Si vous vous approvisionnez auprès d'un fabricant chinois de compresses de gel froid, vous achetez vraiment une qualité reproductible, pas seulement un prix unitaire bas. One weak seam can create leaks, remboursement, and negative reviews at scale. A smart approach in 2026 is simple: define your performance targets, test samples like your customers will, then lock production controls before you expand. This guide gives you a practical system you can apply in one afternoon.

Ce guide vous aidera:

Choose the right cold gel compress China manufacturer for your market and claims

Build a one-page RFQ that improves quote accuracy and sample consistency

Run simple QC tests that predict returns before mass production

Compare OEM and private label options without creating new failure risks

Control price with transparent cost drivers and “no silent substitution” règles

Utiliser 2026 trends to future-proof your supplier choice

What should you tell a cold gel compress China manufacturer first?

The fastest way to get a reliable product is to start with use-case clarity, not material names. A cold gel compress for knee recovery behaves differently than a cold gel compress for lunch bags. If your cold gel compress China manufacturer understands the scenario, they can select a gel and film that match real handling. That reduces random sampling and late changes.

Think about what your customer will do on day one. Will they freeze it overnight, then apply it to skin for 15 minutes. Will they reuse it daily for two months. Will it ship in hot weather and sit in a delivery van. These details matter more than “blue gel pack” descriptions.

Use-case decision tool (interactif)

Answer these five questions and keep the results for your RFQ:

Where will it be used most: sportif, rehab clinic, first-aid kit, home care, or cold-chain accessory

How will it be cooled: congélateur (-18°C), réfrigérateur, ice water, or mixed

How will it touch the body: contact direct avec la peau, cloth barrier recommended, or inside a sleeve

How many reuses you expect: sous 50, autour 100, ou 200+ cycles

Your main risk to avoid: fuite, rigidité, odeur, or label/printing wear

Exemple pratique: If your top risk is leakage, your RFQ should prioritize seal strength and drop testing.

Which product specs matter most to a cold gel compress China manufacturer?

A one-page spec sheet makes every cold gel compress China manufacturer quote and sample the same target. Without specs, two factories may assume different film thickness, gel fill volume, ou emballage. That makes price comparisons misleading and slows your launch. Your goal is to remove guessing.

Start with measurable outcomes. You want flexibility after freezing, stable cooling behavior, and consistent seam integrity. Then define size, poids, and packaging level. Enfin, list your compliance and documentation needs so the supplier prepares correctly.

One-page RFQ template (copy and fill)

Application: récupération sportive / post-op rehab / PREMIERS SECOURS / cold-chain accessory

Size and net gel weight: ___ mm × ___ mm; ___ g

Méthode de refroidissement: congélateur / réfrigérateur / ice water

Flexibility after freezing: doux / moyen / ferme

Leak requirement: no visible seepage after squeeze + drop testing

Conditionnement: en gros / retail-ready / kit-ready

Marque: impression de logos, insert card, barcode, language set

Besoins en matière de documentation: safety file set, batch coding, traceability expectations

Plan pilote: initial quantity + reorder forecast for 3–6 months

| RFQ item | Option A | Option B | Ce que cela signifie pour vous |

|---|---|---|---|

| Flexibility target | Moyen | Doux | Comfort vs cooling intensity feel |

| Edge style | Straight | Rounded | Comfort and seam stress balance |

| Niveau de conditionnement | Bulk carton | Retail-ready | Speed to market vs packaging cost |

Practical tips that reduce sampling rounds

Ask the cold gel compress China manufacturer to label samples with gel code and film code.

Request two samples per option to check repeatability, not a lucky unit.

Define pass/fail rules before you discuss volume discounts.

How does a cold gel compress China manufacturer control gel performance?

Gel performance is the “engine” of a cold gel compress, and it must stay stable across batches. If the gel freezes too hard, customers complain about discomfort and poor fit. If it warms too quickly, customers say it “does nothing.” A strong cold gel compress China manufacturer uses standardized formulas and fill-weight control to keep performance consistent.

You do not need advanced chemistry to evaluate gel behavior. You need simple tests that match real use. Freeze it, bend it, apply it safely through a barrier, and check how evenly it cools. Then repeat after several cycles to see if it changes.

Gel behavior at freezer temperatures (what you should check)

| Performance factor | Quoi “bien” on dirait | Simple test you can do | Ce que cela signifie pour vous |

|---|---|---|---|

| Flexibilité | Still pliable at -18°C | Bend test after 12h freeze | Better comfort and fit |

| Cooling stability | Refroidissement uniforme, pas “ice spikes” | 10-minute comfort check | Moins de plaintes |

| Odeur | Low to none after storage | Seal in bag for 24h | Better reviews |

| Reuse durability | Minimal change after cycles | Freeze–thaw ×5 then retest | Lower replacement cost |

Practical tips for different markets

Rehab and clinic use: prioritize pliability and stable performance across many cycles.

Retail and e-commerce: prioritize odor control and leak resistance to reduce returns.

Kids or sensitive users: require softer feel after freezing and clearer instructions.

Scénario du monde réel: If your pack is stiff and awkward, users stop reordering even if it “works.”

Which materials should a cold gel compress China manufacturer use for skin contact?

Outer film choice affects comfort, durabilité, and chemical compliance expectations. Many buyers request clearer material control when the product touches skin for repeated use. A reliable cold gel compress China manufacturer can explain what film is used, how it behaves in cold conditions, and how changes are controlled.

You do not need to demand one film type for every market. You need a film that stays flexible in cold, resists punctures, and matches your channel expectations. If you plan multiple regions, treat film as a controlled component with change notices.

Film options comparison (convivial pour l'acheteur)

| Film option | Sensation typique | Force typique | Typical risk | C’est mieux pour toi quand… |

|---|---|---|---|---|

| Standard flexible film | Lisse | Modéré | Variation across suppliers | You need strong value pricing |

| Premium flexible film | Plus doux | Plus haut | Higher unit cost | You need better comfort and durability |

| Manche + inner pouch | Comfortable | Depends on pouch | More assembly steps | Tu veux “consumer-friendly” manutention |

Practical tips to prevent “looks same, performs different”

Require a written film code and keep it consistent between sample and production.

Re-test whenever film supplier changes, even if color and thickness look similar.

Avoid ultra-thin film unless you can prove drop and squeeze resistance repeatedly.

What compliance files should you request from a cold gel compress China manufacturer?

Documents reduce your risk during customs, retailer onboarding, and platform checks. A professional cold gel compress China manufacturer can provide a consistent documentation bundle, then keep it aligned with the actual SKU you ship. Your goal is not a pile of PDFs. Your goal is correct, SKU-matched, version-controlled files.

Pour de nombreux programmes, you will request: quality system certificates where relevant, material safety documentation, and product-level test records. If you sell into stricter channels, you may require stronger quality system controls and traceability.

Documentation bundle checklist (facile à auditer)

| Type de document | Ce que vous devriez demander | What you should verify | Ce que cela signifie pour vous |

|---|---|---|---|

| Quality certificates | ISO 9001, ISO 13485 si nécessaire | Factory name and validity | Higher process discipline |

| Material safety file | MSDS for gel | Matches gel formula and SKU | Smoother logistics approval |

| Test records | Seal strength, leak checks | Clear pass criteria | Lower returns and disputes |

| Étiquette + carton rules | Batch code logic | Code appears on cartons | Faster issue tracking |

| Change notice process | Written change control | Notification before substitution | No surprise performance shifts |

Practical compliance guidance (simple and safe)

Keep your product claims consistent across inserts, cartons, and product pages.

If you position for medical channels, request stronger traceability and training records.

If you export widely, standardize invoice wording and carton markings early.

How do you test samples from a cold gel compress China manufacturer in 2026?

You can predict most bulk-order problems with a small, repeatable test plan. Your cold gel compress China manufacturer should welcome these tests because they reduce arguments later. Use the same freezer, the same time window, and the same drop height. Document results with photos and a short log.

Your tests should focus on three risks: fuite, performance stability, et expérience utilisateur. These are the top drivers of refunds and negative reviews. A pass today is not enough, so repeat after freeze–thaw cycles.

The 7-test sample plan (simple et fiable)

| Test | Comment l'exécuter | Pass target | Ce que cela signifie pour vous |

|---|---|---|---|

| Seam squeeze | Press seams 30 secondes | Pas d'infiltration | Lower leak risk |

| Corner drop | 1 meter, corners first | No burst | Better transit survival |

| Freeze–thaw cycle | Freeze 12h, thaw 6h × 5 | No cracks | Réutiliser la confiance |

| Flex check | Bend after freezing | Still pliable | Meilleur confort |

| Contrôle des odeurs | Sealed bag 24h | Low to none | Better reviews |

| Print rub | Damp wipe 20 strokes | Minimal smearing | Cleaner retail look |

| Pack-out shake | Shake in carton 60 secondes | No abrasion damage | Fewer shipping failures |

Bulk-order readiness self-score (interactif)

Donnez-vous 1 point pour chacun “Oui”:

You have a one-page RFQ with clear pass/fail rules.

Your sample labels include gel and film codes.

Two samples of the same spec behave the same after freezing.

Your seams pass squeeze and drop tests with no seepage.

Freeze–thaw cycles do not create cracks or leaks.

Packaging prevents friction damage inside cartons.

You documented results with photos and a simple log.

Guide de notation:

6–7: ready for a pilot bulk order with acceptance checks

4–5: run one improvement round before scaling

0–3: risque élevé, do not deposit yet

How do you verify a cold gel compress China manufacturer without visiting?

Remote verification works when you request evidence that is hard to fake and easy to compare. Many sourcing failures happen because buyers assume the seller is the factory. Your job is to confirm identity, capability, et traçabilité. A good cold gel compress China manufacturer can show production steps, QC records, and batch logic clearly.

Start with factory identity and address consistency. Then request real-time process proof, like a short live video walk-through. Enfin, confirm they can trace a batch to material lots and production lines.

Remote factory verification checklist

Factory name matches invoice and packing list formats.

Live video shows gel filling, scellage, et les étapes d'emballage.

A real QC record is shown (sensitive values may be masked).

Batch code logic is simple and consistent across cartons.

Change control exists for film, gel, impression, et emballage.

| Verification item | Ce que tu demandes | What you should see | Ce que cela signifie pour vous |

|---|---|---|---|

| Live line view | 5–10 minute call | Remplissage + scellage + emballage | Confirms real capability |

| Batch code demo | Explain in one minute | Clear code structure | Résolution des problèmes plus rapide |

| Incoming checks | One example record | Material lot tracking | Stable materials |

Practical tips that protect you

Ask for today’s date written on paper during the live video.

Request carton photos that show SKU and batch code clearly.

Keep a scorecard so you choose based on evidence, not sales pressure.

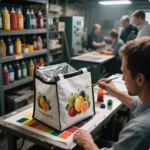

What OEM options can a cold gel compress China manufacturer customize safely?

OEM is valuable when it improves comfort, clarté, and brand differentiation without adding failure points. A capable cold gel compress China manufacturer can adjust size, forme, impression, et emballage. The safest strategy is to keep the pouch structure stable, then customize what customers see and feel.

High-risk customization usually involves ultra-thin film, complex seams, or aggressive contours. Low-risk customization usually involves packaging, label design, and ergonomic sizing. Start with low-risk moves, then expand once performance is stable.

OEM choices that usually increase sales (and reduce complaints)

| OEM element | Low-risk choice | Choix à plus haut risque | Ce que cela signifie pour vous |

|---|---|---|---|

| Forme | Standard rectangle | Complex contour | Comfort vs leak risk |

| Film feel | Medium thickness | Ultra-thin | Durability vs cost |

| Impression | Simple logo | Full wrap print | Setup time and rub risk |

| Conditionnement | Sac + insert card | Multi-piece retail box | Complexity and damage risk |

| Instructions | Icons + short steps | Dense text | Misuse and returns |

Practical packaging and instruction tips

Mettre “how to use safely” on the front panel in four steps.

Use icons so users understand quickly, even if they skim text.

Maintain artwork version control so production never prints an old insert.

Exemple pratique: Clear instructions can reduce misuse-driven refunds without changing the product itself.

How do you control pricing with a cold gel compress China manufacturer?

Price is only meaningful when the same materials and process stay locked from sample to production. The classic failure is “great sample, different mass production.” Your cold gel compress China manufacturer should agree to “no silent substitution” for film, gel, and sealing process. This is your biggest protection.

To compare quotes fairly, normalize specs and trade terms. Ask what is included: conditionnement, printing setup, QC level, and lead time. Then convert everything into a single “landed readiness” view, not a single unit price.

Cost driver map (helps you negotiate intelligently)

| Cost element | What drives it | What you can control | Ce que cela signifie pour vous |

|---|---|---|---|

| Gel materials | formula, fill weight | standardize weights | stable performance |

| Film and sealing | épaisseur, seam style | avoid ultra-thin film | moins de fuites |

| Labor and QC | inspection depth | define acceptance rules | moins de litiges |

| Conditionnement | retail complexity | start simple, scale later | faster launch |

Contract clauses that prevent surprises

Golden sample rule: approved sample is the production reference.

Material code lock: film and gel codes must match the sample codes.

Change notice: written approval required before critical substitutions.

Acceptance standard: define leak tolerance and inspection method clearly.

Nonconforming handling: define rework, ferraille, and replacement rules.

Simple alternative to jargon: If you do not want sampling terminology, écrire “zero leakage allowed in inspection samples.”

2026 tendances: how should a cold gel compress China manufacturer evolve?

Dans 2026, buyers expect more than low cost. They expect faster pilot cycles, clearer traceability, and more stable material controls. Many factories are upgrading automation for fill-weight consistency and seal monitoring. That reduces variability, which is the hidden cost behind returns and reshipments.

Sustainability pressure is also increasing across packaging and adjacent cooling products. Buyers ask for simpler packaging, fewer mixed materials, and clearer material declarations. A future-ready cold gel compress China manufacturer treats this as a process improvement program, not a marketing slogan.

2026 trend snapshot you can act on

Automation upgrades: tighter fill and seal consistency for stable performance

Traceability upgrades: clearer batch coding and basic digital production records

OEM speed: faster sampling and packaging mockups for shorter launch cycles

Material discipline: stronger controls and change notice expectations

Questions fréquemment posées

Q1: How do you know a cold gel compress China manufacturer is reliable? Look for consistent sample performance, une documentation claire, and repeatable QC evidence. A reliable factory can explain batch coding and change control clearly.

Q2: What is a reasonable pilot order size in 2026? Many buyers start with a small pilot that matches a realistic first-month sales forecast. Your goal is learning and stability, not maximum volume.

Q3: How do you reduce leakage in a reusable cold gel compress bulk order? Use a golden sample, lock film and gel codes, and run seam squeeze plus corner drop tests. Scale only after repeatable results.

Q4: Should you prioritize “soft after freezing” ou “stays cold longer”? Choose based on use-case. Rehab users often prefer comfort and fit, while some cold-chain accessory uses prioritize cooling duration.

Q5: What should you do if the factory changes materials after sampling? Treat it as a reset. Re-test the updated material set using the same seven-test plan before approving mass production.

Résumé et recommandations

A cold gel compress China manufacturer should give you consistent gel behavior, strong sealing, and documentation that matches the shipped SKU. Start with a one-page RFQ that defines performance and packaging clearly. Test samples with a repeatable seven-test plan, then verify the factory with evidence-based checks. Enfin, lock your golden sample and material codes so production stays consistent.

Prochaine étape (effacer le CTA)

Shortlist two candidates for cold gel compress China manufacturer.

Send the same RFQ and pass/fail rules to both suppliers.

Run the seven-test plan and score results with photos and notes.

Place a pilot order only after repeatable passes across two samples.

À propos du tempk

Et tempk, we support temperature-control programs across cold-chain use cases and reusable cooling products. We focus on practical specification design, repeatable QC planning, and OEM support that helps you scale with fewer returns. We work with you to define a clear test plan, lock a golden sample, and keep production stable over time.