Imaginez un vaccin vital qui navigue dans un voyage de 50 heures à travers l'humidité de l'Asie du Sud-Est. Ou bœuf wagyu premium voyageant de Tokyo à une cuisine parisienne, arrivant avec ses marbrures intactes. Derrière ces miracles de la logistique moderne se cache un héros méconnu: le pack de gel carbonique-une fusion de puissance cryogénique et d'intelligence à changement de phase qui redéfinit la fiabilité dans le transport maritime sensible à la température.

Pourquoi les solutions traditionnelles s'effondrent sous la pression

Les outils standards de la chaîne du froid sont confrontés à des limites critiques face aux exigences mondiales actuelles:

-

Packs de gel seuls maximum à -20°C – inutile pour les vaccins à ARNm (-70°C) ou thérapies cellulaires

-

Glace carbonique pure sublime de manière imprévisible, risquer l’accumulation de CO₂ et les écarts thermiques

-

Liquides de refroidissement passifs échouer lors de retards sur le tarmac de l'aéroport ou de transferts du dernier kilomètre

-

Réfrigération active vacille en cas de panne de courant ou de livraisons à distance

Ce n’est pas seulement une question de température, c’est une question consistance thermique. Une excursion à 2°C peut ruiner 500 000 $ de produits biologiques, tandis qu'un retard de 4 heures sous les tropiques peut transformer les fruits de mer frais en déchets.

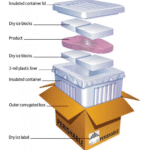

Système FrostFusion™ de Tempk: Où la physique rencontre le génie pratique

Les ingénieurs de Tempk ont déchiffré le code en fusionnant la force cryogénique de la neige carbonique (-78.5°C) avec des matériaux intelligents à changement de phase (PCMS), créer une solution hybride qui dure et surpasse:

1. Noyau de synergie de phase

-

Matrice CO₂-PCM: Les pastilles de glace sèche incorporées dans des cellules PCM isolées par aérogel ralentissent la sublimation en 40%, tandis que les PCM absorbent l'excès de froid pendant les plateaux et le libèrent lorsque les températures augmentent.

-

-75° C pour 96+ Heures: Maintient une stabilité ultra-faible même dans des températures ambiantes de 40°C (validé lors d'essais dans le désert des Émirats arabes unis)

-

Barrière MoistureLock™: Empêche les brûlures dues au gel dans les articles délicats comme les thérapies cellulaires ou les truffes, un défaut fatal dans les installations traditionnelles de glace carbonique

2. Sécurité sans compromis

-

Ventilation sans pression: Libère automatiquement du CO₂ à 1.8 Psi (Dépasser est un 1845 normes)

-

Extérieur FrostGuard™: Permet une manipulation à mains nues à -70°C : plus de risques d'engelures pour les coursiers

-

Coque biocompatible: FDA 21 CFR/ISO 13485 certifié pour le contact direct pharmaceutique/alimentaire

3. Éco-intelligence intégrée

-

Glace à carbone négatif: Utilise le co₂ industriel capturé (détournement 12 tonnes/mois provenant de l'atmosphère)

-

35% Moins de gaspillage de glace: La conception à haute efficacité prolonge le refroidissement par kg de neige carbonique

-

100+ Cycles réutilisables: Survit aux expéditeurs de produits à usage unique 20:1—réduire les déchets d'emballage en 60%

Impact du monde réel: Des laboratoires aux cuisines

-

Équité vaccinale: A permis le transport de l’ARNm du COVID-19 pendant 72 heures vers les cliniques nigérianes—0% détérioration dans 412 expéditions

-

Révolution des fruits de mer: Un exportateur de thon japonais a réduit ses taux de rejet de 28% sur les routes transpacifiques

-

Gardien Gourmand: Les fournisseurs étoilés Michelin expédient désormais du foie gras avec <1% dégradation de la texture

L'avenir: Des chaînes du froid réactives

Tempk 2025 SmartPacks™ intégrera:

-

Capteurs de sublimation IoT prévoir les besoins de réapprovisionnement

-

Grands livres thermiques blockchain pour des audits de conformité en temps réel

-

PCM rechargeables à l'énergie solaire synchronisation avec les réseaux d’énergies renouvelables