[Mis à jour 11 Déc 2025]

Lorsque vous manipulez du poisson ou des crustacés, le contrôle de la température est votre outil le plus important. Normes et équipements de la chaîne du froid pour les produits de la mer assurez-vous que les filets frais arrivent à votre restaurant ou magasin aussi sûrs et savoureux que le jour où ils ont été récoltés.. Garder le poisson dans la bonne fenêtre de température ralentit la croissance microbienne et protège la qualité. Ce guide complet explique quelles normes s'appliquent, comment les respecter et de quels dispositifs vous avez besoin pour maintenir la chaîne du froid.

Cet article répondra:

Quelles exigences de température régissent la chaîne du froid des produits de la mer? Les normes mondiales exigent une température de 0 à 5 °C pour le poisson frais et de ≤ –18 °C pour les produits surgelés.. Nous les traduirons en directives pratiques pour votre exploitation.

Quelles réglementations s’appliquent aux fournisseurs et exportateurs de poisson? HACCP, GMP, Les règles d'hygiène de la FSMA et de l'UE exigent un contrôle et une traçabilité documentés de la température.

Quels équipements et emballages sont essentiels? Des boîtes isothermes et packs de gel aux capteurs compatibles IoT, nous détaillons les outils qui maintiennent les fruits de mer dans la zone de sécurité.

Comment conserver la fraîcheur du poisson pendant le stockage et le transport? Apprenez les bonnes pratiques en matière d'hygiène, contrôle de l'humidité et rotation FIFO.

Quelles sont les dernières 2025 Tendances de la logistique de la chaîne du froid? Découvrez l'optimisation des itinéraires par l'IA, traçabilité blockchain et innovations en matière d'emballage durable.

Quelles exigences de température régissent la chaîne du froid des produits de la mer 2025?

Frais contre. directives gelées – Le poisson frais se détériore rapidement car les enzymes et bactéries naturelles détruisent les tissus. Pour ralentir la détérioration, les normes internationales exigent que vous conserviez le poisson frais entre 0 °C et 5 °C et du poisson congelé à –18 °C ou moins. Les États-Unis. Le Code alimentaire de la FDA précise que les aliments froids, y compris les fruits de mer, doit avoir lieu à 41 °F (5 °C) ou ci-dessous. Le dépassement de ces seuils accélère la croissance microbienne et réduit la durée de conservation.

Comprendre les limites de température maximale pour le poisson réfrigéré

Le Accord relatif au transport international des denrées périssables (ATP) fixe les températures maximales pour le transport de divers aliments. Pour le poisson, le maximum pendant le transport et le stockage est 2 °C. Ces maxima constituent de bonnes lignes directrices à toutes les étapes de la production., distribution et affichage au détail.

Garder le poisson à 0 °C–5 °C maintient la texture et ralentit la croissance bactérienne. La glace fondue dans des conteneurs isothermes régule naturellement les températures autour 0 °C et maintient l'humidité. Une surveillance continue avec des thermomètres calibrés permet de garantir que les produits restent dans les limites de sécurité.

Exigences de température pour les fruits de mer surgelés

Le poisson congelé doit rester à –18 °C ou moins. L'ATP permet une brève augmentation de –15 °C pendant le transport ou la distribution locale, mais les vitrines de vente au détail devraient toujours conserver –18 °C et ne sois jamais plus chaud que –12 °C. Les congélateurs domestiques varient: les congélateurs trois étoiles atteignent en dessous de –18 °C, les congélateurs deux étoiles restent en dessous de –12 °C et les congélateurs une étoile n’atteignent que –6 °C, limiter la durée de stockage à quelques jours.

Conserver le poisson congelé en dessous de –18 °C prévient l'activité microbienne et prolonge la durée de conservation, mais rappelez-vous que la congélation n'est pas un biocide; d'autres réactions physiques et biochimiques peuvent encore se produire. Congélation rapide, un emballage approprié et des températures constantes maintiennent la qualité.

Tableau 1 – Principales plages de température et ce qu’elles signifient pour vous

| Plage de température | Exemples de produits & scène | Avantage | Ce que cela signifie pour vous |

| 0 °C–5 °C | Poisson frais, filets réfrigérés | Maintient la texture, ralentit la croissance bactérienne | Utiliser des chambres réfrigérées ou de la glace; surveiller en continu |

| ≤ –18 °C | Poisson congelé, blocs de poisson | Arrête l'activité microbienne et prolonge la durée de conservation | Investissez dans des congélateurs validés; ne jamais laisser le produit décongeler pendant le transport |

| 41 °F (≈5 °C) | Aliments à haut risque comme les fruits de mer | Garde les aliments hors de la zone de danger | Vérifiez régulièrement les unités de stockage et d'affichage pour vous assurer qu'elles fonctionnent entre 0 et 5 °C. |

| 2 °C (ATP maximum) | Transport de poisson | Maximum international pour le transport | Utilisez des thermomètres calibrés pendant l’expédition; éviter les abus de température |

Conseils pratiques

Détendez-vous rapidement: Le guide de Perennia recommande de réfrigérer les fruits de mer pour 0 °C immédiatement après la capture et son maintien tout au long de la chaîne d'approvisionnement.

Surveiller en continu: Utilisez des enregistreurs de données ou des capteurs IoT pour enregistrer la température en temps réel. Les alertes doivent vous avertir lorsque les lectures dérivent en dehors des plages de sécurité.

Utilisez le bon réfrigérant: La glace fondante est efficace pour le poisson frais; des quantités adéquates de glace et de contenants isothermes maintiennent 0 °C.

Calibrer l'équipement: Assurez-vous que les thermomètres et les capteurs sont précis. Le FDA Food Code recommande de vérifier les températures au moins toutes les quatre heures.

Exemple concret: Un processeur implémenté des codes QR et des journaux numériques pour chaque capture. Lorsqu'un écart de température s'est produit pendant le transport, ils l'ont retracé jusqu'à un lot spécifique et ont contacté les distributeurs en quelques minutes. Ce rappel ciblé leur a évité de retirer un envoi entier des étagères.

Quelles réglementations régissent le respect de la chaîne du froid des produits de la mer?

La chaîne du froid des fruits de mer est réglementée par une mosaïque de règles nationales et internationales. Les ignorer peut entraîner des amendes, retards d'expédition ou rappels de produits.

HACCP, BPF et SSOP

Le fondement de la sécurité des fruits de mer est le Analyse des risques et points critiques pour leur maîtrise (HACCP) système. Il oblige les transformateurs à identifier les dangers, établir les points de contrôle critiques et mettre en œuvre des procédures de surveillance. Bonnes pratiques de fabrication (GMP) et procédures opérationnelles standard d’assainissement (SSOP) compléter le HACCP en fournissant des règles d'hygiène détaillées pour les installations, matériel et personnel. Ensemble, ces cadres réduisent les risques de contamination et constituent la base de la plupart des normes nationales.

Règles de la FSMA aux États-Unis

Le Loi sur la modernisation de la sécurité alimentaire (FSMA) introduit plusieurs règles pertinentes pour les fournisseurs de poisson:

Règle de transport sanitaire: Expédiés, les chargeurs et les transporteurs doivent utiliser des véhicules et des équipements capables de maintenir des températures sûres et de prévenir la contamination croisée.. Ils doivent également tenir des registres de nettoyage et de formation.

Règle de traçabilité des aliments (FSMA 204): Finalisé en 2022, cette règle oblige les entreprises à conserver des enregistrements avec les éléments de données clés lors des événements de suivi critiques. Les produits de la mer figurant sur la liste de traçabilité des aliments doivent fournir des informations à la FDA dans les délais 24 heures. La date de mise en conformité initiale était janvier 20 2026 mais peut être prolongé jusqu'en juillet 20 2028.

Programme de vérification des fournisseurs étrangers (FSVP): Les importateurs doivent vérifier que leurs fournisseurs étrangers se conforment aux normes américaines.. normes de sécurité et maintenir une visibilité de bout en bout sur l’approvisionnement en fruits de mer, manutention et stockage.

Règles de l'Union européenne en matière d'hygiène et de pêche

Réglementation de l'UE 852/2004 précise que pour les aliments qui ne peuvent pas être stockés en toute sécurité à température ambiante, le maintien de la chaîne du froid est essentiel. Les exploitants du secteur alimentaire doivent se conformer aux exigences en matière de contrôle de la température et maintenir la chaîne du froid.. La réglementation européenne sur le contrôle des pêches impose le suivi des navires, déclaration électronique des captures et traçabilité numérique progressive des fruits de mer nationaux et importés.

Documentation et certification

Une paperasse appropriée protège les consommateurs et facilite le commerce. Les documents essentiels incluent un acte de vente, note d'expédition, certificat d'origine, certificats sanitaires et HACCP ou FSSC 22000 certification. Réviser régulièrement la réglementation, automatisez la documentation via des outils numériques et envisagez des certifications tierces pour démontrer la conformité.

Liste de contrôle: êtes-vous conforme?

Connaissez-vous le Exigences de température (0–5 °C pour le frais, ≤ –18 °C pour les surgelés)?

Avez-vous mis en œuvre HACCP avec des points de contrôle critiques et des procédures de surveillance définis?

Est-ce que tu gardes enregistrements de température et journaux de traçabilité pour chaque lot?

Votre transport répond-il Transport sanitaire FSMA exigences?

Avez-vous pris en compte FSMA 204 délais de tenue des dossiers et Règles de l'UE en matière de traçabilité numérique?

Quel équipement maintient les fruits de mer dans la chaîne du froid?

Le maintien de la bonne température ne concerne pas seulement les camions réfrigérés. Cela nécessite une combinaison d’emballages, réfrigérants, dispositifs de surveillance et personnel formé.

Emballages isothermes et réfrigérants

L’emballage compte: Le poisson frais ou congelé doit être protégé de la contamination, perte d'humidité et dommages physiques. L'emballage doit constituer une barrière à l'oxygène et permettre la traçabilité. Boîtes isothermes, l'emballage sous vide et les matériaux résistants à l'humidité prolongent la durée de conservation et préservent l'apparence.

Le Guide des fruits de mer recommande des boîtes en mousse ou des doublures en aluminium/bulles pour l'isolation, emballages étanches tels que des boîtes de cire ou des glacières en plastique, et utiliser des réfrigérants pour maintenir la température. Le type et la quantité d'emballage dépendent des espèces, quantité, distance et mode de transport. Des matériaux respectueux de l’environnement doivent être envisagés pour réduire l’impact environnemental.

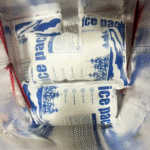

Réfrigérants: Packs de gel (matériaux à changement de phase) sont courants pour les denrées périssables car ils décongèlent sans produire d’excès d’eau. La glace humide fonctionne sur de courtes distances mais nécessite un drainage pour recueillir l'eau de fonte.. Glace sèche (dioxyde de carbone solide) est souvent utilisé pour les produits surgelés; cependant, il peut être dangereux et de nombreux expéditeurs ont des réglementations strictes sur son utilisation.

Matériel de suivi et de traçabilité

Capteurs et enregistreurs de données IoT – Une surveillance en temps réel tout au long de la chaîne du froid est de plus en plus nécessaire. Les principaux opérateurs déploient un réseau de capteurs IoT dans les entrepôts, camions et véhicules du dernier kilomètre pour suivre la température, humidité et emplacement. Lorsqu'un écart se produit, les alertes permettent des actions correctives avant que la détérioration ne se produise.

Plateformes intégrées – Lier les systèmes de gestion d’entrepôt (WMS), Systèmes de gestion des transports (TMS), Planification des ressources de l'entreprise (ERP) et les tableaux de bord IoT offrent une visibilité de bout en bout. Une telle intégration permet aux gestionnaires de suivre chaque palette en temps réel, détecter les goulots d’étranglement et simplifier les audits réglementaires.

Emballage thermique avancé – Même avec des capteurs, un mauvais emballage peut gâcher les expéditions. Les entreprises avancées de la chaîne du froid utilisent des conteneurs isothermes, matériaux à changement de phase et stratification optimisée des palettes pour maintenir les températures pendant le transport multimodal. Ils testent les emballages dans les pires scénarios, comme une chaleur ambiante élevée ou des temps de transit prolongés, pour réduire les risques..

Planification d'itinéraire prédictive – La planification d'itinéraire basée sur l'IA anticipe le trafic, disponibilité des conditions météorologiques et des chambres froides. Les camions frigorifiques peuvent être réacheminés si les capteurs détectent une hausse des températures, empêcher les excursions.

Formation et application des SOP – La technologie à elle seule ne peut empêcher les erreurs si le personnel n’est pas formé. Formation basée sur des scénarios, les procédures opérationnelles standard numériques et les programmes de certification aident le personnel à manipuler correctement les produits sensibles à la température.

Tableau 2 – Options d’équipement et d’emballage

| Équipement/emballage | Description | Exemple d'avantage |

| Boîtes à mousse / conteneurs isothermes | Boîtes isolées qui minimisent le transfert de chaleur; souvent combiné avec des packs de gel | Maintenir 0 °C–5 °C pour le poisson frais pendant le transport de nuit |

| Packs de gel (matériaux à changement de phase) | Packs réutilisables qui se solidifient à une température spécifique et dégagent du froid en fondant | Contrôler la température sans excès d'eau; sûr pour le fret aérien |

| Glace humide | Glace traditionnelle, adapté aux courts trajets lorsque le drainage est disponible | Fournit un refroidissement rapide; idéal pour les livraisons locales |

| Glace sèche | CO₂ solide utilisé pour maintenir les produits surgelés en dessous de –18 °C | Maintient des conditions ultra froides pour les expéditions longue distance |

| Enregistreurs de données/capteurs IoT | Appareils qui enregistrent la température, humidité et emplacement en continu | Fournir des alertes en temps réel et une traçabilité pour les audits réglementaires |

| Chambres froides et congélateurs | Chambres réfrigérées pour 0 °C – 5 °C et installations de stockage congelées à –18 °C ou moins | Inhibe la croissance microbienne et prolonge la durée de conservation |

| Emballage à vide & atmosphère modifiée | Forfaits à oxygène réduit; prolonger la durée de conservation et prévenir les brûlures du congélateur | Améliorer l'apparence, réduire l'oxydation et permettre un transport plus long |

Conseils pratiques pour le choix du matériel

Évaluez vos besoins: Considérez les espèces, quantité, temps de transit et destination. Les produits de grande valeur justifient l'investissement dans des capteurs IoT et des emballages avancés.

Valider l'équipement: Étalonnez régulièrement les thermomètres et les capteurs et conservez des journaux de service pour les audits..

Combiner les solutions: Utiliser une combinaison d'isolation, réfrigérants et surveillance en temps réel. Par exemple, les packs de gel dotés de capteurs IoT peuvent maintenir la température et fournir des alertes.

Pensez durabilité: Choisissez des emballages réutilisables et des matériaux écologiques pour réduire les déchets. Les unités de réfrigération à énergie solaire sont des options émergentes pour les régions disposant d'un électricité limité.

Cas pratique: Un exportateur a utilisé de la glace fondante dans des conteneurs isothermes pour maintenir le poisson à 0 °C tout en utilisant des capteurs IoT pour un suivi en temps réel. Les alertes ont permis à l'équipe d'ajuster l'itinéraire et d'éviter les écarts de température, réduire les pertes et augmenter la satisfaction des clients.

Comment conserver la fraîcheur du poisson pendant le stockage et le transport?

Assurer la sécurité des fruits de mer nécessite plus que du matériel; cela exige des processus disciplinés.

Hygiène et désinfection

Le maintien de l’hygiène des zones de stockage évite la contamination croisée. Les chambres froides et les équipements doivent subir un nettoyage rigoureux avec des produits agréés; étages, murs, les étagères et les ustensiles doivent être désinfectés fréquemment. Les opérateurs doivent porter un équipement de protection individuelle et éliminer correctement les déchets..

Respect des normes sanitaires

Les normes sanitaires établissent des exigences pour les installations, procédures opérationnelles et traçabilité. Les entreprises qui suivent ces règles démontrent leur engagement envers la qualité et la santé des consommateurs.. La tenue de registres de température et de désinfection est particulièrement importante pour les exportateurs confrontés à diverses réglementations internationales..

Emballage approprié et contrôle de l'humidité

L'emballage doit protéger le poisson de la contamination, perte d'humidité et dommages physiques. Utiliser des matériaux résistants à l’humidité et aux basses températures; les emballages sous vide et les boîtes isothermes peuvent prolonger la durée de conservation. Le contrôle de l'humidité évite le dessèchement ou la formation de glace et préserve la texture.

Surveillance et technologie

Les capteurs connectés et les systèmes IoT permettent une surveillance en temps réel de la température et de l'humidité. Les avertissements automatiques permettent des actions correctives immédiates lorsque les conditions s'écartent. Une telle automatisation réduit les erreurs humaines, améliore la traçabilité et diminue les déchets.

Gestion des transports

Les véhicules destinés aux aliments réfrigérés ou surgelés doivent être validés périodiquement et maintenir des températures stables pendant tout le trajet.. Routage intelligent, l'emballage thermique et les processus agiles de chargement/déchargement évitent les oscillations thermiques. AU FIFO (Premier arrivé, Premier sorti) la stratégie garantit que les stocks les plus anciens sont utilisés en premier, réduire les déchets et gérer les dates de péremption.

Formation du personnel et SOP

Un personnel non formé peut introduire des erreurs critiques. Fournir une formation basée sur des scénarios sur la lecture des journaux de température, répondre aux alertes et gérer les stocks de grande valeur. Les SOP numériques et les tableaux de bord gamifiés améliorent la conformité et réduisent les erreurs humaines.

Exemple concret: Un exportateur de produits de la mer a obtenu le FSSC 22000 certification après avoir mis en œuvre une surveillance continue de la température et de l’humidité avec des alertes de violation déclenchant une action immédiate. Le système a réduit le gaspillage et amélioré la préparation à l’audit.

2025 les tendances qui façonnent la logistique de la chaîne du froid des produits de la mer

La logistique de la chaîne du froid évolue rapidement. Les nouvelles technologies et les initiatives de développement durable changent la façon dont les fruits de mer sont transportés et stockés.

Optimisation des itinéraires et analyses prédictives basées sur l'IA

L'intelligence artificielle permet d'ajuster les itinéraires en temps réel en fonction du trafic, météo et fenêtres de livraison. Cela améliore l'efficacité, réduit la consommation de carburant et améliore la fiabilité des livraisons. L'analyse prédictive prévoit la demande, anticiper la maintenance des équipements et détecter les expéditions à risque. La prévision de la demande basée sur l'IA est particulièrement utile pour les fournisseurs de produits de la mer confrontés à des volumes de captures volatiles et à des préférences changeantes des consommateurs..

Blockchain et traçabilité de bout en bout

La blockchain est intégrée aux opérations de la chaîne du froid pour créer des enregistrements immuables des parcours des produits. Cela améliore la transparence, garantit le respect des réglementations en matière de sécurité alimentaire et renforce la confiance des consommateurs. Combiné avec des capteurs IoT, la blockchain peut enregistrer la température, conditions de localisation et de manutention à chaque étape, fournir des preuves vérifiables pour les audits et les réclamations.

Emballage durable et léger

Matériaux écologiques, comme une isolation biodégradable ou recyclable, gagnent du terrain pour réduire les déchets. Léger, des conteneurs d'expédition isolés équipés de capteurs IoT surveillent la température, humidité et localisation en temps réel. Des solutions de réfrigération à énergie solaire sont déployées dans les régions ayant un accès limité à l'électricité, réduire l’empreinte environnementale tout en améliorant la sécurité alimentaire.

Surveillance en temps réel et visibilité de bout en bout

La surveillance continue et le suivi en temps réel deviennent la norme. Les appareils IoT avancés fournissent des données en temps réel sur la température, humidité et emplacement. Les plateformes intégrées permettent une visibilité de bout en bout et permettent des actions correctives immédiates. La visibilité en temps réel améliore la satisfaction des clients en fournissant des informations à jour sur leurs commandes.

Automatisation et robotique

Les installations de la chaîne du froid adoptent des systèmes automatisés de stockage et de récupération (AS/RS) et la manutention robotisée pour remédier aux pénuries de main-d'œuvre et améliorer l'efficacité. Les systèmes automatisés fonctionnent en continu, réduire les erreurs dans le suivi des stocks et fournir un contrôle précis de la température. Des études indiquent qu'environ 80 % des entrepôts ne sont pas encore automatisés, mettant en évidence un potentiel de croissance important.

La durabilité comme valeur fondamentale

Les préoccupations environnementales et les réglementations plus strictes placent la durabilité au premier plan de la logistique de la chaîne du froid. Réfrigération économe en énergie, les sources d'énergie renouvelables et les emballages durables réduisent l'empreinte carbone et minimisent les déchets. Les pratiques durables aident également les entreprises à se conformer aux réglementations environnementales et à éviter les pénalités..

Tableau 3 – Tendances émergentes et leur importance pratique

| S'orienter | Description | Ce que cela signifie pour vous |

| IA & optimisation d'itinéraire | L'IA ajuste les itinéraires en temps réel en fonction du trafic, météo et horaires | Réduisez le temps de transit, coûts de carburant et écarts de température |

| Traçabilité de la blockchain | Enregistrements immuables de température, localisation et manipulation | Bâtir la confiance des consommateurs, simplifier les audits et répondre rapidement aux rappels |

| Emballage durable & réfrigération solaire | Matériaux écologiques et unités alimentées à l'énergie solaire | Atteindre les objectifs de développement durable et réduire les coûts énergétiques |

| Conteneurs compatibles IoT | Conteneurs légers avec capteurs de température, humidité et emplacement | Surveillance continue et durée de conservation améliorée |

| Automation & robotique | Stockage automatisé, systèmes de récupération et de manutention | Coûts de main-d'œuvre réduits, réduire les erreurs et maintenir des températures constantes |

| Visibilité intégrée & analyse prédictive | Plateformes IoT et IA de bout en bout | Gestion proactive des risques, conformité améliorée et meilleure prévision de la demande |

Insistance au marché

Le commerce international et l’expansion de la vente au détail stimulent la croissance de la chaîne du froid. Selon MarketsandMarkets, le marché de la chaîne du froid devrait atteindre USD 372 milliards 2029, à partir de USD 228.3 milliards en 2024. Les tendances alimentaires induites par les influenceurs et les médias sociaux augmentent également la demande de divers produits de la mer.. La région Asie-Pacifique, surtout l'Inde, est prêt à connaître une forte croissance en raison de la forte consommation de produits laitiers et de l’expansion des restaurants à service rapide.

Questions fréquemment posées

À quelle température faut-il conserver le poisson frais et congelé? Le poisson frais doit être conservé entre 0 °C et 5 °C, tandis que le poisson congelé doit rester à –18 °C ou moins. Le maintien de ces températures préserve la saveur et évite la détérioration.

Pourquoi une surveillance continue est-elle nécessaire dans la chaîne du froid des produits de la mer? La surveillance continue à l'aide d'enregistreurs de données ou de capteurs IoT fournit des alertes en temps réel lorsque la température ou l'humidité s'écarte. Il permet des actions correctives immédiates et prend en charge la traçabilité.

Quelles sont les meilleures options d’emballage pour l’expédition de fruits de mer? Utilisez des boîtes isothermes avec des packs de gel pour le poisson frais et de la neige carbonique pour les produits surgelés.. L'emballage doit être résistant à l'humidité et constituer une barrière à l'oxygène..

Dois-je suivre le système HACCP si je transporte uniquement des fruits de mer? Oui. Les principes HACCP s'appliquent à toutes les étapes de la chaîne d'approvisionnement des produits de la mer, y compris le stockage et le transport. HACCP aide à identifier les dangers, établir les points de contrôle critiques et assurer la sécurité alimentaire.

Comment la blockchain améliore-t-elle la traçabilité des produits de la mer? La blockchain crée des enregistrements infalsifiables de chaque étape, de la récolte à la livraison. Couplé à des capteurs IoT, il peut documenter la température et l'emplacement, faciliter les audits et renforcer la confiance des consommateurs.

Résumé et recommandations

Principaux à retenir: Le maintien de la chaîne du froid des produits de la mer nécessite un contrôle précis de la température (0–5 °C pour le frais, ≤ –18 °C pour les surgelés), respect des réglementations comme HACCP, Règles d'hygiène de la FSMA et de l'UE, emballage et réfrigérants appropriés, surveillance continue et systèmes de traçabilité robustes. Tendances émergentes telles que l’optimisation des itinéraires basée sur l’IA, la blockchain et les emballages durables transforment l'industrie. Hygiène, la formation du personnel et la tenue des dossiers restent essentielles.

Plan d'action:

Définissez vos points de contrôle critiques en utilisant HACCP et mettre en place un suivi en temps réel à chaque étape.

Investissez dans le bon équipement: Choisissez un emballage isotherme, des packs de gel ou de la neige carbonique, et capteurs IoT pour une surveillance continue. Calibrer régulièrement les appareils.

Mettre en œuvre des plateformes intégrées pour lier votre WMS, TMS et ERP, garantissant une visibilité de bout en bout et une conformité simplifiée.

Restez conforme: Examiner les exigences de la FSMA et de l’UE, tenir des registres de température et rechercher une certification par un tiers.

Adoptez l’innovation: Optimisation des itinéraires pilotés par l'IA, traçabilité blockchain et solutions d'emballage durables pour réduire les déchets et améliorer l'efficacité.

À propos du tempk

Profil de l'entreprise: Et tempk, nous sommes spécialisés dans les solutions durables pour la chaîne du froid. Nos conteneurs isothermes et nos packs de gel à changement de phase sont conçus pour conserver les fruits de mer à 0 °C–5 °C pour plus 48 heures, tandis que nos alternatives à la glace carbonique maintiennent –18 °C pour les produits surgelés. Nous concevons des emballages réutilisables à base de matériaux recyclables, vous aidant à réduire les coûts et à réduire l’impact environnemental. Avec un R&Centre D axé sur les réfrigérants innovants, nous améliorons continuellement les performances et la sécurité.

Pourquoi nous choisir? Nous proposons une gamme complète d'emballages sensibles à la température, Dispositifs de surveillance et services de conformité compatibles IoT. Nos experts vous accompagnent dans la mise en œuvre du HACCP, Exigences de la FSMA et de l’UE, et nous proposons une formation pour garantir que votre équipe manipule les fruits de mer en toute sécurité. Nous proposons également des solutions personnalisées pour les expéditions à températures mixtes et les exportations longue distance.. Pour savoir comment nos produits peuvent protéger vos fruits de mer et améliorer votre chaîne du froid, contactez notre équipe pour une consultation.