Jede Lieferung verderblicher Waren ist ein Wettlauf gegen die Zeit. Sie benötigen eine Verpackung, die wie ein tragbarer Kühlschrank funktioniert, ohne Strom zu verbrauchen. A vakuumisolierte Box für temperaturempfindliche Lieferketten Genau das gelingt durch die Verlangsamung der Wärmeübertragung mit modernster Isolierung. In 2025 Der Kühlkettenmarkt überstieg USD 29 Milliarden und wird voraussichtlich den US-Dollar übersteigen 55 Milliarden von 2035, Dies unterstreicht die Bedeutung zuverlässiger Verpackungslösungen. Diese Boxen halten die Temperatur sieben bis zehn Tage lang stabil – ein Lebensretter, wenn Ihre Produkte Kontinente überqueren. Dieser Leitfaden erklärt, wie sie funktionieren, Warum sie wichtig sind, und wie Sie eines für Ihre Bedürfnisse auswählen.

Was macht vakuumisolierte Boxen ideal für temperaturempfindliche Lieferketten??

Wie übertreffen vakuumisolierte Boxen herkömmliche Schaumstoffkühler??

Was sind die Schlüsselkomponenten und Einschränkungen der Vakuumisolationspaneel-Technologie??

Wie können Sie die richtige Vakuum-Isolierbox für Ihr Produkt auswählen??

Welche Innovationen und Trends werden Kühlkettenverpackungen prägen? 2025 und darüber hinaus?

Was ist eine vakuumisolierte Box und wie funktioniert sie??

Eine vakuumisolierte Box ist ein starrer Behälter, der evakuierte Platten verwendet, um die Wärmeübertragung drastisch zu reduzieren. Jede Wand besteht aus einem mikroporösen Kern (oft Kieselsäure) in eine gasdichte Barrierefolie eingewickelt und unter nahezu Vakuum versiegelt. Durch die Entfernung der Luft im Inneren der Paneele wird die Konvektion und Leitung weitgehend eliminiert, Dadurch erreichen VIP-Boxen eine geringe Wärmeleitfähigkeit 5 mW/m·K – zehnmal niedriger als herkömmliche Schaumkühler. Um die Temperatur aufrechtzuerhalten, Phasenwechselmaterialien (PCMs) wie Gelpackungen, Um die Nutzlast herum werden Trockeneis oder eutektische Platten angebracht.

Wie die Technologie funktioniert

Innerhalb jedes Panels a poröser Kern aus pyrogener Kieselsäure oder Glasfasern ist in eine mehrschichtige Barrierefolie eingewickelt, die das Eindringen von Gas verhindert. Abstandshalter oder mit Aerogel verstärkte Kerne verhindern, dass die Struktur unter atmosphärischem Druck zusammenbricht. Eine Außenhülle aus Kunststoff oder Faserplatten schützt die Platten vor Durchschlägen und Feuchtigkeit. Wenn die Luft evakuiert wird, wird der Kern zu einem hervorragenden Isolator. Wärme kann nur durch die feste Matrix wandern, Das bedeutet, dass diese Boxen lange Zeit kalte Temperaturen aufrechterhalten 7–10 Tage– zwei- bis dreimal länger als Standard-EPS- oder Polyurethan-Kühler. PCMs im Inneren absorbieren oder geben Wärme ab, um die Temperatur im gewünschten Bereich zu halten, Egal ob 2–8 °C bei Impfstoffen oder –18 °C bei Tiefkühlware.

Warum vakuumisolierte Boxen eine hervorragende Wärmeleistung bieten

Denn der Isolierung wird Luft entzogen, VIP-Boxen können mit nur einem Drittel der Dicke die gleiche Leistung wie ein Schaumstoffkühler erbringen. Eine typische VIP-Wand misst 10–15 mm, im Vergleich zu 25–40 mm für Polyurethan oder EPS. Dünnere Wände geben Innenvolumen frei, So können Sie mehr Produkte versenden oder die Anzahl der Gelpackungen reduzieren. Die geringe Wärmeleitfähigkeit (ca. 0,004–0,005 W/m·K) Dadurch sind Temperaturschwankungen auch bei langen Transporten minimal. Eine einfache Analogie: Stellen Sie sich vor, Sie wickeln ein Eis am Stiel in ein nahezu perfektes Vakuum – Hitze dringt nur schwer ein, so bleibt das Eis am Stiel viel länger gefroren.

| Isolationsmaterial | Ca. Wärmeleitfähigkeit | Wandstärke (für ca. 72 h halten) | Praktische Bedeutung |

| Erweiterter Polystyrol (EPS) | ~36 mW/m·K | 30–40 mm | Niedrige Kosten; leicht zu schneiden, aber sperrig; Haltezeit ca. 2–3 Tage |

| Polyurethanschaum (Pur) | ~22 mW/m·K | 25–35 mm | Bessere Isolierung als EPS, aber immer noch schwerer; Haltezeit ca. 3–5 Tage |

| Vakuumisolationspaneel (VIP) | ~5 mW/m·K | 10–15 mm | Hohe Kosten; zerbrechlich; verlängerte Haltezeit 7–10 Tage und mehr Innenraum |

Praktische Tipps zur Verwendung vakuumisolierter Boxen

Wählen Sie VIPs für hochwertige Waren: Nutzen Sie beim Versand teurer Arzneimittel VIP-Boxen, Biologika oder Speziallebensmittel, bei denen die Verderbskosten die Verpackungskosten bei weitem übersteigen.

Koppeln Sie es mit geeigneten PCMs: Wählen Sie PCMs aus, die zum Temperaturbereich Ihres Produkts passen. Zum Beispiel, Gel-Packs für Sendungen bei 2–8 °C oder Trockeneis für Ultra-Kalt-Transporte.

Vor Durchstichen schützen: Verwenden Sie immer eine Außenhülle aus EPP oder gewelltem Kunststoff, um die Paneele vor Beschädigungen zu schützen.

Planen Sie die Rückwärtslogistik: Bei Verwendung wiederverwendbarer VIP-Boxen, Koordinieren Sie Rücksendungen zur Bergung und Reinigung der Container.

Tatsächlicher Fall: Ein Pharmaunternehmen, das Biologika verschickt, ist auf eine wiederverwendbare Smartbox mit VIP-Panels und PCMs umgestiegen. In der Box blieb die Temperatur 2–8 °C 72 Stunden während der Übertragung von Live-Temperatur- und Standortdaten. Warnungen werden ausgelöst, wenn der Deckel geöffnet wird oder die Temperaturen schwanken, Schutz der hochwertigen Ladung.

Warum vakuumisolierte Boxen ideal für temperaturempfindliche Lieferketten sind

Vakuumisolierte Boxen sind bahnbrechend, da sie eine erweiterte Temperaturkontrolle mit Platzeffizienz und Gewichtseinsparungen kombinieren. Ihre dünnen Wände ermöglichen eine höhere Nutzlast pro Sendung, und ihre geringe Wärmeleitfähigkeit hält den Inhalt tagelang im gewünschten Bereich. Im Vergleich zu Schaumkühlern, VIP-Logen bieten mehrere Vorteile:

Verlängerte Dauer: VIP-Boxen halten die Temperaturbereiche 7–10 Tage lang aufrecht – doppelt so lange wie herkömmliche Kühlboxen.

Raumeffizienz: Dünnere Wände geben Innenvolumen frei, So können Sie mehr Produkte einbauen oder das Kühlmittelgewicht reduzieren.

Gewichtsreduktion: Eine geringere Isolationsdicke und geringere PCM-Anforderungen senken das Versandgewicht und die Kosten.

Temperaturkonsistenz: VIPs sorgen für stabile Temperaturprofile mit minimalen Schwankungen.

Hochwertiger Schutz: Eine strenge Temperaturkontrolle schützt Impfstoffe, Biologika und Spezialnahrung auf langen Strecken.

Einschränkungen und Kompromisse

Trotz ihrer Vorteile, VIP-Logen sind nicht perfekt. Wenn Sie die Einschränkungen kennen, können Sie fundierte Entscheidungen treffen:

Zerbrechlichkeit: Vakuumpaneele sind empfindlich und erfordern möglicherweise Schutzschaum oder Außengehäuse, zunehmende Gesamtdicke.

Höhere Kosten: VIPs kosten im Vorfeld mehr als Schaumkühler und erfordern eine sorgfältige Handhabung. Die Herstellung erfordert hochpräzise Vakuumversiegelung und spezielle Materialien, Daher liegen die Installationskosten zwischen 50 und 100 US-Dollar pro Quadratmeter, verglichen mit 10 bis 20 US-Dollar für Schaumstoff.

Formbeschränkungen: Die Platten lassen sich nicht leicht schneiden und können Wärmebrücken hinterlassen, was den Zusammenbau des Kastens erschwert.

Gewicht: VIP-Kerne sind dichter als einige Schaumstoffe.

Umweltauswirkungen: Die Herstellung von pyrogener Kieselsäure verbraucht Energie und hat einen hohen Anteil an Kohlenstoff. Jedoch, Recyclinginitiativen können die ökologischen Kosten um bis zu reduzieren 95%.

Minderungsstrategien

- - Mit Sorgfalt verarbeiten: Schulen Sie das Lagerpersonal, um Reifenpannen zu vermeiden und Schutzhüllen zu verwenden.

- - Kosten und Nutzen abwägen: Bewerten Sie den Produktwert und die Versandentfernung. Für Waren mit geringem Wert oder kurze Wege, Schaum kann ausreichen; für hochwertige Arzneimittel, VIP-Logen machen sich durch geringeren Schaden bezahlt.

- - Planen Sie die Wiederverwendung: Wiederverwendbare VIP-Behälter reduzieren den Abfall und können die höheren Vorlaufkosten über mehrere Zyklen hinweg ausgleichen.

Beispielrechnung: Versand einer 5-Liter-Impfstoffcharge für fünf Tage. A 20 mm EPS-Kühler benötigt ca 4 Nur kg Gelpackungen und Blätter 6 L Nutzfläche, während eine VIP-Loge mit 10 mm Platten braucht nur 1.5 kg PCMs – das schafft Platz und reduziert das Gewicht.

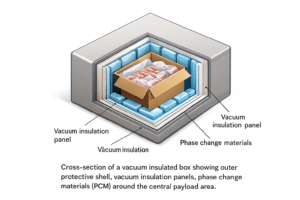

Komponenten einer vakuumisolierten Box (Illustriert)

Unten sehen Sie einen illustrativen Querschnitt einer vakuumisolierten Box. Der zentrale Nutzlastbereich ist von Phasenwechselmaterialpaketen und Vakuumisolationspaneelen umgeben, alles in einer Schutzhülle eingeschlossen.

Entscheidungsrahmen: So wählen Sie die richtige vakuumisolierte Box aus

Die Auswahl des richtigen Behälters erfordert die Abwägung der Produktanforderungen, Transitbedingungen, regulatorische Anforderungen und Kosten. Verwenden Sie dieses Schritt-für-Schritt-Framework:

Bewerten Sie das thermische Profil Ihres Produkts: Identifizieren Sie die erforderlichen Temperaturbereiche (2–8 ° C, –18 °C oder –70 °C) und Zeit halten. Die Haltbarkeit der VIP-Logen beträgt 7–10 Tage, während Hybriddesigns bieten können 72+ Stunden mit dünneren PCMs.

Schätzen Sie die Transitdauer und die Umgebung: Berücksichtigen Sie die Versandentfernung, mögliche Verzögerungen und Umgebungstemperatur. Passive VIP-Boxen eignen sich für Strecken bis zu einer Woche; Für längere Fahrten sind möglicherweise Hybrid- oder Aktivboxen erforderlich.

PCM und Kühlmittel aufeinander abstimmen: Wählen Sie Gelpackungen, Eisbeutel oder Trockeneis, die auf Ihren Zieltemperaturbereich abgestimmt sind.

Bestimmen Sie die Boxgröße und das Nutzlastverhältnis: Dünnere VIP-Wände vergrößern den nutzbaren Raum. Berechnen Sie das benötigte Innenvolumen für Produkt und Kühlmittel und vermeiden Sie übergroße Kisten.

Bewerten Sie die Einhaltung gesetzlicher Vorschriften: Befolgen Sie die Richtlinien der WHO, Das Food Safety Modernization Act der FDA, Gute Vertriebspraktiken und gute Herstellungspraktiken.

Kosten und Leistung in Einklang bringen: Berücksichtigen Sie die Gesamtbetriebskosten einschließlich Wiederverwendungszyklen und potenzieller Verluste durch Verderb.

Denken Sie an Nachhaltigkeit: Entscheiden Sie sich für recycelbare Platten und wiederverwendbare Gehäuse. Kreislaufprogramme können den CO2-Fußabdruck von VIP-Kern um reduzieren 95%.

Schnelle Selbsteinschätzung

Nutzen Sie diesen Schnelltest, um zu entscheiden, ob eine Vakuum-Isolierbox Ihren Anforderungen entspricht:

Temperaturbereich: Benötigt Ihr Produkt 2–8 °C?, –18 °C oder –70 °C?

Dauer: Dauert der Transport weniger als 48 Std., 48–72 Stunden oder mehr 72 Std.?

Produktwert: Ist Ihr Produkt von geringem/mittlerem Wert? (Schaum kann ausreichen) oder hoher Wert (VIP empfohlen)?

Reverse-Logistik: Gibt es ein Rückgabesystem für Mehrwegboxen??

Vorschriften: Welche Standards gelten? (FSMA, WER, GMP/BIP)?

Wenn Sie mit „hoher Wert“ geantwortet haben,„Lange Dauer“ und „Ja“ zur Umkehrlogistik, Eine vakuumisolierte Box ist wahrscheinlich die richtige Wahl.

2025 Entwicklungen und Trends bei vakuumisolierten Boxen

Hybridkühler mit dünneren PCMs

Hybridkühler kombinieren Vakuumisolierung mit dünneren Phasenwechselmaterialien, Aufrechterhaltung präziser Temperaturen für mehr als 72 Stunden bei gleichzeitiger Reduzierung des Energieverbrauchs. Diese Designs optimieren die PCM-Masse und verwenden fortschrittliche Materialien, um die Haltezeit ohne Übergewicht zu verlängern.

IoT-fähige intelligente Verpackung

In intelligente Container sind Sensoren und Datenlogger integriert, um Live-Temperatur- und Standortdaten zu übertragen. Wiederverwendbare Behälter mit VIP-Panels und PCMs können 48–72 Stunden lang eine Temperatur von 2–8 °C aufrechterhalten und gleichzeitig Echtzeitwarnungen senden. Diese Technologie reduziert die Abhängigkeit von Trockeneis und Gelpackungen und ermöglicht ein proaktives Eingreifen bei Temperaturschwankungen.

Behälter mit mehreren Temperaturzonen

Fortschrittliche Container unterteilen den Innenraum in Fächer mit unterschiedlichen Temperaturzonen, Dies ermöglicht gemischte Beladungen wie gefrorenen Fisch und frisches Gemüse. Diese verlassen sich auf VIPs und intelligente Überwachung, um unterschiedliche Wärmeanforderungen gleichzeitig zu verwalten.

Wiederverwendbare und zirkuläre Verpackungsmodelle

Der Markt für wiederverwendbare Kühlkettenverpackungen wird voraussichtlich ab USD wachsen 4.97 Milliarden in 2025 in USD 9.13 Milliarden von 2034. Kreislaufprogramme recyceln VIP-Kerne, Reduzierung der CO2-Emissionen um bis zu 95%. Wiederverwendbare Kartons kosten zwar im Vorfeld mehr, zahlen sich aber durch mehrere Zyklen und weniger Abfall aus.

Selbstgekühlte Smart Boxen

Batteriebetriebene Behälter wie der Ember Cube machen Gelpacks oder Trockeneis überflüssig. Mithilfe der VIP-Isolierung halten sie 48–72 Stunden lang eine Temperatur von 2–8 °C aufrecht, Sensoren und eingebauter Kühlung. Solche aktiven Systeme sind ideal für hochwertige Biologika und abgelegene Standorte.

Integration von KI und Blockchain

Künstliche Intelligenz analysiert Sensordaten, um Geräteausfälle vorherzusagen, Optimieren Sie Routen und reduzieren Sie Verzögerungen. Blockchain bietet manipulationssichere Protokolle von Temperaturdaten und Verarbeitungsereignissen, Verbesserung der Compliance und Überprüfbarkeit.

Markteinblicke und Branchentrends

Wachstum des Kühlkettenverpackungs- und VIP-Marktes

Der globale Markt für temperaturgesteuerte Verpackungslösungen wurde auf rund USD geschätzt 45.23 Milliarden in 2025 und wird voraussichtlich auf USD wachsen 92.17 Milliarden von 2034. Marktanalysten heben fortschrittliche Isolierung hervor (VIPs), Phasenwechselmaterialien und intelligente Verpackungen als wichtige technologische Veränderungen. Aufgrund der Erschwinglichkeit bleiben passive Systeme wie Isolierboxen vorherrschend, Aber aktive Systeme für hochwertige Güter nehmen schnell zu.

Der breitere Markt für Kühlkettenverpackungen (inklusive Schaumstoff, Palettenverlader und VIPs) wird voraussichtlich USD erreichen 134.08 Milliarden von 2032, gegenüber USD 38.51 Milliarden in 2025. Von Palettenversendern wird erwartet, dass sie durchhalten 35.7% des Produktanteils von 2025 durch überlegenen Schutz und effiziente Handhabung, während Fisch, Meeresfrüchte- und Fleischanwendungen ausmachen 34.7% des Marktes.

Einfluss von Lieferkettenunterbrechungen und Nachhaltigkeitsauflagen

Störungen der globalen Lieferkette, wie die Krise am Roten Meer und die Überlastung der Häfen, Die Laufzeiten erhöhen sich und die Nachfrage nach Isolierungen mit längerer Lebensdauer steigt. Klimavorschriften wie der EU Green Deal beschleunigen die Einführung umweltfreundlicher Kältemittel und biologisch abbaubarer Verpackungsmaterialien. Unternehmen verpflichten sich zu Netto-Null-Emissionen, Den Markt in Richtung wiederverwendbarer und zirkulärer Lösungen drängen.

Markttreiber und Herausforderungen für Vakuumisolationspaneele

Der weltweite Markt für Vakuumisolationspaneele wird voraussichtlich USD erreichen 8.51 Milliarden in 2025 und USD 12.07 Milliarden von 2033. VIPs erreichen Wärmeleitfähigkeiten von nur 0.004 W/(m·K), übertrifft herkömmliche Materialien oben 0.035 W/(m·K). Sie werden zunehmend eingesetzt, um die Nutzlastkapazität im Kühltransport zu maximieren, aber vor Herausforderungen stehen:

Probleme mit der Haltbarkeit: Gaspermeation und mechanische Beschädigung können die Leistung um 30–50 % reduzieren 15 Jahre. Eine kleine Punktion kann die Vakuumintegrität beeinträchtigen.

Hohe Produktions- und Installationskosten: Die Herstellung von VIPs erfordert kostspielige Materialien und Spezialausrüstung. Die Kosten liegen zwischen 50 und 100 US-Dollar pro Quadratmeter, verglichen mit 10 bis 20 US-Dollar für Mineralwolle.

Fehlen standardisierter Langzeittests: Es gibt keine allgemein anerkannten Standards zur Bewertung der VIP-Lebensdauer.

Forscher entwickeln biobasierte Kerne wie Lignin und Nanozellulose, wodurch der verkörperte Kohlenstoff um bis zu reduziert werden kann 35%. Die Integration mit Phasenwechselmaterialien und eutektischen Systemen erhöht die thermische Stabilität.

Innovationen bei isolierten Verpackungsunternehmen

Die Aerocore-Technologie von American Aerogel verwendet Aerogel-basierte VIPs in maßgeschneiderten Verpackungen, um eine hervorragende Temperaturstabilität zu gewährleisten, Reduzierung der Versandkosten um bis zu 70% und Ersetzen von Schäumen wie Polyurethan und EPS. Andere Unternehmen investieren in nachhaltige Materialien und intelligente Verpackungen: Faserbasierte Produkte von Huhtamaki, Hochleistungs-Polyurethan-Versandtaschen von Sonoco und isolierte Palettenabdeckungen von Thermal Packaging Solutions. Die Branche setzt auf Mehrwegbehälter, Intelligente Sensoren und modulare Designs zur Verbesserung von Effizienz und Nachhaltigkeit.

Häufig gestellte Fragen

Q1: Was ist eine vakuumisolierte Box??

Eine vakuumisolierte Box ist ein Versandbehälter, dessen Wände vakuumversiegelte Platten aus mikroporösem Siliziumdioxid enthalten. Durch die Entfernung der Luft wird die Wärmeübertragung drastisch reduziert, So kann die Box sieben bis zehn Tage lang kalte oder gefrorene Temperaturen aufrechterhalten.

Q2: Wie lange kann eine vakuumisolierte Box Produkte kalt halten??

Standard-VIP-Logen halten die Temperatur 7–10 Tage lang aufrecht. Hybriddesigns mit dünneren PCMs oder aktiver Kühlung sorgen für präzise Temperaturen 72+ Std..

Q3: Sind vakuumisolierte Boxen wiederverwendbar??

Ja. Viele VIP-Container sind für die Wiederverwendung konzipiert, und der Markt für wiederverwendbare Kühlkettenverpackungen wird voraussichtlich ab USD wachsen 4.97 Milliarden in 2025 in USD 9.13 Milliarden von 2034.

Q4: Welche Nachteile haben vakuumisolierte Boxen??

VIP-Panels sind zerbrechlich, teuer und schwerer als manche Schaumstoffe. Sie erfordern eine sorgfältige Handhabung und eine ordnungsgemäße Entsorgung oder Wiederverwertung.

Q5: Wie wähle ich zwischen passiver und hybrider VIP-Verpackung??

Berücksichtigen Sie die Dauer und den Wert Ihrer Sendung. Passive VIP-Boxen funktionieren für Strecken bis zu einer Woche, Für längere Strecken oder hochwertige Güter, die eine Echtzeitüberwachung erfordern, eignen sich Hybrid- oder Aktivboxen besser.

Zusammenfassung und Empfehlungen

Vakuumisolierte Boxen bieten eine unübertroffene Wärmeleistung, mit einer Wärmeleitfähigkeit von nur 0,004–0,005 W/(m·K) und Haltezeiten von sieben bis zehn Tagen. Sie bieten mehr nutzbaren Raum, leichtere Sendungen und höhere Temperaturstabilität als herkömmliche Schaumstoffkühler. Jedoch, Sie sind zerbrechlich und teuer, Daher ist eine Kosten-Nutzen-Analyse unerlässlich. Beim Versand hochwertiger Arzneimittel, Biologika oder Spezialnahrungsmittel über große Entfernungen transportieren, Vakuumisolierte Boxen sind die Investition wert. Für Waren mit geringerem Wert oder kurze Wege, Schaum kann ausreichen.

Umsetzbare nächste Schritte

Überprüfen Sie Ihre Kühlkettenanforderungen: Produkttypen auflisten, erforderliche Temperaturen und Transitdauern.

Vergleichen Sie Verpackungsoptionen: Bewerten Sie VIP-Boxen im Vergleich zu Schaumstoff- und Hybridlösungen anhand von Kriterien wie der thermischen Leistung, Kosten und Wiederverwendungspotenzial.

Implementieren Sie die Überwachung: Rüsten Sie Sendungen mit Temperatursensoren aus oder entscheiden Sie sich für intelligente Boxen für hochwertige Waren.

Planen Sie Wiederverwendung und Recycling: Wählen Sie wiederverwendbare VIP-Behälter, wenn eine Rückwärtslogistik möglich ist, und nehmen Sie an Recyclingprogrammen teil, um die Umweltbelastung zu reduzieren.

Experten konsultieren: Arbeiten Sie mit einem Kühlkettenspezialisten zusammen, um die Verpackung individuell anzupassen und die Einhaltung von Vorschriften sicherzustellen.

Über Tempk

Gegründet in 2011, Tempk (Shanghai Huizhou Industrial Co., Ltd.) ist auf Forschung spezialisiert, Entwicklung und Produktion von Kühlkettenverpackungsprodukten. Das Unternehmen betreibt sieben Fabriken in ganz China und stellt Gel-Eisbeutel her, Trockeneisbeutel, Isolierte Kisten, VIP-Medizinkühlschränke, Kartoneinlagen und Palettenabdeckungen für große Pharmakonzerne und Lebensmittel-E-Commerce-Unternehmen. Tempk unterstützt Kunden dabei 24/7 Online-Dienst, Echtzeitverfolgung und umweltfreundliche Lösungen. Wir verbinden Innovation, Qualität und Nachhaltigkeit, um Ihnen beim Schutz temperaturempfindlicher Waren zu helfen.

Aufruf zum Handeln: Wenn Sie temperaturempfindliche Produkte schützen müssen, Kontaktieren Sie unser Team für maßgeschneiderte vakuumisolierte Boxen. Wir bewerten Ihre Kühlkettenstrategie, Empfehlen Sie die beste Verpackungslösung und helfen Sie Ihnen, die Compliance einzuhalten und gleichzeitig die Kosten zu senken.