Produktbeschreibung

Produktdetails

Robustes, wiederverwendbares Versandtaschendesign für wiederholte Kühlkettenzyklen, Reduzierung des Schadensrisikos bei der Handhabung und beim Linientransport.

Der PU-Isolierkern unterstützt lange Haltezeiten; Aufgrund der geringen Wärmeleitfähigkeit werden PU-Hartschaumstoffe häufig als hocheffiziente Isolierung eingesetzt. (PMC)

Große interne Nutzlast für konsolidierte Fälle, Meeresfrüchte-Taschen, Tiefkühlkostpackungen, oder E-Commerce-Umkartons.

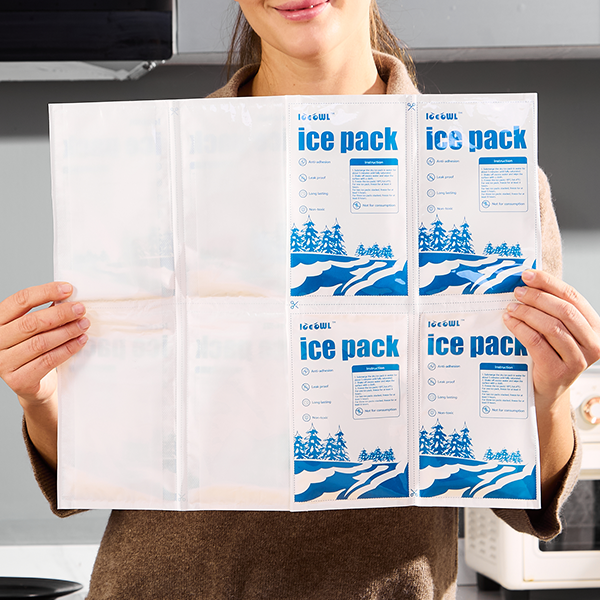

Kompatibel mit gängigen Kühlkettenverpackungen (Gelpackungen, PCM, Eisziegel) und optionale Identifikation (Etiketten/QR/RFID).

Produktvideo

Funktionsdetails

Entwickelt, um die Zunahme der Umgebungswärme zu reduzieren und die Temperaturstabilität durch Inszenierung aufrechtzuerhalten, Laden, und Transit.

Geeignet für den Transport von frischen und gefrorenen Lebensmitteln (Fleisch, Meeresfrüchte, Molkerei, gefrorene Mahlzeiten, Eiscreme, produzieren) im Vertrieb und auf der letzten Meile.

Kann bei Verwendung mit qualifizierten Kältemitteln und Temperaturüberwachung für Pharma-/Biotech-Spuren konfiguriert werden (Datenlogger/Anzeiger).

Unterstützt Reverse-Logistik-Workflows: wiederverwendbar, Reinbar, und betriebskonsistent für den Flotteneinsatz.

Anweisungen

Laden Sie das Produkt, um den Leerraum zu minimieren; Platzieren Sie Kältemittel, um den Wärmefluss zu steuern (oben/seitlich/unten) basierend auf dem Fahrspurrisiko.

Fügen Sie zur Überprüfbarkeit einen Temperaturlogger hinzu, wenn die Versandspezifikation dies erfordert.

Nach Lieferung, sauber, trocken, und inspizieren; Rotieren Sie Assets durch Wartung, um eine konsistente Leistung zu gewährleisten.

Merkmale

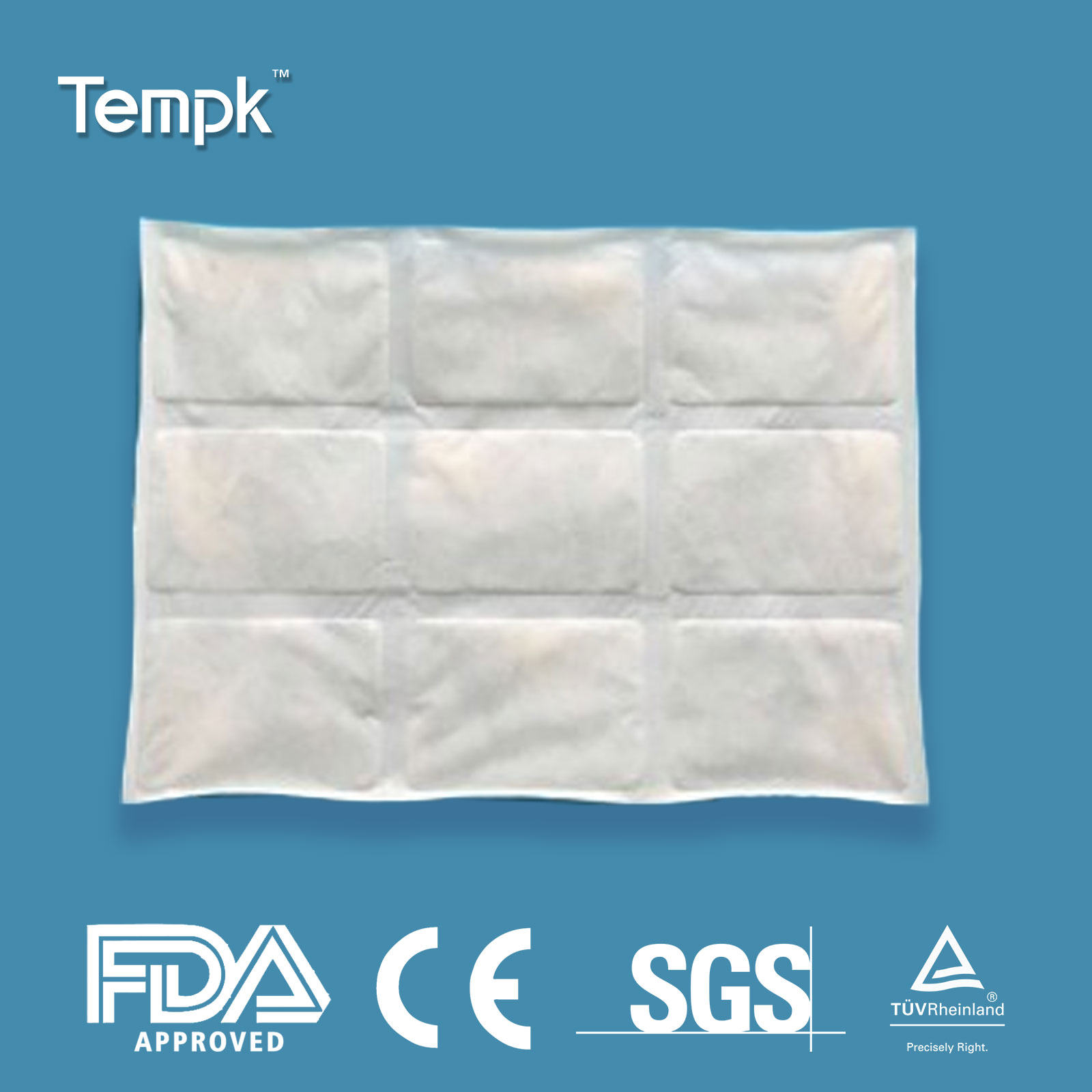

PE-Außenschale + PU-Isolierkern + PS-Innenfutter

Hohe Nutzlastkapazität für die Massenverteilung

Wiederverwendbar, leicht zu desinfizieren für Mehrfahrtenprogramme

Funktioniert mit Standard-Gelpacks / PCM für validierte Packouts

Geeignet für Cross-Dock, Linienverkehr, und Multi-Drop-Lieferung