Última actualización: Enero 12, 2026

Choosing an industrial gel ice China manufacturer is not about buying “cold.” It’s about buying time, consistency, and fewer heat-damage claims. A well-designed system can protect shipments for 24 a 96+ horas, depending on insulation and pack-out design.

If your warm-arrival rate spikes in summer, the right pack-out often pays back fast.

What you’ll learn in this guide:

- How to screen an industrial gel ice China manufacturer with a fast scorecard

- What specs to send for custom gel ice pack sizes (so sampling doesn’t drag on)

- Which tests matter most (and how to spot weak data)

- How to reduce leaks with simple QC checks

- How to build 24–72+ hour pack-outs with fewer packing mistakes

What does an industrial gel ice China manufacturer really do?

Respuesta directa: A strong industrial gel ice China manufacturer delivers sealed gel packs that behave predictably inside your packaging. That means consistent fill, stable freezing behavior, and reliable weld quality. Your gel packs act like a thermal “batería,” absorbing heat and slowing temperature rise.

Explicación expandida: Your shipper is a system. Gel packs are one part, insulation is another, and your packing method is the glue. If your supplier can’t support pack-out design and testing, results become random. If they can, you get repeatable outcomes at scale.

What you’re actually buying (not just “frío”)

- Predictable temperature curves (not vague “72-hora” reclamos)

- Leak-resistant film and welds (so cartons don’t fail)

- Warehouse-friendly formats (so pack-outs are hard to do wrong)

- Batch consistency (so the 10,000th pack behaves like the first)

How to choose an industrial gel ice China manufacturer in 10 minutos

Respuesta directa: Use a scorecard focused on performance proof, sealing discipline, y trazabilidad. Price matters later. Primero, make sure the supplier can deliver predictable outcomes.

The fast supplier scorecard (0–10 puntos)

Give 1 point for each “Sí”:

- They share raw time–temperature curves, not only summaries.

- Curves include your target duration (24/48/72+ horas).

- Curves show worst-case (hot last mile), not averages.

- They explain preconditioning (freeze/chill SOP) claramente.

- They run leak tests and can show logs.

- They control fill weight with recorded checks.

- They use lot codes and can trace complaints by batch.

- They support pack-out placement diagrams for your shipper.

- They offer format options (paneles, ladrillos, edge packs).

- They support a pilot using your real product load.

How to read your score:

- 8–10: Strong fit for scaling

- 5–7: Posible ajuste, but validate hard

- 0–4: High risk—expect surprises

Consejos prácticos que puede usar hoy

- If your lanes vary: ask for “verano” y “leve” pack-outs.

- If you scale fast: prioritize batch consistency over the lowest unit price.

- If you ship fragile items: choose formats that reduce crush risk.

Ejemplo del mundo real: A DTC team reduced warm-arrival tickets by standardizing one 48-hour pack-out and one placement rule.

What specs should you send to an industrial gel ice China manufacturer?

Respuesta directa: Send temperature band, duración del carril, shipper internal size, and worst-case exposure before sampling. This prevents wasted prototypes and shortens the sourcing cycle.

Explicación expandida: Many projects fail because the buyer asks for “paquetes de gel” without defining success. A capable industrial gel ice China manufacturer can’t design efficiently without constraints.

Your one-page RFQ template (copiar/pegar)

- Target temperature band: ______________________

- Lane duration goal: 24 / 48 / 72 / 96 horas

- Worst-case ambient exposure: __________________

- Shipper internal size (L × W × H): ____________

- Carga de producto (total weight + colocación): _______

- Allowed pack count (max packs): ______________

- Pass criteria (one sentence): “Stays within target band for ___ hours”

Quick self-check: are your specs complete?

Date a ti mismo 1 point for each “Sí”:

- You defined a temperature band, not just “cold.”

- You defined a duration, not just “2-day shipping.”

- You provided internal dimensions, not only outer carton size.

- You described worst-case exposure, not only typical weather.

- You wrote one pass/fail sentence.

What tests should an industrial gel ice China manufacturer show you?

Respuesta directa: Demand instrumented testing with raw time–temperature curves. A “aprobar” can hide dangerous spikes. Curves show excursions, which is what damages products.

Explicación expandida: In parcel environments, some teams reference standardized thermal profiles like ISTA STD-7E to compare systems under common conditions. Even if you don’t use that standard, the idea is the same: test under realistic profiles and review the curves.

The 4-step thermal test plan you can request

- Precondition packs using a written SOP (freeze/chill time and setpoint).

- Pack real product load (not empty air only).

- Run hot / moderado / cold profiles (seasonal thinking).

- Review raw curves and refine pack-out placement first.

Qué “bien” data looks like (and what to reject)

| Data item | Aceptable | Bandera roja | Lo que significa para ti |

|---|---|---|---|

| Time–temperature curves | Full time series | Summary claims only | You can’t see excursions |

| Sensor map | Multiple locations | One sensor only | Risk hides in corners |

| Preacondicionamiento | Documented SOP | “We just freeze it” | Results won’t repeat |

| Duración del carril | Matches your target | “Typical performance” | Scaling will fail |

Practical tips to raise success rates

- Test your worst lane first: don’t start with the easy route.

- Add a delay-hold scenario: real life is messy.

- Keep packing method identical: training gaps destroy repeatability.

Case note: One team fixed a mid-route spike by changing pack placement, not adding more gel.

Which formats should your industrial gel ice China manufacturer offer for 24–72+ hour lanes?

Respuesta directa: Start with a simple menu—flat panels, ladrillos, and edge packs—and standardize. More SKUs usually means more mistakes.

Explicación expandida: Format controls cooling, but also packing speed and accuracy. Your best format is the one that your team can’t easily misplace.

Pack-out decision tool (fast and practical)

Responde estas tres preguntas:

- Is your box slim and flat? Choose flat panels.

- Is your route long or unpredictable? Add bricks for thermal mass.

- Is crush risk high? Use edge packs to protect and cool.

Format selection guide

| Formato | El mejor uso | Main advantage | Significado práctico para ti |

|---|---|---|---|

| Flat panels | Anuncios publicitarios, equipos | Colocación rápida | Menos errores de embalaje |

| Ladrillos | Carriles más largos | Higher thermal mass | Better buffer for delays |

| Edge packs | Fragile goods | Protect + Frío | Less crush risk |

Practical tips for warehouse-friendly pack-outs

- Use one-rule placement: “arriba + two sides” is easy to remember.

- Prevent sliding: tight fit or inserts reduce airflow changes.

- Print a photo SOP: visual rules beat long instructions.

How to audit an industrial gel ice China manufacturer for leak-proof quality

Respuesta directa: Focus on seal integrity, corner strength, and fill consistency. Most wet-box failures come from weld defects, film punctures, or inconsistent fill weight.

Explicación expandida: Leak risk isn’t a small annoyance. It destroys cartons, etiquetas, and customer trust. It also creates rework in the warehouse.

The 3-minute incoming inspection (every shipment)

- Drop test one closed carton from typical handling height.

- Deshielo + press packs to stress seams and corners.

- Wipe check for micro-leaks and oily residues.

- Pesar 10 packs to confirm fill consistency.

Common defects and likely root causes

| Defect | lo que ves | Causa probable | Lo que significa para ti |

|---|---|---|---|

| Corner seep | Damp corners | Weak corner weld | Hidden leaks in transit |

| Pinholes | Tiny jets under pressure | Film puncture | Random wet boxes |

| Underfill | Soft pack, warms faster | Fill control issues | Shorter protection time |

Practical tips to reduce disputes

- Require lot codes on every carton, not only master cartons.

- Use an AQL-style sampling plan for leaks and weight variance.

- Ask for change control when film suppliers change.

How to reduce total cost with your industrial gel ice China manufacturer

Respuesta directa: Comparar “cost per protected delivery,” not cost per pack. A cheap pack that leaks or warms early can become the most expensive choice.

How to cut weight without losing protection

- Eliminate void space: warm air is the enemy.

- Improve insulation fit: better contact reduces heat gain.

- Use fewer, smarter packs: large panels often beat many small packs.

- Right-size the shipper: smaller internal volume warms slower.

Ejemplo práctico: A brand cut shipping weight by removing headspace and switching to flatter panels.

Safety and compliance basics for an industrial gel ice China manufacturer

Respuesta directa: Ask for clear documentation and use-case fit. If packs may contact food-adjacent surfaces, request documentation and clarify intended use.

Compliance questions to ask any supplier

- Do you provide SDS documentation when requested?

- Can you state whether materials are intended for food-adjacent cold chain use?

- Do you have clear labeling for handling and disposal?

- Do you provide guidance to prevent freezing risk in chilled lanes?

Practical safe-operation tips

- Train teams for spills: gels can create slip hazards.

- Store packs cleanly: avoid odor transfer.

- Avoid direct contact with products that cannot freeze.

2026 trends shaping industrial gel ice China manufacturer sourcing

Descripción general de la tendencia: En 2026, buyers expect proof and repeatability. They want raw test curves, clear change control, and warehouse-friendly pack-outs. They also expect better documentation and smarter, standardized formats.

Últimos desarrollos a seguir

- More standardized parcel thermal testing: ISTA STD-7E is commonly referenced in parcel contexts.

- More setpoint-focused cooling: PCM-style packs are gaining attention for tighter control.

- Better leak resistance: stronger films and improved weld control reduce wet-box risk.

- Higher documentation expectations: traceability and change control are becoming default.

Insight del mercado: El “winning” industrial gel ice China manufacturer is increasingly the one who helps you deploy at scale with diagrams, fewer SKUs, and fast corrective action.

Preguntas frecuentes

Q1: How do I choose an industrial gel ice China manufacturer quickly?

Start with three checks: raw test curves, leak-proof sealing controls, and batch traceability. If any are missing, risk rises.

Q2: How many gel ice packs do I need for 48 horas?

There is no universal number. It depends on shipper size, aislamiento, calor ambiental, y carga de producto. Pilot your exact pack-out.

Q3: Should I use gel ice or dry ice for cold chain shipping?

Use gel ice for chilled shipments and easier operations. Dry ice is extremely cold and adds handling constraints.

Q4: What thermal testing standard should I ask for in parcel shipping?

Some teams reference ISTA STD-7E for parcel thermal profiles to compare systems consistently.

Q5: What’s the most common gel pack failure in real shipping?

Leaks and underfill. Both reduce cooling performance and create wet-box incidents.

Resumen y próximos pasos

Control de llave: Choosing an industrial gel ice China manufacturer is choosing predictable outcomes. Start with clear specs, then screen suppliers with test curves, leak control, y trazabilidad. Standardize formats and placement rules so your warehouse can repeat the result. Finalmente, validate with a pilot on your worst lane.

Plan de acción (CTA):

- Elige uno “worst lane,” one shipper size, and one product load.

- Send the one-page RFQ and request raw test curves.

- Piloto, revisar curvas, and lock a photo-based pack-out SOP.

- Scale only after the process is repeatable.

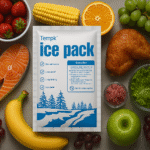

Acerca de Tempk

We build cold chain packaging solutions designed for real operations—stable pack-outs, clear warehouse SOPs, and consistent quality controls. We support standardized gel ice formats, custom options when volumes justify them, and practical validation planning aligned with your lanes.

Siguiente paso: Share your shipper dimensions, duración del carril, and target temperature band. We’ll propose a pilot pack-out plan and a clear acceptance checklist.