Imaginez ce: Un gestionnaire d'entrepôt chargé des vaccins vitaux sur un camion à destination des villages de montagne. Un distributeur de fruits de mer transporte du thon vers les aéroports avant la saison des typhons. Une chaîne de pharmacies garantissant que l’insuline reste gelée pendant une panne d’électricité estivale. Derrière ces opérations critiques se cache une main-d’œuvre invisible :distributeur de blocs de glace—les gardiens silencieux de l'intégrité des chaînes du froid du vrac.

Pourquoi la qualité du distributeur est importante: Au-delà du refroidissement de base

Pendant que les packs de glace grand public s'occupent des boîtes à lunch, les solutions des distributeurs font face à des exigences brutales:

-

Défis d’échelle: Envois de la taille d'une palette nécessitant une stabilité uniforme à -20°C

-

Risques de sécurité: La neige carbonique traditionnelle provoque une suffocation par le CO₂ dans les camions confinés

-

Des échecs coûteux: 1L’écart de °C gâche plus de 25 000 $ de produits biologiques (CDC 2024)

-

Lacunes sur la durabilité: 92% des packs de gel industriels finissent dans les décharges

Les ingénieurs de Tempk ont dépensé 3 années à réinventer la protection de la chaîne du froid en vrac et à relever ces défis de front.

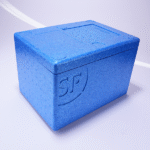

Tempk DryIcePro™: Le refroidissement en vrac révolutionné

1. Performances extrêmes, Zéro danger

-

Maintient -50° C pour 120+ heures—4 fois plus longtemps que la glace carbonique standard

-

Technologie sans CO₂ (aucun risque d'étouffement dans les camions/avions)

-

Breveté “FrostGuard” le revêtement empêche les brûlures de surface

2. Évolutivité intelligente

-

Piles de conception modulaire comme les briques LEGO® pour l'optimisation des palettes

-

Technologie PhaseSync™: Le refroidissement distribué par l'IA garantit une uniformité de ± 1°C pour les expéditions de 2 tonnes

-

Indicateurs d'état visuels (bleu = optimal, rouge = remplacer)

3. Élimination écologique

-

Granulés solubles dans l'eau: Neutraliser au contact (0 déchets mis en décharge)

-

Emballages compostables: Transformez-vous en engrais dans 30 jours

-

Production à bilan carbone négatif via captage de méthane

4. Conception centrée sur le distributeur

-

Activation groupée: Activer 500+ emballe dans 90 secondes

-

Manipulation robotisée: Code QR pour les entrepôts automatisés

-

Résistant à l'écrasement: Résiste à un compactage de 200 kg pendant le transport

Impact du monde réel: Des chiffres qui comptent

Cas de distributeur pharmaceutique (Allemagne 2024)

Après être passé à Tempk:

→ 99.2% conformité de la température sur 12 000 expéditions de vaccins

→ $480k sauvé dans les coûts de remplacement du liquide de refroidissement

→ 0 Incidents CO₂ dans 8 mois

Percée logistique des fruits de mer (Japon)

-

Taux de rejet de la qualité du thon: 31% → 0.6%

-

Réduction du poids du liquide de refroidissement: 40% (réduire les coûts de transport)

-

Empreinte carbone: 73% réduction contre. glace carbonique traditionnelle

La science cachée: Pourquoi les professionnels choisissent Tempk

-

Technologie des protéines arctiques: Le biomimétisme des protéines antigel de poisson empêche la cristallisation de la glace

-

MoistureLock™: Le déshydratant sans silice maintient <10% humidité

-

ImpactShield™: La matrice d'aérogel protège les flacons pendant les transports difficiles

Au-delà de l'industrie pharmaceutique: Applications inattendues

-

Logistique spatiale: Transporter des échantillons du rover martien

-

Distribution Gourmande: Livraisons d'ingrédients étoilés Michelin

-

Conservation: Déplacer des embryons d’espèces menacées

-

Réponse à la crise: Transport de médicaments en zone inondable

La chaîne du froid en vrac de demain aujourd’hui

Tempk 2025 innovations:

-

Packs de recharge solaire: La lumière du jour prolonge le refroidissement de 30%

-

Suivi de la blockchain: Surveillance de la température des palettes en temps réel

-

Palettes auto-refroidissantes: Refroidissement en vrac activé par l'eau

Conclusion

Dans le monde aux enjeux de la logistique du vrac, les packs de glace des distributeurs se transforment de produits de base en infrastructures critiques. Tempk prouve que le refroidissement à l'échelle industrielle peut être simultanément puissant, sûr, et durable. Parce qu’il s’agit de protéger les vaccins d’un village ou la cargaison de truffes d’un chef d’une valeur de 10 000 $, l'excellence dans la chaîne du froid n'est pas seulement une question de température, c'est une question de confiance multipliée par des milliers de livraisons, jour après jour.