Comment choisir et utiliser le meilleur sac isotherme de glace carbonique pour l'expédition sous la chaîne du froid

Expédition de produits sensibles à la température tels que les produits pharmaceutiques, aliments périssables, et les échantillons biologiques nécessitent une précision dans le maintien de conditions optimales. Packs de glace carbonique pour sac isotherme sont devenus une solution essentielle pour que les entreprises répondent à ces exigences strictes. Dans ce guide complet, nous explorerons le fonctionnement des packs de glace sèche dans des sacs réfrigérants, leurs avantages, bonnes pratiques d'utilisation, et comment optimiser vos processus d'expédition sous chaîne du froid en 2025. En sélectionnant le bon pack de glace sèche pour sac isotherme, vous pouvez réduire la détérioration, maintenir l'intégrité du produit, et répondre aux normes réglementaires.

-

Que sont les packs de glace sèche dans des sacs réfrigérants et comment fonctionnent-ils ??

-

Comment utiliser efficacement les packs de glace sèche dans des sacs réfrigérants lors du transport sous chaîne du froid?

-

Quelles sont les meilleures pratiques pour optimiser vos processus d'expédition utilisant de la neige carbonique?

-

Quelles sont les dernières tendances en matière d'emballage de glace carbonique pour 2025?

Que sont les packs de glace sèche dans des sacs isothermes et comment fonctionnent-ils ??

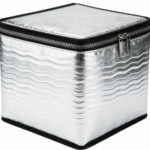

Les packs de glace carbonique pour sacs isothermes sont spécialement conçus pour conserver les articles périssables à des températures ultra-basses pendant le transport.. Ils combinent des sacs isothermes avec du dioxyde de carbone solide (glace carbonique), qui se sublime directement en gaz, maintenir des températures glaciales sans produire d’humidité. Cette fonctionnalité les rend idéales pour expédier des articles comme des vaccins, biologique, et aliments surgelés, où le maintien de l’intégrité de la température est essentiel.

Pourquoi la glace carbonique est préférable pour l'expédition de marchandises sensibles à la température

La glace carbonique offre plusieurs avantages pour le transport sous chaîne du froid:

-

Pas d'eau de fusion: Contrairement à la glace traditionnelle, la neige carbonique se sublime en gaz, empêcher l’humidité d’endommager les produits sensibles.

-

Des températures plus basses: La glace carbonique peut maintenir des températures aussi basses que -78,5°C, idéal pour les articles qui nécessitent des conditions de congélation.

-

Durée de refroidissement plus longue: La glace carbonique peut durer 24-48 heures ou plus, en fonction de la quantité utilisée et de la conception de l'emballage, offrant une période de refroidissement plus longue que la glace ordinaire.

Meilleures pratiques d’utilisation des packs de glace sèche dans des sacs isothermes lors de l’expédition

Pour garantir des performances et une sécurité optimales, il est essentiel de suivre les meilleures pratiques lors de l’utilisation de packs de glace sèche dans des sacs réfrigérants pour l’expédition.

1. Calculer la bonne quantité de glace carbonique

La quantité de neige carbonique dépend de la durée de l'expédition et de la sensibilité à la température des produits transportés.. En général, 5-10 lb de glace carbonique suffisent pour 24 heures de transit. Pour les expéditions plus longues, plus de neige carbonique sera nécessaire.

2. Assurer un emballage approprié

Utilisez des emballages isothermes de haute qualité tels que des boîtes en polystyrène ou des sacs isothermes doublés de Mylar. L'isolation est essentielle pour minimiser les fluctuations de température pendant le transport. En plus, assurez-vous que l'emballage n'est pas entièrement hermétique pour permettre au gaz de glace carbonique de s'échapper en toute sécurité.

3. Surveiller les températures pendant le transport

La surveillance de la température est un aspect essentiel de la logistique de la chaîne du froid. Intégrez des enregistreurs de température ou des capteurs pour suivre la température à l'intérieur de la glacière pendant le transport.. Cela garantit que les produits restent dans la plage de température requise.

4. Étiqueter et emballer correctement

Conformément aux réglementations maritimes internationales, en particulier ceux fixés par l'IATA, les paquets de glace carbonique doivent être correctement étiquetés. Assurez-vous d'utiliser la bonne étiquette « Dioxyde de carbone solide » avec le symbole de danger approprié et indiquez le poids net de la neige carbonique utilisée..

Pourquoi l'isolation est-elle importante lors de l'utilisation de packs de glace sèche dans un sac isotherme?

Une isolation efficace prolonge l'effet rafraîchissant de la neige carbonique en ralentissant le processus de sublimation. Sans isolation appropriée, la neige carbonique s'évaporera trop rapidement, compromettant potentiellement la qualité des produits expédiés.

Types de matériaux d'isolation pour l'expédition de glace carbonique

-

Conteneurs en polystyrène: Ceux-ci sont rentables et largement utilisés, offrant une excellente isolation thermique pour les expéditions prolongées.

-

Matériaux réfléchissants: Les sacs ou conteneurs isothermes contenant des matériaux comme le Mylar réfléchissent la chaleur, aidant à maintenir des températures froides pendant le transport.

| Facteur d'emballage | Pratique recommandée | Pourquoi ça compte |

|---|---|---|

| Quantité de glace carbonique | 5-10 lbs par 24 heures | Empêche les fluctuations de la température |

| Isolation | Utilisez de la mousse de polystyrène ou des matériaux réfléchissants | Prolonge l'effet rafraîchissant de la glace carbonique |

| Contrôle de la température | Ajouter des dispositifs de surveillance de la température | Assure le respect des normes de température |

Comment optimiser les processus d'expédition à l'aide de glace carbonique?

Pour améliorer votre logistique sous chaîne du froid grâce à la neige carbonique, envisager les stratégies suivantes pour optimiser les processus d’expédition, réduire les coûts, et maintenir la conformité réglementaire.

1. Examiner les expéditions passées

L'analyse des données historiques d'expédition peut aider à identifier les inefficacités et les domaines à améliorer. En comprenant les problèmes antérieurs de contrôle de la température et l’efficacité de l’emballage, vous pouvez effectuer des ajustements pour réduire la détérioration et améliorer la précision de l'expédition.

2. Formez votre équipe

Une bonne formation est essentielle lorsque l’on travaille avec de la neige carbonique. Assurez-vous que votre équipe comprend comment manipuler et emballer de la glace carbonique en toute sécurité., comment calculer le montant correct nécessaire pour un envoi, et comment assurer la sécurité pendant le transport.

3. Investir dans la technologie

Utilisez des technologies intelligentes pour améliorer votre processus d’expédition sous la chaîne du froid. Les plateformes basées sur l'IA peuvent aider à optimiser l'utilisation de la glace carbonique en prédisant la bonne quantité pour chaque expédition en fonction de facteurs tels que la température ambiante., durée de l'expédition, et sensibilité du produit.

Dernières tendances en matière de solutions de packs de glace carbonique pour sacs isothermes pour 2025

À mesure que l'industrie de la logistique de la chaîne du froid évolue, plusieurs tendances clés façonnent l’avenir des blocs de glace carbonique pour sacs réfrigérants.

Durabilité dans le transport de glace carbonique

-

Production de glace sèche écologique: Les entreprises se concentrent sur la réduction de l’empreinte carbone en s’approvisionnant en CO₂ provenant des processus industriels, rendre la production de glace carbonique plus durable.

-

Emballage réutilisable: Les emballages isothermes réutilisables plusieurs fois gagnent en popularité, réduire les déchets et les coûts d’expédition à long terme.

Capteurs intelligents et surveillance

-

Dispositifs de surveillance de la température: L'utilisation de capteurs intelligents et d'enregistreurs de température est devenue une pratique courante. Ces appareils permettent de surveiller en temps réel les niveaux de neige carbonique et les conditions de température tout au long du transit..

Solutions hybrides

-

Combinaison de glace sèche et de matériaux à changement de phase (PCMS): Les solutions hybrides sont de plus en plus courantes, où la neige carbonique et les PCM sont utilisés ensemble pour prolonger la durée de refroidissement et réduire les émissions de CO₂.

Questions fréquemment posées

Pourquoi devrais-je utiliser de la glace carbonique pour l'expédition?

La glace carbonique est idéale pour l'expédition de marchandises sensibles à la température, car elle maintient des températures ultra basses sans les dégâts causés par l'eau fondue.. Il conserve des produits comme les produits pharmaceutiques, biologique, et les aliments surgelés dans la plage de température requise pendant de longues périodes.

Est-il sécuritaire de manipuler de la glace sèche?

La manipulation de glace carbonique est sûre à condition que les précautions appropriées soient prises. Portez toujours des gants isolés pour éviter les engelures et travaillez dans des zones bien ventilées pour éviter l'accumulation de CO₂..

Comment puis-je me débarrasser de la glace carbonique en toute sécurité?

La glace carbonique ne doit jamais être jetée dans les éviers, toilettes, ou des poubelles. Laissez-le se sublimer dans un endroit bien aéré jusqu'à ce qu'il se dissipe complètement en gaz.

Conclusion

Les packs de glace carbonique en sac isotherme offrent une efficacité, fiable, et une solution rentable pour le transport sous chaîne du froid. En suivant les meilleures pratiques en matière d'emballage, isolation, et surveillance de la température, vous pouvez optimiser vos processus d'expédition et garantir l'intégrité des produits. Comme 2025 approches, l'adoption de technologies durables et intelligentes continuera de façonner l'avenir des emballages de glace carbonique dans l'industrie de la chaîne du froid.

Suggestions exploitables:

-

Évaluez vos besoins en matière d’expédition sous chaîne du froid pour déterminer le bon emballage de glace carbonique pour vos produits.

-

Formez votre équipe sur la manipulation sûre et l’utilisation appropriée de la neige carbonique pour garantir la conformité réglementaire.

-

Mettre en œuvre des solutions intelligentes d’emballage et de logistique pour réduire la consommation de CO₂ et optimiser l’efficacité des expéditions.

À propos du tempk

Et tempk, nous sommes spécialisés dans la fourniture de solutions logistiques sur mesure pour la chaîne du froid qui répondent aux normes les plus élevées de sécurité et d'efficacité. Nos produits sont conçus pour garantir l’intégrité de vos expéditions, réduire les déchets, et se conformer à 2025 règlements. Avec notre soutien expert, vous pouvez optimiser vos processus d'expédition et améliorer vos opérations commerciales.