Vacuum Insulation Panel Box for Pharmaceutical Cold Chain Solutions: How to Protect Medicines in 2025

Last Updated: Dezember 2 2025 (Pacific Time)

Impfungen, biologics and other temperature sensitive medications need strict cold chain protection. A Vakuumisolierungspanel (VIP) Kasten achieves ultra low heat transfer by combining a microporous core, barrier film, supporting structure and phase change materials (PCMs), allowing it to maintain therapeutic ranges for days. This guide explains why VIP boxes are game changers for pharmaceutical shipping and how you can select the right solution to meet stringent 2025 Standards.

What is a VIP box and how does it work? Learn about its construction—microporous core, multi layer barrier and PCM integration—and why it offers heat conductivity around 5 mW/m·K.

Why choose a VIP box over foam coolers? Discover how VIP boxes extend hold time by 7–10 days and are 5–10 times more effective at insulation.

How to select the best VIP box? Understand how temperature range, Transitdauer, PCM pairing, Größe, compliance and sustainability factor into your decision.

Was sind die 2025 Innovationen und Trends? Explore 4D materials, wiederverwendbare Systeme, IoT -Sensoren, Digitale Zwillinge, AI and blockchain that are reshaping cold chain logistics.

Frequently asked questions and practical tips: Get answers on safe temperatures, hold times, reuse and regulatory compliance.

What Is a Vacuum Insulation Panel Box and How Does It Work?

Direkte Antwort: A VIP box is an advanced cooler that uses a microporous core, laminated barrier film and robust outer shell to create an almost air free interior. Heat conduction is minimized to around 0.005 W/m · k, meaning the box maintains 2 °C–8 °C or even frozen ranges for 7–10 days—two to three times longer than EPS or PUR foam coolers. Phasenwechselmaterialien (PCMs) placed around the payload absorb heat as they melt, stabilizing internal temperature throughout transit.

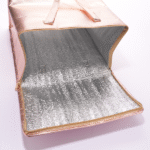

Erweiterte Erklärung: Imagine the VIP box as a thermos on steroids. Its inner core is made of highly porous silica or glass fibres pressed under vacuum. Without air molecules, there is little medium to transfer heat. The core is wrapped in layers of barrier film—aluminium, polyethylene and polyethylene terephthalate (HAUSTIER)—to preserve the vacuum and prevent moisture ingress. Surrounding this are structural panels and a protective outer shell that can be high density polyurethane or tough polypropylene. PCMs (Z.B., water based gel packs for 2 °C–8 °C or salt solution packs for –20 °C) line the inner surfaces; as they melt, they absorb latent heat, buffering against external temperature changes. The result is a lightweight yet powerful cooler that can hold temperatures far longer than foam boxes and with thinner walls. Tatsächlich, VIP insulation can reduce package size by 60 % compared to EPS systems while delivering comparable payload volume.

Components of a VIP Box and Their Roles

| Komponente | Funktion | Bedeutung für die reale Welt |

| Microporous core | Provides a network of voids sealed in a vacuum; typical materials include silica or glass fibre. Thermal conductivity as low as 0.004–0.008 W/(m·K). | Maintains a stable cold environment with minimal material, allowing smaller and lighter boxes. |

| Barrierefolie | Multi layer plastic and aluminium film seals the core, prevents gas permeation and moisture ingress. | Ensures the vacuum remains intact over multiple shipments; improves durability compared to bare foam. |

| Support structure | Typically honeycomb boards or rigid foam frameworks that protect the fragile core from compression. | Allows stacking and prevents damage during transport. |

| Außenschale | Made from polypropylene, aluminium or reinforced plastic. Provides mechanical strength, puncture resistance and compatibility with transport regulations. | Reduces the need for a separate protective shell, enabling lighter packages and lower freight costs. |

| Phasenwechselmaterialien (PCMs) | Gelpackungen, eutectic solutions or dry ice; selected according to desired temperature range. | Buffer against external temperatures; must match the product’s melting point for optimal performance. |

Praktischer Tipp: Matching PCMs to Your Temperature Range

2 °C–8 °C shipments: Verwenden water based gel packs or eutectic plates that melt at ~5 °C. These maintain vaccines and biologics within the CDC recommended range.

–15 °C to –25 °C shipments: Choose salt solution or ammonium chloride PCMs; they freeze at lower points and maintain frozen vaccines or biologics.

Ultrakalt (–70 °C) Sendungen: Trockeneis (–78,5 °C) may be required for mRNA vaccines and cell therapies. Always refer to manufacturer guidelines.

Fallbeispiel: Researchers at a vaccine manufacturer tested microporous polyurethane VIP panels and found they could retain temperatures between –30 °C and 25 °C für bis zu 109 Std. for a 49 L box. This performance outstripped traditional foam boxes and allowed shipping across continents without refreezing.

Why Choose a VIP Box Over Conventional Foam Coolers?

Direkte Antwort: VIP boxes deliver two to three times longer hold time than expanded polystyrene (EPS) or polyurethane foam coolers. With thermal conductivity around 5 mW/m·K, they maintain 7–10 day cold chain integrity. They also reduce packaging volume, cut freight costs and improve environmental footprint.

Erweiterte Erklärung: Conventional foam coolers work by trapping air in pores, but air is a mediocre insulator. To achieve long hold times, foam walls must be thick, resulting in large, bulky boxes. VIP panels are 5–10 times more efficient than foam; as such, a VIP box can maintain temperatures with walls one fifth the thickness of EPS. This means a larger payload fits into a smaller outer dimension, saving space in trucks, planes and storage. Auch, because VIP boxes are lighter, carriers may charge less for shipping. Real world studies show that when a company switched from foam to VIP shippers, the hold time increased from 2–3 days to 7–10 days, reducing the need for extra gel packs and eliminating mid shipment re icing. The intangible benefits include stable temperature profiles (less risk of freezing or overheating) and improved product integrity throughout the distribution chain.

Pros and Cons of VIP Boxes

| Aspekt | Vorteil | Überlegungen |

| Extended hold time | Bis zu 10 days without re icing; suitable for long haul flights and remote deliveries. | Monitoring is still necessary to ensure PCMs remain effective and to detect external excursions. |

| Space and weight efficiency | Thinner insulation means more payload for the same outer size; durable outer film eliminates need for separate EPS shell. | Some VIP boxes may have limited standard sizes; modular designs are emerging to address this. |

| Stabiles Temperaturprofil | Maintains narrow ranges with minimal fluctuations, protecting biologics and cell therapies; less risk of freezing near PCMs. | Improper PCM selection can lead to underperformance; careful validation is key. |

| Nachhaltigkeit | Reusable systems reduce waste; lighter packages decrease carbon emissions. | Manufacturing VIPs is energy intensive; disposal requires proper recycling of barrier films and core materials. |

| Kosten | Higher upfront cost than EPS; payback achieved through reuse and reduced freight. | May not be cost effective for single use or low value shipments. |

| Fragility | Vacuum panels are sensitive to punctures; once the vacuum is lost, insulation performance drops dramatically. | Choose boxes with durable outer shells and handle them carefully. |

Tips to Reduce VIP Costs

Adopt reusable logistics: Many pharmaceutical companies recoup initial investment by using VIP boxes across multiple cycles. A biotech firm using reusable VIP panels cut packaging waste by 40 % and lowered shipping costs while maintaining 2 °C–8 °C for monoclonal antibodies.

Right size your box: Over sizing leads to unnecessary PCM usage and higher freight costs. Use modular VIP systems to match payload volume and reduce wasted space.

Combine with data loggers: Monitoring sensors allow you to track panel performance and schedule preventive replacement instead of discarding entire boxes prematurely.

How to Select the Right VIP Box for Your Pharmaceuticals

Selecting a VIP box isn’t just about picking the highest insulation value. Start with your product’s temperature range and required transit duration, then layer additional considerations like regulatory compliance, payload size and sustainability.

Define the temperature profile and hold time. Determine whether your product needs refrigeration (2 °C–8 °C), frozen conditions (–15 °C to –25 °C) oder extrem kalt (–70 °C). VIP boxes with PCMs matched to these ranges will maintain the correct environment for up to 7–10 days. For shipments exceeding one week, plan for additional PCMs or consider hybrid systems with active refrigeration.

Match PCMs to the box. PCMs must have melting points aligned with your desired range. Water based gels are ideal for 2 °C–8 °C, while salt solutions serve –20 °C shipments. Eutectic mixtures can maintain ultra cold conditions for mRNA vaccines and cell therapies. Place PCMs evenly around the payload to prevent temperature gradients.

Size and payload. VIP panels are more space efficient than foam, but you still need to ensure the internal dimensions fit your vials, syringes or kits. Allow space for PCMs without compressing the product. Larger payloads may benefit from partitioned boxes to separate PCMs and avoid localized freezing.

Vorschriftenregulierung. Gute Vertriebspraxis (BIP), FDA and WHO guidelines require that vaccines remain within 2 °C–8 °C during storage and transport. ISO standards and IATA temperature control regulations govern packaging integrity, Kennzeichnung und Dokumentation. Select VIP systems that are validated and certified to meet these requirements.

Reuse and sustainability. If you frequently ship high value pharmaceuticals, wählen reusable VIP boxes. Their durability and extended lifespan spread the initial cost over many shipments, Senkung der Gesamtbetriebskosten. Look for suppliers offering refurbishment or panel replacement services.

Cost and ROI. Evaluate shipping frequency, product value and failure costs. For expensive biologics with long transit times, VIP boxes pay off quickly by preventing spoilage and reducing re ice interventions. For shorter domestic routes, foam boxes may suffice.

Entscheidungstool: Create a simple checklist: Temperaturbereich → Transittage → payload volume → number of shipments per year. Use this matrix to decide whether a premium VIP box, hybrid active cooler or a budget foam option is appropriate. Include columns for regulatory requirements and sustainability goals to guide final selection.

Industry Use Cases and Scenario Analysis

Biomedical Research Shipping: Protecting mRNA Vaccines

In 2021–2023, global vaccine campaigns highlighted the need for ultra cold shipment. An example from a research network used VIP boxes with dry ice to maintain –70 °C conditions for mRNA vaccines across intercontinental flights. The VIP’s thinner walls and strong outer shell allowed the same payload to be packed into smaller, lighter boxes, saving air freight costs. The hold time extended to 7 Tage, enabling distribution to remote clinics without active refrigeration.

Monoclonal Antibody Therapies: Reusable VIPs Reduce Waste

A mid sized biotech firm partnered with a supplier offering reusable VIP panels. Over the course of a year, they reduced packaging waste by 40 % and benefited from lower shipping costs across multiple cycles, while still maintaining 2 °C–8 °C for monoclonal antibody therapies. The return programme incorporated an e ink display with a QR code for easy return instructions. The company reported improved sustainability metrics and avoided supply disruptions from packaging shortages.

Field Hospital Deployment: Long Range Vaccine Transport

During a humanitarian mission, vaccines needed to reach a remote area where electricity and refrigeration were unreliable. The team used VIP boxes with water based PCMs and integrated data loggers. The boxes kept vaccines within 2 °C–8 °C for over 7 Tage, even when ambient temperatures fluctuated between 10 °C und 35 °C. Data loggers recorded consistent internal temperatures, proving their stability and supporting regulatory compliance. The mission delivered 5000 doses without a single temperature excursion.

2025 Innovations and Trends in Pharmaceutical Cold Chain Packaging

Intelligente Verpackungen, 4D Materials and Sensors

Intelligente Verpackungen refers to containers embedded with sensors and adaptive materials. Advances in PCMs, vacuum insulated panels and shape memory polymers allow packaging to adjust to external conditions and maintain temperature stability. Embedded IoT sensors communicate real time temperature, humidity and location data through low power networks, enabling immediate interventions when conditions deviate. Von 2025, these features have become integral to high value shipments, enhancing compliance and product security.

Praktischer Nutzen: Real time data allows managers to reroute shipments, activate backup cooling or quarantine packages instantly. It also generates audit ready reports for GDP and FDA inspections.

Integrated IoT, AI and Digital Twins

Cold chain providers now use IoT sensors combined with AI analytics to predict equipment failures, optimise routes and detect anomalies before temperature excursions occur. Digital twins—virtual replicas of supply chains—simulate disruptions such as border closures or natural disasters and help companies test contingency plans. This technology reduces risk, lowers costs and improves decision making.

Beispiel: A gene therapy company modelled its supply chain across multiple continents with digital twins. Simulations revealed a bottleneck at a customs hub, so the firm pre booked alternative routes and installed satellite connected IoT devices. During an actual strike, they avoided delays and ensured patients received therapies on schedule.

Reusable and Modular Packaging

Reusable systems are gaining market dominance because they reduce waste and total cost. Manufacturers now invest in vakuumisolierte Paneele, phase change materials and modular designs, offering packaging that can be returned, sterilised and redeployed. Reusable boxes integrate Intelligente Etiketten that display return instructions and track usage counts. They lower the per use cost and support corporate sustainability goals.

Tipp: Evaluate your return logistics; if shipments travel between fixed locations, reuse can drastically reduce costs and environmental impact. For random last mile deliveries, single use or hybrid solutions may be better.

Active Cooling and Self Refrigerated Systems

Emerging technologies include self refrigerated boxes like the Ember Cube, which maintain 2 °C–8 °C for over 72 hours using integrated PCMs and active cooling. These boxes feature real time tracking via cellular radio and GPS, and they have return to sender functions with e ink displays. Portable cryogenic freezers for cell and gene therapies are also becoming mainstream, enabling shipments below –80 °C with built in thaw control.

Sustainable Materials and Natural Fibres

Sustainability drives innovation. VIPs now incorporate recyclable barrier films and cores made from Aerogele Und nanofoams—materials composed of up to 99 % Luft. These can be two to three times more insulating than Styrofoam and reduce package weight by up to 40 %. Natural fibres (Z.B., sheep’s wool, seaweed, Recyclingpapier) are used for moderate temperature shipments and can keep –20 °C for over 120 hours while being compostable. Extended producer responsibility laws in 2025 encourage companies to design packaging with end of life in mind.

Marktwachstum und Investitionen

Der global pharmaceutical cold chain packaging market wird voraussichtlich wachsen USD 17.5 Milliarden in 2024 in USD 71.6 Milliarden von 2034, driven by mRNA and cell therapies and stringent regulatory requirements. VIP adoption is expanding as companies seek thinner, more efficient insulation. Der temperature controlled packaging market, including VIP boxes, is forecast to rise from USD 6.36 Milliarden in 2025 in USD 11.50 Milliarden von 2034, with North America holding the largest share and Asia–Pacific exhibiting the highest growth.

This growth attracts investment in new materials and smart technologies. Expect further integration of AI, blockchain and 5G connectivity to enhance traceability, vorausschauende Wartung und Routenoptimierung.

Regulatory Harmonisation and Compliance

Gute Vertriebspraxis (BIP) guidelines mandate storage between 2 °C und 8 °C for most cold chain medicines. The CDC and WHO recommend continuous digital monitoring and data logging. In 2025, authorities update Annex 11 and USP <1079> to address IoT, AI and blockchain data integrity. Ensuring your VIP packaging solutions are GDP compliant and validated protects your products and positions your business for expansion into new markets.

Häufig gestellte Fragen

What temperature range do VIP boxes maintain? Most VIP boxes hold 2 °C–8 °C using water based PCMs. With appropriate PCMs, they can maintain –20 °C for frozen vaccines or –70 °C for gene therapies. Always select PCMs that match your product’s melting point to ensure stability.

How long can a VIP box maintain temperature? VIP systems typically keep pharmaceuticals within specification for 7–10 Tage. Studies on polyurethane vacuum panels have shown up to 109 Std. of retention for –30 °C to 25 °C-Versand.

Are VIP boxes reusable? Ja. Many manufacturers design VIP boxes for multiple shipment cycles. A reuse programme can cut packaging waste by 40 % und geringere Versandkosten. Inspect panels for punctures and verify that vacuum integrity remains intact.

Do VIP boxes need data loggers or IoT sensors? Ja. Regulatory bodies like the CDC require digital temperature monitoring Für Impfstoffe. IoT sensors provide real time data and ensure compliance with GDP and DSCSA guidelines.

How do VIP boxes compare with active refrigeration? VIP boxes rely on passive insulation and PCMs; they’re lighter, quieter and cheaper than compressor based fridges. Jedoch, active systems provide infinite run time with power supply and may be necessary for extremely long or unpredictable journeys.

What are the common pitfalls when using VIP boxes? Using incorrect PCMs, under estimating payload heat load and rough handling can compromise performance. Always validate packaging with sample shipments and train staff on correct loading and handling techniques.

Zusammenfassung und Empfehlungen

Vacuum insulation panel boxes revolutionize pharmaceutical cold chain logistics by delivering ultra low thermal conductivity and extended hold times. They enable shipping across continents without re icing, cut freight costs through reduced weight and volume, and support sustainability through reuse. To harness their benefits:

Identify your temperature range and hold time, then select matching PCMs and box sizes. VIPs excel for 2 °C–8 °C shipments lasting up to 10 Tage; for ultra long or ultra cold shipments, consider active or hybrid systems.

Invest in reusable VIP systems if you ship high value or frequent loads. They provide long term cost savings and reduce environmental impact.

Integrate real time monitoring via IoT sensors and data loggers to meet regulatory demands, detect excursions and generate audit ready reports.

Stay abreast of innovations: Evaluate smart packaging, digital twins and AI driven route optimisation to enhance efficiency. Adopt sustainable materials like aerogels and natural fibres to comply with evolving regulations.

Bilden Sie Ihr Team weiter on packing, handling and regulatory requirements. Proper training reduces failures and ensures you get the full benefit of VIP technology.

Durch Befolgen dieser Richtlinien, you can protect your temperature sensitive medicines, meet strict regulatory standards, and future proof your logistics operations.

Über Tempk

Tempk ist ein cold chain technology provider specializing in vacuum insulated containers, phase change materials and IoT enabled monitoring. Updated in November 2025, their platform integrates PCMs, IoT sensors and AI analytics to deliver end to end visibility and predictive maintenance. Tempk’s reusable systems support shipments ranging from 2 °C to –80 °C, and their solutions include real time tracking, blockchain traceability and sustainable packaging options. If you’re looking to upgrade your pharmaceutical cold chain or need expert advice on VIP boxes, contact their team for a customised assessment.