Quand vous devez expédier des vaccins, des échantillons de fruits de mer ou de laboratoire dans un vaste pays comme le Canada, le contrôle de la température n'est pas négociable. Feuilles de glace sèche au Canada fournir des températures ultra froides en utilisant du dioxyde de carbone solide (Co₂) qui se sublime à −78,5 °C. Contrairement aux packs de glace ou de gel ordinaires, ces feuilles gardent les marchandises congelées pendant 24–72 heures sans produire d’eau de fonte【270798852816686†L140-L139】. Cet article explique le fonctionnement des feuilles de glace carbonique du Canada, comment les dimensionner et les manipuler en toute sécurité, Et quoi 2025 tendances que vous devez connaître pour maintenir l’intégrité de vos expéditions.

Qu'est-ce qui rend les feuilles de glace carbonique du Canada efficaces? Découvrez la science de la sublimation et pourquoi les températures ultra froides sont importantes.

Comment dimensionner et choisir la bonne plaque de glace carbonique pour votre envoi? Apprendre les formules de poids, taux de charge utile et effets de l’isolation.

Comment pouvez-vous utiliser les feuilles de glace carbonique du Canada en toute sécurité et efficacement? Suivez étape par étape les pratiques d’emballage et de manutention.

Comment les feuilles de glace carbonique se comparent-elles aux packs de gel et aux matériaux à changement de phase (PCM)? Comprendre les plages de température, durée et réutilisation.

Quoi 2025 les innovations et les tendances en matière de durabilité affectent la chaîne du froid du Canada? Explorez l'emballage intelligent, CO₂ recyclé et systèmes hybrides.

Qu'est-ce qui rend les feuilles de glace carbonique du Canada si efficaces?

Sublimation et températures ultra froides

Les feuilles de glace carbonique du Canada sont fabriquées à partir de CO₂ solide comprimé qui se sublime directement en gaz à environ -78,5 °C.. Cela signifie qu'ils contournent entièrement la phase liquide, il n'y a donc pas d'eau qui coule ou qui trempe vos produits. La glace carbonique offre des températures plus froides et une durée plus longue que les packs de gel ou la glace à l'eau, garder les vaccins, biologique, les fruits de mer et les échantillons génétiques en toute sécurité en dessous de leurs seuils critiques. Des plaques de glace carbonique de haute qualité peuvent maintenir des températures gelées jusqu'à 72 heures【270798852816686†L140-L139】, permettant aux expéditions de parcourir de longues distances sans décongeler.

Les packs de gel et la glace d'eau gèlent 0 °C. Alors qu'ils fondent, ils libèrent de l'humidité et se réchauffent progressivement, ce qui peut endommager les produits ou les étiquettes sensibles. La sublimation sur glace carbonique évite ces problèmes, formant une couverture protectrice de gaz froid autour de vos marchandises et empêchant les brûlures de congélation. Pour les marchandises nécessitant une réfrigération (2–8 ° C) plutôt que de geler, les packs de gel restent adaptés car non dangereux et plus faciles à manipuler.

Types de formats de packs de glace sèche au Canada

Différents formats adaptés à différentes expéditions. Blocs ou dalles (2–10 lb) se sublime lentement et offre une endurance de 24 à 72 heures. Les sacs à pellets offrent un refroidissement rapide mais se subliment rapidement, ce qui les rend parfaits pour les conteneurs de préconditionnement. Les feuilles rainurées ou mini dalles sont flexibles, vous permettant d'enrouler de la neige carbonique autour de charges irrégulières sans perdre d'espace. Choisir le bon format vous aide à gérer le taux de sublimation et la durée du froid.

Comparaison des supports de refroidissement

| Milieu de refroidissement | Changement de phase | Plage de température | Durée typique | Implications pratiques |

| Glace sèche (Co₂) | Sublime directement du solide au gaz | ≈ −78,5 °C | 24–48 h (jusqu'à 72 h avec des draps de haute qualité)【270798852816686†L140-L139】 | Fournit des températures ultra froides sans résidus de liquide; idéal pour les vaccins, produits biologiques et aliments surgelés. |

| Packs de gel | Faire fondre du solide au liquide | Autour 0 °C (32 °F) | 6–24 h | Non dangereux, réutilisable et adapté aux produits qui ne doivent pas geler; durée plus courte. |

| Matériaux à changement de phase (PCM) | Transition solide-liquide à des points de consigne spécifiques | 2–8 °C ou −20 °C | 24–96 h | Contrôle de température réutilisable et précis; idéal pour les produits réfrigérés; conformité réglementaire plus facile. |

Comment dimensionner et choisir les feuilles de pack de glace carbonique du Canada pour votre envoi

Règles générales de dimensionnement

Le dimensionnement correct de vos feuilles de glace carbonique Canada garantit que les marchandises restent congelées sans gaspiller de réfrigérant.. Une règle courante consiste à utiliser 5 à 10 lb (2.3–4,5 kg) de glace sèche par 24 heures de transit. Pour les vaccins et les produits biologiques nécessitant des températures ultra froides, utiliser l'extrémité supérieure de cette fourchette; pour plats ou viandes surgelés, moins peut suffire. Une autre règle simple consiste à faire correspondre le poids de la neige carbonique au poids du produit pour les expéditions en 48 heures., ajustement en fonction de la saison et de la complexité de l'itinéraire.

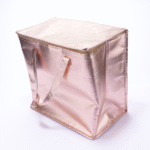

La qualité de l'isolation affecte considérablement les exigences en matière de neige carbonique. La mise à niveau de la mousse EPS de base vers des panneaux isolés sous vide peut réduire les besoins en glace carbonique de 10 à 25 % %. En pratique, les récipients avec des parois de 2 à 3 pouces d'épaisseur conservent le froid plus longtemps et nécessitent moins de glace carbonique que les boîtes minces. Commencez par les formules générales ci-dessous, puis ajustez en fonction du type de conteneur et des conditions ambiantes.

Poids de glace carbonique recommandé par charge utile et durée

| Poids de la charge utile | Glace carbonique pour 24 h | Glace carbonique pour 48 h | Glace carbonique pour 72 h | Ce que cela signifie pour vous |

| 10 lb de charge utile | 5 lb de glace sèche | 10 lb de glace sèche | 15 lb de glace sèche | De quoi expédier des vaccins ou des échantillons de thérapie génique pour un transit de deux jours. |

| 20 lb de charge utile | 10 lb de glace sèche | 20 lb de glace sèche | 30 lb de glace sèche | Convient aux viandes ou fruits de mer surgelés jusqu'à trois jours. |

| 50 lb de charge utile | 25 lb de glace sèche | 50 lb de glace sèche | 75 lb de glace sèche | Utilisé pour les grandes expéditions de viande ou les livraisons industrielles. |

Ces chiffres servent de points de départ. Augmentez le montant de 20–30 % en été ou lors d'expéditions via plusieurs hubs, et diminuer de 10–25 % si vous utilisez une isolation haute performance. Tester différents packs sur votre itinéraire le plus long peut vous aider à affiner vos calculs.

Recommandations spécifiques au produit

Vaccins et produits biologiques ultra froids: Utiliser 5–10 lb de neige carbonique par jour. Maintenir les températures en dessous de −70 °C; ajouter du poids supplémentaire dans les climats chauds.

Fruits de mer et viandes haut de gamme: 1–2 lb de neige carbonique par jour suffit pour les petits envois; doublez-le pour les conteneurs plus grands.

Plats et desserts surgelés: 2–3 lb de neige carbonique par jour garde les repas surgelés solides jusqu'à 72 heures.

Utiliser des formules pour estimer les besoins

Une formule simple des transporteurs logistiques est:

Glace sèche (kg) ≈ (Temps de transit en heures ÷ 24) × (Consommation moyenne par jour)

Si vous prévoyez un envoi en 36 heures et avez besoin 5 lb par jour pour les vaccins, le calcul est (36/24) × 5 = 7.5 kg. L’arrondi garantit un tampon. Utilisez cette formule ainsi que la masse thermique et la qualité d'isolation de votre produit pour dimensionner correctement votre plaque de glace sèche..

Manipulation sécuritaire et conformité réglementaire au Canada

Précautions de manipulation et ventilation

La glace carbonique est sans danger lorsqu’elle est manipulée correctement, mais une mauvaise utilisation peut provoquer des engelures, asphyxie ou explosion de conteneurs. Portez toujours des gants isolés et des lunettes de protection lorsque vous manipulez des feuilles de glace carbonique Canada.. Parce que la neige carbonique libère du gaz CO₂, travailler dans un endroit bien ventilé ou fissurer les vitres du véhicule pour éviter le déplacement de l'oxygène. Ne stockez jamais de glace carbonique dans des contenants hermétiques ou des glacières scellées.; les trous d'aération ou les couvercles à aération automatique permettent au gaz de s'échapper et empêchent l'accumulation de pression.

Exigences en matière d'emballage et d'étiquetage

La glace sèche est classée comme un Classe 9 matières dangereuses pour le transport aérien. Les colis doivent afficher l'ONU 1845 diamant de danger et indiquez le poids net de la neige carbonique. Pour les vols passagers, L'IATA permet aux voyageurs d'emporter jusqu'à 2.5 kg (5.5 kg) de glace carbonique par personne sans déclaration. Les expéditions commerciales peuvent transporter jusqu'à 200 kg mais doit suivre des règles strictes de documentation et d'emballage. Les expéditions terrestres au Canada et aux États-Unis sont soumises à moins de restrictions, mais nécessitent toujours une manipulation sécuritaire..

Lors du transport de matières infectieuses ou d’échantillons biologiques, suivre le règle du triple emballage: un réceptacle primaire étanche, un emballage secondaire étanche avec matériau absorbant, et un conteneur extérieur solide. Chaque couche doit être étanche et le récipient extérieur doit être étiqueté avec le poids de glace carbonique et la classification de danger..

Gestion des meilleures pratiques

Portez un équipement de protection: Utilisez des gants isolés, des lunettes et des manches longues pour éviter les engelures et les brûlures par le froid.

Aérer les espaces de travail: Prévoyez toujours une ventilation lors de l’emballage, transporter ou stocker de la neige carbonique.

Envois d’étiquettes: Marquez les colis avec « Glace sèche » et « Dioxyde de carbone », Solide," y compris le poids net et l'ONU 1845.

Stocker de manière responsable: Conservez la neige carbonique dans une glacière ou un récipient isolé qui permet au gaz de s'échapper.. Évitez les récipients en verre ou en plastique scellés qui pourraient éclater.

Planifier les urgences: Fournissez des instructions pour traiter les engelures : plongez la zone touchée dans de l'eau tiède et consultez un médecin..

Emballage et superposition: Comment utiliser efficacement les feuilles de glace carbonique du Canada

Procédure d'emballage étape par étape

Préconditionner le conteneur: Refroidissez votre glacière ou votre boîte isotherme avant d'ajouter de la neige carbonique pour ralentir la sublimation. Placer de la neige carbonique dans un récipient chaud gaspille de l'énergie de refroidissement.

Préparez et coupez vos draps: Hydratez les feuilles de glace carbonique (si nécessaire) et congelez-les à plat. Quand tu es prêt, coupez les feuilles pour les adapter à votre contenant à l'aide d'un couteau dentelé tout en portant des gants.

Isolation en couche: Placez une couche de carton ou de mousse au fond du récipient pour éviter tout contact direct entre la neige carbonique et vos produits.

Positionnez la glace carbonique de manière stratégique: Placer de la neige carbonique sur vos marchandises permet à l'air froid de couler et assure un refroidissement uniforme. Pour les produits qui ne peuvent pas se congeler dessus, vous pouvez placer de la neige carbonique au fond et sur les côtés et utiliser une barrière pour protéger les marchandises.

Remplir les vides: Utilisez du papier bulle, de la mousse ou des tranches de glace carbonique supplémentaires pour éliminer les espaces vides. La réduction des vides améliore la rétention du froid.

Ventiler et sceller correctement: Fermez bien le récipient mais laissez des trous d'aération ou utilisez un couvercle auto-aéré.. Utilisez du ruban adhésif pour fixer le couvercle sans le rendre hermétique.

Étiquette et document: Attachez le diamant de danger et incluez le poids net de glace sèche et la déclaration de l'expéditeur si nécessaire..

Erreurs courantes pour éviter

Scellement de glace carbonique dans un récipient non ventilé: Cela peut provoquer une explosion dangereuse.

Sous-estimer les limites de poids: Les compagnies aériennes autorisent uniquement 2.5 kg par passager; les envois plus importants peuvent nécessiter des déclarations spéciales.

Utiliser des boîtes génériques: Les cartons fins ou les boîtes non isolées accélèrent la sublimation et risquent de perdre le produit.

Ignorer la masse thermique: Les grosses charges utiles nécessitent proportionnellement plus de neige carbonique; ne présumez pas qu’il existe une taille unique.

Exemple de cas réel

UN Une entreprise canadienne de biotechnologie a expédié des vaccins sensibles à la température à travers le pays en utilisant des feuilles de neige carbonique de haute qualité dans une boîte isolée scellée sous vide.. Les fiches d'emballage ont été placées au-dessus et en dessous des flacons, et un enregistreur de données surveillait les conditions internes. Cette configuration a maintenu des températures inférieures à −70 °C pendant plus de 72 heures et évite les pics pendant le transport, démontrant à quel point une superposition et une surveillance minutieuses peuvent protéger les marchandises sensibles.

Feuilles de banquise sèche du Canada vs. Packs de gel et matériaux à changement de phase

Quand utiliser chaque réfrigérant

Les packs de glace carbonique offrent des températures ultra froides (en dessous de −70 °C) et sont idéaux pour les produits biologiques congelés, produits de thérapie génique, glaces et fruits de mer. Ils offrent une capacité de refroidissement élevée par rapport au poids et ne laissent aucun résidu liquide. Cependant, la glace carbonique est à usage unique et nécessite un étiquetage des matières dangereuses.

Les packs de gel maintiennent des températures juste au-dessus du point de congélation (autour 0 °C) pendant 6 à 24 heures, ce qui en fait un bon choix pour les produits frais, produits laitiers ou pharmaceutiques qui ne doivent pas être congelés. Ils ne sont pas dangereux et réutilisables mais peuvent fuir de l'eau et nécessiter plus de packs pour des durées plus longues..

Matériaux à changement de phase (PCM) maintenir des bandes de température étroites, généralement 2 à 8 °C ou −20 °C, pendant 24 à 96 heures. Les PCM sont réutilisables et non dangereux, offrant un contrôle précis et simplifiant la conformité réglementaire. Leur coût initial élevé est compensé par des économies à long terme et une réduction des déchets..

Aperçu comparatif

| Facteur | Packs de glace sec | Packs de gel | PCM |

| Plage de température | Très froid (≈ −78,5 °C) | Près 0 °C | 2–8 °C ou −20 °C |

| Durée | 24–72 h【270798852816686†L140-L139】 | 6–24 h | 24–96 h |

| Classe de danger | Classe 9 dangereux; nécessite un étiquetage | Non dangereux | Non dangereux |

| Réutilisabilité | Usage unique; conteneur réutilisable | Souvent réutilisable mais peut fuir | Hautement réutilisable |

| Meilleurs cas d'utilisation | Produits biologiques ultra froids, fruits de mer gelés, glace | Aliments réfrigérés, produits pharmaceutiques qui ne doivent pas être congelés | Vaccins, produits biologiques nécessitant une température stable entre 2 et 8 °C ou −20 °C |

Approches hybrides

Pour les charges mixtes, la combinaison de blocs de glace carbonique avec des blocs de gel ou du PCM peut prolonger la durée de refroidissement et créer des zones multi-températures. Par exemple, vous pouvez maintenir des conditions ultra froides pour les produits biologiques dans un compartiment tout en gardant les autres articles au frais entre 2 et 8 °C.. L'emballage hybride réduit la consommation totale de glace carbonique et allège les contraintes réglementaires, ce qui le rend idéal pour les expéditions avec des exigences de température variées.

Durabilité et considérations environnementales

CO₂ recyclé et production circulaire

La sublimation sur glace carbonique libère du gaz CO₂, qui peut contribuer aux émissions de gaz à effet de serre. La plupart de la neige carbonique industrielle est produite à partir de CO₂ recyclé capturé lors de processus tels que la synthèse de l'ammoniac et la production d'éthanol.. Le recyclage valorise les déchets de CO₂ et évite le besoin de nouvelles sources de CO₂ fossiles., réduisant ainsi l'impact environnemental. Lors de la sélection des fournisseurs, demander s'ils utilisent CO₂ biosourcé ou capté. L'industrie canadienne de la glace carbonique investit dans la production locale et le captage du CO₂ pour réduire les émissions liées au transport et renforcer la résilience de l'approvisionnement..

Réduire la consommation de glace carbonique

L'utilisation efficace des feuilles de glace carbonique du Canada minimise l'impact environnemental. La mise à niveau de l'isolation et l'utilisation de packouts hybrides avec PCM peuvent réduire les besoins en glace carbonique de 10 à 25 %. Dimensionner soigneusement les paquets et ajouter seulement 5 à 10 lb par 24 heures—avec ajustements en fonction de la saison et de la complexité de l'itinéraire—évite les émissions excessives de CO₂. Des calculateurs de glace carbonique ou des outils interactifs peuvent aider les clients à estimer la bonne quantité, réduire les déchets et les frais d'expédition.

Alternatives durables et solutions hybrides

L’emballage durable gagne du terrain 2025. Les constructeurs développent expéditeurs thermiques recyclables et packs de gel biodégradables. Les matériaux à changement de phase offrent un refroidissement réutilisable sans classification dangereuse et assurent un contrôle précis de la température.. En combinant la glace carbonique avec le PCM, les expéditeurs peuvent prolonger le temps d’attente, réduire les émissions de CO₂ et simplifier la conformité.

Dynamique du marché et contraintes d’approvisionnement

Le marché de la glace carbonique continue de croître, mais la volatilité de l'offre reste une préoccupation. La consommation a augmenté d'environ 5 % par année, alors que la production de CO₂ n’a augmenté que 0.5 %, provoquant des pénuries occasionnelles et des flambées de prix. Le marché mondial de la glace carbonique devrait croître de USD 1.54 milliards en 2024 en USD 2.73 milliards 2032, un 7.4 % TCAC. Les investissements dans les pôles de production locaux et dans la technologie de captage du CO₂ visent à stabiliser l’offre, mais les clients doivent toujours planifier à l'avance et conclure des contrats pour garantir un accès continu.

Applications industrielles et études de cas

Secteur Pharmaceutique et Biotechnologique

Vaccins, les produits biologiques et les kits de diagnostic nécessitent souvent des températures inférieures à −70 °C. Les feuilles de glace carbonique du Canada sont essentielles à l'expédition de vaccins à ARNm et de vecteurs de thérapie génique. Les laboratoires les utilisent également pour transporter du matériel génétique et des cultures cellulaires, s'assurer qu'ils restent congelés pendant la recherche et les essais cliniques. Dans un exemple, une société de biotechnologie expédiant des vecteurs de thérapie génique a maintenu des températures entre -65 °C et -70 °C pendant 72 heures en superposant des blocs de glace carbonique et des pellets dans un récipient conditionné.

Industrie des aliments et des boissons

Fruit de mer, la crème glacée et les produits carnés dépendent de la glace carbonique pour rester congelés et maintenir leur qualité pendant le transport. Le manque d’eau de fonte de la glace carbonique empêche les emballages détrempés. Pour les entreprises de commerce électronique expédiant des repas surgelés dans les régions éloignées du Canada, la neige carbonique permet des livraisons sans camions réfrigérés. Un exportateur de fruits de mer a utilisé des feuilles de neige carbonique entre des serviettes en papier humides pour expédier des homards vivants du Canada au Japon.; les crustacés sont arrivés frais car l'humidité est restée séparée de la neige carbonique.

Recherche en électronique et biotechnologie

Les composants électroniques sensibles à la température, tels que les semi-conducteurs et les micropuces, peuvent être endommagés par la chaleur.. Les feuilles de glace carbonique protègent ces composants en maintenant des conditions ultra froides. Réactifs de diagnostic, Les échantillons d'ADN et les enzymes expédiés à des fins de recherche bénéficient également de la neige carbonique car ils se dégradent rapidement à des températures plus élevées..

Commerce électronique et livraisons de kits repas

À mesure que les services de livraison à domicile se développent, la glace carbonique aide à maintenir la qualité du produit pendant le dernier kilomètre. Les entreprises de kits repas utilisent des mini-plaques de glace carbonique pour maintenir les repas à −20 °C pendant 24 heures. L'association de glace carbonique avec des doublures isolées sous vide garantit aux clients de recevoir des produits surgelés même dans les régions éloignées. Une start-up a intégré un calculateur de glace carbonique dans son système de commande; les clients ont saisi le lieu et la sélection de repas et ont reçu une suggestion automatique concernant le nombre de blocs de glace carbonique requis, réduire les retours dus aux produits fondus en 30 %.

Recherche scientifique et tests médicaux

Les instituts de recherche et les laboratoires médicaux expédient des échantillons de sang, plasma et autres échantillons sur glace carbonique pour éviter toute dégradation. Un froid constant empêche la dégradation des enzymes et garantit des résultats de test fiables. Un laboratoire de recherche expédiant des échantillons génétiques de Vancouver à Toronto a étiqueté le colis avec la classe 9 diamant de danger, déclaré le poids de glace carbonique et utilisé les trous d'aération. Par conséquent, l'envoi est arrivé à temps et a évité les amendes.

Optimiser votre chaîne du froid: Conseils et cadre de prise de décision

Utilisez un emballage et une isolation de qualité

Une isolation de haute qualité est la base d’une chaîne du froid stable. Les sacs isothermes scellés sous vide peuvent conserver le froid pendant 48 à 72 heures., tandis que les conteneurs en polystyrène fournissent 24 à 48 heures et que les boîtes isolées rigides peuvent dépasser 72 heures. Les doublures réfléchissantes et les aérogels réduisent davantage le gain de chaleur et prolongent la durée. Investir dans des emballages de qualité est rentable en réduisant la consommation de glace carbonique et en évitant la détérioration.

Surveiller la température en temps réel

Utilisez des enregistreurs de données ou des capteurs IoT pour suivre les températures internes pendant le transport. Les packages compatibles IoT envoient des alertes lorsque la température s'écarte de la plage de sécurité. Cela vous permet d'intervenir rapidement en cas de retard ou si la neige carbonique est consommée plus rapidement que prévu.. L'intégration de capteurs aux plates-formes cloud permet une surveillance centralisée de l'ensemble des expéditions.

Planifiez des itinéraires efficaces et tamponnez les retards

Un itinéraire efficace réduit le temps de transit et l’exposition à des températures extrêmes. Travailler avec des transporteurs expérimentés dans la manutention de matières dangereuses et la logistique de la chaîne du froid. Ajouter un 20–30 % marge de sécurité à votre quantité de neige carbonique pour couvrir d'éventuels retards. Lorsque les expéditions impliquent plusieurs zones de température, l'emballage hybride avec PCM garantit que chaque produit reste dans la gamme requise.

Liste de contrôle pour la prise de décision

Déterminer les exigences de température: Choisissez entre ultra froid (≤ −70 °C), congelé (−20 °C), réfrigéré (2–8 ° C) ou réfrigéré (> 0 °C) conditions.

Estimer la durée de l'expédition: Si c'est moins que 72 heures, Du PCM ou des packs de gel peuvent suffire; au-delà 96 heures, La glace sèche est essentielle.

Tenir compte de la complexité réglementaire: Si vous souhaitez éviter la paperasse relative aux marchandises dangereuses, choisissez PCM ou packs de gel. Si vous avez besoin de conditions ultra froides, être prêt à se conformer à la classe 9 règlements.

S'aligner sur les objectifs budgétaires et de durabilité: Le PCM réutilisable a un coût initial plus élevé mais un coût de vie inférieur; la glace carbonique a un coût initial inférieur mais doit être réapprovisionnée à chaque expédition.

Évaluer la sensibilité du produit: Déterminez si votre produit peut tolérer le gel. Certains produits pharmaceutiques ou électroniques ne peuvent pas, donc les packs de gel ou le PCM peuvent être plus sûrs.

Outils interactifs et engagement des utilisateurs

Pensez à ajouter un Calculateur de quantité de glace carbonique à votre site Web, permettant aux utilisateurs de saisir le poids de l'envoi, type de conteneur, température ambiante et temps de transit et recevez une recommandation personnalisée. Cela réduit les incertitudes, améliore l'engagement des utilisateurs et diminue les retours dus à un sous-emballage ou un suremballage. Vous pourriez également proposer quiz d'auto-évaluation pour aider les utilisateurs à déterminer si la glace carbonique ou le PCM est le meilleur choix pour leurs produits.

2025 Tendances et innovations dans la technologie des packs de glace carbonique au Canada

Le secteur de la chaîne du froid évolue rapidement, et rester informé vous aide à rester compétitif. Vous trouverez ci-dessous les principaux développements qui façonnent 2025:

Emballages intelligents et capteurs IoT: Surveillance de la température en temps réel les dispositifs intégrés dans l'emballage envoient des alertes lorsque les températures s'écartent, permettant une intervention proactive.

Production durable de glace carbonique: Les fabricants captent les émissions industrielles de CO₂ pour produire de la neige carbonique, réduire l'empreinte environnementale. Certains producteurs utilisent du CO₂ biosourcé capturé lors de la fermentation de l'éthanol..

Automatisation et efficacité logistique: Les robots et les lignes de conditionnement automatisées optimisent le placement des plaques de glace carbonique et réduisent les erreurs humaines. Un logiciel de logistique permet de prédire l'itinéraire optimal et de planifier le reglaçage.

Solutions hybrides PCM-glace carbonique: La combinaison de glace sèche et de PCM crée plusieurs zones de température et prolonge la durée de refroidissement, réduire la consommation de CO₂.

Matériaux d'isolation avancée: Aérogels, les panneaux d'isolation sous vide et les revêtements réfléchissants améliorent les performances thermiques et réduisent le poids de l'emballage.

Croissance du marché et préférences des consommateurs: Le marché des réfrigérants pour la chaîne du froid devrait grandir à partir de $1.69 milliards en 2025 à $2.92 milliards 2032. Les consommateurs exigent durabilité et transparence, pousser les entreprises à divulguer leurs sources de CO₂ et à investir dans des solutions respectueuses de l'environnement.

Résilience de la chaîne d’approvisionnement: La consommation de glace sèche augmente d’environ 5 % par année, alors que la production de CO₂ augmente seulement 0.5 %, provoquant des pénuries occasionnelles. Les fabricants construisent des centres de production régionaux et captent les émissions pour garantir l’approvisionnement.

Questions fréquemment posées

Q1: Combien de temps durent les feuilles de glace carbonique du Canada?

Des feuilles de glace carbonique de haute qualité peuvent garder les marchandises au froid pendant 24–72 heures, Selon le montant utilisé, qualité de l'isolation et température ambiante. Les blocages durent généralement de 24 à 48 heures, tandis que les feuilles peuvent prolonger la durée jusqu'à 72 heures.

Q2: Quelle est la règle générale pour dimensionner la glace carbonique par rapport au poids du produit?

Une ligne directrice courante est 5–10 lb de glace sèche par 24 heures ou un 1:1 rapport entre le poids de la glace carbonique et le poids du produit pour les expéditions en 48 heures. Ajustez en ajoutant 20 à 30 % plus pour les températures chaudes ou les itinéraires complexes.

Q3: Puis-je réutiliser les feuilles de glace carbonique du Canada?

Non. La glace carbonique se sublime complètement, ne laissant rien à réutiliser. Cependant, l'emballage extérieur et l'isolation peuvent être réutilisés. Pour un refroidissement réutilisable, pensez au PCM ou aux packs de gel, qui peut être recongelé.

Q4: Les feuilles de glace carbonique sont-elles sécuritaires à manipuler?

Oui, Si géré correctement. Utilisez toujours des gants et des lunettes isolants, travailler dans un endroit aéré, et ne scellez jamais de glace carbonique dans un récipient hermétique. Le gaz CO₂ doit s'échapper pour éviter une asphyxie ou une explosion..

Q5: Puis-je combiner de la glace carbonique avec des packs de gel ou du PCM?

Absolument. Les systèmes hybrides prolongent la durée de refroidissement et créent plusieurs zones de température. Les packs de gel ralentissent la sublimation sur glace carbonique, tandis que le PCM fournit des températures intermédiaires stables.

Q6: Quelles réglementations régissent le transport de glace carbonique au Canada?

La glace sèche est un Classe 9 matières dangereuses et doit être étiqueté « Glace sèche » ou « Dioxyde de carbone », Solide » et le poids net. L'IATA autorise jusqu'à 2.5 kg par passager sans déclaration, tandis que les expéditions commerciales peuvent transporter jusqu'à 200 kg. Les expéditions terrestres sont soumises à moins de restrictions mais nécessitent toujours une manipulation sûre.

Q7: Comment puis-je réduire l'impact environnemental de l'utilisation de la neige carbonique?

Source de neige carbonique fabriquée à partir de CO₂ recyclé ou biocapté, utilisez uniquement ce dont vous avez besoin, et adopter packouts hybrides avec PCM pour réduire la consommation totale de glace carbonique. Recyclez ou réutilisez les matériaux isolants et informez les destinataires sur leur élimination appropriée..

Résumé et recommandations

Les feuilles de glace carbonique du Canada offrent des performances ultra-froides inégalées, garder les expéditions congelées jusqu'à 72 heures sans laisser de résidus d'eau. Ils fonctionnent en sublimant le CO₂ solide à −78,5 °C, fournir une prestation continue, un refroidissement sec qui protège les vaccins, biologique, fruits de mer et électronique. Pour les dimensionner correctement, utiliser 5–10 lb par 24 heures ou faites correspondre le poids de la glace carbonique au poids de la charge utile. Améliorez l'isolation et envisagez des emballages hybrides avec PCM pour réduire la consommation de 10 à 25 %. Manipulez toujours la glace sèche avec des gants, assurer la ventilation et respecter la réglementation. Avec une demande croissante, tendances en matière de durabilité, et 2025 innovations – telles que les capteurs IoT et la production de CO₂ recyclé – les plaques de glace carbonique du Canada restent un outil essentiel pour maintenir les chaînes du froid.

Conseils exploitables

Évaluez les besoins en température de votre produit et sélectionnez le réfrigérant approprié (glace carbonique pour ultra froid, packs de gel pour réfrigéré, PCM pour un contrôle précis).

Calculer la quantité de glace carbonique en utilisant les formules fournies, ajouter un tampon pour les retards.

Préparez et emballez soigneusement: Conteneurs de pré-refroidissement, isolation de la couche, positionner correctement la glace carbonique et ventiler les conteneurs.

Utiliser l'enregistrement des données et les capteurs pour suivre les expéditions et ajuster les expéditions en temps réel.

Choisissez des options durables: Collaborez avec des fournisseurs qui utilisent du CO₂ recyclé et intègrent du PCM ou des emballages recyclables.

Éduquez votre équipe et vos clients sur la manipulation de la neige carbonique en toute sécurité et son élimination de manière responsable.

À propos du tempk

Rotation est un spécialiste canadien de l'emballage de la chaîne du froid, connu pour ses blocs de glace carbonique de haute qualité., packs de gel, boîtes isothermes et conteneurs intelligents. Notre souci du développement durable signifie que bon nombre de nos produits sont fabriqués à partir de Co₂ recyclé et conçu pour minimiser l’impact environnemental. Nous servons les produits pharmaceutiques, biotechnologie, secteurs de l'alimentation et du commerce électronique, fournir des solutions d'emballage validées, expertise réglementaire et technologie de surveillance en temps réel. Contactez nos experts pour découvrir les feuilles de glace sèche au Canada et les solutions personnalisées de chaîne du froid qui assurent la sécurité de vos envois., conforme et écologique.