Glace sèchePackagingLabel2025: La conformité ultime & Manuel de performances

1. Why Labels Matter More in 2025

Dry‑ice volumes are up 14 % YoY and regulators digitised acceptance checks.

| 2025 Risque | Impact if Label Fails | New Fine |

|---|---|---|

| Manquant / faded diamond | Cargo hold, détérioration, brand damage | USD 7 500 |

| Wrong net weight | Forced re‑weigh, missed flight | USD 4 800 |

| Paper label peel‑off | Re‑pack, disposal fee | USD 1 250 |

Fin de compte: Un conforme, L’étiquette durable est l’assurance la moins chère que vous puissiez acheter.

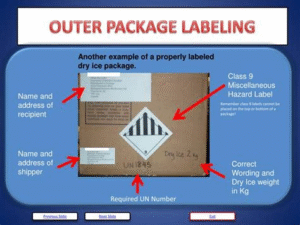

2. Exact 2025 Specs at a Glance

| Spécifier | Minimum Requirement | Why It Exists |

|---|---|---|

| Diamond size | ≥ 100 mm × 100 mm, 7 black stripes | Vision industrielle & human scan |

| Text height | “UN 1845” ≥ 12 mm; net weight ≥ 6 mm | Legibility at ramp distance |

| Facestock | Synthetic PET/PP or poly‑imide | No tearing at –78 °C |

| Adhesive | Polyuréthane, –80 °C service | Zero peel in blast freezer |

| Placement | Top or largest side, away from seams | Avoid tape glare & flex cracks |

| Digital layer | QR to e‑Docs & FDS (facultatif mais intelligent) | 40 % d'acceptation plus rapide par les compagnies aériennes |

3. Comment: Créer & Apply a Perfect Dry‑Ice Label

Estimated time: 2 minutes par boîte

-

Degrease surface with 70 % IPA; wait 5 s.

-

Warm carton to 5 °C (heat‑gun in winter).

-

Peler & stick 100 mm synthetic label; roll 2 kg rubber roller once.

-

Ink net weight (kg, one decimal) next to—not on—the diamond.

-

Scan QR to verify e‑Docs link (IATA DGR checklist PDF).

-

Vent check: Confirm pressure‑relief hole unobstructed.

-

Photo‑log label for airline digital checklist.

-

Repeat on opposite side for ocean or intermodal freight.

-

Log weight in WMS; auto‑notify consignee.

Pour la pointe: Pre‑printed “UN 1845 kg __” labels shave 2 min off FedEx sort‑line tasks.

4. Carrier‑Specific Nuances (2025)

| Transporteur | Extra Rule | Free Stock? | Comment |

|---|---|---|---|

| FedEx | “UN 1845” ≥ 12 mm; Partie #106426 | ✔ | Auto‑reject if reflective tape covers stripes |

| Hauts | Voici pi954 + ISC contract | ✔ | Synthetic only; paper = fail |

| Major airlines | Photo of label in e‑Docs | ❌ | Upload during DG acceptance |

| Fret maritime | 2 opposite faces + “WARNING CO₂ SOLID” | ❌ | Placard if >454 kg aggregate |

5. Smart‑Label Innovations Shipping Managers Love

| Innovation | 2025 Avantage | Retour de retour |

|---|---|---|

| e‑Ink mass meter | Live kg reading ± 2 % | Cuts manual probe checks 40 % |

| Blockchain QR | Tamper‑proof temperature & journal de poids | Meets EU MDR traceability |

| Photoreflective coating | 1 200 pkgs / hr sorter read‑rate | +3 % hub capacity |

| Bio‑PP facestock | 25 % CO₂e reduction | ESG reporting credit |

6. Sustainability Hacks Without Losing Compliance

-

Bio‑based synthetics ≥ 45 % renewable carbon pass IATA abrasion.

-

Water‑soluble backings dissolve in ≥ 5 °C wash‑down, zero landfill.

-

Right‑size dry‑ice with AI route prediction → –18 % CO₂ venting.

-

Bacs réutilisables + swap‑in label sleeves prevent adhesive waste.

7. Troubleshooting in One Table

| Symptôme | Root Cause | 30‑Second Fix |

|---|---|---|

| Label frosts off | Carton surface < –15 ° C | Pre‑warm 5 °C & re‑stick |

| Barcode mis‑scans | Tape glaze or curved surface | Re‑apply flat on face panel |

| Weight mismatch alert | Top‑up not relabelled | Print fresh label via mobile app |

| QR unreadable | Fancy brand colours faded | Use black/white high‑contrast |

8. Questions fréquemment posées (2025 Edition)

Q1 — Do I need a new label when I add dry ice?

Oui. Any weight change requires a fresh net‑kg marking; reuse risks a USD 4 800 fine.

Q2 — Can I hand‑write the whole label?

Only the poids may be hand‑written. “UN 1845” and “Dry Ice” must be pre‑printed ≥ 6 mm.

Q3 — Are QR codes mandatory now?

Not yet, but 67 % of IATA carriers accept e‑Docs only via QR—adding one slashes acceptance time.

Q4 — Best adhesive for –78 °C?

Polyurethane cryogenic‑grade tested to ADR P620 drop criteria.

Q5 — Dry ice vs gel packs?

Use dry ice for ≤ –20 °C lanes ≥ 24 h; switch to gel for 2–8 °C lanes or same‑day e‑commerce.

9. Nine‑Point Label Audit Checklist

-

100 mm diamond, 7 stripes, Class 9 “9” visible

-

“Dry Ice” + “UN 1845” ≥ 12 mm text

-

Net weight kg accurate to 0.1 kg

-

Synthetic facestock, frost‑rated

-

Polyurethane adhesive batch within shelf‑life

-

Haut / largest side, no seam overlap

-

Second label added for ocean freight

-

QR links to e‑Docs & FDS (testé)

-

Photo proof stored in TMS

10. Étapes suivantes & Ressources

-

Télécharger: free Net‑Mass Calculator + QR‑ready label template (no email gate).

-

Audit: prendre 5 outgoing boxes today, run the 9‑point checklist.

-

Consulter: book a 15‑min session with Tempk engineers for custom SOPs.

-

Learn more:

-

Cold‑Chain Packaging 101 (lien interne)

-

PCM vs Dry Ice comparison guide

-

UN 3373 Label How‑To

-