Expédition de viande en pack de glace carbonique: La solution ultime pour une livraison de viande sûre en 2025

Expédition de viande, surtout sur de longues distances, nécessite une gestion minutieuse de la température pour éviter la détérioration et la croissance bactérienne. Dans 2025, expédition de viande de pack de glace sèche est devenue l'une des méthodes les plus fiables pour maintenir la qualité de la viande pendant le transport. La glace carbonique offre une solution de refroidissement qui maintient la viande à des températures ultra basses, ce qui en fait un outil indispensable pour les entreprises du secteur de la logistique de la chaîne du froid. Ce guide explorera les meilleures pratiques, exigences réglementaires, et les tendances qui façonnent le transport de viande sur glace sèche en 2025.

-

Quelle quantité de neige carbonique est nécessaire pour l'expédition de viande?

-

Quelles sont les meilleures pratiques pour emballer la viande avec de la neige carbonique?

-

Quelles sont les dernières innovations en matière d’expédition de viande sur glace sèche en 2025?

-

Comment se conformer à la réglementation et garantir des expéditions sûres?

Pourquoi la glace carbonique est-elle idéale pour l'expédition de viande en 2025?

Glace sèche, la forme solide de dioxyde de carbone (Co₂), est un élément essentiel de la logistique de la chaîne du froid, surtout pour les denrées périssables comme la viande. Contrairement à la glace ordinaire, la neige carbonique se sublime directement en gaz sans laisser de résidu liquide, assurer un processus d'expédition sans gâchis. Voici pourquoi cela reste une option incontournable pour l’expédition de viande:

Contrôle de la température

La glace carbonique aide à maintenir des températures aussi basses que -78,5°C (-109.3°F), idéal pour les produits carnés surgelés. Il est capable de conserver des viandes comme des steaks, saucisses, et rôtis congelés lors des expéditions longue distance, s'assurer qu'ils arrivent frais et exempts de détérioration.

Durée de conservation prolongée

Contrairement aux blocs de glace ou aux packs de gel qui perdent leur effet rafraîchissant en quelques heures, la glace carbonique dure beaucoup plus longtemps, ce qui est particulièrement important pour les temps de transit prolongés, comme les expéditions internationales. Cela rend la glace sèche parfaite pour garantir que la viande reste congelée., même pendant de longues périodes de transit.

Pas de dégâts d'eau

La capacité de la glace carbonique à se sublimer directement en gaz signifie qu'il n'y a aucun risque de dégâts d'eau sur l'emballage ou la viande elle-même.. Cela garantit que la viande reste sèche, prévenir les brûlures de congélation et la détérioration des emballages.

Meilleures pratiques pour emballer la viande avec de la glace carbonique

Pour expédier de la viande, il ne suffit pas de jeter de la neige carbonique dans un conteneur. Un emballage approprié garantit que la viande et la glace sèche maintiennent des conditions optimales pendant le transport.. Suivez ces étapes essentielles pour une expédition sûre et efficace de viande sur glace carbonique:

1. Sélectionnez la bonne quantité de glace carbonique

La quantité de neige carbonique nécessaire dépend de plusieurs facteurs tels que le poids de la viande., durée d'expédition, et les conditions environnementales. En règle générale, utiliser 1–2 livres de neige carbonique par 5 kilos de viande pour chaque 24 heures de transit. Pour les envois plus importants, tel que 20 lbs de viande, il est recommandé d'utiliser autour 6 livres de glace carbonique par 24 heures, ajustement en fonction de la distance et des conditions météorologiques.

| Poids de la viande | Glace sèche (24 heures) | Glace sèche (48 heures) | Application pratique |

|---|---|---|---|

| 5 lbs | 1–2 livres | 3–4 livres | Envois de petits échantillons |

| 10 lbs | 3–4 livres | 5–8 livres | Coffrets d'abonnement ménage |

| 20 lbs | 6 lbs | 10–12 livres | Idéal pour les expéditions familiales |

| 40 lbs | 12 lbs | 18–22 livres | Les expéditions plus importantes nécessitent une isolation supplémentaire |

2. Préparer la viande

Un emballage approprié de la viande est essentiel pour éviter les brûlures et les fuites du congélateur.. Les meilleures pratiques pour préparer la viande comprennent:

-

Scellage sous vide: Élimine l'air pour prévenir les brûlures de congélation et la croissance bactérienne.

-

Double ensachage: Fournit une couche supplémentaire de protection contre les fuites potentielles.

-

Pré-congélation: La congélation de la viande avant son emballage garantit qu'elle est dans son état de congélation optimal avant l'expédition..

3. Emballez de la glace carbonique et de la viande ensemble

Voici comment emballer la neige carbonique et la viande ensemble dans un conteneur d'expédition:

-

Superposez correctement la glace carbonique: Commencez par une couche de neige carbonique au fond du récipient isotherme, déposer la viande dessus, puis ajoutez une autre couche de neige carbonique sur la viande.

-

Utiliser des conteneurs isolés: Optez pour des glacières rigides ou des boîtes en panneaux de fibres, isolé avec de la mousse ou des doublures écologiques, pour ralentir la sublimation sur glace carbonique.

-

Assurer la ventilation: La glace sèche sublimait le dioxyde de carbone, le récipient doit donc permettre au gaz de s'échapper pour éviter l'accumulation de pression. Utilisez des conteneurs avec des évents pour libérer le gaz CO₂ en toute sécurité.

4. Étiquetez le colis

Un étiquetage approprié est crucial pour la conformité et la sécurité:

-

Et 1845 Étiquetage: Étiquetez clairement le colis comme “Glace sèche” ou “Dioxyde de carbone, Solide,” et inclure l'ONU 1845 nombre ainsi que le poids de la neige carbonique.

-

Étiquetage des articles périssables: Marquez la boîte comme « Périssable – Conserver surgelé » pour vous assurer que le transporteur connaît l’urgence de l’envoi..

-

Documentation: Pour les expéditions d'air, inclure le formulaire de déclaration de marchandises dangereuses nécessaire, indiquant le poids total de glace carbonique et le nombre de colis expédiés.

Conformité réglementaire pour l'expédition de viande sur glace carbonique

L'expédition de viande avec de la neige carbonique nécessite le respect de diverses réglementations fixées par des agences comme la Ministère des Transports (POINT) et le Association internationale des transports aériens (Iata). Ces réglementations garantissent une manipulation et un transport sûrs de la neige carbonique, qui est classée comme matière dangereuse. Les principales exigences réglementaires comprennent:

-

Nom d'expédition approprié: Étiquetez toujours l'emballage comme “Glace sèche” ou “Dioxyde de carbone, solide” avec l'ONU appropriée 1845 nombre.

-

Limites de poids de glace carbonique: Pour les expéditions d'air, les quantités de glace carbonique sont plafonnées par des limites de poids (généralement 5 livres par colis pour USPS et jusqu'à 200 kg pour le fret aérien).

-

Ventilation et emballage: L'emballage doit permettre la libération en toute sécurité du gaz CO₂ pour éviter l'accumulation de pression.. Évitez les contenants scellés comme les fûts en acier ou les sacs en plastique hermétiques.

Pour 2025, les nouvelles réglementations mettent l’accent sur l’amélioration ventilation, surveillance de la température, et essai de pression pour l'emballage. Capteurs IoT et lettres de transport aérien numériques (Charme) sont de plus en plus courants pour garantir le respect de ces règles mises à jour.

Tendances qui façonnent l’expédition de viande sur glace sèche en 2025

Alors que le secteur de la logistique de la chaîne du froid continue d'évoluer, plusieurs tendances et technologies façonnent l’avenir du transport de viande sur glace carbonique:

1. Production de glace sèche durable

L'industrie de la glace carbonique se concentre sur la durabilité en utilisant des technologies de captage du carbone pour produire de la glace carbonique plus efficacement et avec moins d'impact sur l'environnement.. Les entreprises intègrent de plus en plus écologique pratiques de production pour réduire leur empreinte carbone, répondre à la demande croissante des consommateurs pour des pratiques durables.

2. Emballages intelligents et capteurs IoT

Les emballages intelligents sont de plus en plus courants dans le secteur du transport maritime. Capteurs IoT intégré dans l'emballage aide à surveiller le température et humidité en temps réel, permettant un meilleur contrôle et garantissant que la viande reste dans des plages de température sûres tout au long du processus de transit.

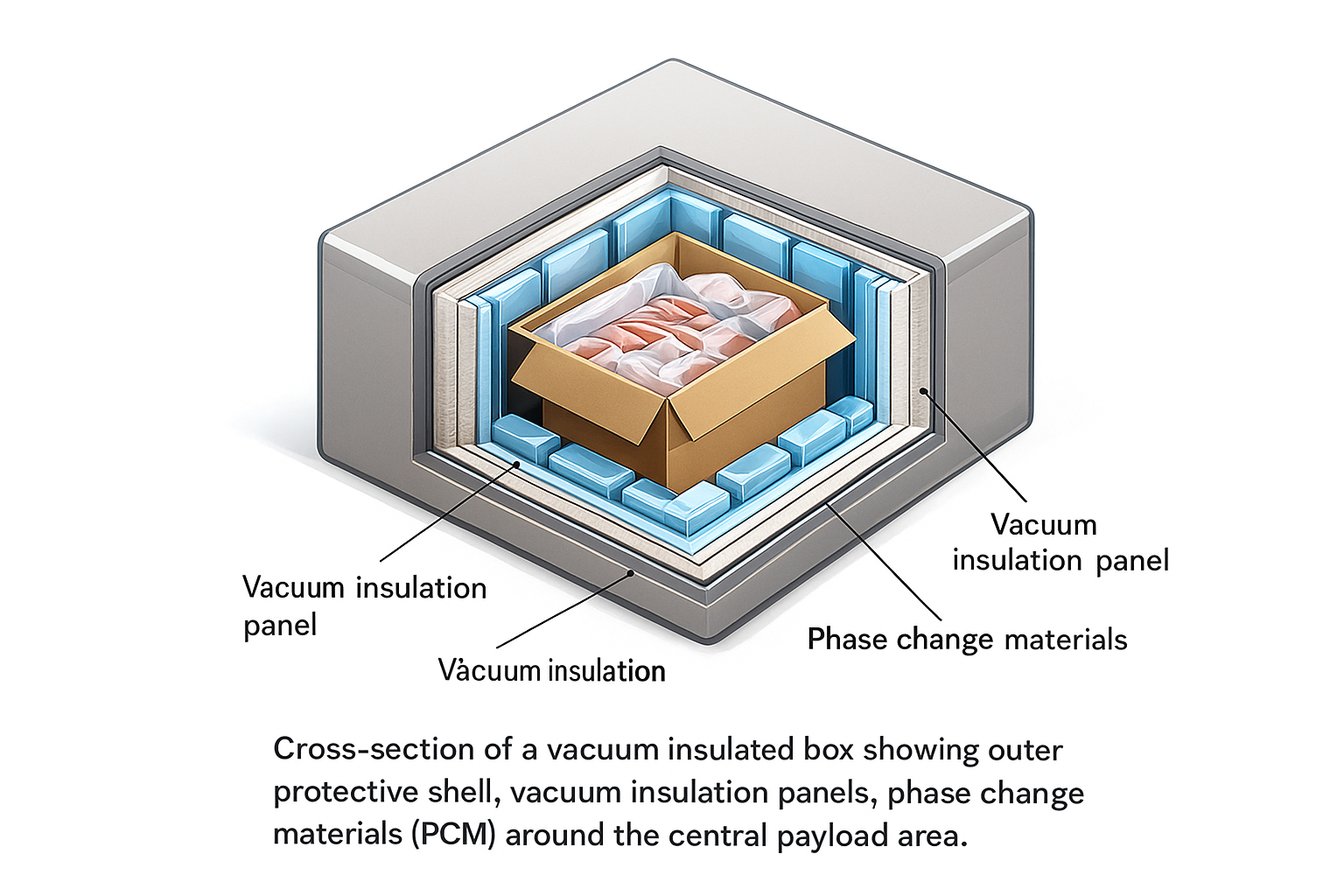

3. Matériaux d'isolation avancée

Nouveaux matériaux d'isolation, tel que Matériaux à changement de phase (PCMS), contribuent à prolonger la durée de refroidissement lors des expéditions de viande. Ces matériaux stockent et libèrent de l’énergie à mesure qu’ils changent de phase, ce qui les rend plus efficaces que les méthodes d'isolation traditionnelles.

Questions fréquemment posées (FAQ)

Q1: Combien de temps dure la glace carbonique lors de l'expédition de viande?

La glace sèche dure généralement 24–72 heures, en fonction de la qualité de l'isolation et des températures ambiantes. La quantité de neige carbonique utilisée et le type d'emballage affectent considérablement la durée.

Q2: La glace carbonique peut-elle endommager la viande pendant le transport?

Lorsqu'il est correctement emballé, la glace carbonique n'endommage pas la viande. Cependant, Un contact direct avec la neige carbonique ou une mauvaise manipulation peut entraîner brûler le congélateur ou déshydratation. Utilisez toujours conteneurs isolés et mise sous vide.

Q3: L'expédition de glace carbonique est-elle coûteuse?

Même si la glace carbonique est souvent plus coûteuse que la glace traditionnelle, sa durée de refroidissement plus longue et ses propriétés sans dégâts en font une option rentable à long terme. Réduire la détérioration et garantir que la viande arrive à destination en toute sécurité peut contribuer à éviter des pertes financières..

Conclusion et prochaines étapes réalisables

En résumé, L'expédition de viande sous glace carbonique est une solution essentielle pour conserver la viande fraîche pendant le transport.. En suivant les bonnes pratiques d'emballage, calculer la bonne quantité de neige carbonique, et en respectant la réglementation, les entreprises peuvent assurer la sécurité, expéditions de viande fiables.

Étapes suivantes:

-

Évaluez vos besoins en glace carbonique en utilisant la formule fournie.

-

Emballage de mise à niveau à une isolation performante et assurer une bonne ventilation.

-

Mettre en œuvre une surveillance de la température pour suivre vos expéditions en temps réel.

-

Formez votre équipe sur les protocoles de sécurité et les directives de manipulation.

À propos du tempk

Rotation fournit des solutions logistiques avancées pour la chaîne du froid, y compris kits d'expédition de glace carbonique, capteurs intelligents, et emballage isolé conçu pour assurer un transport sûr et efficace des marchandises périssables. Contactez-nous dès aujourd'hui pour optimiser votre processus d'expédition avec nos solutions fiables et durables.