L’essor de la livraison de plats chauds et de kits de repas frais a transformé les sacs de livraison de base en unités essentielles de la chaîne du froid en première ligne.. Riders act as mobile couriers, battling traffic and weather to maintain precise food temperatures from kitchen to doorstep. For this vital last-mile task, a dedicated food delivery backpack est essentiel. It must offer far more than space – it needs powerful insulation, comfortable carrying, and safety features, all supporting temperature integrity.

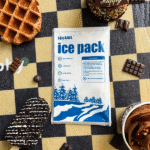

Performance de la chaîne froide de base: Effective thermal barrier technology is key. Insulation layers – typically utilizing reflective foils and specialized foams – block heat ingress or egress (thermal gain/loss). When paired with thermal buffering agents like gel packs or dry ice, the interior environment reliably holds temperatures: below 5°C (41°F) for chilled items or above 60°C (140°F) for hot meals during standard delivery times. Food-contact safe, wipe-clean liners prevent contamination, while reinforced structures and seams protect meal integrity during transit.

Operational Design for Efficiency: Design impacts performance. Carriers handle high volumes daily. Ergonomic padded straps and ventilated backs combat fatigue. High-visibility materials and reflective elements enhance safety. Features like dual-access zones and removable thermal partitions allow riders to easily segregate temperature zones (hot vs. froid) or add extra carriers without disrupting the core thermal payload. Collapsible designs save space when empty and facilitate thorough cleaning.

Rotation: Engineered Cold Chain Performance: Tempk’s Delivery Bag series exemplifies this focus. Leur durable, water-resistant shell withstands constant handling. Key cold chain innovations include:

- Enhanced Thermal Retention: A proprietary core (Mousse EPE + HDPE reflector + vacuum-laminated PCM sheet) significantly extends thermal hold times – up to 35% longer than standard bags – ensuring meals arrive at the intended service temperature.

- Operational Design: Large, reliable zippers function in all weather. Multiple external pockets provide easy access to essentials (sauces, payment devices).

- Scalability & Soins: Expandable sides increase peak-time capacity by 25%, while the bag folds flat for compact storage. The entire design enables easy, thorough cleaning.