national standards (Z.B., FDA, EMA) demand accurate temperature maintenance, Echtzeitüberwachung, secure storage and detailed record keeping. Failure to comply can result in recalls, Bußgelder und Reputationsschäden.

Expanded explanation – understanding guidelines. Der USP-Kapitel 659 defines temperature categories like freezer (–25 °C bis –10 °C) and refrigerator (2 ° C bis 8 °C), offering clear packaging and storage requirements. USP 1079 outlines best practices for storage and transportation, emphasising continuous monitoring, Kalibrierung, backup systems, Gerätequalifizierung, Schulung und Dokumentation. Der ICH Q1A(R2) guideline prescribes 5 ± 3 °C for refrigerators and –20 ± 5 °C for freezers. Der EU-GMP-Anhang 11 Und EU-Verordnung über klinische Studien require validation and data integrity for electronic systems. NIST Und UKAS calibration standards ensure accuracy of monitoring devices.

Regulatory frameworks and key requirements

| Rahmen | Wichtige Anforderungen | Was Sie tun müssen |

| BIP/GMP | Kontinuierliche Überwachung, qualifizierte Ausrüstung, Rückverfolgbarkeit und geschultes Personal | Implement validated systems, record temperatures, Personalbetreuung |

| USP 659 & USP 1079 | Define freezer (–25 °C bis –10 °C), Kühlschrank (2 ° C bis 8 °C) and good storage/shipping practices | Maintain defined ranges, use calibrated devices, document deviations |

| ICH Q1A(R2) | Kühlschrank 5 ± 3 °C; freezer –20 ± 5 °C | Follow defined stability testing conditions for clinical materials |

| EU-GMP-Anhang 11 & BIP | Data integrity and validation of electronic systems | Validate software, maintain audit trails and secure access |

| NIST/UKAS calibration | Calibration of monitoring devices to recognised standards | Regularly calibrate sensors and loggers to ensure accuracy |

Compliance checklist and practical guidance

Maintain accurate temperatures: Keep products within specified ranges (2–8 °C for most vaccines, –20 °C zum Einfrieren, –70 °C or lower for ultra cold).

Nutzen Sie eine kontinuierliche Überwachung: Deploy automated data loggers and real time systems to track temperatures 24/7.

Validate infrastructure: Use certified refrigerators, Gefriergeräte, transport containers and monitoring devices.

Sichere Speicherumgebungen: Control access and use segregated storage areas.

Bereiten Sie Notfallpläne vor: Entwickeln Sie Protokolle für Stromausfälle, equipment failures and temperature excursions.

Personal schulen: Ensure everyone handling cold chain products understands protocols and emergency response.

Dokumentieren Sie alles: Maintain logs of temperature data, calibrations and corrective actions.

Fallstudie: Digitale Datenlogger mit gepufferten Sonden sind mittlerweile der Standard für die Impfstofflagerung in den USA., Gewährleistung einer genauen Messung der minimalen und maximalen Temperaturen. These devices maintain compliance with CDC guidelines and help prevent excursions.

How to Mitigate Risks and Manage Temperature Excursions?

Direct answer – proactive monitoring, rapid response and documentation. Mitigating cold chain risks means detecting deviations early, taking corrective actions immediately, investigating root causes Und recording every step. Real time alerts notify you when temperatures deviate, enabling corrective actions such as adjusting refrigeration, switching to backup units or rerouting shipments. Nach einem Ausflug, thorough investigation and documentation help prevent recurrence.

Expanded explanation – six principles of effective cold chain management. An effective cold chain is built on these guiding principles: temperature control and stability, kontinuierliche Überwachung, nachvollziehbare Dokumentation, proaktives Risikomanagement, staff competency Und validated equipment and processes. A cold chain breach occurs when a product strays from its designated range due to excess heat, excess cold or prolonged time outside limits. Häufige Ursachen sind offene Kühlschranktüren, Geräteausfälle, long unloading times or power outages. Breaches can lead to product degradation, Risiken für die öffentliche Gesundheit, finanzielle Verluste, Regulierungsmaßnahmen, Reputationsschäden und Lieferunterbrechungen.

Risk mitigation techniques and how they help

| Technik | Beschreibung | Profitieren Sie davon |

| Real time alerts and notifications | IoT sensors and GPS trackers send immediate alerts when deviations occur | Enables quick intervention to preserve product integrity |

| Automatisierte Korrekturmaßnahmen | Systems adjust refrigeration, activate backup units or reroute shipments automatically | Minimises human error and reduces response time |

| Notfallplanung | Standardarbeitsanweisungen (Sops) for repackaging, erneute Vereisung, Übertragen auf alternative Speicher und Dokumentieren von Aktionen | Ensures preparedness for unforeseen events |

| Ursachenanalyse | Investigate excursions (Geräteausfall, Stromausfall, menschliches Versagen) und SOPs aktualisieren | Prevents repeat incidents and improves processes |

| Training und Übungen | Regularly train staff on emergency response and conduct simulations | Builds confidence and competence in handling excursions |

Beispiel aus der Praxis: Maersk integrates remote temperature data from reefers with control tower teams who can intervene immediately, helping customers cut product losses and reduce time to market.

2025 Latest Developments and Trends in Pharmaceutical Cold Chain Storage

Trend overview – digital, predictive and sustainable cold chains. Von 2025, cold chain logistics is evolving towards real time visibility via IoT, predictive intelligence via AI, tamper proof traceability via blockchain Und green practices. Demand for cold chain solutions is increasing – investment in temperature controlled logistics accounted for nearly 18 % der Biopharma-Logistikausgaben in 2020, and industry leaders expect steady growth over the next three to five years. Der Aufstieg von Zell- und Gentherapien die eine ultrakalte Lagerung erfordern (unter –80 °C) und die surge in metabolic disorder drugs like GLP 1 agonists are driving expansion. Klimawandel is expanding the range of infectious diseases, increasing demand for temperature sensitive vaccines. Noch bis zu 50 % of vaccines are wasted globally each year due to lack of temperature control.

Latest innovations shaping 2025

IoT and real time precision: IoT systems deliver live updates on temperature and location, allowing proactive intervention and reducing waste.

KI und vorausschauende Logistik: KI-Modelle prognostizieren die Nachfrage, optimise routes and automate inventory management, preventing stock outs and reducing fuel use.

Blockchain und Rückverfolgbarkeit: Blockchain creates tamper proof records, synchronises customs data and simplifies audits.

Grünere Kühlketten: Solarbetriebene Kühlung, compostable packaging and reusable materials reduce carbon emissions.

Widerstandsfähigkeit und Diversifizierung: Diversifying suppliers, using regional distribution centres and adopting cloud based platforms increase supply chain resilience.

Blockchain, AI and solar innovations from Southeast Asia: Southeast Asia leads cold chain innovation with blockchain based tracking, solar powered storage units, IoT-fähige intelligente Sensoren, KI-gestützte Routenoptimierung, tragbare kryogene Gefriergeräte Und nachhaltige Verpackung. Diese Technologien erhöhen die Transparenz, lower energy costs and enable cold storage in remote areas.

Markteinsichten

Cold chain spending growth: Temperature controlled logistics represented nearly 18 % der Biopharma-Logistikausgaben in 2020, and survey data indicate that 70 % of industry leaders expect growth over the next three to five years.

Markt für Zell- und Gentherapie: The CGT market is expected to exceed US$81 billion by 2029, necessitating robust cryogenic logistics.

Infectious disease diagnostics: Der globale Markt für die Diagnostik von Infektionskrankheiten wird voraussichtlich wachsen US$31.5 billion by 2028, wächst bei 8 % jährlich, steigende Nachfrage nach temperaturgesteuerter Verteilung.

Geographical disparities: Regions like Europe, Latin America and Africa are expected to see growth rates of 23 %, 22 % Und 21 %, jeweils, in infectious disease research and manufacturing, highlighting the need for cold chain infrastructure in underserved areas.

FAQ

Frage 1: Welcher Temperaturbereich ist für die meisten Impfstoffe erforderlich??

Die meisten Impfstoffe müssen zwischengelagert werden 2 °C und 8 °C. Staying within this narrow range preserves potency and prevents spoilage. Freezing many vaccines can destroy their efficacy, so avoid temperatures below 0 °C.

Frage 2: Why are IoT sensors important in pharmaceutical cold chain storage?

IoT sensors transmit real time temperature and humidity data, allowing immediate alerts when conditions deviate. They enable proactive interventions, reduce waste and support compliance with GDP/GMP requirements.

Frage 3: Was ist ein Kühlkettenbruch?, and why is it serious?

A cold chain breach—also called a temperature excursion—occurs when a product strays outside its required range. Even brief exposure to excess heat or cold can inactivate vaccines or biologics, leading to therapeutic failure and financial loss.

Frage 4: How do phase change materials improve cold chain packaging?

Phasenwechselmaterialien (PCMs) absorb and release heat during melting and freezing. They maintain precise temperature ranges over long durations, offer reusability and reduce waste, making them superior to traditional gel packs.

Anregung

Key Takeaways: Pharmaceutical cold chain storage is essential for preserving the potency and safety of biologics, Impfungen, Peptide, Zell- und Gentherapien, and specialty drugsl. Different products require specific temperature ranges—from refrigerated (2–8 ° C) zu kryogen (–80 °C bis –150 °C). Modern cold chain management relies on IoT sensors, Datenlogger, RFID, GPS, AI and blockchain for real time visibility. Packaging solutions like phase change materials and vacuum insulation ensure thermal stability. Einhaltung des BIP, GMP, USP and ICH guidelines and continuous monitoring prevents excursions and regulatory violations. Emerging trends in 2025—such as AI powered logistics, blockchain traceability and sustainable packaging—are transforming cold chain operations.

Aktionsplan: Begin by assessing the temperature requirements of each product you handle and mapping your cold chain. Invest in a combination of data loggers and IoT sensors for comprehensive monitoring. Choose packaging solutions with phase change materials or active cooling for long shipments. Train your team in handling, Überwachung und Notfallmaßnahmen. Establish contingency plans for power outages and equipment failures. Stay ahead by adopting technologies like AI for route optimisation, blockchain for traceability and sustainable packaging to meet regulatory and environmental expectations. Kontakt tempk for expert advice on selecting the right packaging and monitoring solutions for your pharmaceutical cold chain.

Um Tempk

Tempk develops innovative cold chain packaging and monitoring solutions for pharmaceuticals, Impfstoffe und Biologika. Wir specialise in reusable phase change materials, insulated shippers and smart thermal devices that maintain precise temperatures for hours or days. Our research and development centre continually explores sustainable materials to reduce waste and carbon emissions. With certifications like Sedex and a commitment to quality, Tempk helps you navigate GDP, GMP and regulatory requirements. Whether you need 0–10 °C insulated boxes or ultra low temperature cases, we provide reliable solutions tailored to your needs.

Machen Sie den nächsten Schritt: Explore Tempk’s solutions for pharmaceuticals shipments, 0–10 °C insulated boxes, ultra cold packaging and reusable ice packs. Consult our experts for personalised recommendations that keep your products safe and compliant.