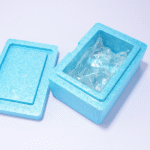

En logistique à température contrôlée, Le maintien de conditions de transit exactes n'est pas négociable. Pour les produits pharmaceutiques, aliments périssables, ou matériaux biologiques, Même les écarts mineurs peuvent compromettre l'intégrité des produits. Packs de glace sèche pour les glacières résoudre ce défi en fournissantTempératures sous-zéro cohérentesSans résidu liquide - les rendre indispensables pour les expéditions à enjeux élevés.

Ce qui rend les packs de glace sec unique?

Les packs de glace sec contiennentPéllets de co₂ solides (-78.5°C / -109.3°F) que sublimé (Convertir directement de solide en gaz). Contrairement aux packs de gel ou à la glace ordinaire:

- CongéZéro humiditéDans les glacières

- LivrerDurée de refroidissement de 3 à 5 fois plus longue

- Exiger 40% Moins d'espace vs. Alternatives à base d'eau

Cela les rend idéaux pour l'expédition compacte des vaccins, échantillons de laboratoire, ou fruits de mer gelés.

4 avantages clés pour les opérations de la chaîne du froid

| Bénéfice | Pourquoi ça compte |

|---|---|

| Poste thermique étendu | Maintient des températures critiques pour 48-72+ heures - idéal pour les transports biologiques internationaux |

| Nœuds d'humidité zéro | Empêche la condensation ruineuse sur les produits pharmaceutiques, électronique, ou dispositifs médicaux |

| Optimisation de l'espace | Les packs flexibles sont conformes aux murs et formes de produits plus frais, Maximiser la densité de fret |

| Opération durable | Co₂ est récupéré à partir de processus industriels; L'emballage recyclable réduit les déchets de décharge |

Applications spécifiques à l'industrie

Pharma & Biologique

- Expédier des vaccins d'ARNm à-70 ° C

- Transporter l'insuline sans risque de congélation

- Sécuriser les échantillons de diagnostic lors de la livraison du dernier mile

Aliments périssables

- Protéger la fraîcheur des fruits de mer en transit

- Maintenir l'intégrité de la structure de la crème glacée

- Assurez-vous que les produits laitiers passent les inspections de la FDA

Consignations critiques

- Matériel d'essai clinique

- Organes de transplantation

- Produits chimiques sensibles à la température

Pourquoi les packs de glace sec de Tempk mènent le marché

L'ingénierie de Tempk fournitFiabilité de la chaîne froide de nouvelle génération:

Durabilité:Emballages à trois couches résiste à 72 heures + manipulation rugueuse

Contrôle de précision:Distribution de refroidissement uniforme (± 2 ° C Variance)

Dimensionnement personnalisé:Configurer des packs pour 10L Medical Filacles à 200 L expéditeurs de fret

Éco-certifié:Production neutre en carbone avec 100% Matériaux recyclables

Données de performance du monde réel:

“Les packs de tempk maintenus -65 ° C pour 78 Heures pendant les expéditions pharmatriques de Singapour-Amsterdam - dépassant les normes GMP de l'UE.” - [Rapport d'audit de la chaîne du froid]

Conclusion: Optimisez votre chaîne froide avec des packs de glace sec

Les packs de glace sec pour les refroidisseurs représentent l'équilibre optimal dePerformance, efficacité, et la fiabilitéEn logistique à température critique. En éliminant les risques d'humidité tout en étendant la protection thermique, Ils réduisent les taux de perte de produits jusqu'à 34% par rapport aux méthodes de refroidissement traditionnelles (Iata, 2023). Les solutions validées de Tempk permettent aux entreprises de garantir la viabilité des produits de la fabrication à l'utilisateur final - transformant la gestion de la température d'un défi en un avantage concurrentiel.