Bolsas de entrega aisladas: ¿Cómo se elige el adecuado en 2025?

Delivery bags insulated help you keep hot food hot and cold items cold during last-mile delivery. En 2025, customers judge you fast. If fries arrive soggy, soup leaks, or ice cream softens, they blame the delivery experience—not traffic. Your best results come from a sistema: the right bag type, the right packing method, and simple routines your team repeats every shift.

You do not win by buying “the thickest bag.” You win by matching delivery bags insulated to your real routes: distancia, detener la cuenta, clima, and what you deliver.

Este artículo te ayudará:

-

Choose delivery bags insulated for caliente, frío, o mixto rutas

-

Understand bag materials and build without confusing jargon

-

Stop spills with leakproof delivery bags insulated for drivers

-

Reduce sogginess using steam-control packing

-

construir un commercial insulated delivery bag cleaning SOP people follow

-

Validate performance with a quick 30-minuto + 3-run field test

What do delivery bags insulated actually do?

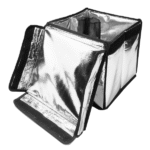

Delivery bags insulated slow temperature change. They do not create heat or cold. In plain language, ellos buy you time by reducing heat transfer and blocking outside air.

Think of the bag like a “jacket” for the order. A better jacket has fewer gaps, stronger structure, and an interior you can actually clean.

Your bag must do three jobs well:

| Job | Cómo se ve "bueno" | What breaks it | Significado práctico para ti |

|---|---|---|---|

| control de temperatura | sello apretado + even insulation | brecha + frequent opening | fewer “arrived cold” complaints |

| Structure protection | upright shape + inserciones | floppy walls | fewer crushed meals |

| control de desorden | forro limpiable + costuras selladas | absorbent fabric + agujeros de costura | menos olor, limpieza más rápida |

Consejos prácticos que puede usar hoy

-

Open time is the enemy. Every long opening dumps hot/cold air.

-

Empty air hurts performance. A giant bag with space inside often performs worse.

-

Stability prevents spills. Most spills come from tipping, no “mala suerte”.

ejemplo real: A driver reduced soup complaints by switching to a bag with a rigid base insert y un forro limpiable. Same route, menos derrames.

Which delivery bags insulated types fit hot, frío, and mixed routes?

Not all delivery bags insulated are built for the same job. If you use one bag for everything, you usually compromise everything.

Common types in 2025

-

Hot-food bags: retención de calor + acceso rápido

-

Cold bags: cold protection + pack sleeves + easy-clean liners

-

Pizza bags: ancho, departamento, estable

-

Backpack bags: hands-free for bikes and dense urban stops

-

Structured hybrid bags: soft outside, rigid inserts inside (best for mixed orders)

| Tipo | Mejor para | Fortaleza | Cuidado |

|---|---|---|---|

| Hot-food bag | comidas, abastecimiento | retención de calor | steam can trap |

| bolsa fria | artículos refrigerados | cold buffering | needs cold packs |

| Pizza bag | pizza | estabilidad plana | not ideal for soups |

| Mochila | bicicleta, stairs | hands-free | corners must clean easily |

| Inserto híbrido | mixed orders | protección contra aplastamiento | slightly heavier |

Regla rápida

-

If you deliver both hot and cold in the same shift, usar un two-bag system (one hot, one cold).

-

If you deliver pizza often, usar un dedicated pizza bag.

-

If your team spills often, priorizar estructura over “thicker insulation.”

How do you judge insulated delivery bag heat retention without a lab?

You can judge delivery bags insulated with simple signals. You do not need testing equipment to spot the big winners.

El 4 signals that predict heat retention

-

Calidad del sello: zipper/flap that closes fully under load

-

Wall continuity: even insulation (corners matter)

-

Right volume: minimal empty air after packing

-

Disciplina de apertura: fewer, shorter openings

A simple “30-minute reality test”

-

Place a sealed hot container in the bag.

-

Close the bag fully.

-

Esperar 30 minutos.

-

Open once, check warmth and condensation.

-

Repeat with a “multi-stop” simulation (2–4 brief openings).

| Factor | Mejor | Peor | Significado práctico para ti |

|---|---|---|---|

| Sello | ajustado, sin espacios | leaks at corners | faster heat loss |

| Empty air | mínimo | lots of space | colder arrival |

| Open time | corto | long rummaging | more complaints |

Consejos y consejos prácticos

-

Usar dividers/inserts to reduce empty space.

-

Train a “close-confirm” habit: hand checks the zipper every time.

-

Organize inside so drivers stop hunting for items.

How do you prevent soggy food inside delivery bags insulated?

Hot food produces steam. If steam gets trapped, fries soften and fried coatings lose crispness. Your goal is balanced humidity: keep heat, but avoid turning the bag into a steam bath.

Anti-soggy strategies that work

-

Keep fried items upright and separated from steamy items

-

Avoid sealing vented containers inside the bag like a vacuum

-

Use a simple divisor to create airflow channels

-

Minimize open time to reduce repeated condensation cycles

| tipo de comida | Main enemy | Best approach | Lo que significa para ti |

|---|---|---|---|

| Fries | vapor | separado + top zone | mejor textura |

| Pizza | heat loss | flat pizza bag | hotter slices |

| Soups | propina | rigid base + transatlántico | menos reembolsos |

| Salads/sushi | calor | cold bag + paquete | safer delivery |

Caso práctico: A restaurant reduced soggy fries by putting fries in a small separate hot bag instead of stacking them under pasta containers.

What makes a leakproof insulated delivery bag in 2025?

“Leakproof” is not just water-resistant fabric. True leak control means spills do not soak into seams and padding.

Leakproof features that matter most

-

Wipeable liner: smooth surface that does not absorb liquids

-

Sealed seams: reinforced or welded wet zones

-

Raised base tray/lip: catches minor spills

-

Rigid base insert: reduces tipping and keeps loads level

| Característica | Helps with | Compensación | Significado práctico para ti |

|---|---|---|---|

| Wipeable liner | limpieza rápida | ninguno | menos olor |

| Sealed seams | spill containment | mayor costo | menos manchas |

| Base tray | liquid accidents | peso | easier resets |

| Rigid insert | estabilidad | a granel | fewer tipovers |

Consejos y consejos prácticos

-

If you carry soups: rigid base + bandeja is your best upgrade.

-

If bags smell: your liner is absorbing liquids—upgrade it.

-

For drinks: agregar un cup carrier system, no “esperanza”.

How do you size delivery bags insulated for real routes?

Sizing is not “bigger is better.” Too big creates empty air (worse temperature control) and more tipping risk. Too small slows drivers and prevents full closure.

A practical sizing method

-

List your top 10 order shapes (cajas de pizza, bowls, clamshells, sopas).

-

Measure your two biggest common shapes.

-

Choose a bag that fits with minimal extra space.

-

Add a second smaller bag for single orders.

| Route style | Best size strategy | Por que funciona | Significado práctico para ti |

|---|---|---|---|

| Short urban | medio + pequeño | velocidad + ajuste apretado | faster drops |

| Suburban | medium/large | longer buffer | hotter arrival |

| Multi-stop | multiple bags | separation by order | menos errores |

How should you pack delivery bags insulated for speed and consistency?

Packing is the hidden performance multiplier. Great bags fail when packing is random. You want a method drivers can repeat under pressure.

The “Three-Zone” packing system

-

zona base: heavy and stable (sopas, bowls, dense meals)

-

Middle zone: boxed items (hamburguesas, sándwiches)

-

Top zone: light items (papas fritas, pasteles) + cup carriers

The S.T.A.B.L.E. método (fast checklist)

-

S — Seal containers (verify lids; quick tape strip if needed)

-

T — Top items last (heavy low, light high)

-

A — Avoid air gaps (tight packing stabilizes temperature)

-

B — Balance the load (prevents tipping)

-

L — Liquids upright (use a divider zone)

-

E — Ensure full closure (close completely, re-check)

| regla de embalaje | Mejor | Peor | Significado práctico para ti |

|---|---|---|---|

| Peso | heavy bottom | heavy top | menos derrames |

| Separación | hot separate cold | mezclado | better quality |

| Zones | labeled zones | chaos | fewer wrong orders |

ejemplo real: A delivery team reduced mistakes by using two medium bags instead of one large bag. Each order stayed in its own zone.

How do delivery bags insulated support cold chain deliveries?

Para artículos refrigerados, the bag is a tampón frío, not a refrigerator. You need cold sources, embalaje apretado, and fewer warm exposures.

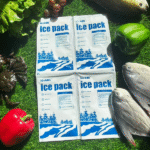

Cold delivery essentials

-

Usar paquetes fríos (or phase-change packs) every run for perishables

-

empezar en frio: pre-chill products and the bag when possible

-

Use a simple layout: cold source below + producto + cold source above

-

Keep the bag away from car heaters and direct sun

-

Reducir el tiempo de apertura de puertas (batch your drops)

| Desafío | Que hacer | Por qué ayuda | Significado práctico para ti |

|---|---|---|---|

| Hot car trunk | sombra + distance from heat | less heat gain | temperatura más segura |

| Muchas paradas | separate cold bag | menos picos cálidos | better quality |

| Condensación | wipeable liners | fácil limpieza | menos olor |

Practical tip you’ll feel immediately

If you deliver ice cream or dairy, treat a dedicated cold bag as mandatory. Mixed bags fail because hot items warm cold items fast.

How do you clean and maintain delivery bags insulated in 2025?

Cleaning protects hygiene, reduces odor, and extends bag life. The key is making the routine short enough that it actually happens.

Commercial insulated delivery bag cleaning SOP (a diario)

-

Empty crumbs and trash (30 artículos de segunda clase).

-

Wipe liner with mild soap solution (2 minutos).

-

Wipe again with clean damp cloth (1 minuto).

-

Towel dry corners and zipper area (1 minuto).

-

Almacenar abierto until fully dry (hands-off).

| Tarea | Frecuencia | Por que importa | Significado práctico para ti |

|---|---|---|---|

| Wipe liner | a diario | higiene + less residue | menos quejas |

| Dry open | a diario | prevents odor | longer bag life |

| Inspect zipper | semanalmente | calidad del sello | mejor tiempo de espera |

| Reemplazar inserciones | según sea necesario | estabilidad | menos derrames |

ejemplo real: A team eliminated “bag smell” complaints by adding one rule: bags must be stored open overnight.

Validate delivery bags insulated performance in 30 minutos (and scale safely)

Marketing claims are not your route. Validate in your own conditions so you stop guessing.

The “3-Run” validation method

-

Correr 1: Indoor baseline (30 minutos)

-

Correr 2: Warm stress (coche caliente / sunny conditions, 30 minutos)

-

Correr 3: Real route (60–90 minutes with 2–4 brief openings)

Registro: start time, end time, opening count, and simple temperature checks if available. Even without sensors, opening discipline + calidad del cierre shows up quickly.

| Prueba | Duración | que grabar | lo que aprendes |

|---|---|---|---|

| Base | 30 mínimo | start/end temp | best-case hold |

| Warm stress | 30 mínimo | peak drift | summer risk |

| Real route | 60–90 min | tiempo + aberturas | operational truth |

Consejos prácticos

-

Pon a prueba tu worst day (heat reveals weak seals fast).

-

Cambiar one variable at a time (packs or bag, no ambos).

-

Turn the winning method into an SOP photo + lista de verificación.

Interactive decision tools

1) Which delivery bags insulated setup fits you?

Paso 1: What do you deliver most?

A) Hot meals B) Pizza C) Caliente mixto + cold D) Groceries/chilled E) Abastecimiento

Paso 2: Typical route time?

Bajo 15 mínimo / 15–30 minutos / 30–60 min

Paso 3: How messy are orders?

Bajo / Medio / Alto (sopas, salsas, bebidas)

Recomendaciones

-

A + 15–30 minutos: medium hot bag, sello apretado, internal divider

-

B: dedicated pizza bag + small bag for sides

-

do: two-bag system (caliente + frío), labeled zones

-

D: cold bag + top/bottom cold sources + forro limpiable

-

mi: structured large bags + inserciones + secondary bag for fragile items

2) Delivery Bags Insulated Fit Score (0–20)

Puntuación de cada elemento 0 (No), 1 (partly), 2 (Sí):

-

Bag closes fully under load

-

Bag stays upright when packed

-

Liner wipes clean in under 60 artículos de segunda clase

-

Seams don’t absorb spills

-

Base resists moisture

-

Fits common orders with minimal empty air

-

Has inserts/dividers

-

Hot/cold separation is easy

-

Drivers open it briefly, not long

-

Bag dries fully between shifts

0–8: High risk → fix seal, apresto, cleaning first

9–14: Medium → improve packing routine + separation

15–20: Strong → optimize route discipline and training

3) Quick ROI model (simple and actionable)

Monthly bag cost = (bag cost ÷ months of use) + replacements/loss

Ahorro mensual = refunds avoided + re-deliveries avoided + time saved

ROI = monthly savings ÷ monthly bag cost

Your biggest ROI levers are usually:

-

calidad del sello + closure discipline

-

structure inserts (menos derrames)

-

cleaning speed (more compliance)

2025 latest trends in delivery bags insulated

En 2025, delivery bags insulated are becoming more operations-first:

-

Better seals: stronger zippers, improved flaps, roll-tops

-

More structure: inserts that prevent crushing and tipping

-

Easier hygiene: removable liners and wipeable materials

-

More two-bag setups: mixed orders are now the default, not the exception

-

More validation habits: short seasonal tests beat guessing

Customers care less about “fancy bags” and more about outcomes: hot food, no spills, manejo limpio. Drivers care about speed and comfort. Your system must satisfy both with repeatable routines.

Preguntas frecuentes

1) How long do delivery bags insulated keep food hot?

It depends on seal quality, espacio aéreo vacío, aberturas, y temperatura exterior. Fewer openings and a tight fit usually extend heat retention most.

2) Are two delivery bags insulated better than one big bag?

A menudo si. Two medium bags reduce empty air, prevent hot/cold cross-impact, and lower spill risk during multi-stop runs.

3) How do you stop soup spills fast?

Use a rigid base insert, un forro limpiable, and keep soups upright in the base zone. Stability solves more spills than “thicker insulation.”

4) Why do fries get soggy inside insulated bags?

Steam builds up and condenses. Separate fried items from steamy containers, pack them in the top zone, and minimize open time.

5) Can delivery bags insulated handle groceries and dairy?

Sí, if you treat the bag as a buffer. Use cold sources above and below items, reduce empty air, and keep the bag away from heat.

6) ¿Qué es el #1 failure point in real operations?

Leaving the bag open too long, overstuffing so it cannot seal, and letting liquids tip during travel.

7) How often should bags be cleaned?

Daily wipe-down and full air-dry is the best baseline. After spills, clean immediately and dry open to prevent odor.

Resumen y recomendaciones

Delivery bags insulated work best when you match the bag type to your route, keep closures sealed, pack with a repeatable method, and maintain hygiene. The highest-impact upgrades are usually calidad del sello, structure inserts, wipeable liners, and hot/cold separation. When you combine those with a simple packing SOP, you reduce refunds, protect food quality, and make drivers faster.

Tus próximos pasos (borrar CTA)

-

Hoy: measure your most common order sizes and choose a bag that fits with minimal empty air

-

Next shift: implementar Three-Zone + S.T.A.B.L.E. packing and label HOT/COLD bolsas

-

Esta semana: enforce daily wipe-and-dry and replace damaged zippers/liners quickly

-

este mes: run the 3-Run validation and lock the best pack-out as your SOP

Acerca de Tempk

Y tempk, we build practical temperature-control packaging and handling solutions for last-mile delivery. We focus on consistent results: fuerte aislamiento, control de fugas, easy cleaning, and repeatable packing routines. Our goal is simple—help you reduce temperature swings, prevenir derrames, and protect customer experience without adding complexity.

Siguiente paso: Share your route pattern (average delivery time, detener la cuenta, hot vs cold mix) and your biggest issue (soggy food, derrames, cold items warming). We can help you define a delivery bags insulated setup and a packing SOP that fits your operation.