Comment fonctionnent les sacs de glace sèche & Les packs révolutionnent le transport sous chaîne du froid 2025?

Dans 2025, les marchandises sensibles à la température sont confrontées à des défis de transport de plus en plus complexes. Pour garantir que les articles périssables comme les produits pharmaceutiques, nourriture, et les échantillons biologiques arrivent à destination en toute sécurité et sans compromis, Les sacs de glace carbonique et les packs de glace carbonique sont essentiels. Ces solutions de chaîne du froid fournissent un, rentable, et méthode écologique pour maintenir des températures ultra-basses. Cet article explique les principes de fonctionnement des sacs de glace carbonique, leurs avantages par rapport aux méthodes de refroidissement traditionnelles, et comment les entreprises peuvent maximiser les économies et l'efficacité opérationnelle.

-

Comment faire sacs et packs de glace carbonique fonction dans la logistique de la chaîne du froid?

-

Quels sont les avantages des packs de glace carbonique par rapport aux solutions traditionnelles de glace et de gel?

-

Comment les entreprises peuvent-elles optimiser leurs coûts d'expédition grâce à la technologie de la glace sèche?

-

Quelles sont les tendances et innovations émergentes en matière de technologie de glace carbonique pour la logistique de la chaîne du froid?

Comment fonctionnent les sacs et packs de glace carbonique dans la logistique de la chaîne du froid?

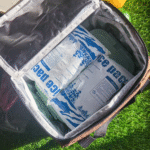

Les sacs et packs de glace carbonique jouent un rôle crucial dans le maintien de l’intégrité des produits sensibles à la température pendant le transport.. Rempli de dioxyde de carbone solide, la glace carbonique se sublime à -78,5°C (-109.3°F) Pour maintenir des températures ultra-basses. Contrairement aux liquides de refroidissement à base d'eau, la neige carbonique se sublime en gaz, ne laissant aucun résidu liquide. Cette propriété unique permet d'éviter des problèmes tels que les dégâts d'eau sur les produits, ce qui en fait une solution idéale pour les industries qui nécessitent un contrôle précis et propre de la température, comme les produits pharmaceutiques et la biotechnologie.

Caractéristiques clés des sacs et packs de glace carbonique:

-

Refroidissement sous zéro: La glace sèche maintient une température extrêmement basse, idéal pour les aliments surgelés, médicaments, et matériel de recherche.

-

Longue durée: Les packs de glace carbonique restent froids pendant de longues périodes, même lors d'envois longue distance.

-

Pas d'eau de fonte: La sublimation de la neige carbonique en gaz CO₂ évite les dégâts des eaux, ce qui peut poser problème avec les packs de glace et de gel traditionnels.

| Avantage | Glace traditionnelle | Sacs à glace sec & Packs | Votre impact |

|---|---|---|---|

| Durée de refroidissement | De courte durée | Longue durée | Durée de conservation prolongée du produit |

| Risque de dommages causés par l'eau | Haut | Aucun | Dégradation réduite |

| Efficacité du stockage | Volumineux, plus lourd | Compact, plus léger | Expédition plus rentable |

Pourquoi les entreprises devraient-elles choisir les packs de glace carbonique plutôt que les méthodes traditionnelles?

La glace carbonique offre plusieurs avantages par rapport aux méthodes de refroidissement traditionnelles telles que les packs de gel et la glace ordinaire.. Voici un aperçu de la façon dont les packs de glace carbonique surpassent la glace conventionnelle:

-

Durée de refroidissement plus longue: Les blocs de glace carbonique peuvent maintenir des températures froides jusqu'à 48 heures, par rapport à la glace ordinaire qui commence à fondre en quelques heures.

-

Efficacité de l'espace et du poids: Puisque la glace carbonique est plus dense que l’eau, il occupe moins d'espace et réduit le poids total de l'envoi, ce qui peut conduire à des économies substantielles dans le transport.

-

Respectueux de l'environnement: La glace sèche sublime dans le gaz co₂, qui ne contribue pas à la contamination de l’eau ou aux problèmes d’élimination des déchets, contrairement aux packs de gel ou à base d'eau.

Exemple:

Une société pharmaceutique qui est passée des blocs de glace traditionnels à la glace carbonique a signalé un 30% réduction des taux de détérioration, et un 15% économies sur les frais d'expédition grâce à la réduction du volume d'emballage et à la diminution des réapprovisionnements pendant le transport.

Comment les entreprises peuvent-elles économiser de l'argent avec les packs de glace carbonique?

Le passage aux packs de glace carbonique peut entraîner des économies significatives de diverses manières:

-

Périodes de refroidissement plus longues: Les packs de glace carbonique réduisent le besoin de réapprovisionnement constant pendant le transport, réduire le coût global des matériaux de refroidissement.

-

Taille d'emballage plus petite: Leur conception compacte permet aux entreprises d'optimiser le stockage et les conteneurs d'expédition, réduisant l'espace et le poids, ce qui se traduit par des frais d'expédition inférieurs.

-

Potentiel de réutilisation: Dans certains cas, les sacs de glace carbonique peuvent être réutilisés, en particulier les matériaux d'emballage extérieur, aidant à réduire les déchets et à économiser de l'argent sur des fournitures supplémentaires.

Étude de cas:

Un distributeur mondial de fruits de mer est passé à la neige carbonique pour ses expéditions long-courriers, résultant en un 20% réduction des taux de détérioration, qualité du produit améliorée, et une diminution des coûts liés au transport de 18% en seulement un quart.

Quelles sont les dernières innovations en matière de technologie de glace carbonique pour la logistique de la chaîne du froid?

Alors que la logistique de la chaîne du froid continue d’évoluer, la demande de plus intelligent, les solutions de refroidissement plus efficaces ont augmenté. Dans 2025, La technologie de glace carbonique intègre plusieurs fonctionnalités innovantes qui améliorent les performances et offrent de nouvelles opportunités de surveillance et de conformité.:

-

Sacs de glace carbonique intelligents: Equipé de capteurs de température, ces sacs communiquent avec des systèmes de suivi, offrant une surveillance de la température en temps réel pour les expéditions sensibles.

-

Matériaux d'isolation avancée: De nouveaux matériaux ont amélioré la capacité des sacs et packs de glace carbonique à maintenir des températures basses sur des périodes prolongées..

-

Matériaux d'emballage durables: Il existe une tendance croissante vers les emballages de glace carbonique biodégradables, aider les entreprises à atteindre leurs objectifs environnementaux et à réduire leur empreinte carbone.

Derniers développements en un coup d'œil:

-

Intégration de technologies intelligentes: La surveillance et le suivi en temps réel des expéditions sensibles à la température garantissent la qualité et la conformité.

-

Innovations respectueuses de l'environnement: L'adoption de matériaux biodégradables et recyclables pour les emballages réduit l'impact environnemental.

-

Matériaux de refroidissement améliorés: Les nouvelles technologies d'isolation prolongent la période de refroidissement efficace, Même dans des conditions difficiles.

Foire aux questions sur les sacs et packs de glace carbonique

Q1: Combien de temps les sacs de glace carbonique durent-ils pendant le transport?

Typiquement, la glace carbonique dure entre 12 à 48 heures, en fonction de la quantité utilisée et de la qualité de l'isolation. Pour les expéditions plus longues, de la neige carbonique supplémentaire peut être nécessaire.

Q2: Les sacs de glace sèche peuvent-ils être réutilisés?

Oui, le matériau d'emballage utilisé pour les sacs de glace carbonique peut souvent être réutilisé, à condition qu'il reste intact et en bon état.

Meilleures pratiques d’utilisation des sacs et packs de glace carbonique

Pour maximiser l’efficacité des sacs et packs de glace carbonique, Suivez ces meilleures pratiques:

-

Superposition correcte: Placez les blocs de glace carbonique dans le conteneur d'expédition pour vous assurer qu'ils sont correctement répartis entre les produits..

-

Ventilation: Utilisez toujours un récipient doté de trous d'aération pour permettre au gaz CO₂ de s'échapper., Empêcher l'accumulation de pression.

-

Surveillance de la température: Utilisez des enregistreurs de température ou des appareils compatibles IoT pour suivre la température pendant le transport et garantir que votre envoi reste dans des plages de température sûres..

Conseils pratiques:

-

Pour les expéditions pharmaceutiques, combiner de la neige carbonique avec des matériaux à changement de phase (PCMS) pour une meilleure stabilité de la température.

-

Pour les livraisons de nourriture, assurez-vous que la neige carbonique est correctement isolée et positionnée pour éviter tout contact direct avec des articles sensibles à l'humidité.

Conclusion

Les sacs de glace carbonique et les packs de glace carbonique continuent de transformer la logistique de la chaîne du froid, fournir aux entreprises une solution efficace et durable pour les expéditions sensibles à la température. En comprenant comment utiliser efficacement ces produits innovants, les entreprises peuvent améliorer leurs opérations, réduire les coûts, et améliorer la qualité des produits et la satisfaction des clients.

Étapes suivantes:

Envisagez de passer à la glace carbonique pour votre prochain envoi afin de bénéficier d'un refroidissement plus durable, meilleure efficacité de stockage, et des économies de coûts. Contactez Tempk dès aujourd'hui pour obtenir des conseils d'experts sur l'optimisation de votre logistique de chaîne du froid avec des solutions de glace carbonique.

À propos du tempk

Et tempk, Nous nous spécialisons dans les solutions de chaîne froide, proposant une gamme de sacs et de packs de glace sèche haute performance conçus pour améliorer la sécurité et l'efficacité des expéditions sensibles à la température. Nos produits répondent aux plus hauts standards de performance et de durabilité, garantir que vos produits restent sûrs et frais pendant le transport.

Appel à l'action: Contactez Tempk pour une consultation sur la façon dont nos solutions de glace carbonique peuvent améliorer votre logistique de la chaîne du froid.