Cubes de glace carbonique ou blocs de glace : quel est le meilleur choix pour l'expédition sous la chaîne du froid?

L’expédition de marchandises sensibles à la température nécessite des solutions de refroidissement fiables. Deux méthodes couramment utilisées sont glaçons carboniques et blocs de glace, chacun offrant des avantages distincts. Cet article examinera les avantages et les inconvénients des deux, vous aider à choisir la meilleure option pour vos besoins d'expédition.

Que sont les glaçons carboniques et les blocs de glace?

Glaçons Sèches

La glace sèche est la forme solide de dioxyde de carbone (Co₂), qui se sublime directement du solide au gaz à -78,5°C (-109.3°F). Contrairement à la glace traditionnelle, la neige carbonique ne laisse pas d’eau derrière elle, ce qui en fait un choix privilégié pour l'expédition de produits surgelés tels que les fruits de mer, viande, et produits pharmaceutiques. Les glaçons carboniques sont des blocs ou des granulés solides, fournissant une puissance de refroidissement longue durée pour les expéditions sensibles à la température.

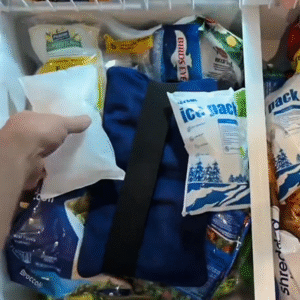

Packs de glace

Packs de glace, également connu sous le nom de packs de gel, sont des sachets remplis d'un gel ou d'un liquide qui gèle pour maintenir une plage de température généralement comprise entre 0°C et 10°C (32° F à 50 ° F). Ils sont généralement plus abordables et plus sûrs à manipuler que la neige carbonique., mais ils n’atteignent pas les températures ultra-basses fournies par la neige carbonique. Les packs de glace sont généralement utilisés pour les produits nécessitant une réfrigération, ne pas geler.

Cubes de glace carbonique vs blocs de glace: Différences clés

| Fonctionnalité | Glaçons Sèches | Packs de glace |

|---|---|---|

| Plage de température | Extrêmement faible (-109.3°F / -78.5°C) | Modéré (32° F à 50 ° F / 0° C à 10 ° C) |

| Sublimation/Fusion | Sublimer le gaz, aucun résidu liquide | Fond dans le liquide, risque de dégâts d'eau |

| Sécurité de manipulation | Nécessite des gants et une ventilation | Manipulation sûre sans précautions particulières |

| Conformité réglementaire | Soumis aux réglementations d'expédition | Généralement pas de réglementation particulière |

| Réutilisabilité | À usage unique | Réutilisable |

| Coût | Plus élevé en raison des exigences d’usage unique et de manipulation | Inférieur, surtout pour les types réutilisables |

Quand utiliser des glaçons carboniques

Marchandises surgelées

Pour les articles comme la crème glacée, viandes surgelées, et fruits de mer, la glace carbonique est la solution idéale. Il garantit que ces produits restent complètement congelés tout au long du processus d'expédition., même lors de voyages longue distance.

Pharmaceutiques et biotechnologie

La neige carbonique est essentielle pour le transport des vaccins, biologique, et fournitures médicales sensibles à la température. Ses températures ultra-basses empêchent la dégradation de ces précieux produits, s'assurer qu'ils arrivent à destination dans des conditions optimales.

Meilleures pratiques d’utilisation de la glace carbonique

-

Ventilation appropriée: Assurez-vous que les conteneurs sont ventilés pour permettre au gaz CO₂ de s'échapper et éviter l'accumulation de pression..

-

Isolation adéquate: Utilisez des matériaux isolants pour ralentir le taux de sublimation et garder les articles congelés le plus longtemps possible.

-

Conformité réglementaire: Soyez conscient des réglementations d’expédition liées à la neige carbonique, y compris les exigences en matière d'étiquetage et de documentation.

Quand utiliser des blocs de glace

Aliments réfrigérés

Les packs de glace sont parfaits pour expédier des articles comme les produits laitiers, fruits, et boissons, qui doivent rester frais mais pas congelés. Ces produits bénéficient d'une plage de température constante de l'ordre de 0°C à 10°C, quels blocs de glace fournissent efficacement.

Fournitures médicales

Certaines fournitures médicales, comme certains vaccins ou échantillons de laboratoire, nécessiter une réfrigération, mais pas gelé. Les blocs de glace conviennent pour maintenir ces températures pendant le transport.

Expéditions à court terme

Pour des expéditions plus courtes, les blocs de glace sont plus que suffisants. Ils assurent un refroidissement fiable jusqu'à 24 heures, ce qui les rend idéaux pour les livraisons rapides ou les expéditions locales.

Comment les glaçons carboniques et les blocs de glace se comparent-ils dans le transport sous chaîne du froid ?

Coût

La glace carbonique est généralement plus chère que les blocs de glace en raison de sa puissance de refroidissement supérieure et de ses exigences de manipulation.. Cependant, il assure un refroidissement plus durable, ce qui peut être plus rentable pour les expéditions longue distance. Les packs de glace sont moins chers, surtout lorsqu'il est réutilisé plusieurs fois, mais ils n'offrent pas le même niveau de refroidissement que la neige carbonique.

Durée de refroidissement

La glace carbonique peut maintenir des températures jusqu'à 72 heures ou plus, en fonction de la taille et de l'isolation de l'envoi. Les packs de glace durent généralement entre 12 et 24 heures et conviennent mieux aux envois courts.

Problèmes d'humidité

Un avantage important de la neige carbonique est qu’elle ne crée pas de résidus d’eau car elle se sublime, contrairement aux packs de glace, qui fond en liquide. Cela fait de la glace carbonique une excellente option pour prévenir les dommages causés par l'humidité aux produits sensibles., comme l'électronique ou certaines fournitures médicales.

Conseils pratiques pour choisir la bonne méthode de refroidissement

-

Évaluer la sensibilité du produit: Si votre produit doit rester congelé, la glace carbonique est le meilleur choix. Pour les articles réfrigérés, les blocs de glace suffisent.

-

Durée de l'expédition: Pour les expéditions longues, la glace carbonique maintiendra des températures ultra basses pendant plusieurs jours. Pour les livraisons à court terme, les packs de glace sont plus économiques et efficaces.

-

Conformité et sécurité: Assurez-vous de respecter toutes les réglementations nécessaires pour les expéditions de glace carbonique, y compris un étiquetage et un emballage appropriés. Les packs de glace ont moins de restrictions et sont plus faciles à manipuler.

Études de cas

Entreprise de fruits de mer expédiant vers des endroits éloignés

Une entreprise de fruits de mer a remplacé les packs de gel par des feuilles de glace carbonique pour ses expéditions à distance. La température ultra-basse a gardé le poisson congelé pendant 72 heures, réduire la détérioration et économiser $15 par expédition. Ils ont réutilisé les plaques de neige carbonique trois fois, ce qui entraîne des économies de coûts à long terme et une réduction des déchets.

Entreprise de fournitures médicales expédiant des vaccins

Une entreprise de fournitures médicales a utilisé de la neige carbonique pour ses expéditions de vaccins, maintenir des températures bien en dessous de zéro. Le produit est arrivé en toute sécurité, adhérant à toutes les normes réglementaires, et garantir l’intégrité des vaccins.

2025 Tendances de la logistique de la chaîne du froid

À mesure que nous approchons 2025, plusieurs tendances façonnent l’avenir de la logistique de la chaîne du froid, y compris des innovations dans l’utilisation de la glace carbonique et l’adoption de pratiques plus durables.

Aperçu des dernières innovations

-

Sacs à glace sec réutilisables: Ces packs gagnent en popularité en raison de leur conception écologique et de leur capacité à être réutilisés plusieurs fois..

-

Capteurs IoT: Des capteurs intelligents assureront un suivi en temps réel des expéditions sensibles à la température, améliorer l'efficacité et réduire la détérioration.

-

Isolation sous vide: De nouvelles technologies d'isolation amélioreront les performances de la neige carbonique en minimisant les échanges thermiques pendant le transport..

Questions fréquemment posées (FAQ)

Q1: Combien de temps dure la glace sèche dans une expédition?

La glace sèche dure généralement entre 24-72 heures, Selon la quantité utilisée, l'isolation, et la durée d'expédition.

Q2: Puis-je utiliser de la neige carbonique pour les expéditions de nourriture?

Oui, la glace carbonique est parfaite pour expédier des aliments surgelés comme les fruits de mer et la crème glacée. Cependant, soyez prudent lorsque vous expédiez des produits frais, car la neige carbonique peut les geler et altérer leur texture.

Q3: Quelle quantité de neige carbonique dois-je utiliser pour un envoi?

Une ligne directrice générale consiste à utiliser 5-10 livres de glace carbonique par jour d'expédition. Ajuster en fonction du type de produit et de la qualité de l'isolation.

Conclusion et prochaines étapes

Les glaçons carboniques et les blocs de glace présentent chacun des avantages uniques en fonction de vos besoins d'expédition.. La glace sèche offre un refroidissement plus durable pour les produits surgelés et les produits pharmaceutiques, tandis que les blocs réfrigérants sont économiques et idéaux pour les expéditions courtes et les articles réfrigérés.. En choisissant la bonne solution de refroidissement, vous pouvez garantir l'intégrité de vos produits sensibles à la température pendant le transport.

Étapes suivantes:

Consultez Tempk pour intégrer des solutions de glace carbonique dans votre stratégie d'expédition. Nos experts vous aideront à sélectionner la bonne combinaison de produits et d'emballages pour répondre à vos besoins spécifiques..

À propos du tempk

Tempk est spécialisé dans la fourniture de solutions logistiques de pointe pour la chaîne du froid. Nous proposons une gamme de produits, y compris des glaçons carboniques, packs de glace, et des systèmes avancés de surveillance de la température, adapté aux besoins de la nourriture, pharmaceutique, et industries biotechnologiques. Laissez-nous vous aider à améliorer votre logistique de chaîne du froid et à garantir que vos produits arrivent en toute sécurité, Peu importe la distance.