Comment les packs de glace sèche garantissent-ils une expédition sûre des vaccins 2025?

Les blocs de glace carbonique sont un élément essentiel pour le transport sûr des vaccins, en particulier ceux nécessitant des températures ultra-basses. Avec des vaccins tels que les vaccins à ARNm contre la COVID-19 nécessitant des températures aussi basses que -70°C, la neige carbonique garantit que les vaccins restent stables et efficaces pendant le transport. Cet article explore comment la neige carbonique maintient la chaîne du froid requise, offrant un service fiable, solution rentable pour la distribution mondiale de vaccins.

-

Pourquoi les packs de glace carbonique sont essentiels pour le vaccin transport?

-

Comment les blocs de glace carbonique maintiennent-ils la température pendant les expéditions?

-

Quelles sont les meilleures pratiques d’utilisation de la neige carbonique pour l’expédition des vaccins?

-

Quelles sont les alternatives à la neige carbonique pour le transport des vaccins?

Pourquoi les packs de glace carbonique sont-ils essentiels pour le transport des vaccins?

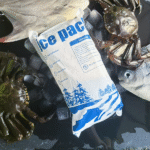

Packs de glace sec jouent un rôle essentiel dans le transport des vaccins car ils maintiennent des températures ultra-basses essentielles à certains vaccins’ stabilité. La glace carbonique se sublime directement à partir du dioxyde de carbone solide (Co₂) en gaz, s'assurer qu'il n'y a aucun résidu liquide susceptible de contaminer le vaccin. Certains vaccins, comme ceux pour le COVID-19, nécessitent un stockage à environ -70°C, faisant de la neige carbonique la solution idéale pour prévenir la détérioration et maintenir l’activité du vaccin pendant le transport sur de longues distances.

Principaux avantages de la glace carbonique dans le transport des vaccins:

-

Entretien de température: La capacité de la glace carbonique à maintenir des températures ultra basses garantit que les vaccins restent efficaces tout au long du processus d’expédition..

-

Pas de résidu d'eau: Contrairement aux blocs de glace, la glace carbonique ne fond pas en liquide, prévenir la contamination.

-

Longue durée de refroidissement: La glace carbonique peut maintenir des températures jusqu'à 72 heures dans des conteneurs correctement isolés, ce qui le rend idéal pour les périodes de transport prolongées.

Comment les packs de glace carbonique maintiennent-ils la température pendant les expéditions de vaccins?

Les packs de glace carbonique offrent une solution unique pour maintenir la chaîne du froid requise dans les expéditions de vaccins. Comme la glace sèche sublime, il assure un refroidissement continu sans fondre dans un liquide, s'assurer que les vaccins ne sont pas exposés à l'humidité pendant le transport. Ceci est particulièrement important pour les vaccins à ARNm qui peuvent être compromis par les fluctuations de température..

Mécanisme de contrôle de la température de la glace carbonique

La glace carbonique maintient une température de -78,5°C, bien en dessous du point de congélation de l'eau. En subissant directement dans le gaz, il fournit un refroidissement constant tout au long du voyage, s'assurer que les vaccins restent dans la plage de température requise.

| Facteur d'emballage | Pratique recommandée | Pourquoi ça compte |

|---|---|---|

| Quantité de glace carbonique | 5-10 lbs par 24 heures | Assure le maintien de la température requise pour les vaccins |

| Étiquetage | Marquer avec des étiquettes de glace carbonique appropriées | Empêche les erreurs de manipulation et assure la sécurité |

| Isolation | Utiliser des conteneurs isothermes | Prolonge l'efficacité du refroidissement, réduit les déchets |

| Surveillance | Ajouter des dispositifs de surveillance de la température | Fournit des données en temps réel pour un transport sûr des vaccins |

Meilleures pratiques pour l’utilisation de glace carbonique dans les expéditions de vaccins

L’utilisation sûre et efficace de la neige carbonique dans les expéditions de vaccins implique plusieurs pratiques essentielles:

Calculer la quantité correcte de glace carbonique

Déterminer la bonne quantité de neige carbonique est essentiel pour maintenir la température souhaitée tout au long du transport. Une règle générale est d'utiliser 5-10 livres de neige carbonique par fenêtre d'expédition de 24 heures, mais le montant peut varier en fonction de la taille de l'envoi et de la durée.

Utilisez des emballages isolés

Une bonne isolation dans les conteneurs d’expédition contribue à prolonger les effets rafraîchissants de la neige carbonique, s'assurer que les vaccins restent à la bonne température. Ces conteneurs doivent également être dotés d'une ventilation pour permettre au gaz CO₂ de sublimation de s'échapper en toute sécurité..

Étiquetage et manipulation appropriés

Les emballages contenant de la neige carbonique doivent être étiquetés avec “Dioxyde de carbone solide” et les symboles de danger appropriés, assurer une manipulation sûre et le respect des réglementations en matière de transport, surtout lors de l'utilisation du fret aérien.

Surveillance de la température

Pour suivre la température tout au long du transport, il est essentiel d'inclure des dispositifs de surveillance de la température tels que des enregistreurs de données. Cela garantit que les vaccins sont maintenus dans la chaîne du froid requise pendant le transport..

Plan d'élimination de la glace carbonique

Quand l'envoi arrive, la glace carbonique doit pouvoir se sublimer dans un endroit bien ventilé, et les destinataires doivent être informés des pratiques d'élimination sûres pour éviter l'accumulation de CO₂ dans les espaces clos..

Alternatives à la glace carbonique pour le transport des vaccins

Alors que la neige carbonique est l’option privilégiée pour les vaccins à ultra-basse température, il existe des réfrigérants alternatifs pour les vaccins qui nécessitent des températures de stockage plus élevées.

-

Packs de gel: Idéal pour les vaccins nécessitant des températures comprises entre 2°C et 8°C, les packs de gel ne sont pas dangereux, réutilisable, et rentable.

-

Matériaux à changement de phase (PCMS): Pour les vaccins nécessitant un contrôle précis de la température, Les PCM offrent une alternative fiable. Ils peuvent maintenir des températures comprises entre -20°C et 5°C et sont de plus en plus utilisés pour le transport de vaccins..

2025 Tendances en matière d’expédition de vaccins sur glace carbonique

Le secteur de la logistique des vaccins évolue, motivé par les avancées technologiques et les tendances en matière de développement durable. Voici un aperçu des développements clés pour 2025:

Défis liés à la durabilité et à l’approvisionnement en CO₂

À mesure que la demande de glace carbonique augmente, l’approvisionnement en CO₂ a été confronté à des contraintes. Le 2025 le marché de la glace carbonique devrait croître d’ici 7.4% annuellement, tirée par la distribution de produits biologiques et de vaccins. Pour répondre durablement à cette demande, les entreprises explorent des méthodes de captage du CO₂ d’origine biologique.

Surveillance de la température en temps réel

De nouvelles solutions de suivi de la température basées sur l’IoT révolutionnent la logistique de la chaîne du froid, offrant des données en temps réel pour surveiller les conditions tout au long du processus de transport. Cela améliore la sécurité des vaccins et garantit la conformité réglementaire.

Innovations dans les formats de glace carbonique

Les entreprises développent de nouveaux formats de glace carbonique, comme des tranches fines ou des coupes personnalisées, qui permettent un refroidissement plus efficace et un meilleur ajustement à l'intérieur de l'emballage, réduire les déchets et les risques de surfusion.

Questions fréquemment posées

Q1: Pourquoi devrais-je utiliser de la neige carbonique pour expédier des vaccins?

La glace carbonique est cruciale pour les vaccins nécessitant des températures ultra-basses, s'assurer qu'ils restent viables et efficaces lors des expéditions longue distance.

Q2: Comment puis-je m'assurer que les vaccins restent à la bonne température pendant l'expédition?

L'utilisation de neige carbonique conjointement avec des dispositifs de surveillance de la température garantit que les vaccins restent dans la plage requise. Une bonne isolation joue également un rôle essentiel dans la prolongation des effets de refroidissement de la neige carbonique..

Q3: Puis-je utiliser de la neige carbonique pour tous les types de vaccins?

Non, la neige carbonique ne convient que pour les vaccins nécessitant des températures ultra-basses. Les vaccins comme la varicelle ne doivent pas être conservés avec de la neige carbonique en raison du froid extrême..

Conclusion et recommandations

Les blocs de glace carbonique sont essentiels pour assurer le transport en toute sécurité des vaccins nécessitant des températures ultra-basses. Suivre les meilleures pratiques, comme la quantité correcte de glace carbonique, emballage approprié, et surveillance de la température, veillera à ce que les vaccins soient livrés en toute sécurité sans compromettre leur efficacité.

Suggestions exploitables:

-

Évaluez vos besoins en matière d’expédition de vaccins et utilisez de la neige carbonique uniquement lorsque cela est nécessaire.

-

Mettez en œuvre le suivi de la température et établissez des partenariats avec des prestataires logistiques expérimentés pour rationaliser le processus d'expédition..

À propos du tempk

Et tempk, nous sommes spécialisés dans la fourniture de solutions complètes de chaîne du froid pour l'industrie pharmaceutique, garantir que les vaccins restent sûrs et ponctuels. Nos produits, y compris des feuilles de glace carbonique, conteneurs isolés, et systèmes de surveillance de la température, sont conçus pour répondre aux normes les plus élevées de la logistique de la chaîne du froid.

Appel à l'action: Contactez-nous dès aujourd'hui pour en savoir plus sur la façon dont nos solutions innovantes de chaîne du froid peuvent optimiser votre processus de distribution de vaccins..