-

3) Combien de glace sèche à utiliser (pour la nourriture & Pharma)

-

5) Étiquettes, paperasserie & règles (NOUS, Air, Transporteurs)

1) Pourquoi la glace carbonique?

Glace sèche (co₂ solide) se situe à −78,5°C (−109,3 ° F) et sublimes- passe du solide directement au gaz - absorbant beaucoup de chaleur au fur et à mesure (enthalpie élevée de sublimation ≈26kJ/mol). C'est pourquoi il peut conserver des températures surgelées pendant des jours lorsqu'il est associé au bon expéditeur..

Note de sécurité: comme il sublime, 1 lb de neige carbonique produit ~ 250 L de gaz CO₂, qui peut rapidement déplacer l'oxygène dans des espaces fermés : ventilez chaque expéditeur et chaque véhicule.

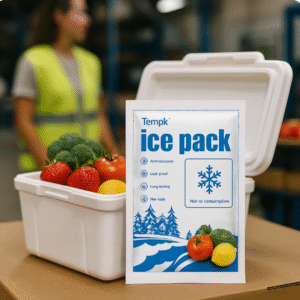

2) Choisissez le bon conteneur

| Récipient | Mieux pour | Pros | Watch-bots |

|---|---|---|---|

| Mousse EPS + carton | Aliments surgelés économiques, itinéraires courts | Faible coût; facile à trouver | Volumineux; Valeur R inférieure à celle du VIP; plus de neige carbonique nécessaire |

| Pur / Mousse PIR | Routes plus longues, contrôle plus strict de la température | Meilleure isolation que le PSE | Plus cher; toujours encombrant |

| VIP (panneau isolé sous vide) expédiés | Produits biologiques de grande valeur / longs trajets | ~5 fois la résistance thermique par épaisseur par rapport aux mousses conventionnelles; empreinte réduite | Coût; ne peut pas être coupé; manipuler avec soin |

Pourquoi VIP est important: La conductivité typique au centre du panneau VIP est d'environ 0.004–0,008W/(m·K), donnant une valeur R par pouce beaucoup plus élevée que l'EPS ou le PUR, donc plus petite, des packs plus légers pour le même temps de tenue.

3) Combien de glace sèche à utiliser (pour la nourriture & Pharma)

La charge dont vous avez besoin dépend de durée, ambient temps, type/épaisseur d'isolation, rapport de charge (produit + glace vs volume interne), et à quelle fréquence la boîte est ouverte. En tant que pratique point de départ pour un envoi en colis fermé:

-

Court-courrier (≤24h): ~ 5 à 10 lb pour une petite glacière EPS (ajoutez-en plus pour les voies chaudes ou un volume plus important).

-

48–72h: évoluer de manière linéaire et préférer les EPS plus épais, Pur, ou VIP pour réduire le poids.

-

>72 h ou voies à haute température: passez aux expéditions VIP ou fractionnez-les pour rester conforme et gérable.

Estimateur (règle de la règle):Dry ice (lb) ≈ (Route days) × (container factor) × 6

-

facteur de conteneur ≈ 1.0 (VIP), 1.3 (Pur), 1.6–2,0 (PSE); ajuster +10–25 % pour >30 Voies °C.

Validez avec un test de voie ou un petit pilote avant la mise à l'échelle. (La physique varie; il s'agit d'une aide à la planification et non d'une certification.)

Pour la planification de la sécurité des avions (Accumulation de co₂), Chevilles de données FAA 1lb → 8.8 ft³ de CO₂; les opérateurs utilisent des calculs de taux de sublimation et de renouvellement d’air pour fixer des limites de sécurité à bord.

4) Emballage étape par étape (fonctionne pour la nourriture ou les spécimens)

-

Préchauffeur: Congeler le produit solide; refroidir l'expéditeur si possible.

-

Doubler & séparé: Placez une doublure ou un carton ondulé entre le produit et la neige carbonique pour éviter les brûlures de congélation..

-

Ordre de chargement: Glace sèche autour et au-dessus produit pour le froid descendant; éviter le placement uniquement en bas.

-

Remplir les vides: Minimisez l’espace libre avec le kraft/bulle (pas hermétique).

-

Secouer: Faire pas scotchez hermétiquement le couvercle intérieur en mousse; laisser un chemin de ventilation pour le CO₂.

-

Fermer le carton extérieur fermement; essai d'agitation (pas de hochets).

-

Marque & étiquette par section 5 (Et 1845, Kg net, Classe 9).

-

Dépôt: Apportez la liste de contrôle du transporteur; déclarer le poids de la glace carbonique sur la lettre de transport aérien.

Ces fondamentaux affinent les méthodes déjà présentes dans vos drafts tout en s'alignant sur 2025 guidage du transporteur.

5) Étiquettes, paperasserie & règles (NOUS, Air, Transporteurs)

Règlements de base (référence rapide)

-

49 CFR §173.217 (US DOT – avion/navire):

Les colis doivent permettre au CO₂ de s'évacuer; pour aéronef, le masse nette (kg) de glace sèche doit être marqué à l'extérieur; l'expéditeur doit organiser avec l'opérateur; des marquages spéciaux sur les navires s'appliquent. -

Iata (Air) – Instructions d'emballage 954 & chèques d'acceptation:

Utiliser le 2025 Liste de contrôle d'acceptation de la glace sèche de l'IATA lorsqu'une déclaration DG n'est pas requise; PI 954 régit les emballages et les marquages. (Les outils de travail typiques des transporteurs et des universités reflètent un 200 kg maximum par colis pour la glace carbonique comme réfrigérant : vérifiez toujours les variations de l'opérateur). -

USPS (Mail):

Glace carbonique par air se limite à 5 lb par envoi postal; l'emballage doit être ventilé et conforme aux 49 CFR 173.217; le courrier de surface peut dépasser 5 lb. Voir Instruction d'emballage 9A et la section 743 pour les denrées périssantes.

De nombreux laboratoires notent que la neige carbonique n'est pas réglementée comme matière dangereuse pour le sol américain (camion) expéditions, bien qu'une ventilation/marquage sûr soit toujours essentiel.

Listes de contrôle des transporteurs (ce que le personnel utilise réellement)

-

FedEx: Marque «Glace sèche» ou «dioxyde de carbone, solide,"Et 1845, Poids net en kg, plus les adresses de l'expéditeur/du destinataire; affixe Classe 9 étiquette; suivre les règles de taille des caractères (Par exemple, 12 mm quand >30 Capacité du colis en kg) et utiliser le Aide au travail sur la glace carbonique (Jan 2025) et listes de contrôle DG lors de l'appel d'offres.

-

Hauts: Utilisez leur liquides de refroidissement/réfrigérants conseils; inclure quantité de glace sèche (ou une déclaration selon laquelle c'est ≤ 2,5 kg / 5.5 kg si autorisé); Ne jamais sceller hermétique; évacuer l'expéditeur.

Anatomie des étiquettes en un coup d'œil:

-

Texte: Glace sèche / Dioxyde de carbone, solide

-

Et: Et 1845

-

Danger: Classe 9 diamant (divers)

-

Quantité: Glace carbonique nette (kg) (en dehors de la classe 9 frontière)

-

Noms/adresses: Expéditeur & Destinataire sur le paquet

6) Notes sur la sécurité alimentaire (0 ° F, refrection)

-

Conservez les aliments surgelés à 0 ° F (−18 ° C) ou ci-dessous; c'est l'objectif standard du congélateur.

-

Si un colis arrive partiellement congelé ou ≤40 ° F (4 ° C), c'est typiquement peut être recongelé ou cuit en toute sécurité, même si la qualité peut baisser, utilisez un thermomètre, pas « ressentir ».

7) Dépannage & conseils de pro

-

Boîte hermétique? Si un couvercle « éclate » ou se gonfle, vous piégez le CO₂ – remballez avec un chemin de ventilation. (N'oubliez pas 1 lb → ~ 250 L de CO₂.)

-

Boîte détrempée par condensation? Ajoutez une doublure en polyéthylène ou un manchon ondulé; ne bloquez jamais les bouches d'aération.

-

Se réchauffer tôt? Augmenter le rapport de charge (plus de masse de produit par rapport aux vides) et déplacez la glace carbonique au-dessus de ainsi qu'autour des marchandises.

-

Voie plus chaude que prévu? Passez au PUR/VIP ou ajoutez une couche supérieure « sacrificielle » de neige carbonique.

-

Exposition au coré: Travailler dans des zones aérées; suivre NIOSH limites (TWA 5 000 ppm; Stel 30 000 ppm).

8) FAQ

Q1) Quel est le meilleur packs de glace carbonique et conteneur pour l'expédition nourriture combo pendant 24 à 72 heures?

Pour la plupart des aliments surgelés, PSE fonctionne jusqu'à quelques jours avec suffisamment de neige carbonique; Pur te donne une marge; VIP réduit le poids pour les itinéraires de 3 à 5 jours et plus. Choisissez en fonction de la durée des voies et du budget, puis validez avec un petit test.

Q2) Puis-je expédier de la neige carbonique à l’international?

Oui, mais règles aériennes (Voici pi954) et Variations de l'opérateur appliquer; attendez-vous à des restrictions selon le pays de destination et à des différences entre les transporteurs. Toujours clair avec le transporteur avant l'offre.

Q3) Comment marquer une case?

Écrire Glace sèche (ou Dioxyde de carbone, solide), Et 1845, Kg net, plus expéditeur / destinataire. Attacher Classe 9 étiquette du même côté que le texte lorsque cela est possible.

Q4) USPS contre. UPS/FedEx : ce qui est différent?

Air USPS couvre la glace carbonique à 5 kg par morceau; UPS/FedEx suivent l'IATA et leurs propres outils de travail; les règles de base diffèrent.

Q5) La glace carbonique est-elle autorisée avec les packs de gel?

Oui, juste séparé produits issus du contact direct avec la neige carbonique (utiliser du carton ondulé/des doublures) et garder les évents clairs.

Q6) Qu’est-ce que l’ONU 1845?

Le numéro ONU identifiant la neige carbonique dans le transport. Vous l'imprimerez sur l'emballage avec le net kg.