Temperature-Controlled Creamery Cheap Solutions in 2025?

Wenn Sie brauchen temperature-controlled creamery cheap solutions, you’re not asking for “the cheapest thing.” You’re asking for the fastest way to protect dairy quality while lowering waste, labor drag, and energy spikes. In most creameries, losses come from tiny habits repeated daily: doors left open, blocked airflow, dock staging “for a minute,” and unclear rotation. Fixing those is cheaper than new equipment—and often works faster.

Dieser Artikel wird für Sie antworten:

-

Wie temperature-controlled creamery cheap solutions reduce spoilage without major upgrades

-

Der beste low-cost cold room upgrades for creameries that pay back quickly

-

A budget dock-to-cooler SOP for dairy that prevents warm shocks on busy shifts

-

How to set up cheap temperature monitoring for dairy storage your staff will use

-

Wie affordable insulated shipping for creamery products cuts complaints by lane tier

-

A decision tool + self-test to choose your next best cheap upgrade

Why do temperature-controlled creamery cheap solutions beat “new equipment” first?

Direkte Antwort: Temperature-controlled creamery cheap solutions usually beat new equipment because your biggest costs come from process leaks, not compressor horsepower. A new unit cannot fix pallets waiting on the dock or vents blocked by “temporary” storage.

Erweiterte Erklärung: Think of margin like a triangle. If any side is weak, profits leak out quietly. The best cheap wins improve at least one side immediately—and don’t require perfect staff behavior to succeed.

The “Cold Chain Profit Triangle” you should manage daily

| Profit triangle side | Wie es aussieht | Cheap fix | Was es für Sie bedeutet |

|---|---|---|---|

| Temperaturstabilität | fewer warm spikes | Türdisziplin + airflow rules | fewer quality claims |

| Zeitkontrolle | short staging time | staging timer rules | less spoilage risk |

| Handling control | weniger Berührungen | Zoneneinteilung + clear lanes | lower labor cost |

Praktische Tipps und Empfehlungen

-

If your team is busy, choose fixes that remove decisions, not add steps.

-

If cash is tight, priorisieren Türen + Luftstrom + Inszenierung before any “tech.”

-

If you’re scaling, standardize routines first—then invest with confidence.

Praktisches Fallbeispiel: One small creamery reduced weekly rework after adding a staging time rule and posting a pack-and-move checklist at the cold room door.

Temperature-controlled creamery cheap solutions: where should you start?

Direkte Antwort: Beginnen Sie mit einem 15-minute walk-through audit using a timer and a notebook. Your first goal is to shorten “time out of cold” and stop warm air from entering cold rooms.

Erweiterte Erklärung: Most creameries have the same repeatable risk moments: Empfang, Inszenierung, Türöffnungen, and airflow blockage. If you can measure and fix those moments, you can cut spoilage and energy waste without buying large equipment.

Low-cost cold room upgrades for creameries: the 15-minute audit

-

Where does warm air enter? (Türen, dock interface, broken seals)

-

Where is cold air blocked? (pallets against fans, Wände, or return vents)

-

Where does product wait too long? (dock staging, QA holds, pick queues)

| Audit target | Worauf Sie achten sollten | Warum ist es wichtig | Ihr praktischer Imbiss |

|---|---|---|---|

| Türen & Siegel | light gaps, torn gaskets | warm air steals cooling fast | replace gaskets before buying new fans |

| Air paths | pallets blocking vents | Hot Spots + slow pull-down | mark “no-block” zones on the floor |

| Frost patterns | heavy ice on coils | efficiency drop + cycling | fix airflow + cleaning schedule |

| Dock-Staging | untracked wait time | warm shocks + Qualitätsverlust | add a visible “out-of-cold” timer |

Praktische Tipps und Empfehlungen

-

Use floor tape today. A taped “keep clear” zone beats a long memo.

-

Write one rule: “No pallet waits longer than X minutes on the dock.”

-

Keep the audit list short. Cheap solutions work best when they get finished.

Praktisches Fallbeispiel: A small creamery cut staging time in half using a timer and a “ready-to-store” lane.

What are the best temperature-controlled creamery cheap solutions for cold room stability?

Direkte Antwort: Der beste temperature-controlled creamery cheap solutions for stability focus on the “big three”: Luftstrom, Türen, and setpoints.

Erweiterte Erklärung: Cold air behaves like traffic. If you block lanes, you create jams and hot spots. Doors are the fastest heat entry point. Setpoints matter, but stability matters more than constant tweaking.

1) Airflow discipline (the cheapest high-impact fix)

Common airflow mistakes:

-

stacking product too close to evaporator fans

-

pushing pallets tight to walls

-

storing tall loads that block return air

Cheap solution: mark “no-stack zones” and teach one simple rule: Halten Sie die Lüftungsschlitze frei, stets.

2) Türdisziplin (heat enters fastest through doors)

Cheap solution: batch moves and close the door between moves. Add a timer and a visible “door score” target per shift.

3) Setpoint sanity (too cold can be expensive)

Lowering setpoints “just to be safe” can increase frosting and energy load.

Cheap solution: define your setpoint range based on product needs and keep it stable.

| Cold room lever | Cheap action | Cost level | Ihr praktischer Nutzen |

|---|---|---|---|

| Luftstrom | floor tape lanes + “no-block” signs | Niedrig | weniger Hotspots |

| Türen | batch pick + Timer + closer habits | Niedrig | fewer temperature spikes |

| Setpoints | documented SOP range | Niedrig | less drift and frosting |

Praktische Tipps und Empfehlungen

-

If you see uneven frost, check airflow blockage first.

-

If compressors run constantly, check doors and seals before buying anything.

-

If product warms near doors, move fast movers away from entrance zones.

Praktisches Fallbeispiel: One creamery improved temperature uniformity after moving tall pallets away from fan zones and repainting aisle boundaries.

How do temperature-controlled creamery cheap solutions reduce energy costs quickly?

Direkte Antwort: They reduce energy cost by reducing heat entry and improving refrigeration Effizienz with basic “energy hygiene.”

Erweiterte Erklärung: If warm air enters constantly, compressors fight a battle you don’t need to pay for. The fastest wins come from gaskets, coil cleanliness, and door-open behavior.

The “5-minute energy sweep” (wöchentlich)

-

Inspect door gaskets for gaps and cracks

-

Check frost patterns for airflow problems

-

Confirm coils are clean (or scheduled)

-

Verify doors close fully without sticking

-

Confirm lights/fans run only when needed

| Energy leak source | Was Sie sehen | Cheap fix | Was es für Sie bedeutet |

|---|---|---|---|

| Worn gaskets | Kondensation, warm edges | replace gaskets | lower heat entry |

| Dirty coils | slow pull-down | cleaning schedule | lower compressor load |

| Door misuse | frequent warm spikes | batch movement | fewer recoveries |

Praktische Tipps und Empfehlungen

-

Hot seasons: tighten door discipline and reduce staging time.

-

Hohe Luftfeuchtigkeit: sealing matters even more to reduce frost load.

-

Older equipment: cleanliness and sealing often outperform upgrades.

Praktisches Fallbeispiel: A creamery cut monthly energy spikes after replacing gaskets and enforcing a “pre-stage before opening” loading rule.

Temperature-controlled creamery cheap solutions for labor efficiency: how do you reduce touches?

Direkte Antwort: Reduce touches by redesigning flow with Zonen, ship-today lanes, Und clear locations.

Erweiterte Erklärung: Every extra move costs labor and adds temperature exposure. If you remove just one touch from finished goods handling, you often see immediate labor relief and fewer excursions.

Use the “Touch Count” method

Count moves after packaging:

-

move to staging

-

move to cold room

-

move to pick zone

-

move to loading

Now remove one move with zoning and lane design.

| Labor waste | Was verursacht es? | Cheap fix | Praktische Bedeutung für Sie |

|---|---|---|---|

| Searching | unclear locations | zone labels + map | faster picks |

| Extra moves | poor layout | ship-date lanes | weniger Berührungen |

| Rework | wrong pallets | visual staging | weniger Fehler |

Praktische Tipps und Empfehlungen

-

Small teams: Etiketten + a whiteboard map beat complex software.

-

Many SKUs: separate A/B/C movers by velocity.

-

Mixed channels: separate wholesale vs retail zones.

Praktisches Fallbeispiel: A creamery reduced overtime after introducing “ship today” lanes and labeling fast movers at eye level.

Which temperature-controlled creamery cheap solutions protect dairy quality best?

Direkte Antwort: Protect quality by minimizing Temperaturschwankungen and reducing time out of controlled environments.

Erweiterte Erklärung: Most quality damage isn’t one big failure. It’s many small warm exposures that chip away at taste, Textur, and shelf-life. Your cheapest quality protection tool is a strict time limit for staging and a repeatable dock routine.

The “Short Exposure Rule” for dairy

-

Stage only what you can move quickly

-

Avoid building orders in warm zones

-

Set and enforce a dock exposure time limit

Packaging and handling matter too

Even inside a cold room, you can damage quality when:

-

cartons absorb moisture

-

labels peel from condensation

-

containers are crushed or shifted

| Quality risk | How it happens | Cheap fix | Praktische Bedeutung für Sie |

|---|---|---|---|

| Texture issues | repeated warm spikes | staging limits | more consistent product |

| Packaging damage | weak pallet pattern | standard pattern | Weniger Renditen |

| Kondensation | Wandkontakt | Abstand + Luftstrom | better labels |

Praktische Tipps und Empfehlungen

-

Wenn sich die Etiketten lösen, reduce condensation by improving seals and avoiding wall contact.

-

If cartons soften, improve airflow and reduce humidity entry via doors.

-

If complaints cluster, map which zone the product came from.

Praktisches Fallbeispiel: A creamery reduced “soft carton” incidents by changing pallet patterns and adding a simple spacing rule.

Temperature-controlled creamery cheap solutions for receiving: the budget dock-to-cooler SOP

Direkte Antwort: Receiving needs one goal: shorten the time between truck and cold storage.

Erweiterte Erklärung: Receiving is where sunlight, warm air, and waiting time hit first. The cheapest improvement is a five-step SOP with lane markings so staff don’t pause to decide where pallets go.

Budget dock-to-cooler SOP you can run every shift

-

Pre-clear a storage slot before the truck arrives

-

Unload to a marked cold-first Fahrbahn

-

Verify temperature and paperwork quickly

-

Move to cold storage within your time limit

-

Log exceptions (so you fix patterns, not one-offs)

| SOP step | Was es kontrolliert | Low-cost tool | Ihr praktischer Imbiss |

|---|---|---|---|

| Pre-clear slot | prevents waiting | slot board | decisions happen before unloading |

| Cold-first lane | keeps priorities clear | floor tape + Beschilderung | stops “temporary parking” |

| Time limit | reduces warm exposure | timer or wall clock | makes accountability real |

| Exception log | finds patterns | one-page checklist | fixes repeat failures |

Praktische Tipps und Empfehlungen

-

Assign a “dock captain” during peak hours to prevent bottlenecks.

-

Treat the timer as policy. One visible clock changes behavior.

-

Use a simple shade barrier if sunlight hits your receiving lane.

Praktisches Fallbeispiel: One team cut warm exposure by creating two lanes: “store now” and “hold for QA,” with different rules.

Cheap temperature monitoring for dairy storage: what should you measure first?

Direkte Antwort: Fangen Sie klein an: monitor the zones where product actually experiences risk—the warm corner, the door area, and the staging zone.

Erweiterte Erklärung: Monitoring fails when it creates dashboards nobody checks. Your best cheap monitoring system is one that produces one daily question: “Any excursions today?” Then it triggers a clear action.

Where to measure first (the high-risk places)

-

Warmest corner of the cold room

-

Loading door area

-

Staging-before-shipment zone

-

One “product core” test location during lane trials

| Überwachungsmethode | Am besten für | Schwäche | Ihr praktischer Imbiss |

|---|---|---|---|

| Min/max thermometer | daily control | no history | good baseline |

| Standalone logger | pattern finding | manual downloads | perfect for testing |

| Drahtlose Sensoren | ongoing oversight | setup complexity | best after SOPs stabilize |

Praktische Tipps und Empfehlungen

-

Place sensors away from fans so readings reflect product zones.

-

Keep review weekly, not “someday.” Unreviewed data is wasted effort.

-

Create a response card: what to do when temps move.

Praktisches Fallbeispiel: A team found a daily warm spike at shift change and fixed it by changing door habits, not equipment.

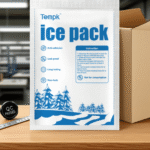

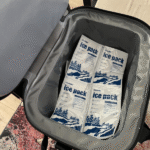

Affordable insulated shipping for creamery products: how do you tier lanes cheaply?

Direkte Antwort: Don’t ship everything the same way. Verwenden lane tiers so you spend more only where risk is high.

Erweiterte Erklärung: Many shipping failures come from poor packout: too much empty space, ice packs in the wrong place, or slow loading delays. Tiering + packout photos are cheap, scalable fixes that reduce complaints fast.

Lane-based shipping tiers

| Lane tier | Wann zu verwenden | Low-cost packaging move | Ihr praktischer Imbiss |

|---|---|---|---|

| Stufe 1 (geringes Risiko) | short local routes | right-sized carton + 1 Pack | control empty space first |

| Stufe 2 (mittleres Risiko) | regional routes | add insulation liner + 2 Packungen | Spielraum für Verzögerungen |

| Stufe 3 (hohes Risiko) | hot/long routes | stronger shipper + more packs | use only where needed |

Praktische Tipps und Empfehlungen

-

Pre-chill product before packing—don’t “cool with packs.”

-

Standardize packout photos so every shift packs the same way.

-

Keep packout time short and track it like a KPI.

-

Pakete platzieren above and beside dairy for better coverage.

Praktisches Fallbeispiel: A creamery reduced warm-month complaints after switching to lane tiers and standard packout photos.

Interactive self-test: find your best temperature-controlled creamery cheap solutions in 10 Minuten

Bewerten Sie jedes Element 0–2

0 = not true, 1 = partly true, 2 = consistently true

-

We have a staging time limit and follow it

-

We batch picks and reduce door-open time

-

Airflow lanes are marked and protected

-

Door seals are inspected monthly

-

Coils have a real cleaning schedule

-

Setpoints are stable and documented

-

We zone storage by ship date or SKU velocity

-

We use a standard pallet pattern per product type

-

We have a “delay rule” for late pickups

-

We review complaints monthly and adjust SOPs

Your total score (0–20):

-

0–7: Start with door discipline, staging limits, airflow lanes

-

8–14: Add zoning, standard pallet patterns, maintenance routine

-

15–20: Focus on monitoring, kontinuierliche Verbesserung, training upgrades

Howto: implement temperature-controlled creamery cheap solutions in 7 Schritte

-

Set a staging time limit and post it at the cold room door

-

Create a “ship today” lane and label it clearly

-

Mark airflow “no-stack” zones with floor tape

-

Batch picks and close doors between moves

-

Inspect and replace damaged gaskets

-

Schedule coil cleaning and log it

-

Review excursions/complaints monthly and change one variable at a time

The “one-variable rule” keeps improvements cheap

If you change five things at once, you never learn what worked. Ändern Sie eine Variable, measure outcomes, then lock it in.

| Schritt | Was du änderst | Was Sie messen | Praktische Bedeutung für Sie |

|---|---|---|---|

| Staging limit | time outside cold | warm-event frequency | weniger Ausfälle |

| Door batching | Türöffnungszeit | energy spikes | lower bills |

| Airflow zones | storage layout | hot spot reduction | bessere Stabilität |

Praktisches Fallbeispiel: A creamery improved consistency after posting one “gold standard” pallet photo at the staging area.

2025 latest developments and trends in temperature-controlled creamery cheap solutions

In 2025, small and mid-sized dairy operators are leaning into “lean cold chain” practices. The focus is not fancy tech first. It’s predictable execution with simple proof.

Aktueller Fortschritts-Snapshot (2025)

-

Visual SOP boards: photos and diagrams replace long manuals

-

Sampling-based monitoring: a few sensors reveal most issues

-

Lane-tier shipping: spend more only where risk is high

-

Micro-audits: 15-minute weekly checks replace rare big audits

-

Habit-based training: door discipline and staging rules taught early

Markteinblicke, die Sie nutzen können

Customers don’t care how expensive your refrigeration is. They care about consistency. Deshalb temperature-controlled creamery cheap solutions gewinnen: they reduce variability more than they reduce temperature.

Häufige Fragen (FAQ)

Q1: What are the fastest temperature-controlled creamery cheap solutions?

Start with door discipline, airflow lane protection, and a staging time limit. These reduce warm spikes without new equipment.

Q2: Can cheap solutions really reduce spoilage?

Ja. Spoilage risk often rises with repeated warm exposure and long staging. Shorter exposure plus better sealing reduces risk quickly.

Q3: What is the cheapest way to lower refrigeration energy cost?

Replace damaged gaskets, keep coils clean, and reduce door-open time. These reduce recovery cycles and run time.

Q4: How do I know if airflow is a problem?

Look for uneven frost, drift in one zone, or repeated issues from the same storage area. Then check for blocked return paths.

Q5: What should I track monthly in a creamery cold chain?

Track warm events, staging violations, door-open patterns, and complaints by SKU and zone. Patterns are where the savings live.

Zusammenfassung und Empfehlungen

Temperature-controlled creamery cheap solutions work because they attack the real causes of loss: heat entry through doors, blocked airflow, inconsistent staging, und vermeidbare Nacharbeit. In 2025, the best low-cost improvements are disciplined and repeatable: airflow lanes, door batching, stable setpoints, gasket checks, FEFO rotation, and simple monitoring that triggers action.

Aktionsplan (klarer CTA)

Wählen zwei upgrades to implement this week:

-

staging time limit + visible timer rule

-

airflow no-stack zones + photo SOP

Measure warm events and complaints for 30 Tage. If results improve, lock the process and move to the next fix.

Über Tempk

Bei Tempk, we help cold chain operators improve performance with practical packaging and workflow systems. We focus on repeatable routines, stable temperature control, and training-friendly SOP design—so your team can execute consistently under real pressure. If you’re building temperature-controlled creamery cheap solutions, we help you prioritize upgrades that deliver ROI before you invest in bigger equipment.

Nächster Schritt: Share your facility size, shipping frequency, and biggest pain point (Energie, Verderb, Arbeit, or compliance). We’ll map a low-cost improvement roadmap tailored to your operation.