Cómo la logística de vacunas y la gestión de la cadena de frío mantienen seguras las dosis 2025

Las vacunas sólo protegen a las personas si llegan potentes. Cuando mueve productos biológicos sensibles entre continentes o gestiona suministros en una clínica, el logística de vacunas y gestión de la cadena de frío El sistema es lo que preserva esa potencia.. En 2025, Los expertos estiman que más de una cuarta parte de las vacunas en todo el mundo se pierden debido a variaciones de temperatura o fallas en los equipos.. Esta guía le muestra cómo construir una cadena de frío confiable, aprovechar las tecnologías modernas y evitar el costoso desperdicio. A lo largo del artículo verá puntos de datos prácticos, por ejemplo, las vacunas convencionales deben permanecer entre 2 °C y 8 °C, mientras que las vacunas de ARNm requieren de –80 °C a –60 °C. También aprenderá sobre el monitoreo en tiempo real., Refrigeración con energía solar y otras tendencias.. Protejamos cada dosis juntos.

Por qué es importante una cadena de frío constante: Descubra el impacto de las excursiones de temperatura y cuántas dosis se pierden por una mala gestión.

Cómo elaborar un plan logístico de vacunas sólido: Conozca la estrategia paso a paso para evaluar riesgos, Selección de equipos y capacitación del personal..

¿Qué tecnologías mejoran la confiabilidad de la cadena de frío?: Descubra cómo funcionan los sensores de IoT, Los registradores de datos y los análisis impulsados por IA reducen el deterioro..

Últimas tendencias para 2025: Comprender innovaciones como los refrigeradores que funcionan con energía solar., drones, Materiales de cambio de fase y modelos predictivos..

Preguntas frecuentes: Obtenga respuestas rápidas sobre tiempos de almacenamiento, Frecuencia de monitoreo y qué hacer durante las variaciones de temperatura..

Lo que define la logística de las vacunas & Gestión de la cadena de frío?

Una cadena de frío es una red de suministro con temperatura controlada que mantiene las vacunas dentro de un rango prescrito desde la fabricación hasta la administración.. A diferencia del envío estándar, La logística de vacunas integra embalajes especializados., transporte refrigerado, unidades de almacenamiento y personal capacitado. Las vacunas convencionales deben permanecer entre 2 °C y 8 °C, mientras que las fórmulas de ARNm como las de Pfizer BioNTech requieren condiciones ultrafrías de –80 °C a –60 °C. Las desviaciones destruyen los ingredientes activos., Lo que lleva a dosis ineficaces y a inversiones desperdiciadas.. La Organización Mundial de la Salud advierte que los equipos poco fiables provocan variaciones de temperatura que reducen la potencia, con 25 % De las vacunas en todo el mundo resultan dañadas por fallos en la cadena de frío..

Por qué la temperatura es importante para la potencia de la vacuna

Incluso una breve exposición a una temperatura incorrecta puede degradar las vacunas. Los componentes biológicos son frágiles: el calor acelera la degradación, mientras que la congelación puede desnaturalizar las proteínas. El Conjunto de herramientas de almacenamiento y manipulación de vacunas de los CDC recomienda mantener los refrigeradores entre 2 °C y 8 °C y congeladores entre –50 °C y –15 °C. Los congeladores ultrafríos para vacunas de ARNm deben mantener entre –90 °C y –60 °C. Un registrador de datos digital (DDL) Proporciona un historial continuo de temperatura y se recomienda para cada unidad de almacenamiento.. Seguir estos rangos y dispositivos de monitoreo previene las variaciones de temperatura y protege la potencia..

| Componente clave | Rango de temperatura recomendado | Uso típico | Beneficio práctico |

| Refrigerador | 2 °C – 8 °C | Vacunas de rutina (gripe, hepatitis) | Mantiene la potencia y cumple con las directrices de la OMS/CDC. |

| Congelador | –50°C – –15°C | Algunas vacunas vivas (varicela) | Extiende la vida útil sin daños por congelación. |

| Congelador ultrafrío | –90 °C – –60 °C | Vacunas de ARNm o de terapia génica | Preserva la estabilidad de las delicadas nanopartículas lipídicas. |

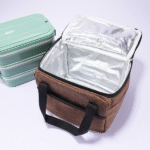

| Contenedor pasivo (caja aislada con bolsas de hielo) | Mantenimiento 2 °C – 8 °C por horas | Transporte de corta distancia | Rentable y ligero |

| Contenedor activo (refrigeración motorizada) | Programable 2 °C – 8 °C o ultra frío | Envíos de larga distancia | Control preciso; adecuado para climas extremos |

Comprensión del proceso logístico de vacunas

La logística de las vacunas cubre todos los puntos de contacto, desde la fabricación, embalaje, almacenamiento y distribución hasta entrega de última milla. Cada fase tiene riesgos específicos: La producción puede implicar envíos a granel que requieren embalaje validado.; las unidades de almacenamiento deben tener energía de respaldo; y el transporte debe planificarse teniendo en cuenta las condiciones meteorológicas., retrasos en tráfico y aduanas. Una investigación emergente señala que la falta de transparencia y supervisión da como resultado un estimado 30 % de vacunas que se pierden durante el tránsito. Para mitigar esto, incorporar monitoreo en tiempo real y procesos sólidos de cadena de custodia, Garantizar que las partes interesadas puedan ver las condiciones a lo largo de la ruta..

Cómo construir una estrategia logística de vacunas confiable

Comience con una evaluación de riesgos—identificar posibles desviaciones de temperatura, cortes de energía, retrasos y errores humanos. Involucrar a equipos multifuncionales, incluidos los gerentes de logística., farmacéuticos e ingenieros. Desarrollar protocolos para el embalaje., almacenamiento, manejo y respuesta a emergencias. Asegúrese de que su plan refleje directrices regulatorias como las Buenas Prácticas de Distribución de la OMS. (PIB) y directrices nacionales de vacunación. Según las recomendaciones de los CDC., Cada instalación debe utilizar un DDL para cada unidad de almacenamiento y transporte y conservar los datos de temperatura durante al menos tres años.. La calibración y la documentación periódicas reducen la responsabilidad y respaldan las auditorías.

Planificación de la cadena de frío paso a paso

Seleccionar equipo validado. Elige refrigeradores, congeladores y contenedores de transporte que cumplan con los estándares de precalificación de la OMS. PQS IMD (Dispositivos de inmunización – Rendimiento, Calidad y Seguridad) desarrollado sobre 52 especificaciones de nuevos productos entre 2019 y 2024, incluidas normas para congeladores ultrafríos, vehículos frigoríficos y frigoríficos portátiles.

Implementar tecnología de monitoreo. Registradores de datos digitales con sondas tamponadas, Los sensores de IoT y los rastreadores GPS proporcionan datos continuos de temperatura y ubicación. Las alertas en tiempo real permiten acciones correctivas rápidas.

Capacitar al personal. El personal debe saber cómo empacar contenedores., interpretar datos y responder a alarmas. Usar el cuatro R de monitoreo de temperatura—Leer, Registro, Restablecer y reaccionar: para establecer rutinas diarias.

Planificar rutas de transporte. Planifica los tiempos de viaje, condiciones climáticas y procedimientos aduaneros. La optimización de rutas impulsada por IA y la entrega con drones pueden reducir los tiempos de tránsito y evitar la congestión.

Preparar planes de contingencia. Identificar fuentes de energía alternativas, almacenamiento de respaldo y contactos de emergencia. Las unidades de almacenamiento en frío deben tener baterías de respaldo y sistemas de alarma..

Seleccionar embalaje & Soluciones de envío

El embalaje determina durante cuánto tiempo un envío puede mantener la temperatura requerida. Sistemas pasivos(como cajas aisladas revestidas con paquetes de gel o materiales de cambio de fase) son adecuadas para viajes cortos. En contraste, sistemas activos Utilice unidades de refrigeración eléctricas que regulan automáticamente la temperatura para viajes más largos.. Actualmente se utilizan tecnologías de envasado innovadoras Materiales de cambio de fase con puntos de fusión duales para mejorar la estabilidad térmica. También se han desarrollado investigaciones contenedores de transporte cilíndricos con modelos predictivos que utilizan redes neuronales artificiales para pronosticar cuándo se derretirá el refrigerante. Estos avances ayudan a mantener un ambiente estable incluso cuando las temperaturas externas fluctúan..

¿Cuáles son los componentes? & Equipamiento de una cadena de frío para vacunas?

Una sólida cadena de frío para vacunas comprende unidades de almacenamiento, dispositivos de monitoreo, sistemas de transporte e infraestructura de apoyo. Así es como cada componente trabaja en conjunto para mantener las dosis viables.

Refrigeración & Equipo congelador

Los modernos equipos de cadena de frío abarcan desde grandes cámaras frigoríficas hasta refrigeradores portátiles.. refrigeradores con energía solar Han ganado importancia porque proporcionan refrigeración confiable en regiones con electricidad inestable.. La OMS informa que la energía solar directa (SDD) Las unidades ya no requieren baterías e incluso generan energía excedente que las clínicas pueden usar para teléfonos o dispositivos pequeños.. UNICEF compró casi 120 000 refrigeradores SDD entre 2014 y 2024, mostrando su escalabilidad. IMD PQS jugó un papel clave al precalificar 24 Modelos SDD y protocolos de prueba de publicación..

Otras innovaciones incluyen vehículos frigoríficos y refrigeradores transportables, ambos con especificaciones publicadas y estándares de prueba. Los refrigeradores portátiles permiten a los equipos de extensión transportar vacunas durante las campañas de última milla, mientras que los camiones frigoríficos garantizan temperaturas estables durante la distribución a granel.

Tecnologías de monitoreo de temperatura

Los dispositivos de monitoreo van desde termómetros básicos hasta sistemas avanzados de IoT. El Los CDC recomiendan registradores de datos digitales con sondas tamponadas y alarmas. Estos dispositivos registran temperaturas a intervalos preestablecidos., proporcionar lecturas mínimas y máximas y alertar al personal sobre excursiones. Sistemas en tiempo real como PraxasNube integrar sensores inalámbricos y paneles de control en la nube, ofreciendo actualizaciones en vivo e informes automatizados. Los marcos habilitados para IoT pueden monitorear todas las unidades de almacenamiento y vehículos, integrar datos en software centralizado y notificar a los administradores sobre irregularidades. El artículo que cita un marco sostenible para la cadena de frío de las vacunas explica que la falta de transparencia conduce a 30 % de vacunas que se pierden durante el tránsito; La implementación del monitoreo remoto reduce esa pérdida..

Datos & Herramientas de trazabilidad

Más allá de la temperatura, las partes interesadas necesitan documentación y trazabilidad. cadena de bloques Puede registrar historiales de temperatura a prueba de manipulaciones., garantizar la rendición de cuentas y prevenir el fraude. Mientras tanto, Etiquetas RFID con códigos de barras únicos rastrea equipos y envíos, permitiendo verificaciones rápidas de inventario. Muchos países están adoptando sistemas electrónicos de precalificación para aprobaciones de equipos y seguimiento poscomercialización, permitir a los reguladores rastrear el rendimiento del dispositivo y señalar problemas recurrentes.

Infraestructura de soporte

La infraestructura incluye respaldos de energía, servicios de calibración y programas de mantenimiento. Las instalaciones deben enchufar solo una unidad de almacenamiento por tomacorriente para evitar que se disparen los disyuntores y programar un servicio regular.. Organizaciones como la OMS y UNICEF ejecutan seguimiento post comercialización (PMM) programas Evaluar equipos en entornos de uso real e informar estándares futuros.. Las inspecciones continuas garantizan que los fabricantes mantengan la calidad y la confiabilidad..

¿Cómo se realiza el seguimiento? & Los dispositivos IoT protegen la potencia de las vacunas?

El monitoreo en tiempo real reduce significativamente el deterioro al alertar al personal sobre las desviaciones de temperatura.. A 2023 Un informe de la industria indica que la adopción de soluciones de seguimiento digital puede reducir las tasas de deterioro hasta en 30 %. Los sensores de IoT integrados en refrigeradores y vehículos transmiten continuamente datos sobre la temperatura, humedad y golpes. Cuando ocurren anomalías, el sistema envía notificaciones a los administradores para que puedan actuar antes de que las dosis se vean comprometidas.

Análisis predictivo & Inteligencia artificial

Los algoritmos de IA analizan los datos entrantes para predecir fallas en los equipos y optimizar la logística.. Por ejemplo, El mantenimiento predictivo impulsado por IA redujo el tiempo de inactividad al 40 % en uno 2024 estudiar. Los modelos de aprendizaje automático pueden predecir cuándo podría fallar un refrigerador, programar el mantenimiento de forma proactiva y ajustar las rutas de entrega según el clima y los patrones de tráfico. Las redes neuronales artificiales también predicen las velocidades de fusión de los materiales de cambio de fase en los contenedores de transporte, Permitir a los operadores intervenir antes de que las temperaturas excedan los límites seguros..

cadena de bloques & Trazabilidad Digital

Blockchain ofrece transparencia al registrar cada lectura y entrega de temperatura en un libro de contabilidad inmutable. Esto evita la manipulación de datos y respalda el cumplimiento de regulaciones como el PIB de la OMS.. Combinado con contratos inteligentes, blockchain puede automatizar la liberación de envíos cuando se cumplen todas las condiciones. Algunos programas piloto integran blockchain con Etiquetas RFID y sensores IoT para proporcionar trazabilidad de extremo a extremo, mejorar la confianza entre los fabricantes, transportistas y agencias de salud pública.

Integración de datos de la cadena de frío

Las plataformas centralizadas agregan datos de múltiples dispositivos, generación de cuadros de mando para gerentes de logística. Herramientas como PraxasCloud muestran gráficos de temperatura en vivo, seguimiento de ubicación y análisis histórico. Cuando se integra con sistemas de inventario, Activan procedimientos de reposición automática o cuarentena.. Estas plataformas también admiten análisis para identificar patrones recurrentes de excursiones e informar sobre capacitación o actualizaciones de equipos..

Cómo gestionar el transporte de vacunas & Entrega de última milla

El transporte es la fase más vulnerable de la cadena de frío. Condiciones de la carretera, retrasos en aduanas y errores de manipulación puede romper la cadena, especialmente en regiones remotas. Siga estas mejores prácticas:

Optimización de ruta: Utilice software impulsado por IA para planificar las rutas más eficientes, Evite temperaturas extremas y minimice el tiempo en tránsito.. Drones y vehículos autónomos ofrecen alternativas en zonas de difícil acceso, reducir la exposición al calor o retrasos.

Transportistas validados: Elija transportistas que ofrezcan vehículos con temperatura controlada y personal capacitado.. Los vehículos frigoríficos precalificados por la OMS cumplen rigurosos estándares de prueba.

Embalaje seguro: Utilice sellos a prueba de manipulaciones, amortiguadores y aislamiento. Considere materiales de cambio de fase dual para amortiguar las fluctuaciones externas..

Seguimiento en tiempo real: Equipe los envíos con GPS y sensores de temperatura que envían actualizaciones en vivo. Las alertas proactivas permiten desviar la ruta o intervenir si las condiciones cambian.

Protocolos de emergencia: Definir procedimientos de cuarentena y reenvío si ocurre una excursión.. Mantenga transportistas de respaldo y almacenamiento en frío disponibles a lo largo de la ruta..

Desafíos de última milla & Soluciones

La entrega de última milla a menudo implica clínicas pequeñas, pueblos remotos o equipos móviles de vacunación. Estos entornos pueden carecer de electricidad confiable o de personal capacitado.. Los refrigeradores solares de accionamiento directo han revolucionado el almacenamiento fuera de la red al eliminar las baterías y proporcionar energía excedente.. Los transportadores de vacunas portátiles con monitoreo digital incorporado garantizan que las dosis permanezcan dentro del rango 2 °C – 8 Rango de °C hasta la administración. La educación es igualmente vital; Los trabajadores sanitarios deben saber cuánto tiempo pueden permanecer las vacunas a temperatura ambiente. (típicamente no más que 20 minutos) y los pasos inmediatos para poner en cuarentena y documentar incidentes si la temperatura se sale del rango.

Desafíos comunes & Soluciones en Gestión de la Cadena de Frío

Mantener una cadena de frío perfecta no es fácil. A continuación se detallan problemas comunes y cómo resolverlos.:

Cortes de energía: La pérdida de electricidad destruye reservas enteras. Utilice generadores de respaldo, Paneles solares y alarmas alimentadas por baterías.. Los refrigeradores solares de accionamiento directo mantienen temperaturas estables sin baterías.

Fallas de equipos: Los dispositivos viejos o no calibrados provocan variaciones de temperatura. Siga los programas de mantenimiento del fabricante y participe en programas de seguimiento posteriores a la comercialización..

error humano: El personal puede dejar las puertas del refrigerador abiertas o leer mal los termómetros.. Implementar capacitación sobre las cuatro R—Leer, Registro, Reiniciar, Reaccionar y reforzar las rutinas diarias.

Lagunas de datos: Sin seguimiento continuo, las excursiones pasan desapercibidas. Instale registradores de datos digitales y paneles de control centralizados para garantizar la transparencia..

Extremos ambientales: Los climas cálidos o los inviernos fríos ponen a prueba los equipos.. Utilice contenedores activos con alto aislamiento., planificar rutas para evitar el calor del mediodía e incorporar materiales de cambio de fase.

Consejos prácticos & Sugerencias para los usuarios

Gestión de clínicas pequeñas.: Utilice refrigeradores médicos especialmente construidos en lugar de unidades domésticas.. Verifique y registre las temperaturas dos veces al día y use un registrador de datos calibrado.

Grandes centros de vacunación: Implemente un monitoreo centralizado en múltiples refrigeradores y congeladores. Programe mantenimiento preventivo y calibre los dispositivos anualmente.

Programas de extensión: Equipar a los equipos con equipos portátiles., portadores activos, refrigeradores y registradores de datos que funcionan con energía solar. Capacitar al personal para reaccionar rápidamente si la cadena de frío se ve comprometida..

Integración de datos: Implementar una única plataforma de software que agregue datos de sensores, inventario y programacion. Utilice análisis para identificar tendencias y ajustar la capacitación.

Caso del mundo real: Una oficina de salud de distrito en África subsahariana redujo el desperdicio de vacunas en 40 % reemplazando los refrigeradores domésticos con unidades de accionamiento solar directo e implementando monitoreo de IoT en tiempo real. El sistema alertó al personal sobre cortes de energía y desviaciones de temperatura., permitiendo una acción correctiva rápida y asegurando que las clínicas siempre tuvieran dosis potentes.

2025Los últimos desarrollos & Tendencias

Descripción general de la tendencia

El panorama de la cadena de frío está evolucionando rápidamente. Se prevé que el mercado de logística de vacunas alcance aproximadamente Dólar estadounidense 3.29 mil millones en 2025, impulsado por nuevos programas de inmunización y la demanda de vacunas de ARNm y de terapia génica. Sin embargo, 25-30 % de las vacunas en el África subsahariana se pierden debido a las variaciones de temperatura, destacando la necesidad de innovaciones. La investigación muestra que los sistemas de cadena de frío mejorados utilizan contenedores optimizados, Los dispositivos de monitoreo avanzados y los modelos predictivos refuerzan los programas de inmunización al minimizar el desperdicio y garantizar que las dosis lleguen a los pacientes.. A continuación se muestran las tendencias clave que están dando forma 2025.

Últimos desarrollos de un vistazo

Refrigeración con energía solar: Los refrigeradores solares de accionamiento directo se han vuelto populares, proporcionando refrigeración estable sin baterías y generando energía excedente para las clínicas.

Optimización de rutas impulsada por IA: Las plataformas logísticas utilizan inteligencia artificial para predecir el tráfico, clima y rendimiento del equipo, reduciendo retrasos y consumo de combustible.

IoT & integración de cadena de bloques: Los sistemas de extremo a extremo combinan sensores con blockchain para permitir la transparencia, Historiales de temperatura a prueba de manipulaciones y automatización de la documentación de cumplimiento..

Materiales de cambio de fase & modelos predictivos: Los nuevos contenedores de transporte utilizan materiales de cambio de fase dual y redes neuronales artificiales para mantener la estabilidad térmica y pronosticar las tasas de fusión..

Entrega autónoma y con drones: Drones entregan vacunas a zonas remotas, evitando los desafíos de infraestructura y reduciendo el tiempo de tránsito. Los vehículos autónomos mantienen temperaturas constantes sin error del conductor.

Mercado & Perspectivas de políticas

Los reguladores y las organizaciones globales están actualizando los estándares para reflejar estas innovaciones.. IMD PQS revisado 43 estándares existentes y desarrolló especificaciones para vehículos refrigerados y refrigeradores portátiles entre 2019 y 2024. También precalificó 187 nuevos productos en 10 categorias. El cambio climático está provocando demandas de equipos sostenibles; La eliminación gradual del refrigerante R 134a y la adopción de sistemas de energía solar reducen las emisiones de gases de efecto invernadero.. La pandemia de COVID 19 puso de relieve vulnerabilidades, estimulando la inversión en almacenamiento ultrafrío, vigilancia y preparación para emergencias. Los países están integrando el almacenamiento de otros productos sanitarios sensibles a la temperatura en la cadena de frío de las vacunas., que requieren mayores capacidades y coordinación intersectorial.

Preguntas frecuentes

Pregunta 1: ¿Cuánto tiempo pueden permanecer las vacunas fuera del frigorífico??

La mayoría de las vacunas no deben exceder 20 minutos fuera del +2 °C a +8 rango de grados centígrados. Si ocurren exposiciones, poner en cuarentena las dosis, manténgalos dentro del alcance y documente el incidente. Consulte siempre las directrices del fabricante..

Pregunta 2: ¿Con qué frecuencia debo verificar la temperatura de mi unidad de almacenamiento de vacunas??

El NHS y CDC recomiendan controlar las temperaturas dos veces al día—una vez al inicio y otra al final de la jornada laboral. Utilice registradores de datos digitales para monitoreo continuo y registros manuales para redundancia.

Pregunta 3: ¿Puedo utilizar un frigorífico doméstico para guardar vacunas??

No. Los frigoríficos domésticos tienen una distribución desigual de la temperatura y carecen de controles precisos. Utilice siempre refrigeradores médicos especialmente diseñados para vacunas..

Pregunta 4: ¿Qué debo hacer si mi registrador de datos emite una alarma??

Confirme inmediatamente la temperatura con un termómetro secundario., ajustar el termostato o trasladar las vacunas a una unidad de respaldo. Documentar el evento y notificar a los supervisores.. Siga las cuatro R—Leer, Registro, Reiniciar y reaccionar.

Pregunta 5: ¿Cómo mejoran los dispositivos de IoT la transparencia de la cadena de frío??

Los sensores de IoT registran la temperatura, datos de humedad y ubicación en tiempo real y transmitirlos a paneles de control en la nube. Las partes interesadas reciben alertas cuando se producen desviaciones y pueden intervenir rápidamente.

Resumen & Recomendaciones

Control de llave: Un sistema exitoso de logística de vacunas y gestión de la cadena de frío mantiene rangos de temperatura estrictos, utiliza equipos validados y aprovecha el monitoreo en tiempo real. Las variaciones de temperatura destruyen la potencia de la vacuna y contribuyen a hasta 25 % pérdidas a nivel mundial. El uso constante de registradores de datos digitales y sensores de IoT reduce el deterioro y mejora el cumplimiento. Refrigeración con energía solar, Los materiales de cambio de fase y los análisis impulsados por IA representan las principales innovaciones de 2025.

Plan de acción: Comience por auditar su cadena de frío actual: verifique la antigüedad del equipo, Registros de mantenimiento y prácticas de seguimiento.. Actualice a refrigeradores y congeladores especialmente diseñados con registradores de datos digitales. Implementar una plataforma integrada que agregue datos de sensores, inventario y planificación de rutas. Capacite al personal sobre las cuatro R y los procedimientos de emergencia.. Explore soluciones de energía solar o híbrida para sitios fuera de la red. Considere los marcos blockchain o IoT para una trazabilidad transparente. Finalmente, Revise periódicamente las actualizaciones regulatorias y las tecnologías emergentes para mantener su sistema preparado para el futuro..

Acerca de Tempk

Tempk es especialista en soluciones de seguimiento y envasado de cadena de frío. Diseñamos cajas aislantes reutilizables, paquetes de gel y contenedores activos que mantienen temperaturas precisas durante horas o días. Nuestras unidades alimentadas por energía solar y registradores de datos habilitados para IoT lo ayudan a cumplir con las pautas de la OMS y los CDC y, al mismo tiempo, reducen el impacto ambiental.. Con décadas de experiencia en logística alimentaria y farmacéutica., entendemos los desafíos que enfrenta. Nuestros productos son rigurosamente probados., fácil de usar y respaldado por un equipo de soporte dedicado.

Necesita orientación personalizada? Póngase en contacto con nuestros expertos para analizar los desafíos de la logística de sus vacunas y descubrir soluciones que mantengan sus dosis seguras.. Estamos aquí para ayudarle a construir una cadena de frío resiliente y proteger la salud pública..