Comment les feuilles de glace carbonique peuvent-elles améliorer la logistique de la chaîne du froid pour les expéditions plus fraîches?

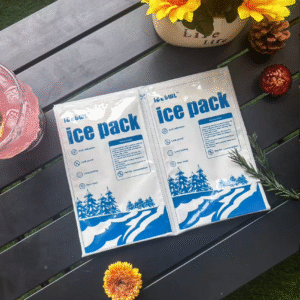

Feuilles de glace carbonique sont une innovation révolutionnaire dans la logistique de la chaîne du froid. Ces feuilles garantissent que les marchandises sensibles à la température, comme les produits pharmaceutiques, nourriture, et autres produits périssables, restent à leur température idéale pendant le transport. Avec une demande croissante d’efficacité et de fiabilité dans l’industrie de la chaîne du froid, Les feuilles de glace carbonique offrent une solution pratique pour les entreprises souhaitant améliorer leurs opérations d'expédition. Cet article expliquera comment les feuilles de glace carbonique améliorent les expéditions de refroidisseurs., leurs avantages, et les meilleures pratiques à utiliser dans l'espace logistique de la chaîne du froid en 2025.

-

Pourquoi les plaques de glace carbonique sont-elles cruciales pour la logistique de la chaîne du froid?

-

Comment les feuilles de glace carbonique améliorent-elles le contrôle de la température pendant le transport?

-

Quelles meilleures pratiques les entreprises devraient-elles suivre lorsqu'elles utilisent de la neige carbonique pour des expéditions plus fraîches ??

Pourquoi les feuilles de glace carbonique sont-elles cruciales pour la logistique de la chaîne du froid?

Les feuilles de glace carbonique jouent un rôle indispensable pour garantir l'intégrité des marchandises sensibles à la température pendant le transport.. En maintenant une température basse constante sans risque de dégâts d’eau, ces feuilles réduisent le risque de détérioration et de dégradation, en particulier pour les produits comme les produits pharmaceutiques, aliments surgelés, et des échantillons biologiques.

La glace carbonique se sublime à -78,5°C, maintenir une température ultra-basse qui garantit que les articles périssables restent congelés pendant le transport. Cela évite le problème de l'eau de fonte associé à la glace traditionnelle., ce qui peut endommager les produits. En fait, la mise en œuvre de plaques de glace carbonique a conduit à une réduction des taux de détérioration jusqu'à 75% dans certaines industries.

Avantages clés:

-

Pas d'eau de fusion: Glace sèche sublimate, éviter les résidus de liquide.

-

Contrôle de température fiable: Garantit que les marchandises, produits particulièrement sensibles comme les vaccins, rester dans la plage de température requise.

-

Rentable: En réduisant la détérioration, Les plaques de glace carbonique aident les entreprises à réduire les coûts associés à la perte de produits.

Comment les feuilles de glace carbonique améliorent-elles le contrôle de la température pendant le transport?

Les feuilles de banquise maintiennent un, température froide constante pendant de longues périodes, ce qui en fait une solution très efficace pour expédier des marchandises nécessitant une gestion stricte de la température. Ces feuilles sont particulièrement utiles lors de l'expédition de produits périssables ou de produits pharmaceutiques sensibles qui doivent rester congelés ou réfrigérés..

Par exemple, les vaccins et les produits biologiques doivent être conservés à un niveau stable, basse température. Les plaques de glace carbonique fournissent la puissance de refroidissement nécessaire, s'assurer que les marchandises restent dans la plage de température requise tout au long du processus d'expédition. Dans l'industrie alimentaire, la glace carbonique est essentielle pour garder les articles congelés et préserver leur fraîcheur, empêcher le dégel pendant le transport.

| Facteur d'emballage | Pratique recommandée | Pourquoi ça compte |

|---|---|---|

| Quantité de glace carbonique | 5-10 lbs par 24 heures | Empêche les fluctuations de la température, maintient la sécurité |

| Étiquetage | Marquer avec des étiquettes de glace carbonique appropriées | Garantit une manipulation sûre et la conformité réglementaire |

| Isolation | Utilisez un emballage isotherme approprié | Prolonge l'efficacité de refroidissement de la glace carbonique |

| Surveillance | Mettre en œuvre le suivi de la température | Assure la conformité réglementaire et la sécurité des produits |

Meilleures pratiques pour l’utilisation de glace carbonique dans les envois plus frais

-

Déterminer la quantité correcte de glace carbonique: Pour des performances optimales, les entreprises devraient utiliser 5-10 livres de glace carbonique par 24 heures d'expédition. Cependant, des ajustements peuvent être nécessaires en fonction des spécificités de l’expédition et de la sensibilité du produit.

-

Étiquetage approprié: Il est essentiel d'étiqueter clairement les envois avec “Dioxyde de carbone solide” pour assurer le respect de la réglementation des transports.

-

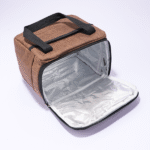

Utilisez des emballages isolés: Des sacs ou des boîtes isothermes bien isolés aident à maximiser l'efficacité de la glace carbonique, réduisant la pénétration de chaleur et garantissant que les températures restent basses plus longtemps.

-

Surveillance de la température: Utiliser des dispositifs de surveillance de la température pour garantir que les marchandises restent dans la plage de température souhaitée pendant tout le processus d'expédition.

-

Élimination sécuritaire de la glace carbonique: Éduquer les destinataires sur les procédures d’élimination appropriées, s'assurer que la glace carbonique se sublime dans un endroit bien ventilé pour éviter l'accumulation de pression ou les dommages.

Quels sont les principaux avantages de l’utilisation de feuilles de glace sèche?

Les feuilles de glace carbonique offrent de multiples avantages lors de l'expédition de marchandises sensibles à la température, en particulier dans les industries comme l'alimentation et la pharmacie. Leur capacité à maintenir des températures basses pendant des durées prolongées, combiné au fait qu'ils subliment plutôt que fondent, leur donne un avantage distinct sur les autres méthodes de refroidissement comme les packs de gel ou la glace traditionnelle.

Contrôle de température cohérent

La glace carbonique garantit que les fluctuations de température sont minimisées, ce qui le rend idéal pour l'expédition de marchandises de grande valeur ou très sensibles qui pourraient se dégrader ou perdre leur efficacité s'ils sont exposés à des changements de température, même mineurs..

Solutions rentables

Même si la glace carbonique peut sembler coûteuse au départ, la réduction de la détérioration et l'élimination des dommages liés à l'eau de fonte en font une solution très rentable à long terme. Cela réduit également le besoin de blocs de glace qui autrement nécessiteraient d'être réapprovisionnés lors d'expéditions plus longues..

Respectueux de l'environnement

La glace carbonique est une option plus écologique que les autres matériaux de refroidissement. Puisqu'il se sublime directement en gaz, il n'y a pas de ruissellement de liquide, et cela ne contribue pas au gaspillage d’eau. Cela en fait une alternative plus durable pour les entreprises qui cherchent à améliorer leur empreinte environnementale..

Comment les entreprises peuvent-elles optimiser leur processus d'expédition avec de la neige carbonique?

Pour garantir que la logistique de la chaîne du froid soit optimisée, les entreprises devraient envisager plusieurs stratégies clés lors de l’intégration de la neige carbonique dans leurs processus d’expédition.

Effectuer une analyse de l’efficacité des expéditions

L'examen des données historiques d'expédition aide les entreprises à évaluer la quantité optimale de neige carbonique requise pour différents types d'expédition., leur permettant de s'adapter en fonction des besoins spécifiques et des conditions environnementales.

Mettre en œuvre la technologie et suivre les expéditions

L'intégration de capteurs de température basés sur l'IoT et d'un suivi en temps réel peut fournir aux entreprises des données précieuses sur leurs expéditions., leur permettant de remédier à tout écart de température avant qu’il ne devienne un problème.

Former les employés et les partenaires

S'assurer que le personnel interne et les partenaires logistiques sont correctement formés à la manipulation de la neige carbonique et suivre les meilleures pratiques peut minimiser les erreurs et augmenter l'efficacité opérationnelle..

Collaborer avec des prestataires logistiques expérimentés

Un partenariat avec des prestataires logistiques possédant une vaste expérience dans la gestion des expéditions de glace carbonique peut fournir un aperçu des meilleures pratiques., conformité réglementaire, et plus efficace, méthodes rentables.

Application du monde réel: Comment la glace carbonique a aidé une entreprise pharmaceutique à réduire la détérioration

Une société pharmaceutique a récemment intégré des blocs de glace carbonique dans son processus d'expédition pour livrer des vaccins dans des zones reculées.. En calculant la quantité précise de neige carbonique nécessaire sur la base de données historiques et en surveillant les conditions de température, ils ont pu réduire la détérioration en 50% et améliorer significativement la satisfaction client.

2025 Tendances et innovations en matière d’expédition de glace carbonique

L'industrie du transport de glace carbonique connaît plusieurs innovations qui rendent la logistique plus efficace, rentable, et respectueux de l'environnement. Voici un aperçu de certaines des dernières tendances qui façonnent l’industrie:

Matériaux d'emballage durables

À mesure que la durabilité devient de plus en plus importante, de nouveaux matériaux d'isolation écologiques sont en cours de développement pour améliorer le transport sous chaîne du froid tout en réduisant l'impact environnemental.

Logistique basée sur l'IA

L'intelligence artificielle est utilisée pour prédire la quantité exacte de neige carbonique requise pour des expéditions spécifiques, aider les entreprises à réduire leurs déchets et à améliorer l'efficacité de leurs processus de chaîne du froid.

Solutions d'emballage hybrides

Emballage hybride, qui combine la neige carbonique avec d'autres matériaux sensibles à la température, gagne en popularité grâce à sa capacité à prolonger la durée de conservation des denrées périssables tout en réduisant la quantité de CO₂ utilisée.

Questions fréquemment posées

Q1: Pourquoi la glace carbonique est-elle utilisée pour l'expédition?

La glace carbonique maintient des températures ultra-basses et se sublime en gaz, ce qui le rend idéal pour conserver les produits sensibles à la température pendant le transport.

Q2: La manipulation de glace carbonique est-elle sans danger?

Oui, avec les précautions appropriées. Manipulez toujours la neige carbonique avec des gants et assurez une ventilation adéquate pour éviter l'accumulation de CO₂..

Conclusion et recommandations

Les plaques de glace carbonique sont un outil essentiel dans la logistique de la chaîne du froid, fournir aux entreprises un moyen fiable et rentable de garantir l'intégrité des produits sensibles à la température. En adoptant les meilleures pratiques et en gardant une longueur d'avance sur les dernières tendances, les entreprises peuvent optimiser leurs processus d'expédition et améliorer la satisfaction des clients.

Étapes exploitables:

-

Évaluez vos besoins en matière d'expédition et envisagez d'utiliser de la neige carbonique pour les marchandises sensibles à la température..

-

Investissez dans la formation et la technologie pour rationaliser votre logistique de la chaîne du froid.

-

Collaborez avec des partenaires logistiques expérimentés pour une expédition plus sûre et plus efficace.

À propos du tempk

Et tempk, nous sommes spécialisés dans la fourniture de solutions logistiques de pointe pour la chaîne du froid, des feuilles de glace carbonique aux emballages isolés et à la surveillance de la température en temps réel. Notre objectif est d'aider les entreprises à transporter des marchandises périssables de manière sûre et efficace., respecter les réglementations de l’industrie tout en minimisant l’impact environnemental.

Contactez-nous aujourd'hui pour découvrir comment nous pouvons optimiser vos solutions d'expédition sous chaîne du froid.