Der Kaltkettenindustrie ist das Rückgrat der globalen Ernährung, Pharma- und Biotech-Lieferketten. In 2025 Dieser Sektor boomt – im Wert von ca 436,30 Milliarden US-Dollar mit Prognosen über 1,3 Billionen US-Dollar 2034. Geopolitische Störungen, Das Wachstum des E-Commerce und strengere Vorschriften verändern die Art und Weise, wie temperaturempfindliche Waren gelagert und transportiert werden. In diesem Leitfaden erfahren Sie, warum die Kühlkettenbranche wichtig ist, wie es sich entwickelt und was Sie tun können, um an der Spitze zu bleiben.

Warum ist die Kühlkettenbranche von entscheidender Bedeutung? 2025? Verstehen Sie seine Rolle und Wachstumstreiber, einschließlich pflanzlicher Lebensmittel, Pharmazeutika und Welthandel.

Welche Technologien verändern die Kühlkettenlogistik?? Erfahren Sie mehr über KI-gestützte Routenoptimierung, Blockchain, solarbetriebene Speicher und IoT-Sensoren.

Welchen Einfluss haben Vorschriften und Nachhaltigkeit auf den Betrieb?? Entdecken Sie FSMA 204 Rückverfolgbarkeitsregeln und HFKW-Beschränkungen beginnen 2025.

Welche Markttrends und regionalen Erkenntnisse die Branche prägen? Entdecken Sie Prognosen für globale und nordamerikanische Märkte und den Aufstieg der Schwellenländer.

Wie können Sie Ihre Abläufe optimieren?? Erhalten Sie praktische Tipps zur Überwachung, Ausbildung, erneuerbare Energien und Notfallplanung.

Wofür gibt es die neuesten Innovationen? 2025 und darüber hinaus? Sehen Sie sich neue Geräte an, neue Produktkategorien und neuartige Liefermethoden.

Was ist die Kühlkettenbranche und warum ist sie von entscheidender Bedeutung? 2025?

Definition und Bedeutung: Die Kühlkettenbranche umfasst alle zur Handhabung eingesetzten Prozesse und Technologien, Lagern und transportieren Sie temperaturempfindliche Güter unter Einhaltung strenger Temperaturbereiche. Hierzu zählen auch Kühllager, isolierte Fahrzeuge und hochentwickelte Überwachungssysteme. In 2025 Die Branche ist unverzichtbar, Unterstützung der globalen Nahrungsmittelversorgung, Impfungen, Biologika und pflanzliche Lebensmittel.

Wachstumstreiber: Die Nachfrage steigt rasant, weil die Verbraucher Frische erwarten, sichere Produkte und Regulierungsbehörden setzen strenge Lebensmittel- und Arzneimittelstandards durch. Untersuchungen schätzen den Markt für Kühlkettenlogistik auf 436,30 Milliarden US-Dollar im Jahr 2025, voraussichtlich übertreffen 1,3 Billionen US-Dollar 2034 mit a 13.46 % CAGR. Dieses Wachstum wird durch den zunehmenden weltweiten Handel mit verderblichen Lebensmitteln vorangetrieben, der Aufstieg von Online-Lebensmittellieferungen und E-Commerce-Lieferungen sowie schnelle technologische Innovationen. Schwellenländer mit steigenden Einkommen und Urbanisierung erhöhen die Nachfrage.

Neue Produktkategorien: Pflanzliche Proteine, Glutenfreie und biologische Lebensmittel werden zum Mainstream. Bloomberg Intelligence hat vorausgesagt, dass pflanzliche Lebensmittel eine Rolle spielen könnten 7.7 % des globalen Proteinmarktes durch 2030 mit a 162 Milliarden US-Dollar Wert. Für diese Produkte sind spezielle Kühlkettendienste erforderlich, und viele Produzenten sind kleine oder mittlere Unternehmen, die Beratung benötigen.

Pharma- und Biologika-Boom: Biopharmazeutika, mRNA-Impfstoffe und Gentherapien erfordern extrem niedrige Temperaturen. Global Market Insights betont, dass Biologika und mRNA-Impfstoffe extrem niedrige Lager- und Transporttemperaturen erfordern, Logistikdienstleister werden unter Druck gesetzt, ihre Ausrüstung zu modernisieren. Als ungefähr 20 % neuer Medikamente In der Entwicklung befinden sich Gen- und Zelltherapien, Die Fähigkeit zur Tiefkühllogistik wird zu einer Wettbewerbsnotwendigkeit.

Operative Herausforderungen: Alternde Infrastruktur, Ineffizienzen und regulatorischer Druck zwingen Unternehmen zur Modernisierung ihrer Anlagen. Viele Kühlgebäude sind 40–50 Jahre alt und erfordern eine Modernisierung der Automatisierung, Nachhaltigkeit und Sichtbarkeit. Gleichzeitig, hohe Betriebs- und Energiekosten, Arbeitskräftemangel und Temperaturschwankungen gefährden die Rentabilität.

Komponenten einer modernen Kühlkette

Kühlsysteme: Kompressoren, Kondensatoren und Verdampfer senken die Produkttemperaturen auf den entsprechenden Bereich, Sicherstellen, dass die Waren innerhalb bestimmter Schwellenwerte bleiben.

Temperaturkontrollierte Lagerung: In Kühllagern kommen Isolierplatten zum Einsatz, automatisierte Lager- und Bereitstellungssysteme und hochdichte Palettenregale zur Minimierung von Temperaturschwankungen.

Verkehrsinfrastruktur: Isolierte LKWs, Kühlcontainer, Kühltriebwagen und tragbare kryogene Gefriergeräte halten die Temperatur während des Transports aufrecht. Einige Einrichtungen verwenden mobile Kryoanlagen, die für Biologika eine Temperatur von –80 °C bis –150 °C aufrechterhalten können.

Überwachungs- und Kontrollsysteme: IoT-Sensoren und Datenlogger übertragen die Temperatur in Echtzeit, Luftfeuchtigkeit und Standortdaten, Ermöglicht sofortiges Handeln bei abweichenden Bedingungen.

Qualitätssicherungsprotokolle: Temperaturkartierung, Notfallpläne und First-In-First-Out (FIFO) Die Bestandsverwaltung gewährleistet die Einhaltung von Vorschriften und minimiert Verschwendung.

Typische Temperaturbereiche

| Temperaturbereich | Zweck | Beispielprodukte | What It Means for You |

| Ambient (59–86 °F) | Kontrollierte Raumtemperatur für haltbare oder risikoarme Waren | Trockenfutter, einige Arzneimittel | Minimale Kühlkosten; Sorgen Sie für eine ausreichende Belüftung, um einen Hitzestau zu verhindern |

| Cool (50–59 °F) | Milde Kühlung, um Geschmack und Textur zu bewahren | Käse, frische Produkte | Reduziert den Verderb; erfordert isolierte Behälter und kurze Transportzeiten |

| Gekühlt (32–50 °F) | Verhindert Bakterienwachstum und sorgt für Frische | Impfungen, Milchprodukte | Strenge Temperaturregelung; Nutzen Sie IoT-Sensoren zur Echtzeitüberwachung |

| Gefroren (–22–32 °F) | Langzeitkonservierung verderblicher Waren | Fleisch, Meeresfrüchte, gefrorene Desserts | Erfordert Tiefkühlgeräte und Redundanzpläne für Stromausfälle |

Praktische Tipps und Empfehlungen

Planen für Eventualitäten: Entwickeln Sie Notfallprotokolle für Geräteausfälle oder Stromausfälle, um Schäden zu verhindern.

Nutzen Sie IoT-Sensoren: Installieren Sie intelligente Sensoren an Lagereinheiten und Fahrzeugen, um Temperatur und Luftfeuchtigkeit zu überwachen und Warnungen zu automatisieren, wenn Grenzwerte überschritten werden.

Trainiere dein Team: Informieren Sie das Personal regelmäßig über die Handhabungsverfahren, Datenprotokollierung und Notfallreaktionen zur Aufrechterhaltung der Produktintegrität.

Beispiel aus der Praxis: In 2024 CJ Logistics America kündigte eine Kühllageranlage in der Nähe von Kansas City mit automatisierten Systemen an, Energieeffiziente Kühlung und IoT-Überwachung – zeigen, wie moderne Kühllager Technologie und Nachhaltigkeit verbinden.

Welche Technologien verändern die Kühlkettenlogistik? 2025?

KI-gestützte Routenoptimierung und prädiktive Analysen

Künstliche Intelligenz (Ai) analysiert historische und Echtzeitdaten, um Geräteausfälle vorherzusagen, Optimieren Sie Lieferrouten und prognostizieren Sie die Nachfrage. KI-Algorithmen berechnen die effizientesten Pfade unter Berücksichtigung des Verkehrs, Wetter- und Lieferfenster, Reduzierung des Kraftstoffverbrauchs und Sicherstellung, dass die Waren innerhalb der Temperaturspezifikationen bleiben. Die vorausschauende Wartung nutzt Sensordaten, um Ausfälle von Kühlaggregaten zu antizipieren, Dies ermöglicht proaktive Reparaturen und reduziert Ausfallzeiten. Nachfrageprognosen modellieren saisonale Konsummuster, Unterstützung von Unternehmen bei der Anpassung des Lagerbestands und der Reduzierung von Abfall.

IoT-fähige Echtzeitüberwachung

Das Internet der Dinge (IoT) bezieht sich auf ein Netzwerk verbundener Geräte – beispielsweise intelligente Sensoren, GPS-Tracker und Datenlogger – die Daten in Echtzeit sammeln und teilen. IoT-Geräte bieten eine durchgängige Transparenz über die gesamte Kühlkette, Übertragungstemperatur, Feuchtigkeits- und Standortinformationen an zentrale Plattformen. Zu den Vorteilen gehört die Verhinderung von Verderb durch kontinuierliche Überwachung, Sicherstellung der Einhaltung gesetzlicher Vorschriften durch Bereitstellung überprüfbarer Aufzeichnungen, und Aufbau des Kundenvertrauens durch den Austausch von Live-Daten. In 2022 das Hardware-Segment zur Kühlkettenverfolgung blieb zurück 76 % des Marktanteils, Dies unterstreicht die schnelle Akzeptanz dieser Geräte.

Blockchain für verbesserte Rückverfolgbarkeit

Die Blockchain-Technologie erstellt fälschungssichere Aufzeichnungen über Produktreisen, Dies ermöglicht eine lückenlose Rückverfolgbarkeit und verbessert die Transparenz. Zum Beispiel, Pharmaunternehmen können Temperatur- und Standortdaten in einem Blockchain-Ledger protokollieren, Herstellern erlauben, Transportunternehmen und Kliniken können auf dieselbe unveränderliche Aufzeichnung zugreifen. Dadurch wird das Risiko einer Datenmanipulation verringert, vereinfacht Audits und unterstützt die Einhaltung der FSMA 204 Anforderungen an die Rückverfolgbarkeit. Der Wert von Blockchain geht über Pharmazeutika hinaus: Es stärkt das Vertrauen der Verbraucher und hilft Marken, ihre Authentizität zu beweisen.

Solarbetriebene Kühlung und nachhaltige Innovationen

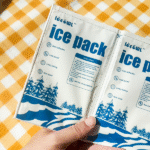

Der Energieverbrauch ist ein wesentlicher Kostentreiber in der Kühlkette. Solarbetriebene Kühleinheiten nutzen – insbesondere in ländlichen oder energiearmen Regionen – Solarpaneele, um Kühlspeicher mit Strom zu versorgen, Verringerung der Abhängigkeit vom Netzstrom. In den Vereinigten Staaten, Die kommerziellen Solarstromtarife liegen zwischen 3.2 Zu 15.5 Cent pro kWh, bietet potenzielle Einsparungen im Vergleich zu durchschnittlichen Stromtarifen. Zu den weiteren Innovationen zählen tragbare Kryo-Gefriergeräte, die für biologische Arzneimittel extrem niedrige Temperaturen aufrechterhalten können, leichte, intelligente Versandbehälter mit IoT-Sensoren und nachhaltige Verpackungslösungen wie biologisch abbaubare Verpackungen und wiederverwendbare Kühlakkus.

Die Rolle der KI, IoT, Blockchain und Solar in Ihrem Unternehmen

| Innovation | Beschreibung | Praktische Vorteile |

| KI-gestützte Routenoptimierung | Algorithmen analysieren den Verkehr, Wetter- und Lieferpläne, um effiziente Routen zu finden. | Schnellere Lieferungen, geringere Kraftstoffkosten und weniger Ausschuss. |

| Vorausschauende Wartung & Analytik | KI sagt Geräteausfälle und Nachfragetrends voraus. | Weniger Ausfallzeiten und höhere Kundenzufriedenheit. |

| IoT-Sensoren und Echtzeit-Tracking | Geräte überwachen die Temperatur, Luftfeuchtigkeit und Standort. | Sofortige Benachrichtigungen, weniger Produktverluste und eine bessere Einhaltung gesetzlicher Vorschriften. |

| Rückverfolgbarkeit der Blockchain | Verteilte Hauptbuchaufzeichnungen gewährleisten manipulationssichere Daten. | Mehr Transparenz, weniger Betrug und vereinfachte Prüfungen. |

| Solarbetriebene Kühlung | Sonnenkollektoren versorgen Kühllager mit Strom. | Niedrigere Energiekosten und geringerer CO2-Fußabdruck. |

| Tragbare kryogene Gefriergeräte | Mobile Einheiten halten –80 °C bis –150 °C aufrecht. | Ermöglicht den flexiblen Vertrieb von ultrakalten Biologika und Zelltherapien. |

| Nachhaltige Verpackung | Recycelbare Behälter und biologisch abbaubare Verpackungen reduzieren den Abfall. | Unterstützt die Nachhaltigkeitsziele des Unternehmens und die Einhaltung gesetzlicher Vorschriften. |

Beispiele und Fallstudien aus der Praxis

Fallstudie – Blockchain in Südostasien: Pharma-Lieferketten in Südostasien nutzen Blockchain-basierte Trackingsysteme zur Temperaturaufzeichnung, Luftfeuchtigkeit und Reisezeit in einem verteilten Hauptbuch. Echtzeitdaten bieten Stakeholdern einen sicheren Zugriff und gewährleisten die Einhaltung von Vorschriften, während solarbetriebene Speicher und IoT-Sensoren Medikamente schützen.

Einführung neuer Geräte: Global Market Insights berichtet, dass der Markt für Kühlkettenlogistikausrüstung weiter wachsen wird 94,3 Milliarden US-Dollar im Jahr 2025 auf 179,8 Milliarden US-Dollar 2034 mit a 7.4 % CAGR. Hersteller entwickeln energieeffizientere Kühlsysteme, automatisierte Handhabungsgeräte und schnelle Überwachungssysteme zur Aufrechterhaltung der Qualität. Unternehmen wie Carrier Transicold und Thermo King setzen Elektro- und Hybridkühlgeräte ein, um Emissionen zu reduzieren.

Wie prägen Vorschriften und Nachhaltigkeit die Kühlkettenbranche??

FSMA 204 Anforderungen an die Rückverfolgbarkeit

An Januar 6 2025, Die Gesetz zur Modernisierung der Lebensmittelsicherheit (FSMA) Abschnitt 204 trat für Lebensmittel in Kraft, die auf der Lebensmittelrückverfolgbarkeitsliste der FDA stehen. Unternehmen, die produzieren, Verfahren, Wer diese Lebensmittel verpackt oder lagert, muss für jedes kritische Tracking-Ereignis wichtige Datenelemente aufzeichnen, um eine schnelle Rückverfolgbarkeit zu gewährleisten. Compliance erfordert, dass Unternehmen diese Aufzeichnungen der FDA innerhalb von 24 Stunden vorlegen 24 Std., Förderung von Investitionen in digitale Aufzeichnungen und Echtzeitüberwachung.

HFKW-Beschränkungen und Nachhaltigkeitsvorschriften

Auch Vorschriften zwingen die Betreiber dazu, umweltfreundliche Kältemittel einzusetzen. Anfang Januar 1 2025, Bestimmte Technologien verwenden möglicherweise keine Fluorkohlenwasserstoffe mit hohem Treibhauspotenzial mehr (HFKW) oder HFC-Gemische. Für die Herstellung gelten Verbote, Verteilung, Verkauf, Installation und Export von Produkten, die eingeschränkte HFKW enthalten. Diese Beschränkungen beschleunigen den Übergang zu natürlichen Kältemitteln und energieeffizienten Systemen und sind oft mit steuerlichen Anreizen oder Strafen bei Nichteinhaltung verbunden.

Modernisierung der alternden Infrastruktur

Viele Kühllageranlagen, die vor 40–50 Jahren gebaut wurden, sind ineffizient und erfordern Modernisierungen zur Verbesserung der Automatisierung, Nachhaltigkeit und Sichtbarkeit. Betreiber ersetzen alte Gebäude oder rüsten sie durch automatisierte Lager- und Bereitstellungssysteme nach, Hocheffiziente Isolierung und IoT-fähige Überwachung. Verschärfung der Vorschriften für synthetische Kältemittel (H-FCKW und FKW) und steigende Energiekosten sind wesentliche Treiber dieser Modernisierung.

Nachhaltigkeit als Wettbewerbsvorteil

Investoren und Kunden bewerten Kühlkettenbetreiber zunehmend anhand ihrer Umweltleistung. Zu den Nachhaltigkeitsinitiativen gehören::

Natürliche Kältemittel: Verwendung von Ammoniak (NH₃), Kohlendioxid (Co₂) oder Kohlenwasserstoffe, die ein geringeres Treibhauspotenzial haben als HFKW.

Energieeffizienz: Einsatz hocheffizienter Kompressoren, Drehzahlgeregelte Antriebe und Wärmedämmung reduzieren den Energieverbrauch. Solarbetriebene Kühlung ist besonders in Regionen mit hohen Stromkosten attraktiv.

Umweltfreundliche Verpackung: Biologisch abbaubare oder recycelbare Verpackungsmaterialien reduzieren Abfall und entsprechen den Erwartungen der Verbraucher.

Green-Building-Standards: LEED-zertifizierte Kühllager nutzen natürliches Licht, energieeffiziente HVAC-Systeme und nachhaltige Materialien zur Minimierung der Umweltbelastung.

Vorschriften schaffen Chancen

Einhaltung der FSMA 204 und HFKW-Beschränkungen können belastend erscheinen, aber es eröffnet auch neue Geschäftsmöglichkeiten. Unternehmen, die in Rückverfolgbarkeitstechnologien investieren, Erneuerbare Energien und nachhaltige Kühlung können sich unterscheiden, Sichern Sie sich Premium-Kunden und vermeiden Sie Bußgelder. Regulatorische Anreize, wie Steuergutschriften für Energieeffizienz und Kältemittel mit niedrigem Treibhauspotenzial, kompensieren die anfänglichen Investitionskosten.

Was sind die wichtigsten Markttrends und regionalen Erkenntnisse für die Kühlkettenlogistik??

Globale Markttrends

Marktforschungsagenturen prognostizieren ein starkes Wachstum in allen Segmenten der Kühlkettenbranche. Precedence Research berichtet, dass der globale Markt für Kühlkettenlogistik weiter wachsen wird 436,30 Milliarden US-Dollar im Jahr 2025 auf 1,359 Billionen US-Dollar 2034, A 13.46 % CAGR. Treiber enthalten:

Ausweitung des globalen Lebensmittelhandels: Erhöhte Nachfrage nach frischen Produkten und Meeresfrüchten, gekoppelt mit vernetzten Lieferketten, kurbelt Investitionen an.

E-Commerce-Boom: Online-Lebensmitteleinkäufe und Lieferservices für Essenspakete erfordern zuverlässige, temperaturkontrollierte Liefernetzwerke.

Wachstum bei Pharmazeutika und Biologika: Die steigende Nachfrage nach Impfstoffen und personalisierter Medizin treibt Investitionen in Ultrakühllager voran.

Regulatorische Anforderungen: Lebensmittelsicherheitsvorschriften wie FSMA und ähnliche Standards weltweit schreiben eine strenge Temperaturüberwachung und -dokumentation vor.

Nachhaltigkeitsdruck: Umweltbewusstsein drängt Unternehmen dazu, energieeffiziente Technologien und umweltfreundliche Verpackungen einzuführen.

Regionale Einblicke

Asien–Pazifik: Rasante Urbanisierung, Steigende Einkommen und eine wachsende Mittelschicht treiben das Wachstum der Kühlkette in der Region voran. MarketsandMarkets-Projekte sollen die globale Kühlkettenbranche erreichen 372 Milliarden US-Dollar von 2029, Der asiatisch-pazifische Raum ist aufgrund der starken Nachfrage nach organisiertem Einzelhandel und verarbeiteten Lebensmitteln führend. Indiens hoher Milchkonsum (427 g pro Kopf im Vergleich zu einem weltweiten Durchschnitt von 305 G) und der Aufschwung von Schnellrestaurants (voraussichtlich 20–25 % Wachstum im Geschäftsjahr 2024) unterstreichen die dringende Notwendigkeit einer zuverlässigen Logistik.

Nordamerika: Der nordamerikanische Kühlkettenmarkt ist erreicht 116,85 Milliarden US-Dollar im Jahr 2024 und wird voraussichtlich um a wachsen 9.50 % CAGR zwischen 2025 Und 2034, greifen 289,58 Milliarden US-Dollar. Der reife, aber expandierende Markt der Region wird von der biopharmazeutischen Nachfrage angetrieben, Wachstum des E-Commerce und Investitionen in neue Lagereinrichtungen und grenzüberschreitenden Transport. Die Betreiber übernehmen nachhaltige Praktiken, energieeffiziente Geräte und fortschrittliche Überwachungssysteme.

Europa: Umweltbewusstsein und strenge Vorschriften zwingen europäische Betreiber dazu, umweltfreundliche Technologien und energieeffiziente Praktiken einzuführen. Die veraltete Infrastruktur wird modernisiert, um den aktuellen Effizienz- und Nachhaltigkeitsstandards zu entsprechen.

Schwellenländer: Länder in Südostasien, Afrika und Lateinamerika investieren stark in Kühlkettenkapazitäten, um wachsende Verbrauchermärkte und Arzneimittelbedürfnisse zu decken. Solarbetriebene Kühlung und Blockchain-Rückverfolgbarkeit sind besonders wertvoll in Regionen mit unzuverlässiger Stromversorgung oder regulatorischen Herausforderungen.

Marktsegmentierung und Chancen

Der Kühlkettenmarkt kann segmentiert werden nach Servicetyp (Transport, Lagerhaltung und Mehrwertdienste), Temperaturbereich (Ambient, Cool, gekühlt, gefroren), Technologie (Kühlfahrzeuge, IoT-Lösungen, Automatisierung) Und Endverwendung (Essen und Getränk, Arzneimittel, Biotechnologie). Zum Beispiel:

Trockeneis-Technologie gefangen genommen 55.16 % des Marktanteils in 2024, während Kühllager vertreten 238,29 Milliarden US-Dollar.

Vorkühlanlagen im asiatisch-pazifischen Raum generiert 204,4 Milliarden US-Dollar im Umsatz in 2024, Hervorhebung der Bedeutung der frühzeitigen Kühlung von Obst und Gemüse.

Segmentierung der Servicetypen: Der nordamerikanische Kühlkettenmarkt ist in Kühllagerung und Kühltransport aufgeteilt, mit Lagerinvestitionen mit Schwerpunkt auf Automatisierung und Nachhaltigkeit.

Endverwendungssegmentierung: Pharmazeutika, Fleisch und Meeresfrüchte, Milch- und Tiefkühlprodukte tragen maßgeblich dazu bei.

Bemerkenswerte Branchenentwicklungen (2024–2025)

Anlagenerweiterungen: Nordamerikanische Betreiber investieren in neue Lagereinrichtungen und grenzüberschreitende Transporte. CJ Logistics America plant ein Kühllager in der Nähe von Kansas City. Lineage Logistics führt grenzüberschreitende Transportdienste ein, die die USA und Kanada verbinden. Agile Cold Storage investiert 45,9 Millionen US-Dollar in einem automatisierten Kühllager in Louisiana. United States Cold Storage erweitert sein Lager in Tulare North um 8.56 Millionen Kubikfuß.

Technologische Fortschritte: Hersteller bringen neue Elektro- und Hybrid-Transportkühlgeräte auf den Markt. Zum Beispiel, Thermo King stellte 2019 die vollelektrischen A 500e- und Hybrid-S 750i-Geräte vor 2025, während Carrier Transicold den Vector S vorstellte 15 Anhängereinheit mit kompletter Elektrotechnik.

Nachhaltigkeitsinitiativen: Unternehmen investieren in natürliche Kältemittel, energieeffiziente Kompressoren und erneuerbare Energien. Daikin Industries und Carrier Transicold stellen energieeffiziente Kompressoren und E-Drive-Technologie vor, um den gesetzlichen Anforderungen und der Kundennachfrage gerecht zu werden.

Wie können Unternehmen ihre Kühlkettenabläufe optimieren? 2025?

Entwickeln Sie eine robuste Überwachung und Steuerung

Setzen Sie IoT-Sensoren und automatisierte Datenlogger in Lagereinheiten und Fahrzeugen ein, um die Temperatur zu überwachen, Luftfeuchtigkeit und Standort in Echtzeit. Zentralisierte Dashboards können diese Daten analysieren und Warnungen auslösen, wenn die Bedingungen abweichen. Kontinuierliche Überwachung hilft, Verderb zu verhindern und stellt die Einhaltung der FSMA- und Arzneimittelvorschriften sicher.

Planen Sie Eventualitäten und Resilienz

Ausfälle der Kühlkette sind häufig auf Stromausfälle zurückzuführen, Geräteausfälle oder Wetterstörungen. Erstellen Sie Notfallpläne, die redundante Stromversorgungen einschließen (wie Generatoren und Batterie-Backups), Notfallprotokolle und proaktive Wartungspläne. Regelmäßige Stresstests und Übungen stellen sicher, dass Ihr Team bei Störungen schnell reagieren kann.

Investieren Sie in Mitarbeiterschulung und -kultur

Menschliches Versagen trägt zu vielen Temperaturschwankungen bei. Führen Sie regelmäßige Schulungen zu den Handhabungsverfahren durch, Datenprotokollierung und Notfallreaktion. Fördern Sie eine Kultur der kontinuierlichen Verbesserung, indem Sie Feedback fördern und Best Practices abteilungsübergreifend austauschen. Eine qualifizierte Belegschaft verbessert die Compliance und die Kundenzufriedenheit.

Bewerten Sie erneuerbare Energien und nachhaltige Verpackungen

Bewerten Sie die Machbarkeit der Installation von Solarmodulen auf Lagerdächern und Kühlfahrzeugen. Vergleichen Sie langfristige Einsparungen und verfügbare Steueranreize mit den Vorabkosten. Integrieren Sie biologisch abbaubare oder recycelbare Verpackungen, um Abfall zu reduzieren und den Erwartungen der Verbraucher gerecht zu werden.

Integrieren Sie KI und Datenanalyse

Nutzen Sie KI-Tools, um Routen zu optimieren, Prognostizieren Sie den Bedarf und prognostizieren Sie Geräteausfälle. Integrieren Sie diese Systeme mit menschlichem Fachwissen – nutzen Sie KI als Entscheidungsunterstützungstool und behalten Sie gleichzeitig erfahrenes Personal bei, das sich an unvorhergesehene Bedingungen anpassen kann. Beginnen Sie mit Pilotprojekten, um den Nutzen vor der Skalierung zu bewerten.

Arbeiten Sie mit erfahrenen Partnern zusammen

Kleinen und mittleren Unternehmen, die in die Kühlkettenbranche einsteigen, mangelt es oft an Logistikkompetenz. Arbeiten Sie mit erfahrenen Anbietern zusammen, die über umfangreiche Netzwerke verfügen, Technologieinfrastruktur und regulatorisches Wissen, um einen sicheren und effizienten Transport temperaturempfindlicher Güter zu gewährleisten. Zusammenarbeit reduziert das Risiko, verbessert die Sichtbarkeit und hilft bei der Skalierung von Abläufen bei steigender Nachfrage.

Welche neuesten Entwicklungen und Innovationen werden erwartet? 2025 und darüber hinaus?

Neue Produkte und Geräte

Der weltweite Markt für Kühlkettenlogistikausrüstung wird voraussichtlich wachsen 94,3 Milliarden US-Dollar im Jahr 2025 auf 179,8 Milliarden US-Dollar 2034. Innovationen umfassen:

Alle Elektro- und Hybrid-Kühlgeräte: Unternehmen wie Thermo King und Carrier Transicold bringen elektrische und hybride Transportkühlgeräte auf den Markt, um den Kraftstoffverbrauch und die Emissionen zu reduzieren. Der A 500e und der Hybrid S 750i liefern Langstreckenleistung ohne Diesel, während Carriers Vector S 15 nutzt die rein elektrische E-Drive-Technologie.

Digitales Scout AI-Tool: Emerson Electric führte im September 2025 Scout AI ein – ein digitales Tool, das Echtzeitdiagnosen ermöglicht, vorausschauende Wartung und Fernüberwachung für Kühlkettengeräte. Solche Lösungen erhöhen die Zuverlässigkeit und senken die Wartungskosten.

Intelligente Behälter und tragbare kryogene Gefriergeräte: Leichte, isolierte Behälter, die mit IoT-Sensoren ausgestattet sind, überwachen die Temperatur, Luftfeuchtigkeit und Standort. Tragbare Kryo-Gefriergeräte halten ultrakalte Temperaturen für Biologika und Zelltherapien aufrecht.

Nachhaltige Verpackungsmaterialien: Unternehmen entwickeln umweltfreundliche Verpackungen wie biologisch abbaubare Thermoverpackungen und wiederverwendbare Kühlakkus. Diese Materialien minimieren die Umweltbelastung und erfüllen gleichzeitig die gesetzlichen Anforderungen.

Neue Servicemodelle und Vertriebsstrategien

Verteilte Mikrolager: Um die Transitzeiten zu verkürzen und die Zustellung auf der letzten Meile zu verbessern, Einige Betreiber errichten kleinere regionale Einrichtungen näher an den Verbrauchern. Dies verbessert die Flexibilität und verringert das Risiko von Temperaturschwankungen während der Endlieferung.

Intelligente Routenplanung: KI-gestützte Software integriert Verkehrsdaten, Wettermuster und Lieferfenster, um dynamisches Routing zu generieren, Verbesserung der Effizienz und Belastbarkeit.

Kühllager auf Anfrage: Tragbare modulare Einheiten bieten temporäre Lagerung für saisonale Spitzen oder abgelegene Standorte. Sie ermöglichen es Unternehmen, ihre Kapazitäten ohne große Kapitalaufwendungen zu skalieren.

Aufstrebende Märkte und Produktkategorien

Pflanzliche Lebensmittel: Die wachsende Beliebtheit pflanzlicher Alternativen steigert die Nachfrage nach spezialisierter Kühlkettenlogistik. Kleine und mittlere Produzenten benötigen eine robuste Infrastruktur, um die Qualität aufrechtzuerhalten.

Pharmazeutische Innovation: Gen- und Zelltherapien, Biologika und personalisierte Medizin erfordern ultrakalte Logistikkapazitäten. Tragbare kryogene Gefriergeräte und Blockchain-fähige Rückverfolgbarkeit gewährleisten die Produktintegrität und die Einhaltung gesetzlicher Vorschriften.

Ausweitung des Welthandels: Regierungen starten beispielsweise Exportprogramme, das britische Milchexportprogramm – zur Steigerung der Milchexporte im Wert von mehr als 100 % 2,47 Milliarden US-Dollar jährlich zu 135 Länder. Solche Programme steigern die Nachfrage nach fortschrittlichen Kühlkettenlösungen.

2025 Neueste Trends und Entwicklungen

Überblick über Markt- und Technologietrends

Die Kühlkettenindustrie in 2025 zeichnet sich durch hohes Wachstum und schnelle Innovation aus. Weltweit expandieren die Märkte; Es wird erwartet, dass der weltweite Marktwert überschritten wird 1 Billion US-Dollar innerhalb des Jahrzehnts. E-Commerce-Wachstum, Der weltweite Lebensmittelhandel und die Arzneimittelnachfrage erhöhen den Druck auf Logistikdienstleister, in großem Umfang und mit Präzision zu liefern. Regulatorische Mandate, wie FSMA 204 und HFKW-Ausstiege, beschleunigen die Einführung digitaler Rückverfolgbarkeit und nachhaltiger Kühlung.

Neueste Entwicklungen auf einen Blick

Geopolitische Einflüsse: Geopolitische Unruhen haben sich auf die Transitzeiten und die Kapazitätsverfügbarkeit ausgewirkt, Dies hat in einigen Regionen Folgewirkungen auf die Lagerbestände. Die Kühlkettenbranche baut ihre Widerstandsfähigkeit auf, um Störungen zu bewältigen.

Sichtbarkeitsinvestitionen: 2025 wird weiterhin in Software investieren, die die End-to-End-Transparenz verbessert. Ununterbrochene Daten sind für die Bewältigung von Störungen sowie für eine einfache Standortverfolgung und Temperaturüberwachung unerlässlich.

Infrastruktur-Upgrades: In die Jahre gekommene Kühllager werden ersetzt oder modernisiert, Einführung der Automatisierung, Nachhaltigkeit und bessere Sichtbarkeit.

Vertriebsstrategien: Die Anlagen werden näher an Produktionsstandorten oder Häfen positioniert, Dies ermöglicht eine bessere Integration und größere Kapazitäten.

Marktwachstum: Der globale Markt für Kühlkettenlogistik wurde mit bewertet 293,58 Milliarden US-Dollar im Jahr 2023 und wird voraussichtlich erreicht werden 324,85 Milliarden US-Dollar im Jahr 2024, mit einer Prognose von 862,33 Milliarden US-Dollar von 2032 (13 % CAGR). Es wird erwartet, dass der Pharmasektor erreichen wird 1,454 Billionen US-Dollar 2029, Betonung der Notwendigkeit einer zuverlässigen Kühllogistik.

Markteinsichten

Verbraucher fordern zunehmend Transparenz und Nachhaltigkeit. Soziale Medien machen Verbraucher mit neuen Küchen bekannt und beeinflussen Konsummuster. Die Einhaltung gesetzlicher Vorschriften ist nicht verhandelbar, mit FSMA 204 Die Forderung nach detaillierten Aufzeichnungen für Lebensmittel in der Rückverfolgbarkeitsliste und der Ausstieg aus HFKW drängen die Betreiber auf Kältemittel mit niedrigem Treibhauspotenzial. Investition in Technologie – KI, IoT, Blockchain – steigert die Effizienz und reduziert das Risiko. Aufstrebende Märkte und kleine Produzenten benötigen Partnerschaften mit erfahrenen Logistikanbietern, um die Komplexität zu bewältigen.

Häufig gestellte Fragen

Q1: Was ist die Kühlkettenbranche und warum ist sie wichtig??

Die Kühlkettenindustrie umfasst Prozesse und Technologien, die dies ermöglichen, Lagerung und Transport temperaturempfindlicher Produkte, Einhaltung strenger Temperaturbereiche von der Produktion bis zum Verbrauch. Dies ist von entscheidender Bedeutung, da es die Qualität und Sicherheit verderblicher Waren wie Lebensmittel bewahrt, Arzneimittel und Biologika, Verhinderung von Verderb und Sicherstellung der Compliance.

Q2: Wie groß ist der Kühlkettenmarkt? 2025?

Untersuchungen zeigen, dass der globale Markt für Kühlkettenlogistik geschätzt wird 436,30 Milliarden US-Dollar im Jahr 2025 und wird voraussichtlich übertroffen werden 1,3 Billionen US-Dollar 2034, mit a 13.46 % CAGR. Allein in Nordamerika wird ein Wachstum erwartet 116,85 Milliarden US-Dollar im Jahr 2024 Zu 289,58 Milliarden US-Dollar von 2034, Erreichen eines 9.50 % CAGR.

Q3: Welche Technologien revolutionieren die Kühlkettenlogistik??

KI-gestützte Routenoptimierung, vorausschauende Wartung, IoT-Sensoren zur Echtzeitüberwachung, Blockchain-Rückverfolgbarkeit und solarbetriebene Kühlung verändern die Kühlkettenlogistik. Diese Technologien steigern die Effizienz, den Kraftstoffverbrauch reduzieren, Verhindern Sie den Verderb und verbessern Sie die Einhaltung gesetzlicher Vorschriften.

Q4: Welche Vorschriften wirken sich auf den Kühlkettenbetrieb aus? 2025?

FSMA 204 Unternehmen, die mit Lebensmitteln auf der Lebensmittelrückverfolgbarkeitsliste der FDA umgehen, müssen ab Januar wichtige Datenelemente für kritische Nachverfolgungsereignisse aufzeichnen 6 2025. HFKW-Beschränkungen ab Januar 1 2025 Verbieten Sie bestimmten Technologien die Verwendung von Kältemitteln mit hohem Treibhauspotenzial.

Q5: Wie können Unternehmen ihre Kühlkettenabläufe verbessern??

Implementieren Sie IoT-Sensoren und KI-Analysen, in die Schulung des Personals investieren, Entwickeln Sie Notfallpläne und erkunden Sie erneuerbare Energien wie Sonnenkollektoren. Arbeiten Sie mit erfahrenen Kühlkettenanbietern zusammen, um Netzwerke und Fachwissen zu nutzen.

Schlussfolgerung und Empfehlungen

Der Kaltkettenindustrie befindet sich aufgrund der steigenden Nachfrage in einem rasanten Wandel, technologische Innovation und regulatorische Veränderungen. Marktprognosen gehen von einem Wachstum auf mehr als aus 1 Billion US-Dollar innerhalb des nächsten Jahrzehnts. Um wettbewerbsfähig zu bleiben, Unternehmen müssen in moderne Infrastruktur investieren, Nutzen Sie KI und IoT für Transparenz und prädiktive Analysen, Halten Sie sich an die sich ändernden Vorschriften und achten Sie auf Nachhaltigkeit. Zusammenarbeit mit erfahrenen Anbietern, Durch die Schulung des Personals und die Planung von Eventualfällen werden die Belastbarkeit und die Kundenzufriedenheit erhöht. Jetzt ist es an der Zeit, Ihre Abläufe zu überprüfen, Modernisieren Sie veraltete Anlagen und integrieren Sie digitale Rückverfolgbarkeit, um sicherzustellen, dass Sie die Erwartungen von 2025 und darüber hinaus erfüllen.

Über Tempk

Wir sind Tempk, ein Anbieter von isolierten Verpackungslösungen und Kühlkettendienstleistungen. Zu unseren Produkten gehören Gel-Eisbeutel, Isolierboxen und wiederverwendbare Thermobeutel, die Ihre Waren im optimalen Temperaturbereich halten. Wir legen Wert auf Innovation – wir bieten umweltfreundliche Materialien und IoT-fähige Systeme zur Verbesserung der Sichtbarkeit. Wir arbeiten eng mit Lebensmittelproduzenten zusammen, Pharmaunternehmen und Logistikdienstleistern dabei helfen, Lösungen zu entwickeln, die auf ihre spezifischen Bedürfnisse zugeschnitten sind.

Umsetzbare nächste Schritte:

Erfahren Sie mehr darüber, wie Tempk Ihre Kühlkettenabläufe unterstützen kann, Entdecken Sie unsere Lösungen für die Essenslieferung, Arzneimittelversand und kundenspezifische Kühlkettenverpackung. Für eine individuelle Beratung, Wenden Sie sich an unser Team, um zu besprechen, wie wir Ihnen bei der Optimierung Ihrer temperaturgeführten Lieferkette helfen können.