What Is Cold Chain Temperature Control and Why Is It Important?

Cold chain temperature control refers to maintaining specific temperature ranges throughout the handling, stockage et transport de marchandises sensibles à la température. Unlike ambient logistics, cold chain systems must preserve precise conditions across manufacturing, entrepôts, transport et livraison du dernier kilomètre. Typical temperature zones include température ambiante contrôlée (20–25 ° C), refrigerated ranges (0–8 ° C), frozen ranges (–20 ° C) et températures ultra basses (–60 °C à –150 °C) pour produits biologiques et thérapies cellulaires.

Pourquoi le contrôle de la température est important

Keeping products within their required temperature range prevents spoilage, potency loss and regulatory violations. Dans 2025, cold chain failures remain costly:

Perte de nourriture: Les États-Unis. Department of Agriculture estimates up to one third of food is wasted aux États-Unis.

Pharma waste: Even minor temperature excursions can invalidate vaccines; some biologics lose potency after a single hour outside +8 °C, leading to expensive recalls.

Impact économique: Global cold chain losses result in billions of dollars in wasted goods each year. International trade programs such as the UK Dairy Export Programme emphasize exports worth over USD 2.47 milliards par an, underscoring the value of safeguarding perishable goods.

With stricter regulations and soaring demand for perishable goods, temperature control has become a strategic imperative rather than a niche function.

How Does a Temperature Control System Work?

A robust cold chain system combines hardware, software and processes to monitor and maintain temperature integrity from origin to destination. Les composants clés comprennent:

| Composant | But | Example Technology | Ce que cela signifie pour vous |

| Équipement de réfrigération | Provides cooling for storage and transport. Includes compressors, condenseurs et évaporateurs. | Copeland’s ZB and CF scroll compressors offer high efficiency and handle low GWP refrigerants. | Upgrading to modern compressors can deliver up to 8 % higher capacity and better energy efficiency. |

| Capteurs de température & bûcherons de données | Record temperature and humidity over time. Les enregistreurs de données fournissent des enregistrements historiques; IoT sensors enable real time alerts. | GO trackers and wireless loggers surveiller la température, location and humidity and consolidate data in a cloud portal. | Des alertes en temps réel vous aident à intervenir avant que la détérioration ne se produise. |

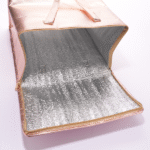

| Emballage intelligent | Protects goods during transport and insulates against ambient temperature. | Panneaux isolés sous vide (Vips), phase change materials and gel packs maintain set temperatures without continuous power. | Reduces reliance on mechanical refrigeration during transit. |

| Monitoring platforms | Consolider les données des capteurs, provide dashboards and generate compliance reports. | Cloud portals integrated with AI deliver predictive maintenance and automated documentation. | Simplifies compliance with HACCP and GDP and provides audit ready reports. |

| Power systems | Provide energy to refrigeration equipment; essential for remote or mobile units. | Solar power and battery storage reduce reliance on grid electricity. | Lowers operating costs and ensures resilience during outages. |

Astuces et conseils pratiques

Choose sensors based on your data needs: Data loggers are affordable for historical audits, while IoT sensors offer real time alerts. In high value shipments, combine both to balance cost and coverage.

Map your temperature zones: Identify which stages require refrigeration, conditions glaciales ou ultra froides. Use multi zone trucks and warehouses to avoid over cooling everything.

Invest in modern compressors: Replace outdated refrigeration units with high efficiency, low GWP compressors like Copeland’s ZB and CF series for improved capacity and lower emissions.

Exemple de cas: At a 268,000 square foot cold storage facility in Maryland, operators installed solar panels producing over 2.5 millions de kWh d'énergie renouvelable par an. The project reduced grid reliance and cut energy costs while maintaining consistent freezer temperatures.

Advanced Technologies Shaping Temperature Control in 2025

Optimisation des itinéraires basée sur l'IA

Intelligence artificielle is transforming logistics by analysing traffic patterns, conditions météorologiques et fenêtres de livraison pour ajuster les itinéraires en temps réel. AI powered route optimization improves efficiency, réduit la consommation de carburant et améliore la fiabilité des livraisons. Combiné avec des capteurs IoT, AI algorithms detect potential temperature excursions and recommend corrective actions before goods are compromised.

Blockchain pour une traçabilité améliorée

La blockchain crée immutable records of product journeys, providing end to end visibility and preventing data tampering. By storing temperature readings and location data on a distributed ledger, blockchain ensures transparency, compliance with food safety regulations and consumer trust.

Surveillance compatible IoT & Analyse prédictive

Les capteurs IoT suivent en permanence la température, humidité, shock and door events across trucks and warehouses. Real time data allows immediate corrective actions when deviations occur, while predictive analytics uses historical patterns to anticipate equipment failures and route risks.

Low GWP Refrigerants & Refrigeration Innovation

Regulations are phasing out high global warming potential (PRP) réfrigérants. Modern systems adopt Co₂ (R744), propane (R 290) and new A2L refrigerants to reduce environmental impact. Copeland’s CF series compressors support A2L and A3 refrigerants, delivering high capacity with reduced emissions. Oil free centrifugal compressors eliminate lubricating oil, Amélioration supplémentaire de l'efficacité.

Solar Powered Cold Rooms & Énergie renouvelable

Energy intensity is a major challenge—refrigeration can account for jusqu'à 70 % de la consommation totale d’énergie dans les entrepôts frigorifiques. Solar powered cold rooms with scroll inverter technology provide renewable energy in remote areas, ensuring consistent cooling while reducing energy costs. Battery storage systems smooth out fluctuations and provide backup during peak demand periods.

Smart Shipping Containers & Emballage durable

Léger, insulated shipping containers equipped with IoT sensors track temperature, humidité et localisation en temps réel. Sustainable packaging solutions use recyclable materials to minimize environmental impact while maintaining insulation. Phase change materials and dry ice monitors maintain ultra cold conditions (–80 °C à –150 °C) pour produits biologiques et thérapies cellulaires.

Tableau: Comparing Temperature Control Technologies

| Technologie | Avantage clé | Limitation | Real World Use |

| Capteurs IoT & tableaux de bord cloud | Surveillance continue en temps réel; analyse prédictive; alertes automatisées | Dependence on network connectivity; data security concerns | High value shipments and cross border logistics |

| Chaîne de blocs | Immutable record of temperature and location; améliore la traçabilité | Requires stakeholder adoption; transaction costs | Pharmaceuticals requiring strict compliance |

| Chambres froides à énergie solaire | Réduire les coûts énergétiques; provide cooling in remote areas | High upfront investment; reliant on sunlight | Rural farms or clinics with unreliable grid power |

| Low GWP refrigeration systems | Lower greenhouse emissions; future proof against regulations | May require equipment replacement; limited availability in some regions | New warehouses and retrofits |

| Conteneurs intelligents & emballage durable | Provide real time data and reduce packaging waste | Coût plus élevé; may require specialized handling | International shipping of pharmaceuticals or seafood |

Conseils de sélection

Evaluate environmental impact: Choose low GWP refrigerants and sustainable packaging to meet corporate ESG goals.

Adopt hybrid monitoring: Combine data loggers with IoT sensors to balance cost and real time visibility.

Look for AI integration: Predictive maintenance reduces unplanned downtime and extends equipment lifespan.

Prioritize data security: Use encryption, access controls and regular updates to protect sensitive temperature and location data.

Navigating Regulatory Requirements

Temperature control is governed by a patchwork of international, regional and industry specific regulations. Understanding these frameworks is essential for compliance and market access.

International & Règlements régionaux

HACCP and Food Safety Regulations: EU Regulation EC 852/2004 mandates hygiene duties and HACCP based procedures. The European Commission’s 2022 guidance on Food Safety Management Systems (FSMS) embeds food safety culture and harmonizes implementation.

Bonne pratique de distribution (PIB): EU GDP guidelines require risk based temperature control, route planning to minimize thermal risk, and calibrated monitoring devices with secure records. Pharmaceutical shipments must demonstrate continuous temperature control and provide documentation for audits.

Accord ATP: The UNECE ATP framework sets performance classes for insulated and refrigerated road equipment, specifying thermal performance for multi stop routes and cross border movements.

Énergie & Sustainability Directives: The EU’s F gas Regulation (UE 2024/573) accelerates the phase down of high GWP refrigerants, pushing cold stores towards CO₂ and hydrocarbons. The Energy Performance of Buildings Directive requires “zero emission buildings” and solar readiness for new warehouses, while the Energy Efficiency Directive embeds the “energy efficiency first” principle.

CSRD & ESG Reporting: The Corporate Sustainability Reporting Directive (CSRD) demands granular, audited energy and climate data from logistics operations, beginning with large listed companies.

Compliance Best Practices

Valider l'équipement: Effectuer l'installation (QI), opérationnel (QO) et les performances (PQ) qualification for all temperature controlled equipment.

Cartographie de la température: Conduct mapping studies to identify hot and cold spots in cold rooms, freezers and trucks.

Documentez tout: Maintain continuous monitoring records, deviation investigations and corrective actions.

Qualify partners: Audit logistics providers and packaging vendors to ensure they meet temperature control requirements and have contingency plans.

Former le personnel: Develop SOPs and train personnel on temperature control, monitoring protocols and emergency procedures.

Conseils pratiques

Use cloud dashboards to generate audit ready reports and share temperature logs with regulators and clients.

Plan de licenciement: Deploy backup generators, secondary refrigeration units and disaster recovery plans to maintain temperature during outages.

Restez à jour: Monitor evolving regulations, including low GWP refrigerant transitions and energy performance mandates.

Durabilité & Energy Efficiency Strategies

Energy accounts for the lion’s share of operating costs in cold storage. Refrigeration consumes up to 70 % de la consommation totale d’énergie, and facilities may use environ 25 kWh par pied carré par an pour le refroidissement. With energy costs rising, operators are adopting strategies to cut consumption and emissions.

Énergie renouvelable & Solar Integration

Installing solar panels reduces dependence on the grid and provides predictable energy costs. Dans le Jessup Cold Storage Solar Project, a 268,000 sq ft facility generates over 2.5 million kWh of renewable energy annuellement. Solar plus battery storage allows facilities to manage peak demand and participate in demand response programs, earning incentives up to $100 per kW annually.

High Efficiency Refrigeration & Inverter Technology

Modern compressors use inverter technology to adjust output based on load, improving seasonal energy efficiency. Copeland’s scroll inverter technology offers up to 8 % capacity advantage and integrates with solar power for remote cold rooms.

Zoned Temperature Control & Smart Facility Design

Zoning ensures only areas that need cooling are refrigerated, reducing energy waste. High efficiency HVAC systems, optimized slotting and reduced dwell time in warehouses cut energy consumption. Smart building management systems automatically adjust airflow, lighting and refrigeration based on real time conditions.

Emballage durable & Matériaux recyclables

Sustainable packaging not only protects goods but reduces environmental impact. Manufacturers adopt recyclable insulated containers, biodegradable thermal wraps and palettes réutilisables pour minimiser les déchets. Some companies are experimenting with raising standard freezer temperatures from –18 °C to –15 °C to reduce energy consumption without compromising food safety.

Advice for Energy Efficiency

Réaliser des audits énergétiques: Identify inefficiencies and prioritize upgrades.

Retrofit old equipment: Replace legacy refrigeration units with low GWP, high efficiency models.

Leverage incentives: Explore state or regional incentives for renewable energy and energy efficiency improvements.

Mesure & rapport: Use sustainability metrics to track progress and satisfy CSRD and ESG reporting requirements.

Tendances du marché & Projections de croissance

The cold chain sector is growing rapidly across multiple segments:

Marché de la logistique de la chaîne du froid: Évalué à USD 341 milliards en 2024, it is forecast to reach USD 1.19 mille milliards par 2034 (TCAC 15.3 %).

Marché de la surveillance de la chaîne du froid: Estimé à USD 45.19 milliards en 2025, projeté d'atteindre USD 266.66 milliards 2034 (TCAC 21.88 %). Le composant matériel représente 79 % of revenues, while software grows at 23.72 %.

Marché de la chaîne du froid alimentaire: Expected to be USD 65.8 milliards en 2025 et atteindre USD 205.3 milliards 2032 (TCAC 17.5 %). Frozen foods account for over 59.7 % of food cold chain volume, emphasizing the need for low temperature control.

Energy intensive operations: Cold chain facilities use about 4–5 times more energy than standard commercial buildings, with refrigeration representing up to 70 % de la consommation d'énergie. Operators are investing heavily in renewable energy, battery storage and energy efficiency to remain competitive.

Facteurs du marché

Commerce électronique & épicerie en ligne: The e commerce logistics market reached USD 426.2 milliards en 2023, growing more than 14 % annuellement. Online grocery sales increased by 14.2 %, driving last mile cold chain demand.

Global trade & exportations: International trade of perishable goods is expanding; le US baked goods exports reached USD 4.21 milliards en 2022, à partir de USD 3.73 milliards en 2021. UK government programs support dairy exports valued at over USD 2.47 milliard.

Urbanisation & QSR growth: Rapid urbanization and the rise of Quick Service Restaurants (QSR) are accelerating cold chain demand in markets like India, where daily milk consumption averages 427 g par habitant, bien au-dessus de la moyenne mondiale. The Indian QSR sector is expected to grow 20–25 % au cours de l'exercice 2024.

Pression réglementaire: Stricter food safety laws and GDP requirements compel businesses to adopt real time monitoring and traceability solutions.

Acteurs clés & Innovations

Major cold chain companies like Americold Logistics, Logistique de la lignée, Nichirei, Burris Logistics and A.P. Moller Maersk are investing in digital monitoring, renewable energy and low emission vehicles. Technology providers such as Copeland are launching compressors with AI diagnostics, mobile apps and low GWP refrigerants to drive efficiency.

Défis & Solutions in Temperature Control

Défis

Coûts énergétiques élevés: Cold storage facilities consume 4–5 times more electricity than standard buildings. Energy volatility exposes operators to significant cost risk.

Lacunes en matière d’infrastructures: Remote regions often lack reliable power or road infrastructure, provoquant 25 % of temperature excursions during last mile delivery.

Implementation costs: Comprehensive IoT monitoring systems can cost plus de dollars américains 50,000 par centre de distribution. Small businesses may struggle to justify the investment.

Complexité réglementaire: Fragmented standards across regions increase compliance costs by 15–20 %.

Sécurité des données: IoT devices and cloud platforms pose cybersecurity risks if not properly secured.

Solutions

Hybrid monitoring strategies: Use a combination of data loggers and IoT sensors to control costs while capturing real time data.

Informatique de pointe: Process data locally on devices to trigger alerts in areas with poor connectivity.

Maintenance prédictive: Employ AI to forecast equipment failures and schedule maintenance proactively.

Chambre froide modulaire: Deploy portable, solar powered cold rooms with low GWP refrigerants to serve remote areas.

Entraînement & change management: Provide staff training on interpreting dashboards, responding to alerts and maintaining equipment.

Exemple du monde réel: A mid size dairy cooperative installed IoT sensors in refrigerated trucks. Pendant une canicule estivale, sensors detected a temperature deviation; le système a envoyé des alertes instantanées, enabling drivers to adjust refrigeration and prevent spoilage. La coopérative a signalé un 15 % reduction in product loss and improved compliance documentation.

Emerging Innovations & Real World Cases

Solar Powered Cold Rooms & Remote Farms

Remote areas often lack reliable power, jeopardizing temperature control. Copeland’s scroll inverter technology enables solar powered cold rooms that deliver high energy efficiency and stable temperatures. In rural India, solar cold rooms equipped with Copeland compressors allow farmers to store produce locally, reducing spoilage and improving income.

Low GWP Refrigeration & AI Diagnostics

Transitioning to low GWP refrigerants like CO₂ and propane reduces emissions and ensures future compliance. AI diagnostics embedded in mobile apps (Par exemple, Copeland’s Scout AI) allow technicians to scan a product and receive instant troubleshooting guidance, reducing downtime and energy waste.

Congélateurs cryogéniques portables

Portable freezers maintain ultra low temperatures between –80 °C et –150 °C pour produits biologiques et thérapies cellulaires. Their compact design facilitates safe transport to remote clinics or research sites.

Emballage durable & Systèmes réutilisables

Eco friendly packaging materials and reusable insulated containers reduce waste and support ESG goals. Innovations in smart containers integrate temperature sensors directly into packaging, enabling real time monitoring without extra devices.

Digital Dashboards & Client Visibility

Modern warehouses feature web based dashboards providing live inventory visibility, expiration tracking, FEFO (First Expired, Premier sorti) logic and automated alerts. Clients can access data remotely, améliorer la transparence et la confiance.

Market Impact

These innovations help reduce waste, improve compliance and drive sustainability. They also enable new business models, such as subscription based monitoring services and pay per use cold rooms for small producers.

2025 Derniers développements et tendances

Aperçu de la tendance

2025 signals a shift toward predictive, sustainable and integrated temperature control systems. Les principaux développements comprennent:

IA & predictive route optimization: Real time AI adjusts delivery routes based on traffic and weather, reducing fuel consumption and preventing temperature excursions.

Traçabilité de la blockchain: Supply chains adopt blockchain for tamper proof records, garantir la conformité et la confiance des consommateurs.

Solutions alimentées à l'énergie solaire: Solar refrigerated units and solar battery storage cut energy costs and increase resilience, en particulier dans les zones reculées.

Low emission vehicles: Electric and hybrid refrigerated trucks, along with energy efficient transport refrigeration units (eTRU), support compliance with CO₂ reduction targets.

Emballage durable: Eco friendly materials meet consumer demand and regulatory requirements.

Growth of micro fulfillment: Petit, multi temperature warehouses near urban centers accelerate e commerce deliveries.

Aperçu des derniers progrès

Composite sensors integrate temperature, humidity and shock data with AI algorithms, offering deeper insights and predictive maintenance.

Informatique de pointe reduces latency by processing sensor data locally, enabling faster reactions to temperature deviations in areas with poor connectivity.

Matériaux avancés: New insulation materials such as aerogels and bio based foams provide superior thermal performance with lower environmental impact.

Policy changes: The EU F gas Regulation and Energy Performance Directives accelerate adoption of low GWP refrigerants and zero emission buildings.

Insistance au marché

Croissance régionale: Asia Pacific is the fastest growing cold chain market due to rising incomes, urbanization and government investment. North America maintains the largest market share in 2025.

Hardware vs. logiciel: Comptes matériels pour 79 % of cold chain monitoring revenues but software adoption is rising as AI and analytics become standard.

Aliments surgelés & commerce électronique: Frozen foods account for over 59.7 % of food cold chain volume and e commerce growth amplifies demand for last mile cold chain logistics.

Tableau des prévisions du marché

| Segment | 2025 Valeur | 2034/2032 Prévision | Moteur de croissance |

| Logistique de la chaîne du froid | USD 341 milliard | USD 1.19 mille milliards par 2034 | Commerce électronique, commerce mondial, Pharma |

| Surveillance de la chaîne du froid | USD 45.19 milliard | USD 266.66 milliards 2034 | Capteurs IoT & IA |

| Chaîne du froid alimentaire | USD 65.8 milliard | USD 205.3 milliards 2032 | Rising demand for frozen & aliments frais |

| Frozen foods share | 59.7 % de volumes | Growing with frozen meals & fruit de mer | Need for precise low temperature control |

Questions fréquemment posées

What temperature ranges define cold chain temperature control? Selon le produit, cold chain temperature zones range from controlled room temperature (20–25 ° C) réfrigérer (0–8 ° C), congelé (–20 ° C) and ultra low temperatures for biologics (–60 °C à –150 °C).

How do IoT sensors improve temperature control? Les capteurs IoT fournissent une, surveillance en temps réel de la température, humidité, choc et localisation. Ils transmettent des données aux plateformes cloud, where AI analyzes patterns and predicts failures, enabling proactive interventions and regulatory compliance.

Why is AI powered route optimization important? AI can adjust delivery routes based on real time traffic and weather, réduire le temps de transit, consommation de carburant et risque d'excursions de température.

Quel rôle joue la blockchain? Blockchain technology creates immutable records of temperature and location, améliorer la traçabilité, conformité et confiance des consommateurs.

How can businesses reduce cold chain energy costs? By installing solar panels, using inverter compressors, adopting zoned temperature control and integrating battery storage, businesses can reduce energy consumption and mitigate price volatility.

What are low GWP refrigerants? Low GWP refrigerants such as CO₂ (R744), propane (R 290) and A2L blends have significantly lower climate impact than traditional HFCs. Transitioning to these refrigerants helps meet environmental regulations and reduces carbon emissions.

Are portable cryogenic freezers available? Oui. Compact portable freezers can maintain ultra low temperatures (–80 °C à –150 °C) pour produits biologiques et thérapies cellulaires, making them ideal for remote clinics and research shipments.

Résumé & Recommandations

Cold chain temperature control is the foundation of safe and efficient logistics. The market is booming—cold chain logistics is expected to exceed USD 1 mille milliards par 2034—and regulations are tightening. Technologies émergentes comme les capteurs IoT, IA, blockchain, solar power and low GWP refrigerants are transforming how we monitor and maintain temperature.

To stay ahead in 2025:

Auditez votre chaîne d'approvisionnement: Identify where temperature excursions occur and prioritize monitoring investments.

Deploy real time monitoring: Use IoT sensors and cloud dashboards to capture continuous data.

Leverage AI: Implement predictive analytics to forecast equipment failures and optimize routes.

Adopter des solutions durables: Investissez dans une réfrigération économe en énergie, solar power and low GWP refrigerants.

Assurer la conformité: Document temperature history, validate equipment and train staff to meet HACCP, GDP and ATP standards.

Planifier la résilience: Prepare contingency plans with backup power, secondary refrigeration units and disaster recovery procedures.

By embracing technology, durabilité et conformité, vous pouvez protéger la qualité du produit, reduce waste and position your business for success in the rapidly evolving cold chain landscape of 2025.

À propos du tempk

Rotation is a leader in thermal management and cold chain solutions. We specialize in designing energy efficient compressors, capteurs intelligents, reusable packaging and cloud platforms that keep temperature sensitive goods safe. Nos produits utilisent réfrigérants à faible PRG, AI diagnostics et renewable energy integration to deliver high efficiency and reliability. With decades of experience across food, pharmaceutical and biotechnology sectors, Tempk helps businesses reduce waste, achieve regulatory compliance and meet sustainability goals.

Appel à l'action

Ready to optimize your cold chain temperature control? Contact Rotation today for a customized assessment. Our experts will help you implement IoT monitoring, Analyse de l'IA, energy efficient refrigeration and sustainable packaging tailored to your operations. Protect your products and reduce costs—partner with Tempk.