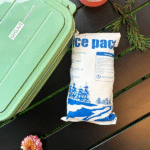

If you’re selecting a gel ice pillow North America supplier, you’re not just buying “cold.” You’re buying fewer temperature excursions, moins de fuites, and fewer costly reships. Dans 2026, lanes are longer, weather swings are sharper, and customers judge your brand at the unboxing moment. This guide gives you a clear supplier checklist, simple lane tests, and pricing math you can use today.

How Do You Define Success With a Gel Ice Pillow North America Supplier?

Success means your gel ice pillow North America supplier keeps your product in range with repeatable results, stable specs, and predictable lead times. You should define your target band, maximum transit hours, and failure tolerance before you compare suppliers.

| Lane input | Option A | Option B | Ce que cela signifie pour vous |

|---|---|---|---|

| Plage cible | 2–8 ° C | 0–4 ° C | Drives pillow mass and risk level |

| Temps de transit | 24–48 hr | 48–72 hr | Sets quantity and pillow thickness |

| Saison | Summer peak | Mixed seasons | Changes failure modes |

| Charge utile | Dense | Airy | Affects heat gain speed |

| Manutention | Doux | Rough | Drives film and seal strength |

What Quality Control Should a Gel Ice Pillow North America Supplier Prove?

A gel ice pillow North America supplier should prove consistency in fill weight, intégrité du joint, and film durability—because these three items predict leaks and temperature drift. If a supplier cannot explain their controls, assume variance exists.

| Audit layer | Que chercher | Quick test | Ce que cela signifie pour vous |

|---|---|---|---|

| Conception | Rounded seals, reinforced edges | Bend/flex frozen unit | Fewer crack leaks |

| Processus | Controlled fill, étanchéité constante | Peser 20 unités | Predictable cooling |

| Manutention | Packing guidance, pallet rules | Drop test in carton | Fewer warehouse leaks |