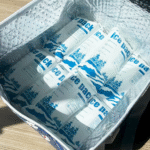

Imaginez un monde où votre livraison de café du matin arrive tiède, votre commande d'épicerie en ligne se gâte avant d'arriver à votre porte, ou les vaccins critiques perdent leur efficacité pendant le transport. Ces scénarios mettent en évidence l’équilibre fragile du contrôle de la température dans les chaînes d’approvisionnement mondiales – un défi où sacs isothermes personnalisés s’imposent comme des alliés indispensables. Allier innovation et durabilité, ces sacs remodèlent la façon dont les industries conservent les denrées périssables, réduire les déchets, et répondre aux demandes changeantes des consommateurs.

La crise de la chaîne du froid: Pourquoi la personnalisation est importante

L’industrie de la chaîne du froid face à une double crise: la hausse des températures mondiales et les attentes des consommateurs en matière de produits frais, produits sûrs. Les solutions traditionnelles universelles ne parviennent souvent pas à répondre aux besoins de niche, comme maintenir des températures précises pour les échantillons de laboratoire ou protéger les produits biologiques délicats. Des études montrent que 20% des denrées périssables sont perdues en raison d’une gestion thermique inadéquate, coûte des milliards aux entreprises chaque année1.

Les sacs isothermes personnalisés relèvent ces défis grâce à:

-

Isolation sur mesure: Compartiments réglables et épaisseur du matériau (Par exemple, 60–80 microns pour une durabilité légère1) répondre à des produits spécifiques, des fruits de mer surgelés aux médicaments sensibles à la température.

-

Rentabilité: En réduisant la taille des emballages de 10 à 30 %, les entreprises économisent jusqu'à 40% sur les coûts logistiques, reflétant les avantages des solutions gonflées à l'air comme celles utilisées dans l'électronique et l'emballage du vin1.

-

Durabilité: Les conceptions réutilisables remplacent les plastiques à usage unique, s'aligner sur les mandats mondiaux de réduction des déchets. Par exemple, 100% Les matériaux PET recyclables sont désormais une référence en matière d'emballages respectueux de l'environnement.1.

Sacs isothermes de Tempk: Pionnier intelligent, Solutions durables

Rotation, un leader de l'innovation thermique, a redéfini les sacs isothermes personnalisés avec son Série EcoGuard Pro, intégrer une technologie de pointe à la gestion de l’environnement:

1. Performance thermique de qualité militaire

Les sacs Tempk utilisent doublures infusées d'aérogel et matériaux biosourcés à changement de phase (PCMS), maintenir des températures entre -25°C et 50°C jusqu'à 48 heures. Cela surpasse la mousse EPS traditionnelle en 35%, garantissant que la crème glacée reste congelée et que les produits pharmaceutiques restent stables même en cas de chaleur extrême.

2. Intelligence basée sur l'IoT

Les capteurs intégrés assurent un suivi en temps réel de la température, humidité, et niveaux de choc. Synchronisation des données avec les applications mobiles, alerter les équipes logistiques des écarts, une fonctionnalité essentielle pour la conformité aux réglementations de la FDA et de l'OMS.

3. Conception d’économie circulaire

-

Matériels: À partir de 100% plastiques recyclés destinés aux océans et adhésifs sans toxines, Les sacs Tempk réduisent l'empreinte carbone de 15 kg par unité par an.

-

Modularité: Les pièces interchangeables prolongent la durée de vie du produit de 300%, tandis qu'un programme de rachat réutilise les sacs retraités en matières premières1.

4. Personnalisation centrée sur la marque

Offres Tempk:

-

Image de marque haute résolution: Impressions résistantes à la décoloration qui survivent à l'humidité et à l'exposition aux UV.

-

Compartiments adaptatifs: Séparateurs réglables pour livraisons multi-températures (Par exemple, plats chauds accompagnés de desserts frais).

-

Intégration du code QR: Améliore la traçabilité et l'engagement des clients grâce à des informations sur les produits ou des promotions numérisables.

L'avenir: Où la durabilité répond à la demande des consommateurs

À mesure que le commerce électronique se développe, il devrait atteindre $8.1 mille milliards d’ici 2026 : les sacs isothermes personnalisés deviennent un différenciateur stratégique. UN 2025 une enquête a révélé que 68% des consommateurs préfèrent les marques utilisant des emballages écologiques, alors que 72% suivi de livraison en temps réel. Les solutions de Tempk permettent aux entreprises de:

-

Réduire les émissions: Les conceptions légères réduisent la consommation de carburant de transport de 20%1.

-

Renforcez la confiance: Les journaux de température transparents partagés avec les clients augmentent la satisfaction et les commandes répétées.

-

Se conformer à l'échelle mondiale: Respectez les interdictions européennes sur le plastique et la règle FSMA de la FDA 204 sans effort.

Conclusion

Les sacs isothermes personnalisés ne sont plus facultatifs mais essentiels pour être résilients, chaînes du froid durables. La série EcoGuard Pro de Tempk illustre ce changement, précision du mélange, intelligence, et l'éco-conscience. Dans un monde où l’action climatique et les attentes des consommateurs se heurtent, ces innovations ne sont pas seulement des outils, elles sont un modèle pour une glacière, un avenir plus vert.