Este artículo te ayudará:

Pick a recyclable insulated shipping box that is practical in your region

Match your eco-friendly insulated box to transit time, estación, and product risk

Avoid common “verde” claims that break down in real cold chain use

Use a simple decision tool to choose materials, tamaño, and refrigerant

Plan de reutilización, regresa, and validation so you can scale with confidence

¿Qué hace? “Ecológico” Mean for an Eco-Friendly Insulated Box in 2026?

An eco-friendly insulated box is “ecológico” only when it reduces impact without increasing spoilage, daño, or re-ships. En 2026, that usually means three things: the materials have a credible end-of-life path, the design uses only what you need, and the performance is proven for your lane. Think of it like buying a fuel-efficient car. If it breaks down, you will spend more resources fixing problems than you saved.

En la práctica, you should judge an eco-friendly insulated box by the full system, not one label. A “compostable” liner that ends up in landfill is not a win. A “recyclable insulated shipping box” that most customers cannot sort correctly is also risky. Your best option is the one that fits how you ship, how your customers dispose, and how strict your temperature limits are.

Recyclable insulated shipping box: the 3-part reality check

A recyclable insulated shipping box should pass a quick test before you commit:

Local path: Can your customer actually recycle the insulation where they live?

Separación: Can they separate the insulation from the outer box in under one minute?

Limpieza: Will the insulation stay clean enough to be accepted by recycling streams?

Si alguna respuesta es “No,” you can still choose the material. You just need a different plan. That plan could be a take-back program, a drop-off point, or a switch to a reusable eco-friendly insulated box.

| Eco option | How it insulates | Likely end-of-life | Lo que significa para ti |

|---|---|---|---|

| Cellulose paper liners | Traps air like a winter jacket | Curbside recycling in some areas (check rules) | Easy for customers, but needs dry handling |

| Molded fiber panels | Grueso “egg carton” structure holds air | Often recyclable with paper if clean | Good protection, slightly bulkier |

| Starch-based foam | Lightweight foam made from plant starch | Compostable in industrial systems (si está disponible) | Low weight, but needs moisture control |

| Mycelium panels | Grown structure with natural air pockets | Compostable in some conditions | Strong story, but lead times can vary |

| Reusable hard-shell tote | Durable walls + inserciones | Reuse many cycles, then recycle by material | Great for loops, needs reverse logistics |

Consejos prácticos que puede usar hoy

If you ship to many states or countries: Choose an eco-friendly insulated box that works in the “promedio” disposal system.

If you sell direct-to-consumer: Make unboxing simple, with clear separation steps on the lid.

If you ship high-value product: Prioritize temperature performance first, then optimize material impact.

If your customers complain about waste: Consider a reusable eco-friendly insulated box with pickup or return labels.

Ejemplo del mundo real: A meal-kit brand replaced thick foam with a paper-based eco-friendly insulated box and right-sized the carton. They reduced box volume per order and saw fewer “too big” complaints. The key was testing summer lanes first, then rolling out gradually by region.

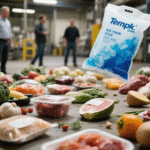

Which Materials Should You Trust for an Eco-Friendly Insulated Box?

The best material for an eco-friendly insulated box depends on your lane, not your marketing claims. A cold chain box is like a raincoat. A thin raincoat is fine for a drizzle. It fails in a storm. Materials behave the same way under heat, humedad, and long transit.

Start by separating materials into two roles: the outer structure and the insulation layer. The outer structure is usually corrugated cardboard. The insulation layer can be paper-based liners, bio-foam, capas reflectantes, or reusable inserts. Your job is to pick a combination that matches your temperature “presupuesto” for the trip.

Paper-based insulation liners for cold chain: when they shine

Paper-based insulation liners for cold chain work well when you need balanced performance and easy handling. They usually feel like dense paper quilts or molded panels. They trap air, just like a puffy jacket. They also pair well with gel packs or phase change materials.

Paper-based options are often a good fit when:

Your transit is 1–2 days and you ship chilled, not deeply frozen.

You can right-size the carton so there is less empty air space.